I have been printing another large MEH. Finally got it finished and vaguely measured. It is 630mm wide and 360mm tall. The horn is 350mm long without the comp

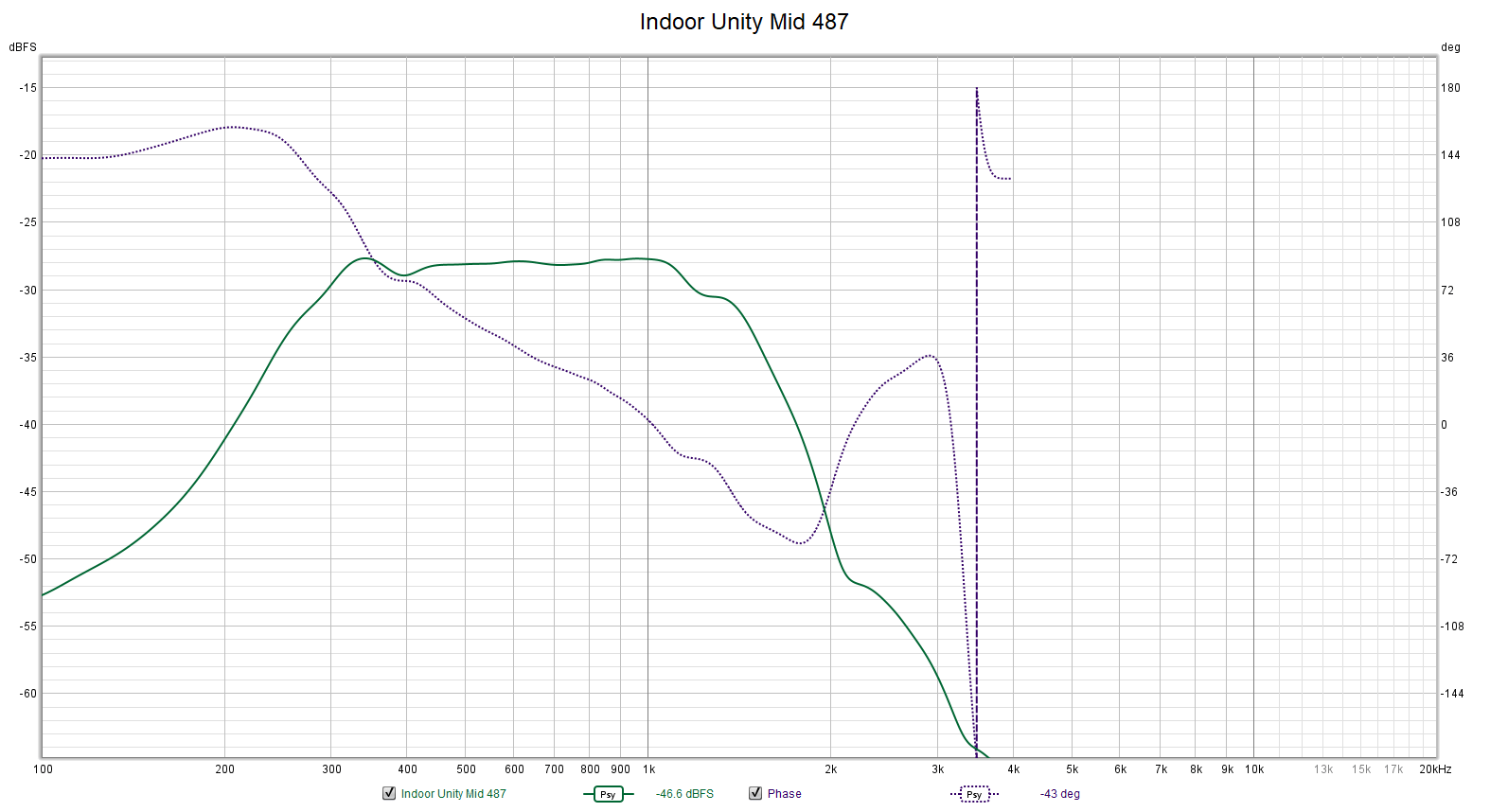

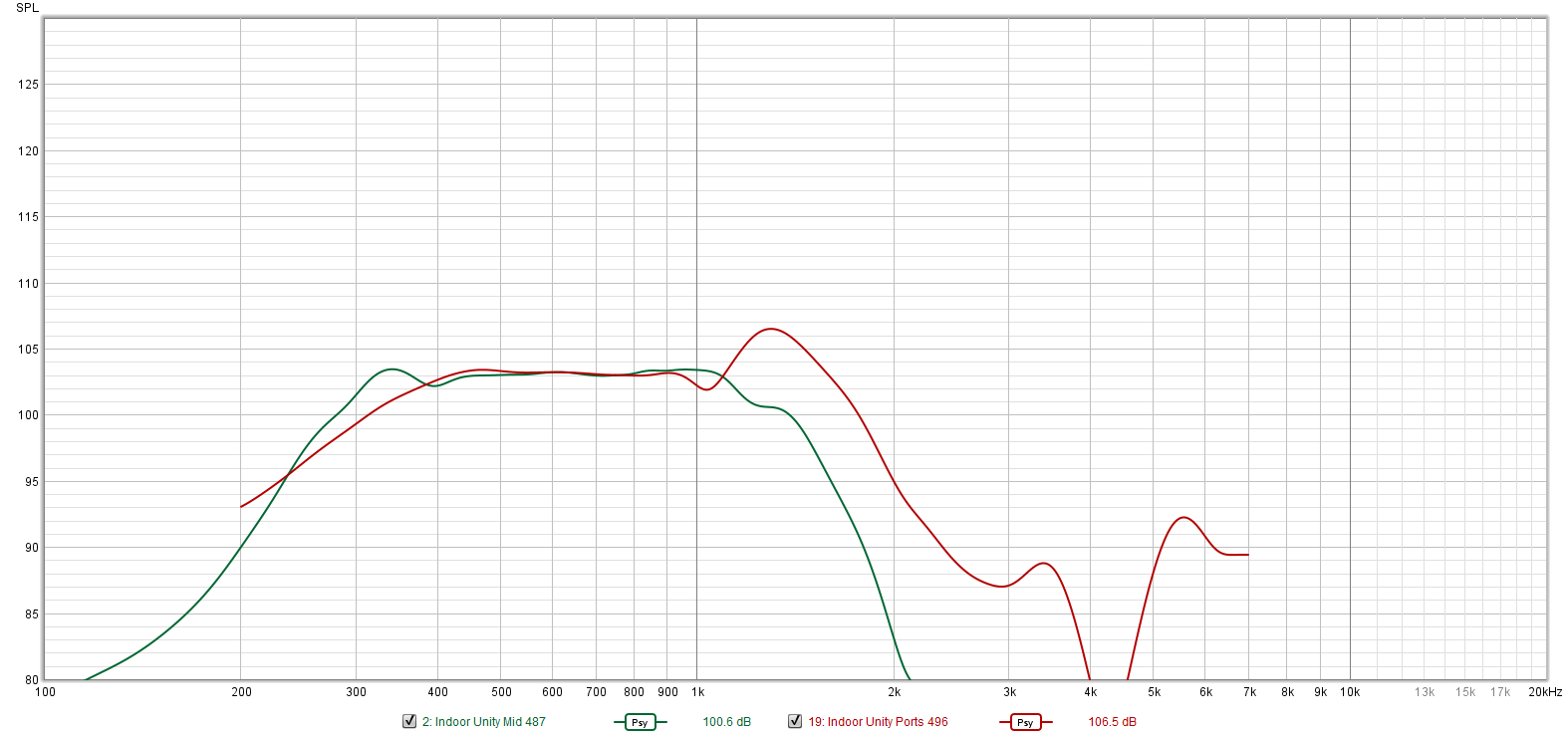

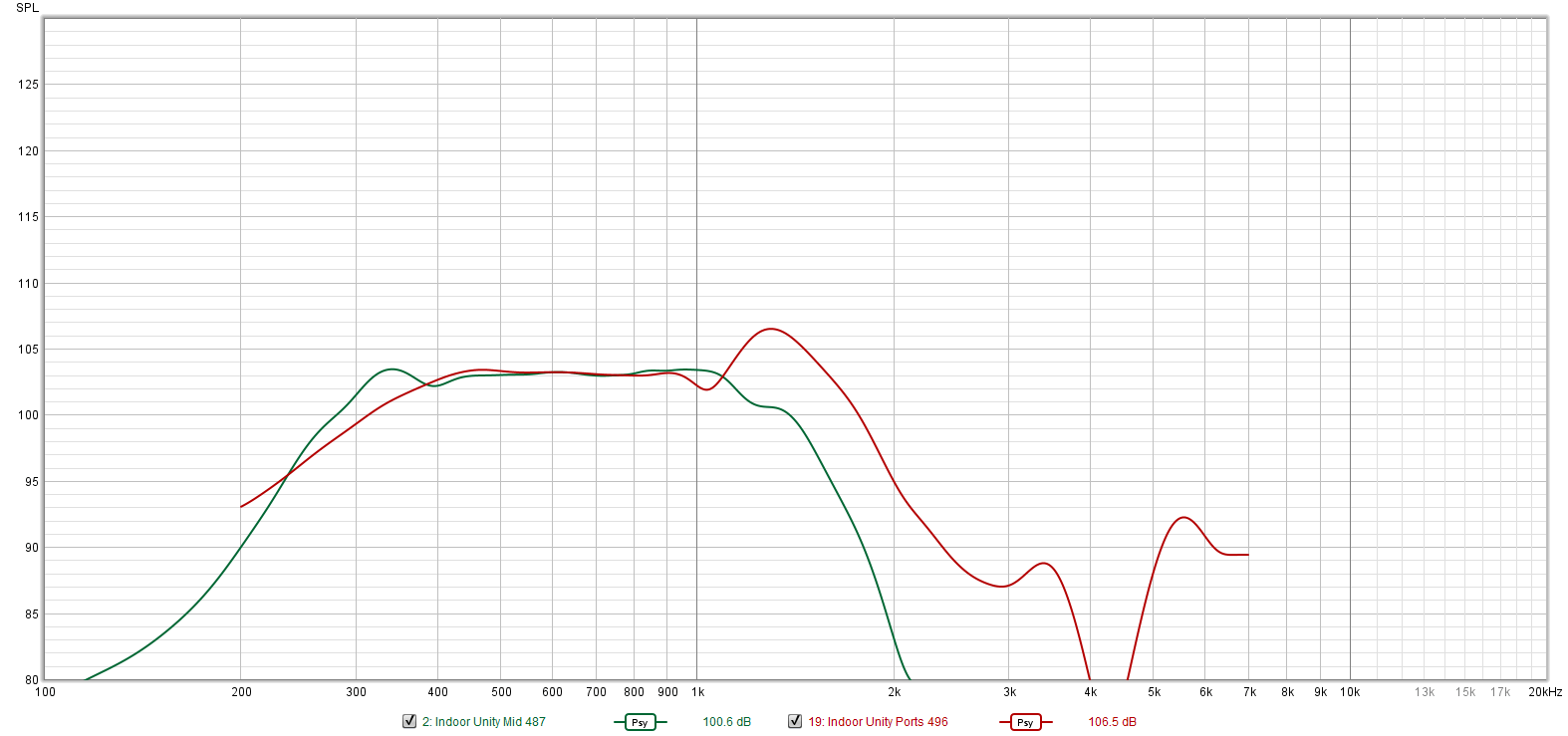

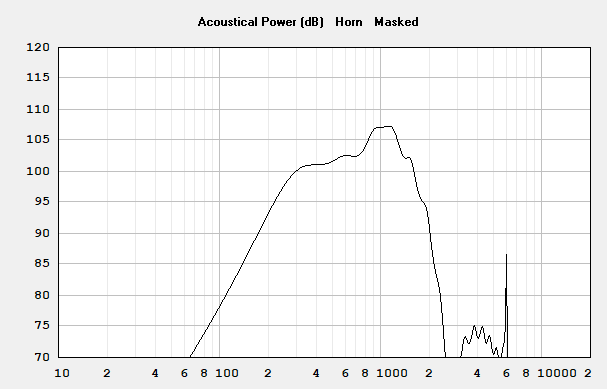

Here are the measurements:

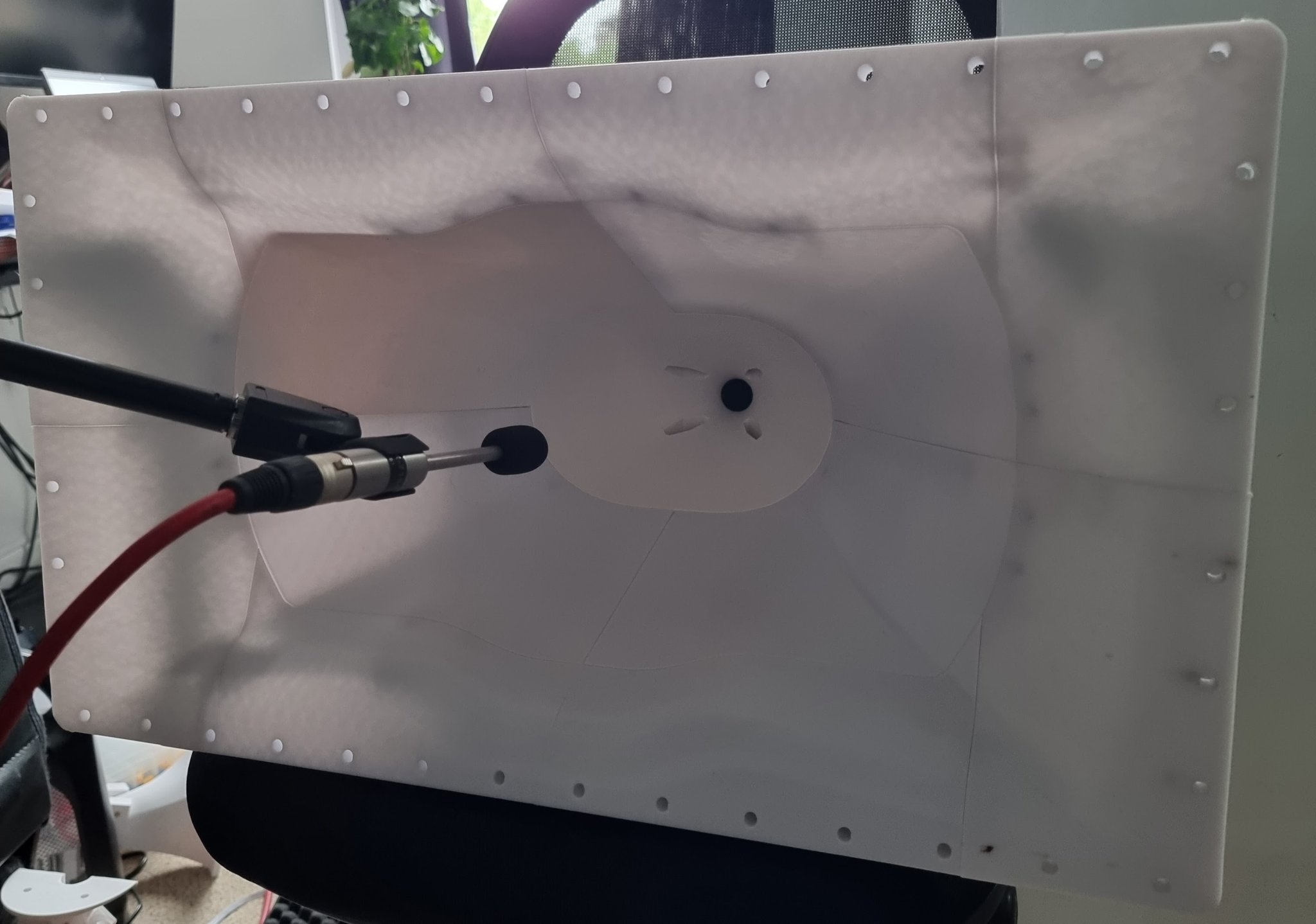

The measurements were taken with the mic at the mouth in a small room as in the image above so they aren't ideal but I will try and get some better measurements soon.

With the sims I had managed to get it up to around 2khz however it drops off rapidly above 1.3khz. I have managed to get smaller drivers up to 2khz before so thinking it is cancellations across the cone?

I might try doing some modelling in Akabak of just the front chamber and taps to see what I end up with.

Here are the measurements:

The measurements were taken with the mic at the mouth in a small room as in the image above so they aren't ideal but I will try and get some better measurements soon.

With the sims I had managed to get it up to around 2khz however it drops off rapidly above 1.3khz. I have managed to get smaller drivers up to 2khz before so thinking it is cancellations across the cone?

I might try doing some modelling in Akabak of just the front chamber and taps to see what I end up with.

Wow great project, I’m planning something along these lines too! The 4ndf34 is a little gem.. did you measure them and the compression driver with the same power? And what a nice print, how big is your 3d printer and which material did you print?

What dispersion pattern did you choose? Did you put the drivers top and bottom because of tighter vertical dispersion and therefore closer spacing?

What dispersion pattern did you choose? Did you put the drivers top and bottom because of tighter vertical dispersion and therefore closer spacing?

Nice project. 🙂

I am also playing with the 4ndf34, I have spent a fair amount of time working with internal phase plug/rings to push it up higher / remove cancellation within the single driver. Not much measured at the moment, currently moving house so its been put on the backburner for a little while (again). Would be cool if you share some details on how you fit the driver to the horn / port design etc. Even just your thought behind the design you have chosen would be awesome. 🙂 You may also find that a very small closed back on the driver helps. 🙂

I am also playing with the 4ndf34, I have spent a fair amount of time working with internal phase plug/rings to push it up higher / remove cancellation within the single driver. Not much measured at the moment, currently moving house so its been put on the backburner for a little while (again). Would be cool if you share some details on how you fit the driver to the horn / port design etc. Even just your thought behind the design you have chosen would be awesome. 🙂 You may also find that a very small closed back on the driver helps. 🙂

I would be happy to cross the CD lower if possible, so maybe you have other ideas otherwise it doesn't seem a problem. Of course, polars may show the bigger picture.however it drops off rapidly above 1.3khz.

To add another data point, pair of 4NDF34's measured indoors at 1m with some eq on the upper corner. Horn is an 18Sound XT1464.

Post the raw responses, whats with people scared to post raw responses?? These super smoothed FR's are only good for use during crossover design and give no hint of the true nature of the actual response. A raw response that is as smooth as the above does not sound like a response that is only as smooth after applying smoothing to it....Psy smoothing or not. OK so its an indoor measurement, the raw response shows directivity character. At least show a smoothed response and a raw one, my goodness.

Last edited:

I think it's more the comparative size of the driver's chambers- the 2" that made it to 2kHz had much less ATC (area of throat chamber) and the area and depths of the ports responsible for the 1.3K pass roll off.With the sims I had managed to get it up to around 2khz however it drops off rapidly above 1.3khz. I have managed to get smaller drivers up to 2khz before so thinking it is cancellations across the cone?

Here are some smoothed (ha ha Camplo) responses showing centered ports on a BC 4NDF34-8 driver compared to moving the ports to the edge of the cone.

The port depth was 1/2", clamped directly to the speaker gasket, no cone filler used:

4NDT BC 4NDF34-8 in 5" cube cabinet on carpeted floor measured at 10” from cone.

4ND1.25 As above with a cover plate with a 1.25” x 1” port (1.25 sq. inch)

4ND1.25O As above, port moved to cone surround edge

4ND.3 1.25” x .25 port (.3125 sq. inch, about equivalent to a 5/8” circle)

4ND.3O As above, port moved to cone surround edge

The smaller ports rolled off ~1/3 octave lower than the larger ports (and reduced low mid output).

Moving the port off center did reduce the acoustic LP frequency slightly.

Moving the port off center reduces the out of band response peaks.

The difference in the port location on the HF driver response may be more important than the port offset..

Art

I'd recommend doing what Art did, build a box that makes measurement experiments easy.

Doing such for the task at hand, blow models away afaict.

Doing such for the task at hand, blow models away afaict.

Nice work Art.The smaller ports rolled off ~1/3 octave lower than the larger ports (and reduced low mid output).

Moving the port off center did reduce the acoustic LP frequency slightly.

Moving the port off center reduces the out of band response peaks.

The difference in the port location on the HF driver response may be more important than the port offset..

Art

Your observations/conclusions are the same I've come to.

I have been away for the week so only just managing to check this thread.

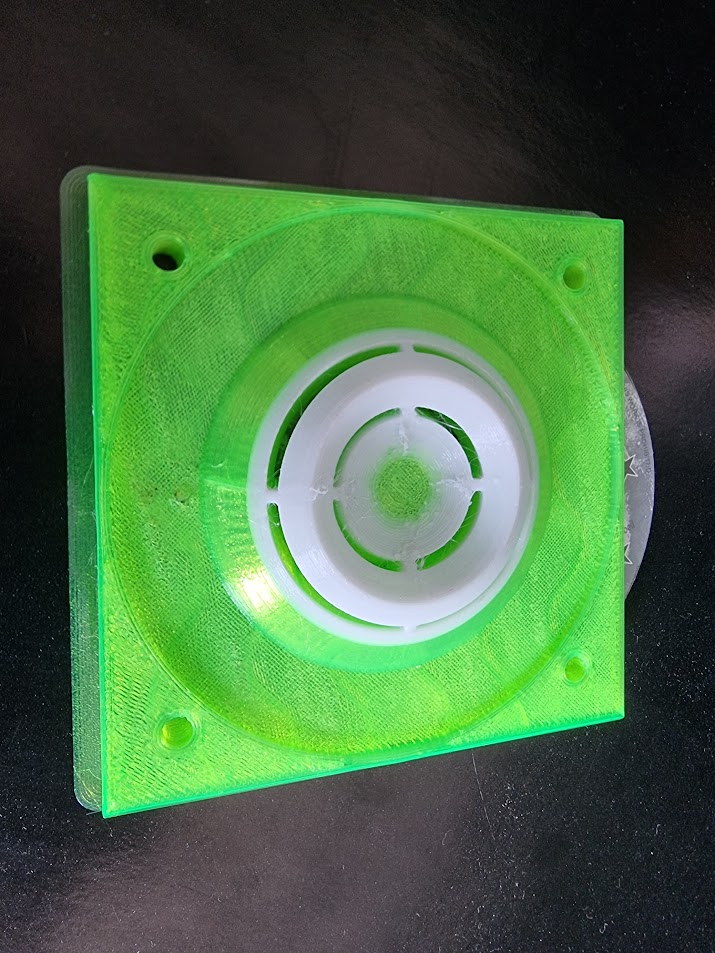

Those results look good @weltersys I have started doing a similar thing earlier this week by printing off specifically the port part of the horn and measuring it.

Was that a single port at the edge of the cone vs the center? I have noticed that before, with a 4" driver 1/2 wavelength across the cone is around 1700hz (from memory) so will start cancelling below that, I would have thought having the taps in the center would mitigate that.

I'm gonna test more things but had to order more fillament which has now arrived 😀

I'm going to test this sort of thing but I don't think I will be able to get the taps short enough/close enough to the start of the horn to be able to make it workable. Also currently with that the area of the taps get smaller as they go, it needs a lot more figuring out with CAD I reckon.

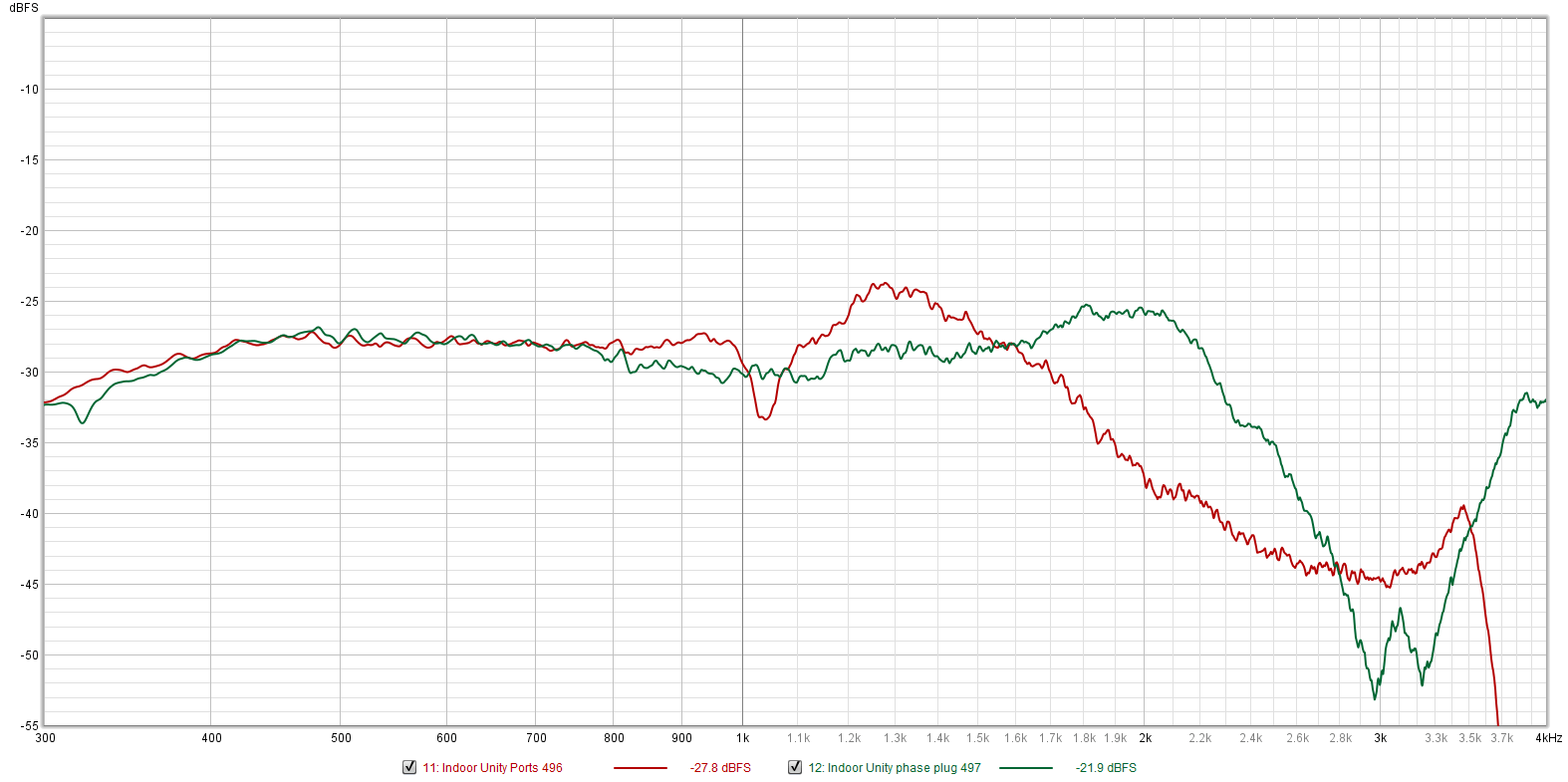

I measured the taps vs in the horn: (Gain/Everything uncalibrated and added a random amount of gain to line the graphs up so ignore everything other than the shape)

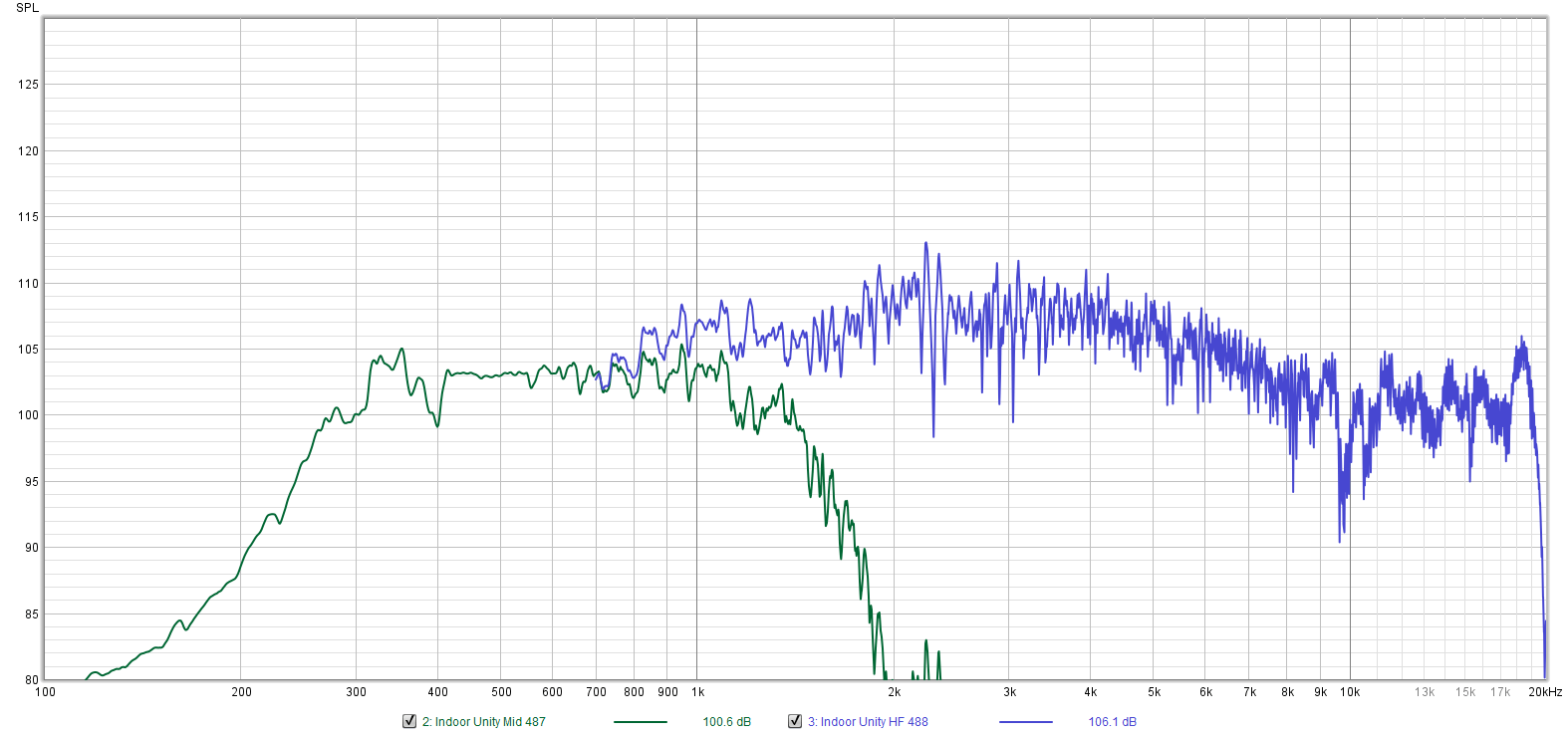

@camplo here are some unsmoothed graphs for you:

I might put it back together and go and measure it outside properly now it's warm and dry again

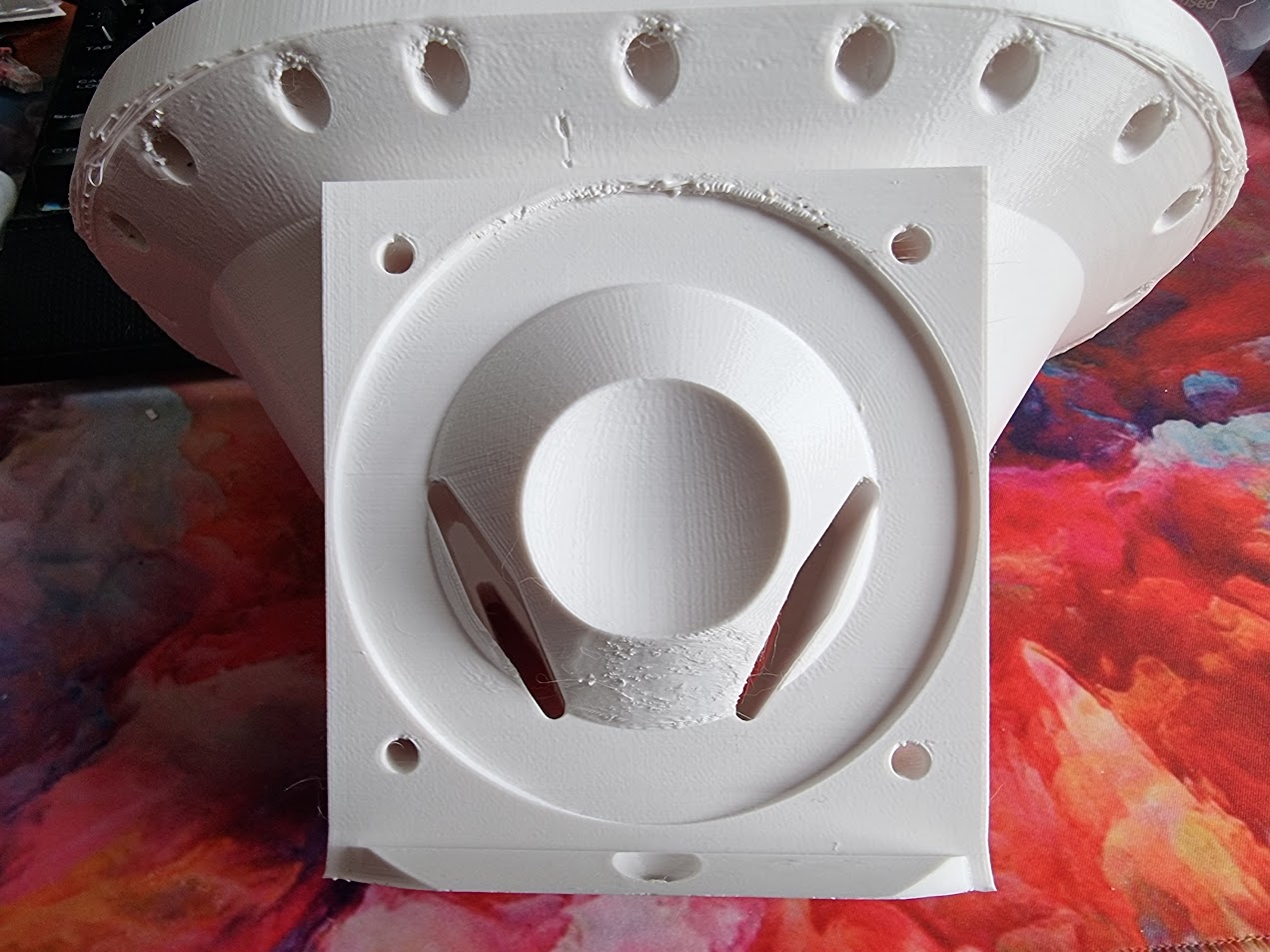

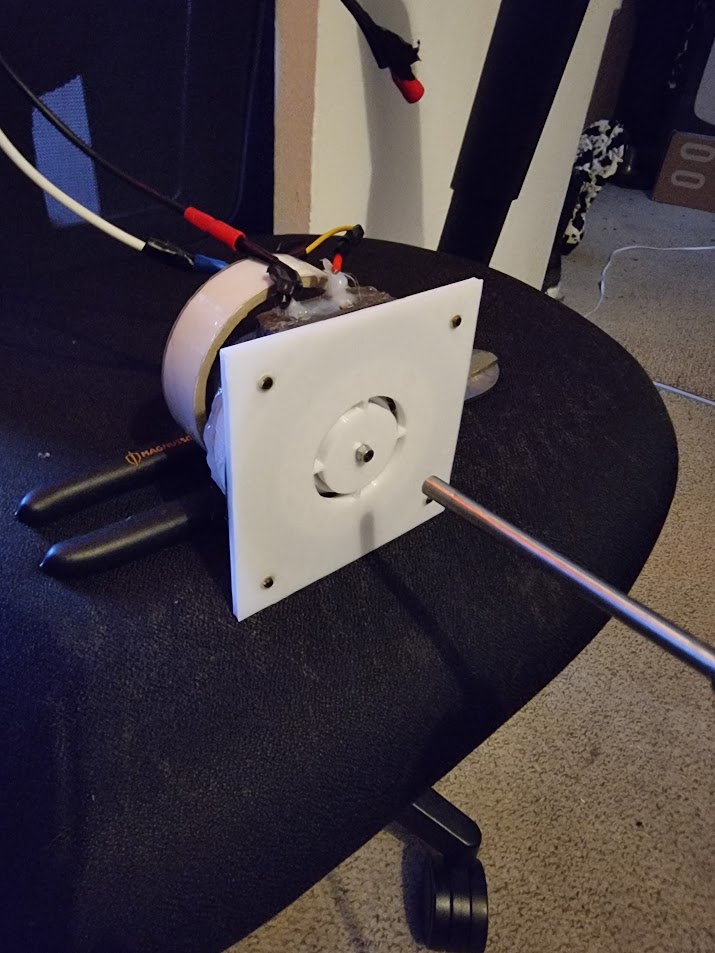

I have done quite small rear chambers and front chambers for this:

The front chamber is 2.5mm from the cone all over

The rear chamber going back into the basket of the driver with a cutout for the cone

@AllenB The CD I have can do 1.6khz but I now kinda just want to design something that can take this driver up to 2khz even though I feel like it will sacrifice some max SPL but I think it should be possible

@zettairyouiki I might release some STL at some point but it isn't too hard to make this sort of thing with ATH and Fusion. Feel free to PM me if you want any help

Those results look good @weltersys I have started doing a similar thing earlier this week by printing off specifically the port part of the horn and measuring it.

Was that a single port at the edge of the cone vs the center? I have noticed that before, with a 4" driver 1/2 wavelength across the cone is around 1700hz (from memory) so will start cancelling below that, I would have thought having the taps in the center would mitigate that.

I'm gonna test more things but had to order more fillament which has now arrived 😀

I'm going to test this sort of thing but I don't think I will be able to get the taps short enough/close enough to the start of the horn to be able to make it workable. Also currently with that the area of the taps get smaller as they go, it needs a lot more figuring out with CAD I reckon.

I measured the taps vs in the horn: (Gain/Everything uncalibrated and added a random amount of gain to line the graphs up so ignore everything other than the shape)

@camplo here are some unsmoothed graphs for you:

I might put it back together and go and measure it outside properly now it's warm and dry again

I have done quite small rear chambers and front chambers for this:

The front chamber is 2.5mm from the cone all over

The rear chamber going back into the basket of the driver with a cutout for the cone

@AllenB The CD I have can do 1.6khz but I now kinda just want to design something that can take this driver up to 2khz even though I feel like it will sacrifice some max SPL but I think it should be possible

@zettairyouiki I might release some STL at some point but it isn't too hard to make this sort of thing with ATH and Fusion. Feel free to PM me if you want any help

Is that your finding or the manufacturer spec, because manufacturer specs don't usually apply in a domestic situation.The CD I have can do 1.6khz

Sorry for the double post with the same image but with it rolling off earlier when measured inside the horn I think I need to sort out the front chamber and also the location of it in the horn. I think maybe the taps being quite long maybe the distance between the 4" cone and the diaphagm of the CD would give me that cancellation

Is that your finding or the manufacturer spec, because manufacturer specs don't usually apply in a domestic situation.

That is the manufacturers spec but I do want to use this loud not just at home

Those results look good @weltersys I have started doing a similar thing earlier this week by printing off specifically the port part of the horn and measuring it.

Was that a single port at the edge of the cone vs the center?

The front chamber is 2.5mm from the cone all over

Yes, single port at the edge of the cone vs the center.

I measured 2.5, 1.8, .9 square inch ports also.

The B&C 4NDF34 has 3.5mm Xmax, and 5.7mm Xvar, with the front chamber just 2.5mm from the cone you will be reducing lower frequency output potential by more than -7dB, and unless you severely peak limit the driver the sound of the cone hammering the plug will be objectionable.

If I recall correctly, the 4NDF34 Xlim is ~7mm.

I used 1/4" (6mm) standoffs, a 3/4" round port hole and no filler plug on the 4NDF34 in my 3way "Boat Horn".

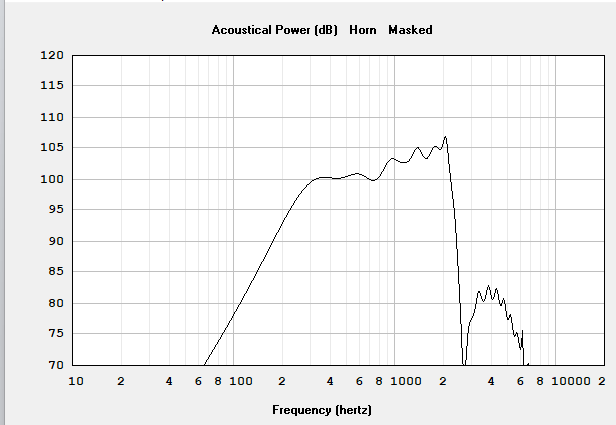

Response was ragged due to the driver entrance location into the folded EV PA60 horn, but usable past 1200Hz as seen in green:

The PA60 mid drivers have good response 600-6kHz, but I chose ~1000Hz passive 2 pole crossover as the 4NDF34 sounded much better than the compression drivers in the 600-1000Hz range.

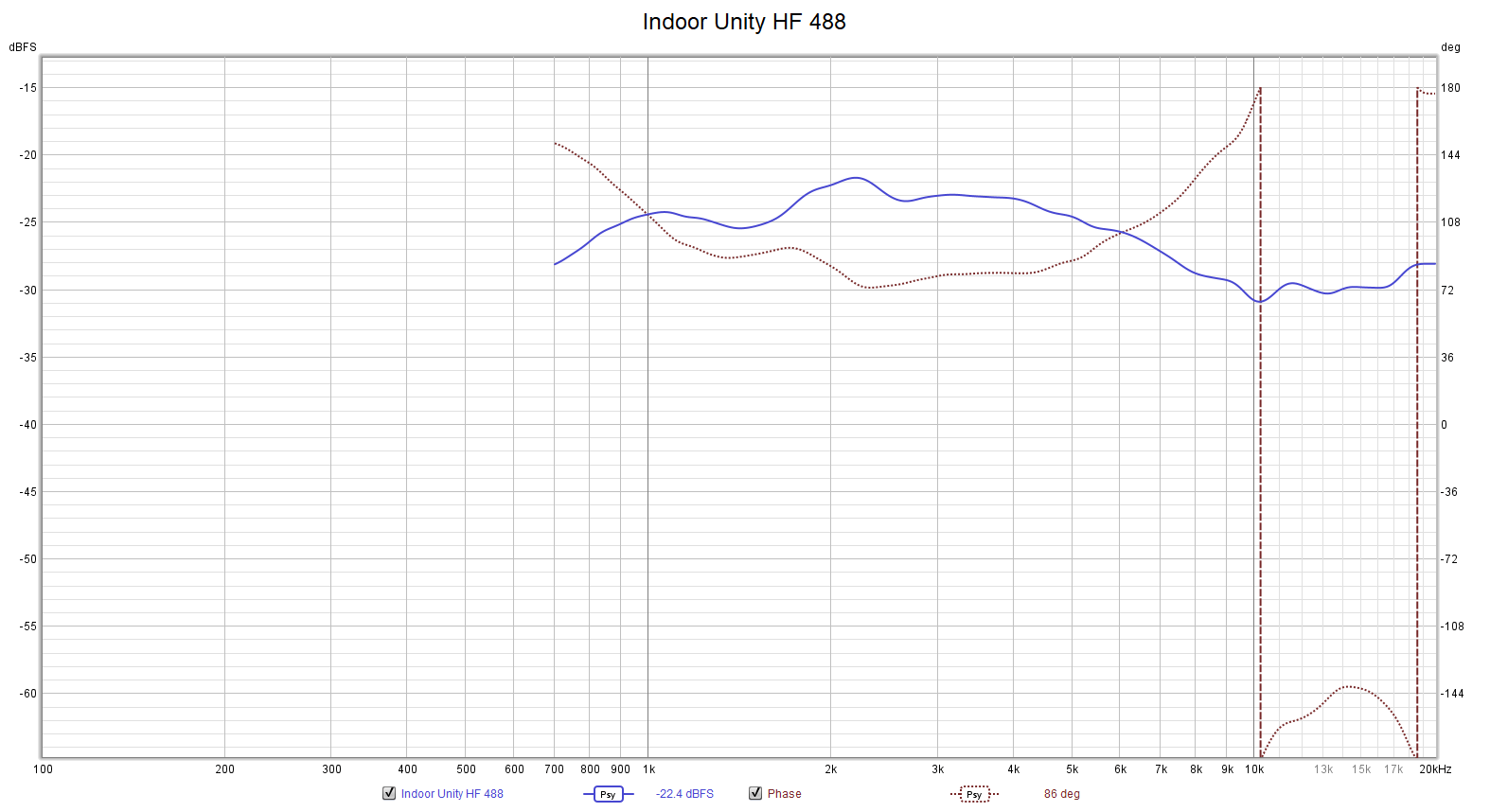

Your Lavoce (DF10.142LKS ?) HF driver appears to be loading well below 1000Hz, will be interested in hearing what you think of the cone/HF driver sound comparison at various crossover points at high SPL.

Art

Last edited:

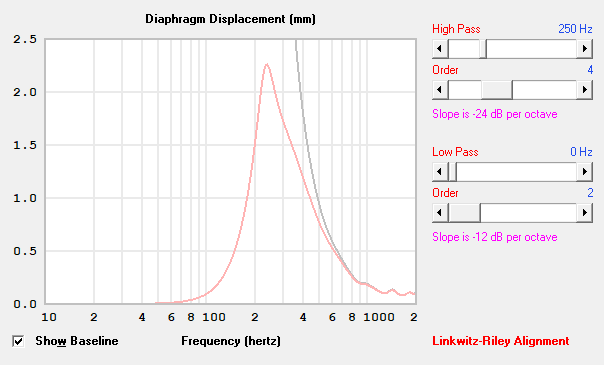

Nice, from my sims with it in the horn I ran out of power before xmax with a high pass within the band at the low end. A high pass of 350hz limited it to less than 2.5mm xmax.

I have tried some more measuring and I think I just need to tune the ports on it to get to 2k, the front chamber seems to be small enough

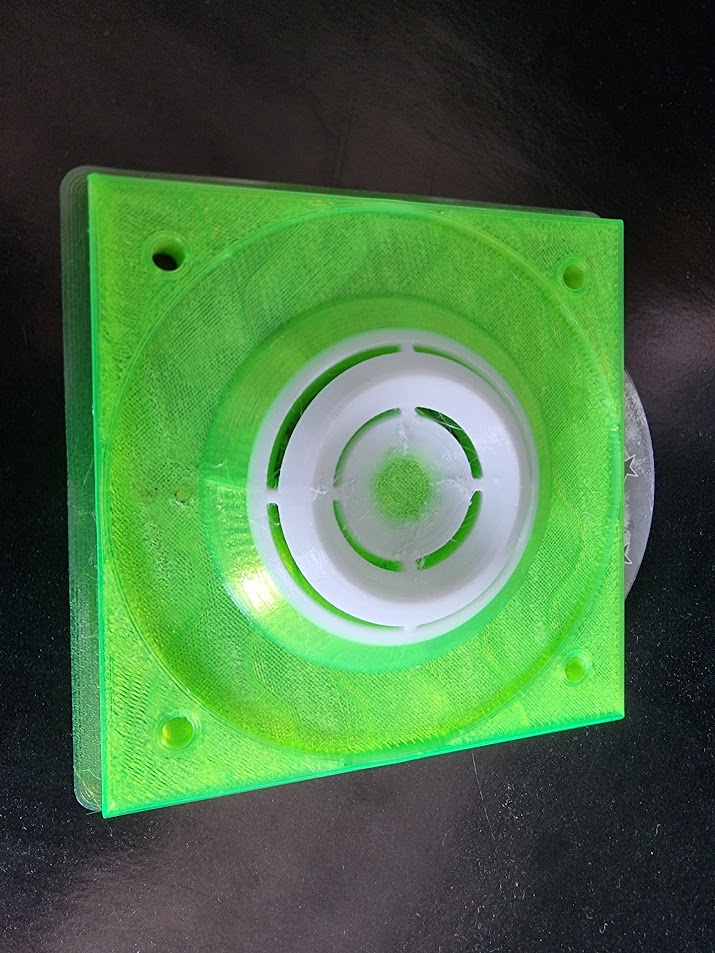

(I reprinted this to be a bit better)

Ignore everything other than the shape of this, I need to do it SPL and Gain calibrated but I did manage to get it reasonably flat up to 2khz although I'm not sure how this would do in the horn. I'm gonna print and test some more ports, I think I ideally need to get the ports a bit closer to the CD

@weltersys looking at your sim vs measurement you are getting a similar cancellation to me above 1200hz which could be something that Hornresp wouldn't account for? I have been trying to avoid using Akabak for this because it takes so long but it might show some more of what is happening haha

I am currently printing a piece that has 0mm gap between the cone and the filler bit so I can test different thickness gaskets, I will print a few gaskets then measure different combinations.

Also a picture of how it was measured haha:

I have tried some more measuring and I think I just need to tune the ports on it to get to 2k, the front chamber seems to be small enough

(I reprinted this to be a bit better)

Ignore everything other than the shape of this, I need to do it SPL and Gain calibrated but I did manage to get it reasonably flat up to 2khz although I'm not sure how this would do in the horn. I'm gonna print and test some more ports, I think I ideally need to get the ports a bit closer to the CD

@weltersys looking at your sim vs measurement you are getting a similar cancellation to me above 1200hz which could be something that Hornresp wouldn't account for? I have been trying to avoid using Akabak for this because it takes so long but it might show some more of what is happening haha

I am currently printing a piece that has 0mm gap between the cone and the filler bit so I can test different thickness gaskets, I will print a few gaskets then measure different combinations.

Also a picture of how it was measured haha:

Looks like you may be simming a very small rear chamber which would limit excursion.Nice, from my sims with it in the horn I ran out of power before xmax with a high pass within the band at the low end. A high pass of 350hz limited it to less than 2.5mm xmax.

The average power seldom exceeds 1/8th the peak power for music above ~125Hz.

Hornresp does not account for any non-pistonic attributes of the driver.@weltersys looking at your sim vs measurement you are getting a similar cancellation to me above 1200hz which could be something that Hornresp wouldn't account for?

The sim was from Kipman725, included only to show that a "very small throat chamber" (VTC) upper response didn't appear to roll off much higher than the relatively large VTC used in the Boat Horn.

The response of your phase plug reaching ~2.2kHz is impressive, wonder what it would look like if the clearance is increased to ~7mm (or whatever Xlim is)?

I am now looking at how I could do the phase plug style port and move the ports closer to the CD but I'm not sure it will fit.

I did sim them with a very small rear chamber. I got that volume using the model from B&C after designing my rear chamber caps I measured all the space left inside the model.

The port area and length in both the phase plug style and two ports are very similar areas but not length

Phase Plug: 20mm length and 5.05cm2 area

Two Ports: 30mm length and 4.73cm2 area

I think we would lose a lot of the high frequency based on sims, I can give it a go once I have printed this other part.

I also feel like I should print one with the same port area and length as the phase plug style one to see what that is like.

From what I have simmed hornresp also doesn't account for cancellations in the front chamber based on it's size/shape or cancellations across the horn for example only running one of the mid drivers in a MEH would give you a cancellation between the tap/driver and opposite wall of the horn.

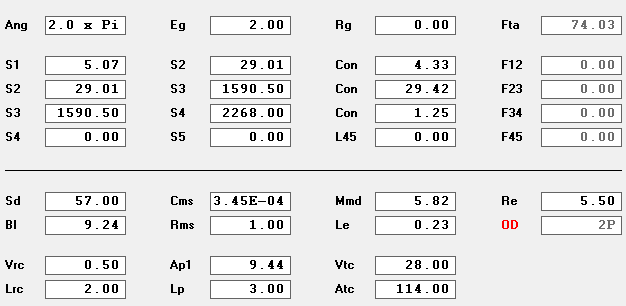

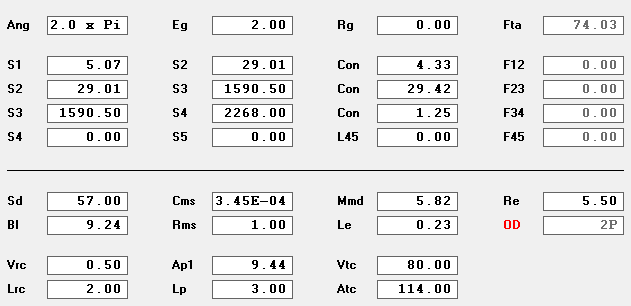

Here are two sims with 2.5mm front chamber and 7mm front chamber:

2.5mm

7mm

Then for reference: (with a very small rear chamber)

2mm

7mm

200w with 250hz high pass and some EQ to flatten it out a bit. This is something I would need to test in practice though, I would definitely be able to hear it if it starts touching haha.

I did sim them with a very small rear chamber. I got that volume using the model from B&C after designing my rear chamber caps I measured all the space left inside the model.

The port area and length in both the phase plug style and two ports are very similar areas but not length

Phase Plug: 20mm length and 5.05cm2 area

Two Ports: 30mm length and 4.73cm2 area

I think we would lose a lot of the high frequency based on sims, I can give it a go once I have printed this other part.

I also feel like I should print one with the same port area and length as the phase plug style one to see what that is like.

From what I have simmed hornresp also doesn't account for cancellations in the front chamber based on it's size/shape or cancellations across the horn for example only running one of the mid drivers in a MEH would give you a cancellation between the tap/driver and opposite wall of the horn.

Here are two sims with 2.5mm front chamber and 7mm front chamber:

2.5mm

7mm

Then for reference: (with a very small rear chamber)

2mm

7mm

200w with 250hz high pass and some EQ to flatten it out a bit. This is something I would need to test in practice though, I would definitely be able to hear it if it starts touching haha.

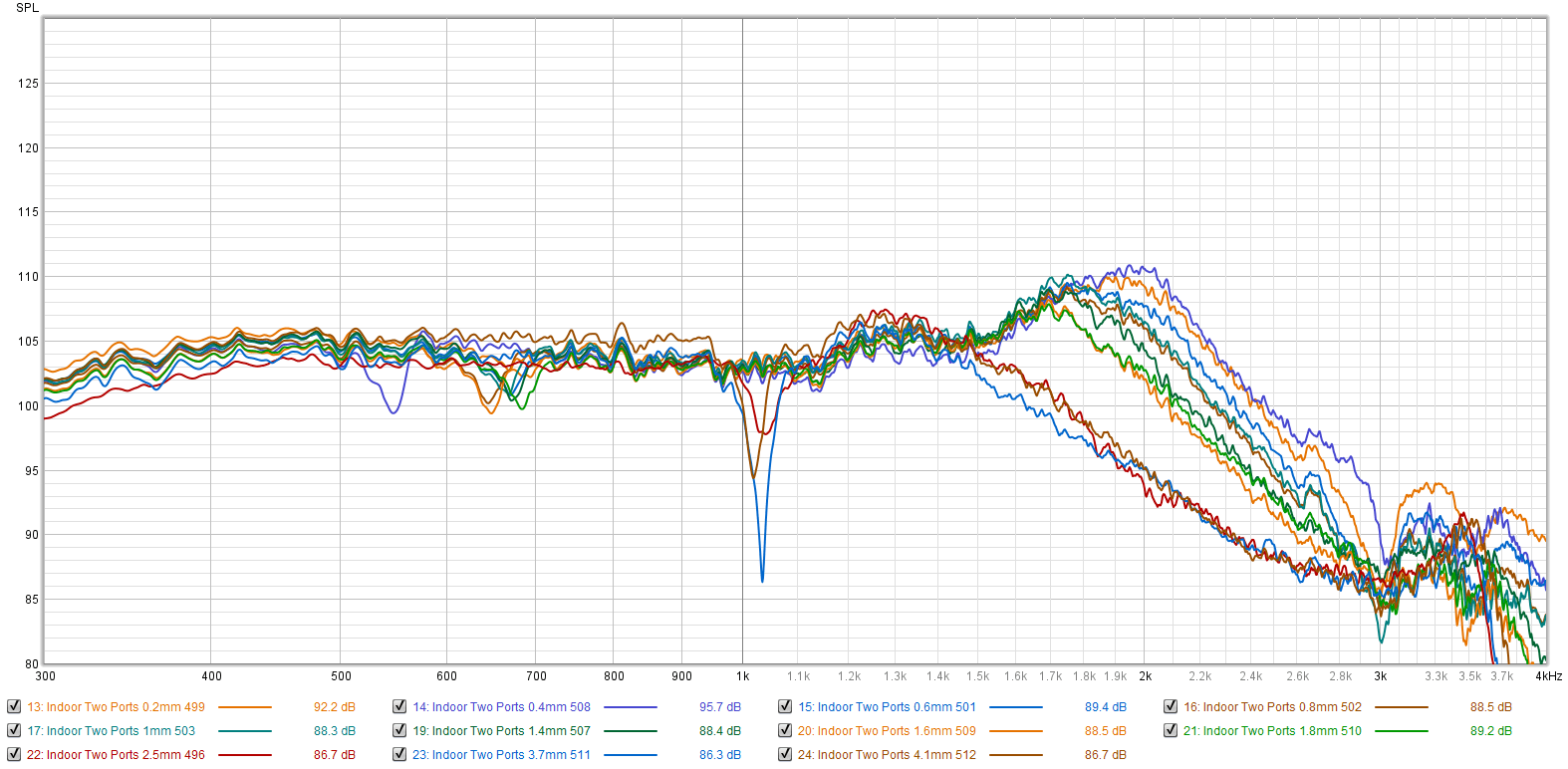

I have done some testing of different front chamber sizes with the two ports

I'm not sure whether it was worth doing or not but it is interesting that I started getting more and more of a dip just over 1k with the larger front chamber.

All the measurements up to 1.8mm were done with a piece I printed with 0mm front chamber then various gaskets

All the measurements above that were done with the original piece that was 2.5mm then the gaskets to increase it.

I am now printing a piece with a port in the middle with the same area as the phase plug just straight rather than spaced out around the cone, will see how that turns out

I'm not sure whether it was worth doing or not but it is interesting that I started getting more and more of a dip just over 1k with the larger front chamber.

All the measurements up to 1.8mm were done with a piece I printed with 0mm front chamber then various gaskets

All the measurements above that were done with the original piece that was 2.5mm then the gaskets to increase it.

I am now printing a piece with a port in the middle with the same area as the phase plug just straight rather than spaced out around the cone, will see how that turns out

- Home

- Loudspeakers

- Multi-Way

- Another 3d printed MEH