Hi there, thanks for letting me in ;-)

I am from Denmark, but live in sunny south of Spain. This is the 10th country where I live, which meant a lot of international moving, which again meant getting rid of my Large and Heavy B&W speakers and ditto amps etc. But now, settling down, I want to experience that high end sound again. So cue Troels Gravesen Illuminator 5 project. But.... the WAF (Wife Acceptance Factor) was really nil on his build, so I decided for a total overhaul.

I liked several things about this project, they are time aligned, the quality of the drivers involved, the fact that Wilson Audio Alexx is exactly the same. I will be amping the bottom with a Hypex FusionAmp with active crossover and having a passive crossover for the mids and tweeter with external amp.

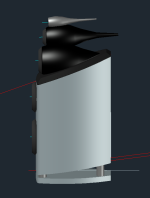

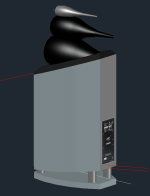

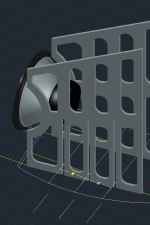

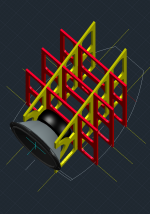

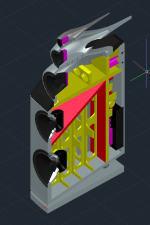

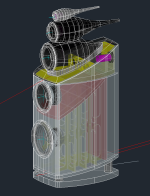

And now, after 3 weeks of spending every spare hour (read: 8 hours per day ) designing and planning and drawing, the finalized design is done. The enclosures correspond to all volumes in the original project, but obviously the upper part looks (and will behave) very different from the original design, so.... crossover modifications etc. But that's more than enough for a later thread. Suffice to say that this is a complex design, and while paper is grateful, it also has to be possible to actually assemble the darn thing, so a lot of planning went into that.

For now, I'd like to ask here if anyone has experience with casting of Cabinets such as these mid-tone and tweeters. What resin or material did you use ? Molding or casting in 2 shell parts or in one go ? I am thinking along the lines of reinforced epoxy with chopped glass fiber, which should give a lot higher density and very strong modulus. But this decision is not set in concrete (wait, perhaps I should try that ?! 🧐) and I for sure would like some suggestions before beginning - which is sometime next weekend.

I enclosed a few screenshots of how the design looks like, and for sure I'd also love to hear all sorts of comments and advice on what problems you see in this, your solutions and basically whatever you can think of.

I am from Denmark, but live in sunny south of Spain. This is the 10th country where I live, which meant a lot of international moving, which again meant getting rid of my Large and Heavy B&W speakers and ditto amps etc. But now, settling down, I want to experience that high end sound again. So cue Troels Gravesen Illuminator 5 project. But.... the WAF (Wife Acceptance Factor) was really nil on his build, so I decided for a total overhaul.

I liked several things about this project, they are time aligned, the quality of the drivers involved, the fact that Wilson Audio Alexx is exactly the same. I will be amping the bottom with a Hypex FusionAmp with active crossover and having a passive crossover for the mids and tweeter with external amp.

And now, after 3 weeks of spending every spare hour (read: 8 hours per day ) designing and planning and drawing, the finalized design is done. The enclosures correspond to all volumes in the original project, but obviously the upper part looks (and will behave) very different from the original design, so.... crossover modifications etc. But that's more than enough for a later thread. Suffice to say that this is a complex design, and while paper is grateful, it also has to be possible to actually assemble the darn thing, so a lot of planning went into that.

For now, I'd like to ask here if anyone has experience with casting of Cabinets such as these mid-tone and tweeters. What resin or material did you use ? Molding or casting in 2 shell parts or in one go ? I am thinking along the lines of reinforced epoxy with chopped glass fiber, which should give a lot higher density and very strong modulus. But this decision is not set in concrete (wait, perhaps I should try that ?! 🧐) and I for sure would like some suggestions before beginning - which is sometime next weekend.

I enclosed a few screenshots of how the design looks like, and for sure I'd also love to hear all sorts of comments and advice on what problems you see in this, your solutions and basically whatever you can think of.

Attachments

Impressive CAD skills.

You have your work cut out for you in fabrication. I cast a few spheres by combining hemispheres. I used cheap HPDE serving bowls as the molds with Epoxy resin and a chopped filler as well…………waaaaay too much work and cost…..I would not repeat the effort again.

You have your work cut out for you in fabrication. I cast a few spheres by combining hemispheres. I used cheap HPDE serving bowls as the molds with Epoxy resin and a chopped filler as well…………waaaaay too much work and cost…..I would not repeat the effort again.

Mayhem13, Thanks 🙂 Wait until you hear about how I will be making my own laminate structure for the wood needed 😵🤣

I am very interested in hearing about the cast wall thickness and if the speaker cab ended being acoustically dead. How would you describe it ?

I am very interested in hearing about the cast wall thickness and if the speaker cab ended being acoustically dead. How would you describe it ?

You're on the wrong track: Cast the woofer cabinet from concrete to make it heavy, and separate the top/mid cabinets from the bass. B&W Nautilus is 2/3 gimmick on the inside. But yes to smooth curves on the outside of the mids and highs.

Beautiful cabinet, good work and I like the modelisation process 🙂

Like the idea of physical offset.

But 5 ways ?

Do you have an idea of crossover frequency and slope ?

Do you know which driver you are going to use ?

You build a speaker around the drivers or the contrary ? Do you know the volume of the baffle to put the drivers ?

Good idea : Isolate bass from mid

But I think go to heavy of light boxes, depend on how you suppress parasitic vibrations.

Last but not least : your room ! You can have the best loudspeaker but your room can ruined all your effort.

Like the idea of physical offset.

But 5 ways ?

Do you have an idea of crossover frequency and slope ?

Do you know which driver you are going to use ?

You build a speaker around the drivers or the contrary ? Do you know the volume of the baffle to put the drivers ?

Good idea : Isolate bass from mid

But I think go to heavy of light boxes, depend on how you suppress parasitic vibrations.

Last but not least : your room ! You can have the best loudspeaker but your room can ruined all your effort.

Hi Jerome, Thanks for your kind words ! As I wrote above, the initial project is a Troels Gravesen Illuminator 5 (Google it and look at it. It resembles strongly a Wilson Audio Alexx). While I liked a lot about this project, the time alignment, the drivers used, I just couldn't accept the form factor, and decided to go my own way on that. I also liked a lot the 5-way, you can read more about that argumentation in the description of the project on Troels's homepage.

Drivers are Illuminator ScanSpeak, which are, of course, very very good. Volumes are decided by Troels.

The speakers will weigh around 80 kg each, so I don't think vibrations will be a problem. Woofer cabinet is, as you can see, braced extensively. The cabinet I am making laminating 10 layers of wood, fiber glass and heavy rubber together in a press. This is done to obtain a laminate, which furthermore is curved, that is much stronger, heavier and acoustically better than a normal piece of bent wood. Upper drivers are still undecided, but... trust me... they will be solid !

Only yesterday I finally decided to ditch the passive crossover for the mids and tweeter and go 100% active, 5 channels each speaker, 1.100 W / 4 ohm, 700 W / 8 ohm. The amps are Hypex and have active crossover. So measuring the room and dialing in the speaker is easier than ever. You're completely right, the room is THE single most important factor in how something sounds, and I really think that active crossover is the ONLY way to address this issue.

I attach the last tweaks on the design with aluminum profile accents and the final aluminum wall support for the amps. Wood will be Walnut Burl. I hope you like it !

Drivers are Illuminator ScanSpeak, which are, of course, very very good. Volumes are decided by Troels.

The speakers will weigh around 80 kg each, so I don't think vibrations will be a problem. Woofer cabinet is, as you can see, braced extensively. The cabinet I am making laminating 10 layers of wood, fiber glass and heavy rubber together in a press. This is done to obtain a laminate, which furthermore is curved, that is much stronger, heavier and acoustically better than a normal piece of bent wood. Upper drivers are still undecided, but... trust me... they will be solid !

Only yesterday I finally decided to ditch the passive crossover for the mids and tweeter and go 100% active, 5 channels each speaker, 1.100 W / 4 ohm, 700 W / 8 ohm. The amps are Hypex and have active crossover. So measuring the room and dialing in the speaker is easier than ever. You're completely right, the room is THE single most important factor in how something sounds, and I really think that active crossover is the ONLY way to address this issue.

I attach the last tweaks on the design with aluminum profile accents and the final aluminum wall support for the amps. Wood will be Walnut Burl. I hope you like it !

Attachments

@JacobDIY very cool project, I prefer your design, better look and acoustically better.

The illuminator 5 has crossover frequency 80Hz, 180Hz, 900Hz, 3.1kHz LR2. My feeling is 12dB slope could be not enough because you have negative effect between drivers, too close crossover frequency and low slope, not know how it is audible but visible in the simulation. You have to test to find the better compromise.

Follow with attention your work in progress 🙂

The illuminator 5 has crossover frequency 80Hz, 180Hz, 900Hz, 3.1kHz LR2. My feeling is 12dB slope could be not enough because you have negative effect between drivers, too close crossover frequency and low slope, not know how it is audible but visible in the simulation. You have to test to find the better compromise.

Follow with attention your work in progress 🙂

@jerome69 Thanks again !

The whole crossover thing was making me very nervous about the project, because I knew that I'd have to tweak and change. The high end crossover I intended to build was also very expensive, and in the end it would always be sort of a compromise, as all crossovers are. So with the active crossover DSP it will be much easier - and it really was the main reason for going 100 % active. Through the software, the possibilities are endless.

The whole crossover thing was making me very nervous about the project, because I knew that I'd have to tweak and change. The high end crossover I intended to build was also very expensive, and in the end it would always be sort of a compromise, as all crossovers are. So with the active crossover DSP it will be much easier - and it really was the main reason for going 100 % active. Through the software, the possibilities are endless.

- Home

- Loudspeakers

- Multi-Way

- 5-way high end, casting of mid tone and tweeter enclosures