Re the CDM1 (mk1) mechanism.

Does the spindle motor shaft come out from the top, or the bottom? Must I remove the disk turntable (how???), or the motor rotor to get it to come apart?

Thanks

Does the spindle motor shaft come out from the top, or the bottom? Must I remove the disk turntable (how???), or the motor rotor to get it to come apart?

Thanks

Thanks Lourens! That diagram is exactly what i needed!

It's in a ReVox B226.

The spindle is a little "stiff" or feels heavily damped. No audio problems yet, but the disc stops immediately the power is shut off - there is no inertial run-on. I imagine there should be some free-wheeling of the spindle and disc, although the motor does not yet seem to be struggling to overcome the load. What prompted me to investigate this is that the transport has become a little noisier than I remember it being.

Whats the problem with the CDM-1 Steerpike?

It's in a ReVox B226.

The spindle is a little "stiff" or feels heavily damped. No audio problems yet, but the disc stops immediately the power is shut off - there is no inertial run-on. I imagine there should be some free-wheeling of the spindle and disc, although the motor does not yet seem to be struggling to overcome the load. What prompted me to investigate this is that the transport has become a little noisier than I remember it being.

I had the same with my CD304MK2 CDM1, sometimes the toc won't read. I removed the underside motor parts only. The spindle rests on a teflon plate, it was lightly oxidated(brown), cleaned it(beware of scratches on axle, did that with a fingernail), new clock oil on bushes/spindel and some grease on teflon plate and its allright now.

You have to align the bearing until it turns freely when reassembled with locking of screws.

Good luck

You have to align the bearing until it turns freely when reassembled with locking of screws.

Good luck

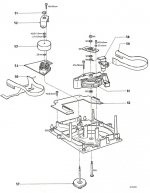

Lourens said:See attached exploded view from the service manual.

Lourens, you wouldn't happen to have a service manual for the CDM1.2 by any chance?

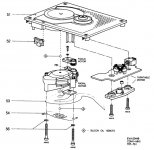

AFAIK there is no dedicated sm for Philips CDM1 mkII (the one you're looking for?). I found this exploded view of it in the Philips CDD882 manual.

For complete servicing information of the CDM1 mkII you need to have the Philips CD880 manual as well.... Both, and many others on one cd, obtainable from http://ultranalog.com/

For complete servicing information of the CDM1 mkII you need to have the Philips CD880 manual as well.... Both, and many others on one cd, obtainable from http://ultranalog.com/

Attachments

tonyptony said:Thanks!

Hi.

A complete set of the servicing manuals for CDM0 - CDM9 is available from CAS, Germany

service[at]cas-germany[dot]com

about 10e

Andy

I had a similar problem (Revox B226) which seems to be quite common with CDM1. The motor spindle runs on a teflon plate (part#51 in the posted drawing). This plate is some kind of screw and can be used to adjust the laser focus by adjusting the height of the CD platter.

Over the years the motor spindle digs a little "hole" in the teflon plate and as a result the distance between laser and CD decreases and at some point the laser has difficulties to focus. Then the playes starts to have problems with reading some CDs or with the last tracks on a CD.

The cure is to replace the teflon screw or make one or two turns of the screw to compensate for the "loss of height" and lift the CD platter up a bit to its original position. As the hole in the teflon screw is most likely off center you can only make full turns. One or two should do the job. When replacing the screw measure the height of the CD platter BEFORE you remove the old screw to have a starting point for the reassembly of the new screw.

When replacing the screw measure the height of the CD platter BEFORE you remove the old screw to have a starting point for the reassembly of the new screw.

I never bought a new telfon screw but I've heard that they are still available from Philips and Revox. If somebody has a service manual for CDM-1 could you please look up the service part number of the screw and post it here? It's part 51 in the drawing posted by Lourens.

Cheers

joe

Over the years the motor spindle digs a little "hole" in the teflon plate and as a result the distance between laser and CD decreases and at some point the laser has difficulties to focus. Then the playes starts to have problems with reading some CDs or with the last tracks on a CD.

The cure is to replace the teflon screw or make one or two turns of the screw to compensate for the "loss of height" and lift the CD platter up a bit to its original position. As the hole in the teflon screw is most likely off center you can only make full turns. One or two should do the job.

When replacing the screw measure the height of the CD platter BEFORE you remove the old screw to have a starting point for the reassembly of the new screw.

When replacing the screw measure the height of the CD platter BEFORE you remove the old screw to have a starting point for the reassembly of the new screw.I never bought a new telfon screw but I've heard that they are still available from Philips and Revox. If somebody has a service manual for CDM-1 could you please look up the service part number of the screw and post it here? It's part 51 in the drawing posted by Lourens.

Cheers

joe

part #

Part number is 4822 502 11701

If you find a source for it, please tell me/us!

I experienced similar problems with a Studer A727 and second your analysis & conclusions 😉

grtz

Lourens

Part number is 4822 502 11701

If you find a source for it, please tell me/us!

I experienced similar problems with a Studer A727 and second your analysis & conclusions 😉

grtz

Lourens

With time the soft teflon gets a greater indentation spot from curved spindle end. In my case the spindle was oxidated a little, check this also, and remove this oxidation, or the soft teflon will wear fast again.

Thanks Joe for the info.

I have noted that problem; every few years I turn in that screw to bring the focus servo back to the 'centre' of its range (best done while watching the focus error signal on an oscilloscope).

The current problem is the stiffness of the shaft. I figured it just needs some lubrication, but i'm not keen to just ADD oil, and would prefer to clean first, then re-oil.

Other than me feeling that the spindle was stiff when I opened the machine to replace the o-rings on which the drawer rolls, I would not have known anything was wrong - the player does not malfunction in any way.

I have noted that problem; every few years I turn in that screw to bring the focus servo back to the 'centre' of its range (best done while watching the focus error signal on an oscilloscope).

The current problem is the stiffness of the shaft. I figured it just needs some lubrication, but i'm not keen to just ADD oil, and would prefer to clean first, then re-oil.

Other than me feeling that the spindle was stiff when I opened the machine to replace the o-rings on which the drawer rolls, I would not have known anything was wrong - the player does not malfunction in any way.

Thank you guys, I will keep you in the loop. I have a Studer A725 waiting to come back to live. Unfortunatley somebody glued the screw in, so it's impossible to (re)move it without destruction. I'm curious to hear a proper implementation of the 14 bit chip set as I was already very surprised of a cheap Philips player with cdm2.

BTW: According to the Revox service manual no lubrication is needed.

BTW: According to the Revox service manual no lubrication is needed.

The teflon could run without oil, but the sintered bronze bearings need some oil, especially after about 20 years of duty!

Guys, I have to admit that I'm a little afraid of doing this kind of work myself on my Proceed PDT3 (CDM1.2). Can anyone recommend someone who can do a quality cleaning, relube, new belts (if needed), and realign of this old mechanism? Someone who can be trusted to do the job right at a reasonable cost?

tubee said:The teflon could run without oil, but the sintered bronze bearings need some oil, especially after about 20 years of duty!

Tubee,

Oh yes, I agree.

Btw. I've read in another thread that you have same schematics of a CD880. If you have them as scans could you please email them to me? I bought a CD880 fitted with a Trichord clock on ebay. Unfortunatley the PSU of the clock is connected to the Analog PSU. This probably not the best way to do it. And some cap replacements won't hurt as well.

Tonyptony,

Sorry, I don't know.

joe

Joe, have a copy of 2 pages of it, a friend of my has the original (paper) manual.

Try: http://user.planetaclix.pt/

Try: http://user.planetaclix.pt/

- Home

- Source & Line

- Digital Source

- CDM1: help please: removal of spindle motor shaft