A LS165w-2T is an SMPS producing 300v @ 0.3A and 6.3v @ 5A. It's available at AliExpress and is inexpensive and small. There is a review at another forum at

https://www.head-fi.org/threads/review-ls165w-2t-switch-mode-power-supply-for-tube-amp-use.975587/

Would one or more of the experts on this forum be interested in creating something similar to AmyAlice or PO89ZB that could reduce the noise in the 300v output?

If there is already such a circuit, could you let me know where it is?

ray

https://www.head-fi.org/threads/review-ls165w-2t-switch-mode-power-supply-for-tube-amp-use.975587/

Would one or more of the experts on this forum be interested in creating something similar to AmyAlice or PO89ZB that could reduce the noise in the 300v output?

If there is already such a circuit, could you let me know where it is?

ray

Beware, I'm not an expert, but I play one on TV . . . and like most TV characters I like to be long winded.

I have seen switching power supplies for tube amps several times before in discussions, and the general consensus is use at your own risk, your mileage may vary, and success comes down to both your skill at grounding and how much noise you can tolerate. There is another version more expensive and maybe not as capable you can find if you search "250W Tube Amp Power Supply" on ebay. At the very least, be prepared to be underwhelmed as to whether the supply can perform up to spec in terms of power output. Most run them at way less than the rated power to avoid reliability/lifespan and thermal issues.

I don't believe the problem with these supplies is the noise on the 300V. I say that because for a typical tube high voltage supply, you are going to want to use larger capacitors (~47uF or higher) for fast, low impedance supply reserve available for the output plates, and you typically have enough voltage headroom to use larger value resistors in a C-R-C filter or even a choke, which should me more effective than the designs you referenced.

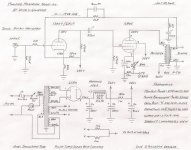

Much more problematic is the filament supply, and the overall EMI output. The filament 6.3 or 12.6V will be high current, and the ripple on this supply is much more difficult to deal with. The ripple will likely be across a range of frequencies, and at high current will likely produce alternating magnetic coupling within audible frequencies to surrounding circuitry. Even with correct twisting and routing of the heater wires this can be a problem. Noise can also couple between the heater filament and the enclosing indirectly heated cathode, because the cathode typically runs at a higher voltage than the heater, and can act like a plate attracting electrons boiling off of the heater creating a hum. This can be remedied in a design using a linear supply as Dave Gillespie did in his 8600 series mods (schematic below) by creating a virtual center voltage with 100 Ohm resistors across the filament secondary and attaching this to the cathode so the heater voltage is centered around the cathode voltage. For the SMPS, the filament ground may be connected to the 300V ground, (not floating) and this may not be possible. Other ways to mitigate filament switching noise would be with large capacitors, but you can't employ much of a C-R-C filter without incurring too large of a voltage drop (unless you can adjust filament voltage up to compensate, but it's still a lot of trouble.

The final problem is that in such an open frame switching supply, there is a LOT of EMI radiating off of everything- the components, back out onto the AC power input, as well as the outputs. Some claim they can use these supplies with little problem from noise. Check out this design. Others have gone to extreme lengths to contain the noise- encasing the supply in a box, LC filtering of the AC inputs, boutique filter designs you brought up, and lots of other methods, and still suffer audible hiss and hum.

In the future I do plan on buying one of these supplies for use in a development/prototype build platform, and after playing with that, if the noise proves acceptable perhaps build a full design using one of these, but I would be cautious.

I have seen switching power supplies for tube amps several times before in discussions, and the general consensus is use at your own risk, your mileage may vary, and success comes down to both your skill at grounding and how much noise you can tolerate. There is another version more expensive and maybe not as capable you can find if you search "250W Tube Amp Power Supply" on ebay. At the very least, be prepared to be underwhelmed as to whether the supply can perform up to spec in terms of power output. Most run them at way less than the rated power to avoid reliability/lifespan and thermal issues.

I don't believe the problem with these supplies is the noise on the 300V. I say that because for a typical tube high voltage supply, you are going to want to use larger capacitors (~47uF or higher) for fast, low impedance supply reserve available for the output plates, and you typically have enough voltage headroom to use larger value resistors in a C-R-C filter or even a choke, which should me more effective than the designs you referenced.

Much more problematic is the filament supply, and the overall EMI output. The filament 6.3 or 12.6V will be high current, and the ripple on this supply is much more difficult to deal with. The ripple will likely be across a range of frequencies, and at high current will likely produce alternating magnetic coupling within audible frequencies to surrounding circuitry. Even with correct twisting and routing of the heater wires this can be a problem. Noise can also couple between the heater filament and the enclosing indirectly heated cathode, because the cathode typically runs at a higher voltage than the heater, and can act like a plate attracting electrons boiling off of the heater creating a hum. This can be remedied in a design using a linear supply as Dave Gillespie did in his 8600 series mods (schematic below) by creating a virtual center voltage with 100 Ohm resistors across the filament secondary and attaching this to the cathode so the heater voltage is centered around the cathode voltage. For the SMPS, the filament ground may be connected to the 300V ground, (not floating) and this may not be possible. Other ways to mitigate filament switching noise would be with large capacitors, but you can't employ much of a C-R-C filter without incurring too large of a voltage drop (unless you can adjust filament voltage up to compensate, but it's still a lot of trouble.

The final problem is that in such an open frame switching supply, there is a LOT of EMI radiating off of everything- the components, back out onto the AC power input, as well as the outputs. Some claim they can use these supplies with little problem from noise. Check out this design. Others have gone to extreme lengths to contain the noise- encasing the supply in a box, LC filtering of the AC inputs, boutique filter designs you brought up, and lots of other methods, and still suffer audible hiss and hum.

In the future I do plan on buying one of these supplies for use in a development/prototype build platform, and after playing with that, if the noise proves acceptable perhaps build a full design using one of these, but I would be cautious.

Attachments

Thanks for your lengthy reply. I am mostly interested in the 300v solution rather than the 6.3v since we already have PO89ZB and AmyAlice for low voltages. Like you, I am interested in a high voltage SMPS solution for test purposes and also for reduced weight issues. After all, a simple transformer / CLC or CRC solution is more than adequate.

Perhaps I should use PO89ZB as a model and just increase the voltage ratings of the caps and the voltage rating of the diode (or multiples). I can create my own PCBs with Kicad. Speaking of which, I have turned 77 and I find Kicad a wonderful tool for brain exercise, particularly PCB layout. I often create PCBs just for fun without planning to send them off for manufacture.

ray

Perhaps I should use PO89ZB as a model and just increase the voltage ratings of the caps and the voltage rating of the diode (or multiples). I can create my own PCBs with Kicad. Speaking of which, I have turned 77 and I find Kicad a wonderful tool for brain exercise, particularly PCB layout. I often create PCBs just for fun without planning to send them off for manufacture.

ray