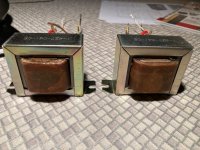

For sale here is a nice pair of the Sony Tamura output transformers. There’s a rumor they have nickel cores, can’t confirm, but I can confirm that they sound fantastic.

These are 5K to 8ohm with 600 ohm secondaries as well. They were gapped for 60 ma. , and sound great with EL84, 6V6GT, etc..

120€ paypal friends and family

These are 5K to 8ohm with 600 ohm secondaries as well. They were gapped for 60 ma. , and sound great with EL84, 6V6GT, etc..

120€ paypal friends and family

Attachments

Hey Bas! You still listening to the pair I sent you? They are great little outputs arent they?😎

I have some of the permalloy versions in a nice oak box for a SE 45 amp.

I just finished a 45 amp a month or two ago with these transformers, sounds fantastic!😎🤌🏻

I’ve noticed that you tend to remove the mounting channels, and then clamp the transformers in wood. Does that have an effect on the sound?

I've never done a before and after listening test. I doubt it even has an audible effect. It's just something I like to do. I'm weird like that.

An anecdote about an objective effect: I wound crossover inductors with two double-c cores (Vitroperm 500) at first clamping the halves with plastic zip ties when I prototyped the winding. Then I wound the actual coils and clamped the cores with metal bands (sorry, don't know the term in english, the stuff used to clamp transformer cores...) and found the Q had dropped to half of what it was before. I then switched the metal clamping bands for Hellerman Tyton KR plastic bands and Q was back at 250.I’ve noticed that you tend to remove the mounting channels, and then clamp the transformers in wood. Does that have an effect on the sound?

I didn't do a listening test (didn't have 4 sets of cores to set up a proper ABX test) so I can't tell if that has a subjective effect as well.

Got them thanks! Best packaging ever!

Busy varnishing the laminates against possible corrosion..unlikely cause they seem to have a wax layer.

Anyway pleasure doing business.

Busy varnishing the laminates against possible corrosion..unlikely cause they seem to have a wax layer.

Anyway pleasure doing business.

Oh great!! I’m glad they arrived ok.

I don’t wanna give the post any chance to ruin anything, I tried to package things like they will be dropped from a building🫣😂

I don’t wanna give the post any chance to ruin anything, I tried to package things like they will be dropped from a building🫣😂

@Bas Horneman

Thank you for showing the OPTs you received. I'm curious as to the reasons you took the housing frame out, and how you installed them? Interesting!🤔

Joe

Edited: ah.... I see. You varnish the laminates and then would put the frames back as usual. 👍

Last edited:

Hey Joe,

No I don't put them back in the frames. Only if the frames are brass.

I have several methods. My favourite one is in oak boxes (not available at Ikea anymore)

where I just push keep em stuck to the bottom by glueing in some wood.

Or like this.

Or like this in my zen clone (the only versions that I have that are permalloy I think) Also bought from mctavish.

No I don't put them back in the frames. Only if the frames are brass.

I have several methods. My favourite one is in oak boxes (not available at Ikea anymore)

where I just push keep em stuck to the bottom by glueing in some wood.

Or like this.

Or like this in my zen clone (the only versions that I have that are permalloy I think) Also bought from mctavish.

And the reason I take them off is because they are ferrous. Extremely magnetic 🙂

Here is a picture of a MagneQuest autoformer. Tightened with a copper band to a non magnetic stainless mounting plate.

Lundahl old style:

Magnetic.

Lundahl new style. Non magnetic stainless steel.

Here is a picture of a MagneQuest autoformer. Tightened with a copper band to a non magnetic stainless mounting plate.

Lundahl old style:

Magnetic.

Lundahl new style. Non magnetic stainless steel.

So I asked a question on this forum why...got no answers except from a guy on facebook:

"there is actually a lot of issues caused by the magnetic shrouds and chassis. I was recently told by Jack Elliano of Electraprint transformers that the old school method of doing horizontal transformers caused untold issues from the core flux coupling with the steel chassis that was parallel to the core in that configuration. Apparently designers never really thought much about it until fairly recently it was standard build practice in consumer electronics and guitar amps. Bud Purvine was advocating non magnetic screws 20+ years ago as well."

I noticed Magnequest also uses brass bolts in his EI cored transformers and plate chokes.

"there is actually a lot of issues caused by the magnetic shrouds and chassis. I was recently told by Jack Elliano of Electraprint transformers that the old school method of doing horizontal transformers caused untold issues from the core flux coupling with the steel chassis that was parallel to the core in that configuration. Apparently designers never really thought much about it until fairly recently it was standard build practice in consumer electronics and guitar amps. Bud Purvine was advocating non magnetic screws 20+ years ago as well."

I noticed Magnequest also uses brass bolts in his EI cored transformers and plate chokes.