Hello,

I'm started to design master clock and need to know your opinion about this idea,

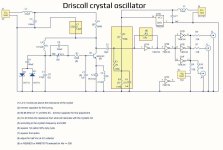

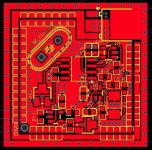

This OCXO idea is master clock for https://www.ti.com/lit/ds/symlink/lmk05318b.pdf ! The final master clock out will be trought it and will be fine corrected trought gps, thats for later. This oven also have oven controled voltage reference 2.5V which I going to use for J.D. regulator which will supply this OCXO. I done pcb oven design, picture 3, pcb will be canaled from all sides and an metal case will be soldered on booth top and botton layer, over those metal case going another metal case isolated by silicone. I thinked to do Driscoll crystal driver but it is complicated, instead I think I will do it with Comtrue CT7302PL since that ic have 190db dynamic range and an thd+n -175db, it will drive SC Cut 3rd ot crystal perfectly well and will give me master clock on their mclk out in TTL format. Oven is driven by darlington MJD122 and 40 resistors 1k which give around 25 ohm load, those 40 resistors will evenly heat the central part of the pcb on which is placed sc cut crystal and AD780 bangap reference which have temperature out which I have used for oven fine control. Waiting your opinion regarding circuit schematic design! Thank you!

I'm started to design master clock and need to know your opinion about this idea,

This OCXO idea is master clock for https://www.ti.com/lit/ds/symlink/lmk05318b.pdf ! The final master clock out will be trought it and will be fine corrected trought gps, thats for later. This oven also have oven controled voltage reference 2.5V which I going to use for J.D. regulator which will supply this OCXO. I done pcb oven design, picture 3, pcb will be canaled from all sides and an metal case will be soldered on booth top and botton layer, over those metal case going another metal case isolated by silicone. I thinked to do Driscoll crystal driver but it is complicated, instead I think I will do it with Comtrue CT7302PL since that ic have 190db dynamic range and an thd+n -175db, it will drive SC Cut 3rd ot crystal perfectly well and will give me master clock on their mclk out in TTL format. Oven is driven by darlington MJD122 and 40 resistors 1k which give around 25 ohm load, those 40 resistors will evenly heat the central part of the pcb on which is placed sc cut crystal and AD780 bangap reference which have temperature out which I have used for oven fine control. Waiting your opinion regarding circuit schematic design! Thank you!

Attachments

Last edited:

Gps 1pps correction is just one of the options but is not needed at all if not needed, just option. The important thing here is oven control principe, vref and sc cut crystal driver. Later LMK carefull design as it will be used for mutli freq out. Oven is the most important here as it need to fe very precise, can be done by this in decimal-two or even maybe in 3 decimal precise temperature.

Last edited:

Google translate. I'm corrected "our" to "this" : )Our... who are "we"?

Why involve GSP?

//

Which temperature sensor do you expect to use to give that precision? I think it would be a challenge to get 3 decimals even with PT100. Nesting one fine control oven inside a coarse control oven is a possibility for enhanced precision.Oven is the most important here as it need to fe very precise, can be done by this in decimal-two or even maybe in 3 decimal precise temperature.

At that level of control you might have to worry about other things affecting a xtal oscillator such as mechanical forces (i.e. gravity, stray magnetic fields) and long term drift.

The AD780 temperature output is rated at 1.9mV/C with no noise data given, I wonder if it is much use for ultra-fine temperature control.

Also how are you going to verify the oven's thermal performance?

Thanks! Yes I definitely have no equipment to verify thing, only which I can do is hack using an gps 1pps interupt to verify frequency of the LMK and adjust them for fine freq. So in general I even have no way to verify temperature in decimal but just quesing that this oven is self adjustable and will stop at an certain temperature and stay on it stabile?

At the moment, you don't have a single reference size at your home or "neighbor" with which you could measure something and compare it with these required performances, FORGET THE VOLTAGE if you don't have a 6+ digit HP/Fluke, custom A/D ahhh better don't.

Temperature, eh, how do you measure it directly, it MUST be via voltage!

And in the end what is left??? Smile

Measuring, or more precisely COMPARING the frequency of that whole circuit we are making, with what? Smile

With REFERENCE OSCILLATOR, whatever frequency, where did you get that from? Smile

That's the main HACK of this story, GPS!!!

Almost every "online newsagent" has it, which according to some specifications have extremely good "long-term" characteristics (0.01ppm frequency stability), while the short-term ones are questionable, it has a jitter that is, unfortunately, quite large, on the order of +/-120ns.

The only device that can "iron out" that jitter is the LMK, and with it 0.01ppm long-term stability would be maintained, while the clock-jitter would be almost COMPLETELY ELEMENTARY with about +/-120fs (femto seconds) RMS jitter !!!

LMK is designed for MASTER clcok in some system, even a specifically optimized combination for GPS + OCXO, when it has GPS and is stable it works with it and clears all anomalies, and if it is not there, it automatically switches to the HOLD-OVER oscillator, i.e. OCXO if we put it so that even after losing the GPS signal, there is still an accurate and stable signal frequency that "holds water" for some time.

And that OCXO starts to slide in one direction and it all starts to deviate and there is an exact measure for these deviations as they are allowed in certain time periods, for some devices, for example, up to 1ppm is allowed within 3 hours so that the device guarantees that it will not fail from the allowed level of synchronization and can work, after that if there is still no GPS it must report that it is in "non-synchronized" state.

Therefore, frequency measurement with the help of GPS is currently the only VERY ACCURATE mechanism for DIY to get results of that level of accuracy so that you can experiment with your own and other oscillators and measure/monitor behavior.

Temperature, eh, how do you measure it directly, it MUST be via voltage!

And in the end what is left??? Smile

Measuring, or more precisely COMPARING the frequency of that whole circuit we are making, with what? Smile

With REFERENCE OSCILLATOR, whatever frequency, where did you get that from? Smile

That's the main HACK of this story, GPS!!!

Almost every "online newsagent" has it, which according to some specifications have extremely good "long-term" characteristics (0.01ppm frequency stability), while the short-term ones are questionable, it has a jitter that is, unfortunately, quite large, on the order of +/-120ns.

The only device that can "iron out" that jitter is the LMK, and with it 0.01ppm long-term stability would be maintained, while the clock-jitter would be almost COMPLETELY ELEMENTARY with about +/-120fs (femto seconds) RMS jitter !!!

LMK is designed for MASTER clcok in some system, even a specifically optimized combination for GPS + OCXO, when it has GPS and is stable it works with it and clears all anomalies, and if it is not there, it automatically switches to the HOLD-OVER oscillator, i.e. OCXO if we put it so that even after losing the GPS signal, there is still an accurate and stable signal frequency that "holds water" for some time.

And that OCXO starts to slide in one direction and it all starts to deviate and there is an exact measure for these deviations as they are allowed in certain time periods, for some devices, for example, up to 1ppm is allowed within 3 hours so that the device guarantees that it will not fail from the allowed level of synchronization and can work, after that if there is still no GPS it must report that it is in "non-synchronized" state.

Therefore, frequency measurement with the help of GPS is currently the only VERY ACCURATE mechanism for DIY to get results of that level of accuracy so that you can experiment with your own and other oscillators and measure/monitor behavior.

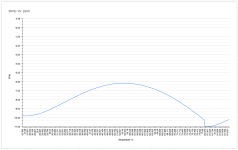

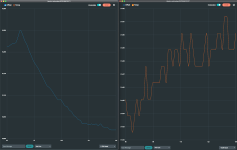

Look at these graphs, it was made by programming the Black Pill to show the frequency of its oscillator with the XTAL on the board connected via GPS and 1PPS to measure that frequency (left graph) which I know SHOULD be, so the graph actually shows only the deviation that is DIRECTLY dependent on the temperature of the PCB, which is measured there via the MCU and its internal temperature sensor!

PS: Anyone who understands this graph can practically see that maintaining the temperature according to the measured temperature is much more problematic than maintaining the temperature according to the measured frequency!

PS: Anyone who understands this graph can practically see that maintaining the temperature according to the measured temperature is much more problematic than maintaining the temperature according to the measured frequency!

Attachments

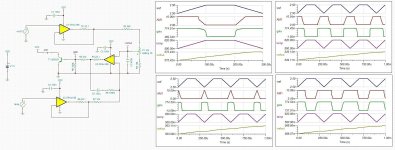

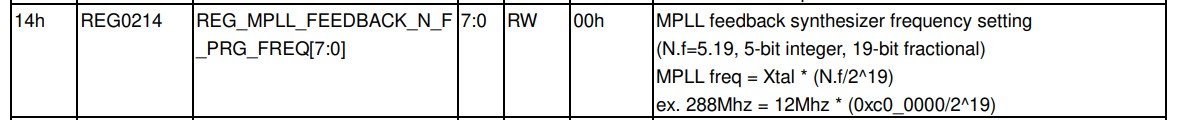

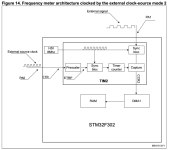

CT7302 would be I think wery well as a sc cut crystal driver? Tricky thing here is we can use I2S mclk as a master clock! For example if we put some fake pwn to their i2s input and at the output we can get I2S mclk! But take a look at this picture, thats in relation to I2S clock! So fine tune freq is possible trought ct7302 registers for i2s mclk! That way LMK is not needed at all since fine tune can be done trought ct7302. But I will not use i2s mclk, instead I will go with LMK since it will give me several different frequencies which can be also fine tuned trought LMK registers and from time to time gps sinchronisation will be need.

For the victim, one piece of ct7302 just to act as a driver for the crystal, I don't like Driscoll because then I would have to put it in the oven, but I don't have to put ct7302 because it is made in such a way that it depends only on the stability of the crystal. Opinions?

For the victim, one piece of ct7302 just to act as a driver for the crystal, I don't like Driscoll because then I would have to put it in the oven, but I don't have to put ct7302 because it is made in such a way that it depends only on the stability of the crystal. Opinions?

Attachments

Last edited:

Its I think excatly simetric to theit vref noise? But if vref is inside stable oven the noise is much less? Thats curenlty what I wory.The AD780 temperature output is rated at 1.9mV/C with no noise data given, I wonder if it is much use for ultra-fine temperature control.

AN895 might be interesting for fine temp measurement within 0.05C, but reguire an stable master clock for acurate temperature measurement. For example an stm32 which have an hrtimer can be used to drive an temperature generation circuit by their precise pwm?

Soldering an stm32 with their crystal on a custom pcb based on copper and temperature couple that pcb with an copper rail, adding gps module with 1pps signal, add one peltier on copper rail and keep that rail at constant temperature with help of peltier for example driven by H bridge and HRPWM, synchronize internal clock from stm32 by adjusting temperature until with help from gps clock get at exactly e.g. 10000000Hz and keep that rail constantly at that particular temperature, then that stm32 becomes a very accurate device for measuring frequency up to the frequency of the internal clock. ; )

Last edited:

How to get ocxo from the first post to excatly 10MHz, simply connect ocxo from the post 1 to an stm32 as a mclk, measure frequency on stm32 with help of their internal 32bit freq counter sychronised to 1pps gps interupt, you can get excatly their frequency in femto secconds, that way we can fine tune oven until freq is excatly at 10MHz, the same time we can watch things, plot things... etc, no need to know oven temperature, only frequency is important!

In relation to post 9 and graph. The internal temperature sensor from F401 is sampled with 12bit but in the MSPS range, so even 1024x oversampling is done in order to filter the measurement noise and get more on the measurement resolution, which is finally 0.001*C. You can even see above how "furry" graphs he makes for temperature, he can't sample better than that, that's how the regulation will work, hot unstable for that level of stability.

On the other hand, the frequency measurement is even "cheekily" made completely at the HW level with counters, I mentioned 0ppm error compared to the reference and it is a phenomenal mechanism, see above how it is super-finely sampled with 1PPB resolution, the analogy is not mixed at all , no A/D converter, no voltage references, only dry measurement and comparison of some two frequencies of some digital signals.

On the other hand, the frequency measurement is even "cheekily" made completely at the HW level with counters, I mentioned 0ppm error compared to the reference and it is a phenomenal mechanism, see above how it is super-finely sampled with 1PPB resolution, the analogy is not mixed at all , no A/D converter, no voltage references, only dry measurement and comparison of some two frequencies of some digital signals.

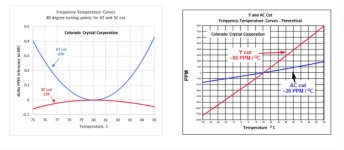

New concept! Hybrid phase locked temperature control! Two crystals is used, one is sc cut and seccond one is an at cut for example, booth must be e.g. 10MHz, booth diferent freq curve based on teperature, seccond one is used as a temp sensor.

Attachments

This is temperature zone of crystal on black pill, so an similar crystal can be chosed as a temp sensor for new concept : ) The same recording should be done with SC-cut to accurately see its behavior, and then from those two curves a lot can be concluded and decisions can be made about the choice of operating points and temperature zones in which the oscillator should operate.

Putting all together with an fine pwm controler e.g. stm32 with HRTIMER for precise oven control. Even an peltier can be integrated for e.g. an constant @25C

Putting all together with an fine pwm controler e.g. stm32 with HRTIMER for precise oven control. Even an peltier can be integrated for e.g. an constant @25C

Attachments

Last edited:

E.g. temp curve of two diferent types of crystals, for example AT cut have oposite temp curve than one from black pill! Keeping things in phase lock and oven temperature can be ultra precisely maintained, I think beter than 0.001C ?? : )

Attachments

Last edited:

- Home

- Source & Line

- Digital Line Level

- Diy OCXO with vRef 2.5V, need your opinion!

![IMG_20241120_122702_327_LL[1].jpg](/community/data/attachments/1290/1290676-e51b1a270bd2cd38468333e05e74c5d2.jpg?hash=8X3pYvIdcA)