Hello everyone,

A collegue and I are planning to make ourselves subwoofers. I did try to find all the information required on the internet including a lot of information on this forum.

As I think will be the case for most people, I tried to balance the size, cost, volume and lowest frequency to have something we are happy with.

I would love to hear your input on the design. While I do like the idea of it being my own design, if someone has a suggestion for a design that performs better for a similar price and size, I would be open to it.

For the driver I went with the SB Acoustics SB34SWPL76-4

For the amplifier I plan to use the Dayton Audio SPA300-D

Both of us use a receiver with significant EQ options for the subwoofer.

Targets for the design:

Comfortably plays up to a 105 dB or more

Frequency deep in the 20's (preferably sub 25Hz at -6dB)

Total budget max 750 euro per subwoofer. (which leaves about 600 for driver and amplifier)

Play up to 100 Hz for crossover of smaller speakers.

Internal volume is about 40L excluding driver and port.

Port is devided into two by a brace, making it 2x 25x150mm and 710 mm long

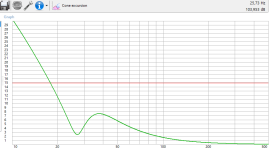

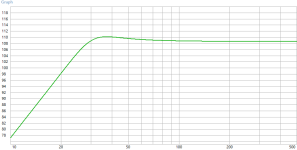

I have included a couple of screenshots from WinISD and the drawing of the enclosure.

In addition to apreciating general feedback, there are a few questions/concerns I still have.

At the maximum 300W power, the volume is much higher than required, but the port velocity also goes up 24 m/s. I am most certain this would create a lot of port noise. However, I think at 200W I already have quite the volume for my space. At that power level velocity caps out at 20 m/s. I have seen the guideline 18 m/s max. Is this expected to be a problem if the port end is rounder off? Obviously I only care about port noise in real world scenarios and not test tones.

I found a lot of people finding that for these long port lengths, the required length for the tuning is actually shorter than calculated. I am hoping for this effect, as all desired parameters will improve in this case. I would be more than happy with the calculated results.

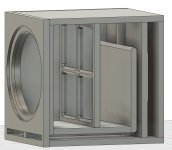

At work we have large CNC mill suitable for MDF, so we plan on milling out the shapes of the plates in such a way that they fit perfectly. (See the picture of a side panel)

Does anyone have any experience with this? At work the people that actually use this machine thought it was a good idea, but we don't typically build speakers. They did know the tolerances required for nice fits in MDF, so I am assuming that would work.

All the rounded edges will be done using a rounding bit on a handheld router.

Is my placing of bracing correct? I have about 20 mm distance from the rear of the driver for the cross brace. I feel like the brace in the port is required as one side doubles as internal volume. Is that correct, or can I leave that out?

I see a lot of debate about panel thickness. Lower weight is higher eigen frequency, but thicker is stiffer and higher eigen frequency. I am doubting between 16 and 22 mm MDF, which are both easily available to us. Does it make a significant difference?

Would a high pass filter be required for this subwoofer? I can't imagine the driver being damaged with real world use due to large cone excursion, but maybe someone can tell me otherwise. WinISD calculates Xmax at 19.5 Hz at 300W. I can't find the Xlim of this driver.

Thank you in advance.

A collegue and I are planning to make ourselves subwoofers. I did try to find all the information required on the internet including a lot of information on this forum.

As I think will be the case for most people, I tried to balance the size, cost, volume and lowest frequency to have something we are happy with.

I would love to hear your input on the design. While I do like the idea of it being my own design, if someone has a suggestion for a design that performs better for a similar price and size, I would be open to it.

For the driver I went with the SB Acoustics SB34SWPL76-4

For the amplifier I plan to use the Dayton Audio SPA300-D

Both of us use a receiver with significant EQ options for the subwoofer.

Targets for the design:

Comfortably plays up to a 105 dB or more

Frequency deep in the 20's (preferably sub 25Hz at -6dB)

Total budget max 750 euro per subwoofer. (which leaves about 600 for driver and amplifier)

Play up to 100 Hz for crossover of smaller speakers.

Internal volume is about 40L excluding driver and port.

Port is devided into two by a brace, making it 2x 25x150mm and 710 mm long

I have included a couple of screenshots from WinISD and the drawing of the enclosure.

In addition to apreciating general feedback, there are a few questions/concerns I still have.

At the maximum 300W power, the volume is much higher than required, but the port velocity also goes up 24 m/s. I am most certain this would create a lot of port noise. However, I think at 200W I already have quite the volume for my space. At that power level velocity caps out at 20 m/s. I have seen the guideline 18 m/s max. Is this expected to be a problem if the port end is rounder off? Obviously I only care about port noise in real world scenarios and not test tones.

I found a lot of people finding that for these long port lengths, the required length for the tuning is actually shorter than calculated. I am hoping for this effect, as all desired parameters will improve in this case. I would be more than happy with the calculated results.

At work we have large CNC mill suitable for MDF, so we plan on milling out the shapes of the plates in such a way that they fit perfectly. (See the picture of a side panel)

Does anyone have any experience with this? At work the people that actually use this machine thought it was a good idea, but we don't typically build speakers. They did know the tolerances required for nice fits in MDF, so I am assuming that would work.

All the rounded edges will be done using a rounding bit on a handheld router.

Is my placing of bracing correct? I have about 20 mm distance from the rear of the driver for the cross brace. I feel like the brace in the port is required as one side doubles as internal volume. Is that correct, or can I leave that out?

I see a lot of debate about panel thickness. Lower weight is higher eigen frequency, but thicker is stiffer and higher eigen frequency. I am doubting between 16 and 22 mm MDF, which are both easily available to us. Does it make a significant difference?

Would a high pass filter be required for this subwoofer? I can't imagine the driver being damaged with real world use due to large cone excursion, but maybe someone can tell me otherwise. WinISD calculates Xmax at 19.5 Hz at 300W. I can't find the Xlim of this driver.

Thank you in advance.

Attachments

Thanks for the advice. Guess I have to make just a slightly bigger box to accommodate for it.

@GM I will look into it. I have currently no idea what this entails. But now I have something to look for.