So I’m looking to replace the drivers on a set of 80’s kenwood jl850 speakers. Obviously the old drivers are no longer in production and the ones in it need to be replaced. The speakers are fairly sensitive and easy to drive with about 125rms and 250w peak. The drivers are the old paper cone type on all drivers. I’m doing this for my grandfather who bought them new back around 86’ and wants to keep the original system. Not looking to break the bank here just give him some good sound that he lost. The tweeters are 2”cone , mids are 4.5” cones and woofer is 15” cone. I’m thinking possibly a premade crossover also since I don’t possess the skills to make one from scratch. Any and all suggestions are welcome here. Even if someone has any ideas about crossovers I would take them. Thanks to all who can help with this.

Attachments

Assuming they still work, do they just need new foam surrounds? IF you could find some that fit, and IF you could do the work yourself, than it would be a labour of love. Otherwise just replace them with something else.Obviously the old drivers are no longer in production and the ones in it need to be replaced.

jeff

Further to what Jeff says, renew/restart not restore.

I have disassembled many similar. Mid+tweter are usually junk with single caps as XOs. Sometimes the woofer is decent, but if the surround on the woofer is gone, wjat you have left is a poorly constructed box — that can be improved).

At that point you start shopping. Figure out the net volume of the box after you brace it up and account for midTweeter enclosure volume. Annew front baffle will be needed.

There are lots of ways to approach this.

Single FR driver — maybe CHN-110 https://www.madisoundspeakerstore.com/approx-6-fullrange/markaudio-chn110-silver-6.75-full-range/

WAW (Woofer Assisted Wideband). FInd a nice midTweeter and add a helper woofer.

Conventional multi-way: 2 or 3-way, Find one you like that fits the volume you have,

Pay attention and you will end up with something Kenwood never dreamed of.

dave

I have disassembled many similar. Mid+tweter are usually junk with single caps as XOs. Sometimes the woofer is decent, but if the surround on the woofer is gone, wjat you have left is a poorly constructed box — that can be improved).

At that point you start shopping. Figure out the net volume of the box after you brace it up and account for midTweeter enclosure volume. Annew front baffle will be needed.

There are lots of ways to approach this.

Single FR driver — maybe CHN-110 https://www.madisoundspeakerstore.com/approx-6-fullrange/markaudio-chn110-silver-6.75-full-range/

WAW (Woofer Assisted Wideband). FInd a nice midTweeter and add a helper woofer.

Conventional multi-way: 2 or 3-way, Find one you like that fits the volume you have,

Pay attention and you will end up with something Kenwood never dreamed of.

dave

Last edited:

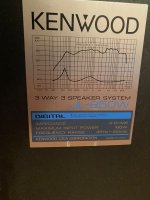

At least Kenwood is so honest to print the frequency response on the front of them. A serious warning.

"Repairing" a 3-way speaker from new bought drivers simply doesn't work.

A possible, relative simple way to make them function again, without constructing a new speaker, could be using a full range speaker and a cheap 15". If a 4 Ohm full range and an 8 Ohm woofer are combined, this could fit in levels. As a crossover a single coil (the one originaly used) and a cap can be enough to make this work. Just leave the tweeter as a dummy, unconnected.

The bad thing about building such a combination, you need just the same skills like it would take to construct a real HIFI speaker. Combining cheap speaker to something not 100% ugly sounding is not easy. The less you know about speaker building, the harder to understand, I know.

At least you would need a jig saw to make the front holes fit. If there are no drivers to fill the holes, a new front baffle, glued on the old one is a usual fix. While at it, you should glue a few stripes of particle board or MDF over the inside walls, as these will be resonating and blurr the sound.

So some basic tools and wood working skills are needed too.

If that is a problem to you, for the same money you will spent on drivers and parts you could as well buy a much better sounding, small to mid sized, commercial speaker and use the old ones as stands for them if the have some sentimential value.

Then, the usual places for used gear are a great option to get good speaker for very little money, even without paying ridiculous summs for P&P and even the option to listen to them first. You just have to search a little.

"Repairing" a 3-way speaker from new bought drivers simply doesn't work.

A possible, relative simple way to make them function again, without constructing a new speaker, could be using a full range speaker and a cheap 15". If a 4 Ohm full range and an 8 Ohm woofer are combined, this could fit in levels. As a crossover a single coil (the one originaly used) and a cap can be enough to make this work. Just leave the tweeter as a dummy, unconnected.

The bad thing about building such a combination, you need just the same skills like it would take to construct a real HIFI speaker. Combining cheap speaker to something not 100% ugly sounding is not easy. The less you know about speaker building, the harder to understand, I know.

At least you would need a jig saw to make the front holes fit. If there are no drivers to fill the holes, a new front baffle, glued on the old one is a usual fix. While at it, you should glue a few stripes of particle board or MDF over the inside walls, as these will be resonating and blurr the sound.

So some basic tools and wood working skills are needed too.

If that is a problem to you, for the same money you will spent on drivers and parts you could as well buy a much better sounding, small to mid sized, commercial speaker and use the old ones as stands for them if the have some sentimential value.

Then, the usual places for used gear are a great option to get good speaker for very little money, even without paying ridiculous summs for P&P and even the option to listen to them first. You just have to search a little.

I’m having the speakers delivered to me by a family member so I can get into them and see what the insides look like. I know both dust caps on the mids are damaged and one of the mids is seized up with no movement at all….i believe one of the tweeters surrounds is gone out because I hear the sound of paper crackling when I touch it lightly. I definitely planned on getting the volume for the interior so I can match up a decent woofer if needed but only if the others aren’t working. I’ll check out the XO also and see what it has if any. I’ll post back when I know what I’m dealing with in a few weeks after I get them. I’ll also be bracing them and repacking with sound deadening material for sure to tighten them up.

I hear warning bells! Remember that any volume loss by putting something inside a cabinet will reduce bass response. Bracing is not done by making walls thicker. You only need a few stripes of 1/2-3/4 board, about 1.5. to 2" high, run over the most hollow sounding areas, usually the center. Use your fingers to knock on the outside. The "tock"sound at a corner is good, the deep thump in the middle of a side is bad. No rocket science to correct this.

So don't think that a lot of volume and mass will improve anything. Just a few, strategically placed braces do the job with minimum volume loss.

A 30cm chassis will only need very little to no damping material. Some cheap pieces of Rockwoll over the walls is more than enough. Don't stuff it.

PS don't buy drivers and ask here later if things dont work, but ask what drivers to buy first! There are helpfull and knowing people here, that will help you if you take advice. Better don't act from what you might have "heard" about speaker building, but trust the forums knowledge.

So don't think that a lot of volume and mass will improve anything. Just a few, strategically placed braces do the job with minimum volume loss.

A 30cm chassis will only need very little to no damping material. Some cheap pieces of Rockwoll over the walls is more than enough. Don't stuff it.

PS don't buy drivers and ask here later if things dont work, but ask what drivers to buy first! There are helpfull and knowing people here, that will help you if you take advice. Better don't act from what you might have "heard" about speaker building, but trust the forums knowledge.

Thanks for the reply turbo and I’ll keep the bracing to the minimum so not to change the bass response to much and I’ll look into the Rockwoll for the padding!

While we are at it, please find a budget for this project. There are complete speaker kits that might fit your volume. It might be a good option to go for such a proven, complete set of drivers and crossovers.

One point most newbies miss: Even as there are universal crossovers on sale, these do not work. Never , not a little, just 100% absolutely not. They are just there to make profit on unknowing customers who would not spend money if told the truth.

Any driver you buy needs it's own crossover, made for it in your enclosure. Making such a crossover needs complicated measurements and parts are often more expensive then the drivers used. Just a warning.

Todays simulations, done by someone who knows what he does, are very good and will lead to useable results. This is what may help you to a good result, even if it will not be "high end".

One point most newbies miss: Even as there are universal crossovers on sale, these do not work. Never , not a little, just 100% absolutely not. They are just there to make profit on unknowing customers who would not spend money if told the truth.

Any driver you buy needs it's own crossover, made for it in your enclosure. Making such a crossover needs complicated measurements and parts are often more expensive then the drivers used. Just a warning.

Todays simulations, done by someone who knows what he does, are very good and will lead to useable results. This is what may help you to a good result, even if it will not be "high end".

Thanks turbo….i actually like the idea of speaker /driver kits for the replacements and when I get the volume of the inside then I’ll have a starting point to work with. I was looking at the norez material that GR research sales for the inside also. Or would that be overkill for this project….it would help eliminate some rez without using to much bracing so as not to cut into the volume of space and interfere with the bass response.

See, if you buy some 1300% overpriced damping "norez" material, you will gain about 0.01% in sound quality in your case. If you invest this kind of money into the drivers, you get 100% of the investment back as better sound. Stay away from sales people that tell you otherwise.

Think of someone fitting a formular 1 instrument cluster into his Toyota Yaris and telling you it drives faster now. That is what such material is in your case. Too expensive and useless for a Yaris, but important, for obvious reasons, in a F1 car, even as it would drive just as fast a top speed without it.

You need some glue, some cheap stripes of wood and a set of speakers with a matching crossover, maybe some sheets of Rockwool. That's it.

Just because something is simple to apply, like self adhesive damping pads, it will not work better than a correct brace.

If you can not cut wood and dont know how to glue some together, you can not replace these skills with expensive materials. Something many in the industry prey on.

PS you get this damping stuff in any car parts shop to silence large sheet metal surfaces. It is even there, overpriced. You use that stuff in all kinds of industries, but for a very small fraction of the price some questionable "speaker improving" sellers charges. Don't buy anything just because you don't understand how it works. There is just too much snake oil out there.

Think of someone fitting a formular 1 instrument cluster into his Toyota Yaris and telling you it drives faster now. That is what such material is in your case. Too expensive and useless for a Yaris, but important, for obvious reasons, in a F1 car, even as it would drive just as fast a top speed without it.

You need some glue, some cheap stripes of wood and a set of speakers with a matching crossover, maybe some sheets of Rockwool. That's it.

Just because something is simple to apply, like self adhesive damping pads, it will not work better than a correct brace.

If you can not cut wood and dont know how to glue some together, you can not replace these skills with expensive materials. Something many in the industry prey on.

PS you get this damping stuff in any car parts shop to silence large sheet metal surfaces. It is even there, overpriced. You use that stuff in all kinds of industries, but for a very small fraction of the price some questionable "speaker improving" sellers charges. Don't buy anything just because you don't understand how it works. There is just too much snake oil out there.

Last edited:

Thanks again turbo for the response. Once I get the speakers in house I’ll be looking at the drivers and baffle cutouts and getting the interior volume and all. Then I’ll post the drivers and specs I find that seem to match and ask for y’all’s thoughts. I have to wait about 17 days now before they’re in my hands to get all the specs. I’ll be going the rockwoll and bracing strips approach to keep the pricing down . I have some wood working skill but not a pro so it shouldn’t be a problem. I am however still learning the XO part and designing those seems to be a little more in depth so that part may take the longest if I can’t fine premade.

- Home

- Design & Build

- Parts

- Old Kenwood JL850Ws need replacement drivers