Hey all,

I have been a diy speaker builder for the last 10 years and have built a number of successful projects over the journey.

Recently I started to get into horns. I built my dad a ecconowave type speaker a few years back and more and more as time has gone on I seem to love how they sound. I have a very large shed/man cave and so horns make a lot of sense for my next speakers.

This project started as I had a bunch of material left over from various woodworking and renovation works.

Basically a year or so ago I built some smith horns with left over 26mm laminated beech that I had from making bathroom vanities. Taken from plans on another forum and Adjusted to 5 cell and 90* horizontal pattern. I'm aware that diffraction horns have a mixed reception but they look cool af so that's where I started.

I have recently picked up some new in box faital pro 3fe22 8ohm drivers of Facebook marketplace for a very good price decided to give it a go in the smiths as I have some time at the moment to play with things- self employed, wife and 2 young kids......

Started with a very rudimentary 2 litre airtight bucket filled with polystuff as the back chamber (obviously this is too big but just playing as a test of concept). Made a 15mm ply and 3mm mdf ring with a 25mm square hole for the entry to the horn- see attached (this is before file work to make it all neat and even so it looks pretty basic in the pic).

More to follow

I have been a diy speaker builder for the last 10 years and have built a number of successful projects over the journey.

Recently I started to get into horns. I built my dad a ecconowave type speaker a few years back and more and more as time has gone on I seem to love how they sound. I have a very large shed/man cave and so horns make a lot of sense for my next speakers.

This project started as I had a bunch of material left over from various woodworking and renovation works.

Basically a year or so ago I built some smith horns with left over 26mm laminated beech that I had from making bathroom vanities. Taken from plans on another forum and Adjusted to 5 cell and 90* horizontal pattern. I'm aware that diffraction horns have a mixed reception but they look cool af so that's where I started.

I have recently picked up some new in box faital pro 3fe22 8ohm drivers of Facebook marketplace for a very good price decided to give it a go in the smiths as I have some time at the moment to play with things- self employed, wife and 2 young kids......

Started with a very rudimentary 2 litre airtight bucket filled with polystuff as the back chamber (obviously this is too big but just playing as a test of concept). Made a 15mm ply and 3mm mdf ring with a 25mm square hole for the entry to the horn- see attached (this is before file work to make it all neat and even so it looks pretty basic in the pic).

More to follow

Attachments

All connected up for some testing. And to run some sweeps.

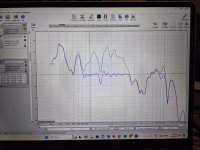

Attached is the REW sweep, as you can see it looks pretty horrible! Measured at 1m gated at 4.4ms, First sweep with horn and driver, 2nd with just horn in its 'bucket' and no horn.

I'm assuming that it's the horn mouth as it enters the smith horn, hence why I measured without the horn but with the lense.

I wasn't expecting much tbh but this is God awful so I'm hoping for some advice on improving the >3k performance

I'll take any leads or experiences

Attached is the REW sweep, as you can see it looks pretty horrible! Measured at 1m gated at 4.4ms, First sweep with horn and driver, 2nd with just horn in its 'bucket' and no horn.

I'm assuming that it's the horn mouth as it enters the smith horn, hence why I measured without the horn but with the lense.

I wasn't expecting much tbh but this is God awful so I'm hoping for some advice on improving the >3k performance

I'll take any leads or experiences

Attachments

You don't have a phase plug placed over the driver feeding the horn? Not saying that's the total issue but it can't hurt to look into the JBL CMCD to get a couple of ideas. What does the driver response look like in the back chamber without the horn? How about without the cover with the throat?

Rob 🙂

Rob 🙂

Attachments

No phase plug currently, something I was thinking of. However my thinking is that's not enough to explain the poor quality in full (again I'm horn novice so happto be corrected).

The second measurement is the horn in the chamber with the throat attached.

I'll take one without the back chamber that is a good idea!

The second measurement is the horn in the chamber with the throat attached.

I'll take one without the back chamber that is a good idea!

You should not expect much above 2-3 k from this - you could improve the low end by having a small back enclosure - I usually use 0.3 - 0.6 l on my MEHs. The volume in front of the driver together with the horn throat create a low pass filter.

You have adapted a driver with a 5 square inch Sd to a throat that should be under 1 square inch.I wasn't expecting much tbh but this is God awful so I'm hoping for some advice on improving the >3k performance

Even if you were to make a phase plug (very difficult with the cone profile and it's non-pistonic behaviour) to reduce the acoustic band pass effect, the driver has a relatively weak motor (only 4.5BL, compared to ~20 for compression drivers) so the high end will still be poor.

My advice would be to use a decent 1" exit high frequency compression driver on your Smith horn.

I will try a phase plug, I'm interested in how much of an improvement I can get from the current set up.

I actually have a pair of Tymphany DFM-2535R00-08 that I can use- however I was wanting to crossover to the smiths ~600ish and whilst I understand thats technically possible that seems to low to safely run a 1" compression driver in the large area I will play them.

I actually have a pair of Tymphany DFM-2535R00-08 that I can use- however I was wanting to crossover to the smiths ~600ish and whilst I understand thats technically possible that seems to low to safely run a 1" compression driver in the large area I will play them.

Just made a very rudimentary phase plug as per the guide provided by cowanaudio.

Looks much better, still a lot of improvements to be had before I'm happy but goes to show what a difference a little bit of knowledge can do!

Attached is the before (same as yesterday) and then the after phase plug.

Still with no back chamber or horn Attached

Next I'll refine the design a bit and see if I can't get more

Looks much better, still a lot of improvements to be had before I'm happy but goes to show what a difference a little bit of knowledge can do!

Attached is the before (same as yesterday) and then the after phase plug.

Still with no back chamber or horn Attached

Next I'll refine the design a bit and see if I can't get more

Attachments

There is a difference, but still not even a single octave that has a +/-6dB response.

Try measuring the front loaded 3fe22 with the bucket and the Tymphany DFM-2535R00-08 on the horn so you have something to compare to, both in sensitivity and frequency response.

Try measuring the front loaded 3fe22 with the bucket and the Tymphany DFM-2535R00-08 on the horn so you have something to compare to, both in sensitivity and frequency response.

Yeah it's still a very long way from usable. I'm thinking I'm not going to be able to get this set up to be good enough but I'm just experimenting to see how far we can get

Did as you recommend and measured the dfm compression driver on the smith horn.

Still doesn't look good, I'm starting to think that the horn itself is a big part of the problem. I know that the smiths have a somewhat coloured reputation, but this is awful haha.

Still doesn't look good, I'm starting to think that the horn itself is a big part of the problem. I know that the smiths have a somewhat coloured reputation, but this is awful haha.

Attachments

WozzaLee,Still doesn't look good, I'm starting to think that the horn itself is a big part of the problem.

I forgot many people are copying a plan with a gross mistake.

The gross mistake is would explain the terrible response you have measured.

The "plug" in the design you copied should not be there, Smith's DSH horn, and all those made by JBL (and me 😉 ) have a clear shot from the driver throat entry to the exponential horn vanes, as can be seen in Bob Smith's January 1951 Audio Engineering article, "A Distributed Source Horn".

https://www.worldradiohistory.com/Archive-All-Audio/Archive-Audio/50s/Audio-1951-Jan.pdf

https://www.audioheritage.org/vbulletin/showthread.php?9148-DIY-500Hz-Smith-Horn-Please-help-me-design-one!&highlight=smith horn

As Steve Schell (R.I.P.) pointed out in 2006, " Note that Dr. Smith mentions that his design was to be used above 750Hz, even though it has an exponential flare constant of 375Hz...People are often confused by what looks like a rounded triangular section in the throat in the drawing. It is only there to show the angles of the "torpedo" dividers, not to indicate a solid structure."

Although the Smith D.S.H. primarily relies on diffraction for it's vertical expansion, it's high (and low) frequency response still would benefit from rounding the mouth exit, similar to JBL's 2397:

Have fun,

Art

Thanks again Art.

I actually came across another one of your posts back when I was making the horns and so knew to make them without the plug so that isn't the issue here.

Obviously there is something else at play. I'm learning that the entrance to the horn and how it merges in the throat is extremely important and thinking that something there is an issue.

I'm now thinking on going away from the smith and more towards a yuichi horn. I originally was tossing up between the 2 and only landed on the smith as I had enough materials left over to build them at that time.

It's a shame as they look good and as a hobbyists woodworkler I hate wasting wood (especially hard wood), which is how I ended up in the diyaudio hobby as a combination of my love for audooand woodwork!

At least it gives me another reason to play in the shed

I actually came across another one of your posts back when I was making the horns and so knew to make them without the plug so that isn't the issue here.

Obviously there is something else at play. I'm learning that the entrance to the horn and how it merges in the throat is extremely important and thinking that something there is an issue.

I'm now thinking on going away from the smith and more towards a yuichi horn. I originally was tossing up between the 2 and only landed on the smith as I had enough materials left over to build them at that time.

It's a shame as they look good and as a hobbyists woodworkler I hate wasting wood (especially hard wood), which is how I ended up in the diyaudio hobby as a combination of my love for audooand woodwork!

At least it gives me another reason to play in the shed

WozzaLee,Obviously there is something else at play. I'm learning that the entrance to the horn and how it merges in the throat is extremely important and thinking that something there is an issue.

I'm now thinking on going away from the smith and more towards a yuichi horn.

The Smith horn is really pretty forgiving, if it's made correctly (as you say yours is) there really is no reason it should not be within +/- 6dB from ~750Hz to above 10kHz with a decent driver.

Beech is rather porous, if you have not sealed the throat vanes with varnish or paint, some high frequency absorption would be expected, but not near as much as posted. The vanes should be very sharp so as to not reflect sound waves back to the throat.

The on axis HF response should actually increase a bit in the HF.

That said, normally there is a center vane on axis, your five cell variant may have better response on axis to the vanes either side of center.

Before you give up on the Smiths, I'd still suggest you measure your front loaded 3fe22.

If it does not look similar on axis (within +/-3dB) to the factory curve above ~200Hz, something is probably wrong in your measurement set up.

Art

Righto,

Sorry been away for a little had a bit on at work and just doing bits and bobs as time permits.

After you posted that I had a light bulb moment where I realised that I haven't used REW since I got this new laptop.

And you were correct that there were some weird soundcard settings that were interfering a bit.

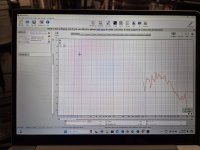

This is the tymphany on the smith measured at 50cm with 1/12 smoothing.

Still not setting the world on fire but a lot better. A bit of EQ and it could be usable

Sorry been away for a little had a bit on at work and just doing bits and bobs as time permits.

After you posted that I had a light bulb moment where I realised that I haven't used REW since I got this new laptop.

And you were correct that there were some weird soundcard settings that were interfering a bit.

This is the tymphany on the smith measured at 50cm with 1/12 smoothing.

Still not setting the world on fire but a lot better. A bit of EQ and it could be usable

Attachments

Also done some work on the throat mouth and phase plug and got some progress from the faital as well.

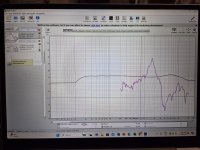

This is raw with same measuring as above. The purple line is REWs predicted response after a few cuts to even out.

Again not what I would normally accept however I'm interested to plug it in and see how it sounds with a 800ish xo just for giggles

This is raw with same measuring as above. The purple line is REWs predicted response after a few cuts to even out.

Again not what I would normally accept however I'm interested to plug it in and see how it sounds with a 800ish xo just for giggles

Attachments

- Home

- Loudspeakers

- Multi-Way

- Cone loaded Smith horn