Here are the speakers I designed in the last months.

It's a 2,5 ways design with two 6,5' Purifi Midwoofers and a TW29TXN-8 SB Acoustics tweeter.

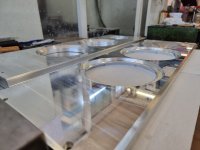

The front plate is made by CNC milling, the internal volume is 38L each ( for both midwoofers ).

I placed two Dayton Audio 8' passive woofers for each box, tuned at 32Hz.

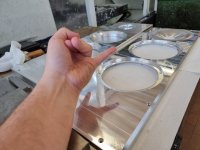

As I don't like the original SB used for the BNWG version, as, for me, it's too deep and with a too narrow dispersion angle, I designed and printed a custom adapter with an HP JetFusion printer.

In the past I made some printed waveguides and I found out that, in a standard room and, mostly, if we don't listen to the speakers just in a single fixed position, the lack of high frequencies given by a low dispersion angle ( let say less than 120° ) is something I don't wanna have.

It seems like ( and the measurements confirm it ) as a waveguide becomes deeper and narrower, the distortion at high frequency increases.

The adapter plate size is critical as there is a very little space to fit the screws and the waveguide throat ( and basically that's why SB makes a so deep WG, in my humble opinion ).

The waveguide is CNC milled in 1 piece with the front baffle but I'm gonna make some CNC waveguides which can be mounted on every baffle if somebody is interested in.

It seems like Purifi also followed the same rules with their new tweeter waveguide design, modeling a less deep, wider waveguide.

Here are the first measurements, maybe if someone is interested in I can also make some plate + CNC WG kits.

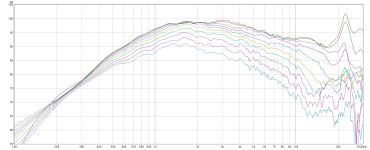

In the measurements you can find both the first and the second midwoofer response and than:

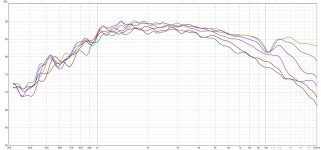

Pict N°1 : TW29TXN-8 + WG response at 0-15-30-45-60-75 degrees

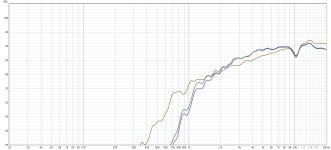

Pict N°2 : the tweeter with three different filters ( 1.8uF, 2,7uF+0,47mH, 2,7uF+0,55mH )

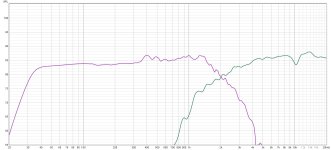

That dip around 10KHz is given by the inner WG throat diameter or bu the wide tweeter surround.

I don't actually think it is something relevant or audible because it's just a point discontinuity, just something not so good to be seen on a graph.

The out of axis behavior is definitely better than the SB Acoustics WG for me, which I think matches better my needings.

Regards!

It's a 2,5 ways design with two 6,5' Purifi Midwoofers and a TW29TXN-8 SB Acoustics tweeter.

The front plate is made by CNC milling, the internal volume is 38L each ( for both midwoofers ).

I placed two Dayton Audio 8' passive woofers for each box, tuned at 32Hz.

As I don't like the original SB used for the BNWG version, as, for me, it's too deep and with a too narrow dispersion angle, I designed and printed a custom adapter with an HP JetFusion printer.

In the past I made some printed waveguides and I found out that, in a standard room and, mostly, if we don't listen to the speakers just in a single fixed position, the lack of high frequencies given by a low dispersion angle ( let say less than 120° ) is something I don't wanna have.

It seems like ( and the measurements confirm it ) as a waveguide becomes deeper and narrower, the distortion at high frequency increases.

The adapter plate size is critical as there is a very little space to fit the screws and the waveguide throat ( and basically that's why SB makes a so deep WG, in my humble opinion ).

The waveguide is CNC milled in 1 piece with the front baffle but I'm gonna make some CNC waveguides which can be mounted on every baffle if somebody is interested in.

It seems like Purifi also followed the same rules with their new tweeter waveguide design, modeling a less deep, wider waveguide.

Here are the first measurements, maybe if someone is interested in I can also make some plate + CNC WG kits.

In the measurements you can find both the first and the second midwoofer response and than:

Pict N°1 : TW29TXN-8 + WG response at 0-15-30-45-60-75 degrees

Pict N°2 : the tweeter with three different filters ( 1.8uF, 2,7uF+0,47mH, 2,7uF+0,55mH )

That dip around 10KHz is given by the inner WG throat diameter or bu the wide tweeter surround.

I don't actually think it is something relevant or audible because it's just a point discontinuity, just something not so good to be seen on a graph.

The out of axis behavior is definitely better than the SB Acoustics WG for me, which I think matches better my needings.

Regards!

Attachments

Last edited:

Yes sure, here they are!

Attachments

-

20230406_211339.jpg347.5 KB · Views: 148

20230406_211339.jpg347.5 KB · Views: 148 -

20230408_161756.jpg505.5 KB · Views: 127

20230408_161756.jpg505.5 KB · Views: 127 -

20230408_162547.jpg556.5 KB · Views: 120

20230408_162547.jpg556.5 KB · Views: 120 -

20230408_171132.jpg512.4 KB · Views: 124

20230408_171132.jpg512.4 KB · Views: 124 -

20230408_171142.jpg465.9 KB · Views: 126

20230408_171142.jpg465.9 KB · Views: 126 -

20230603_141830.jpg415.2 KB · Views: 124

20230603_141830.jpg415.2 KB · Views: 124 -

20230603_141702.jpg423.2 KB · Views: 132

20230603_141702.jpg423.2 KB · Views: 132 -

20230603_140956.jpg402.5 KB · Views: 132

20230603_140956.jpg402.5 KB · Views: 132 -

20230603_141004.jpg315.9 KB · Views: 120

20230603_141004.jpg315.9 KB · Views: 120 -

20230604_115556.jpg520.4 KB · Views: 136

20230604_115556.jpg520.4 KB · Views: 136 -

20230605_171528.jpg570 KB · Views: 146

20230605_171528.jpg570 KB · Views: 146 -

20230605_171536.jpg592.1 KB · Views: 160

20230605_171536.jpg592.1 KB · Views: 160 -

20230606_164647.jpg454.6 KB · Views: 139

20230606_164647.jpg454.6 KB · Views: 139 -

20230606_164700.jpg251.9 KB · Views: 157

20230606_164700.jpg251.9 KB · Views: 157 -

20230606_164709.jpg301.2 KB · Views: 155

20230606_164709.jpg301.2 KB · Views: 155

The CNC aluminum work is nice.

Looks like you need to do more work with cheep MDF or the like to get rid of the +5dB notch at 10kHz.

Looks like you need to do more work with cheep MDF or the like to get rid of the +5dB notch at 10kHz.

Ciao,

Actually I don't think I will spend time on that notch.

The only thing I can do actually is to print a 1mm spacer to close the gap between the WG and the tweeter front.

The only way to avoid that notch is to glue the tweeter to the wg.

Doing so you can model the WG shape without a first cylindrical throat section ( which actually is the main reason of the notch presence ).

Btw, once filtered, the notch is a -3dB on a very narrow frequency, I don't even think someone can hear it, maybe my dog.

Actually I don't think I will spend time on that notch.

The only thing I can do actually is to print a 1mm spacer to close the gap between the WG and the tweeter front.

The only way to avoid that notch is to glue the tweeter to the wg.

Doing so you can model the WG shape without a first cylindrical throat section ( which actually is the main reason of the notch presence ).

Btw, once filtered, the notch is a -3dB on a very narrow frequency, I don't even think someone can hear it, maybe my dog.

Hi,

your WG profile seems to be similar to Jantzen WG. I measured that combo and there is not notch at 10kHz.

Though the audibility of that notch is likely low, it is worth looking at it more closely. Is there ~2-3mm step at the beginning of the profile? That could created the reflection and on axis cancellation.

your WG profile seems to be similar to Jantzen WG. I measured that combo and there is not notch at 10kHz.

Though the audibility of that notch is likely low, it is worth looking at it more closely. Is there ~2-3mm step at the beginning of the profile? That could created the reflection and on axis cancellation.

Attachments

Hi,

you're totally right, the first two cylindrical mm actually are the reason of that notch.

If you don't wanna glue the WG, that cylindrical part is compulsory so well, I can make it even shorter if I'll machine some WG but, on my project, as the baffle are pretty big, I'm not gonna put them again in the machining center.

I saw your speakers last week and well, amazing creations I have to say.

I also have a 3 way speaker with an MW16TX but I'm now using a T25A-6 tweeter from Bliesma ( with a Waveguide too ) and a Seas W26FX001 with a Seas SL26R passive radiator.

you're totally right, the first two cylindrical mm actually are the reason of that notch.

If you don't wanna glue the WG, that cylindrical part is compulsory so well, I can make it even shorter if I'll machine some WG but, on my project, as the baffle are pretty big, I'm not gonna put them again in the machining center.

I saw your speakers last week and well, amazing creations I have to say.

I also have a 3 way speaker with an MW16TX but I'm now using a T25A-6 tweeter from Bliesma ( with a Waveguide too ) and a Seas W26FX001 with a Seas SL26R passive radiator.

Use a little blue-tack to fill in the voids, use a few pieces of blue tape to hold the thing on.

Give it a test drive and see what the measurements look like. This temporary approach is not difficult.

If all is good put on a couple of clips to hold it together.

Yes But?

Give it a test drive and see what the measurements look like. This temporary approach is not difficult.

If all is good put on a couple of clips to hold it together.

Yes But?

- Home

- Loudspeakers

- Multi-Way

- Purifi 6,5' 6+ W29TXN-8 CNC Waveguide 2,5 ways