This project started as a three way speaker using some Audax drivers I had. I built a test box and was completely disappointed with the results so I ended giving the drivers away. While working on this design I looked at a lot of tweeters and ended up thinking the ScanSpeak H2606 might work well in a two way with the Audax HM170Z0 woofers I had. Eventfully I settled on the Dayton RS180P-4 with a paper cone, the breakup wasn’t too bad and it had decent sensitivity to match the tweeter.

This is the original thread.

https://www.diyaudio.com/community/...ential-3-way-using-some-older-drivers.398375/

Design Goals

1. Design a stand mount speaker with the potential to play 2 channel music without a sub-woofer

2. Try to use drivers in my inventory

3. Use materials in my inventory

4. Keep costs to a minimum

Plans and more detailed information can be found on the website.

https://www.bellarossafabrica.net/brf-27b

This is the original thread.

https://www.diyaudio.com/community/...ential-3-way-using-some-older-drivers.398375/

Design Goals

1. Design a stand mount speaker with the potential to play 2 channel music without a sub-woofer

2. Try to use drivers in my inventory

3. Use materials in my inventory

4. Keep costs to a minimum

Plans and more detailed information can be found on the website.

https://www.bellarossafabrica.net/brf-27b

Attachments

Last edited:

One of original goals was to use what I had on hand so I used some ¾ inch birch plywood from Home Depot, I know it is not ideal but Baltic Birch is $200.00 a sheet and would cost more than the drivers. I also had some high quality ¾ inch MDF from my last project so I made the baffles, backs and braces with it. For finishing I had enough Sapele veneer for the sides and tops and enough matte black Formica to cover the bezels, bottoms and backs.

I went back and forth between sealed or vented cabinets but eventually deciding on vented because these were to be used for two channel listening and possibly without a sub-woofer. By modeling with WinSID I ended up with a 19.9 liter enclosure with a 2 ½ by 8 ½ inch port tuned to 42.5 Hz. The only problem with this box alignment is the cone excursion exceeds Xmax at 30 watts with a signal below 35 Hz. This could be solved with a high pass filter but the component values are just too large. Therefore I chose to live with distortion below 35 Hz and risk damaging the woofer. I used three internal braces to tie all the sides together. The box has a 1 ½ inch chamfer on all the front edges, this was actually a mistake as the plans only had them on the sides and top. This happened when I was cutting the completed boxes on a table saw and accidently cut the bottom of one of the boxes. So like any wood worker I turned my mistake into a design decision and cut the other box too. I will not change the plans and if anyone decides to build these (not likely) they can be more careful.

I went back and forth between sealed or vented cabinets but eventually deciding on vented because these were to be used for two channel listening and possibly without a sub-woofer. By modeling with WinSID I ended up with a 19.9 liter enclosure with a 2 ½ by 8 ½ inch port tuned to 42.5 Hz. The only problem with this box alignment is the cone excursion exceeds Xmax at 30 watts with a signal below 35 Hz. This could be solved with a high pass filter but the component values are just too large. Therefore I chose to live with distortion below 35 Hz and risk damaging the woofer. I used three internal braces to tie all the sides together. The box has a 1 ½ inch chamfer on all the front edges, this was actually a mistake as the plans only had them on the sides and top. This happened when I was cutting the completed boxes on a table saw and accidently cut the bottom of one of the boxes. So like any wood worker I turned my mistake into a design decision and cut the other box too. I will not change the plans and if anyone decides to build these (not likely) they can be more careful.

Attachments

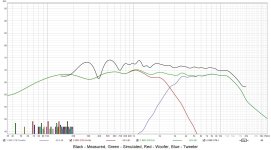

I made polar measurements of the drivers in the enclosure on a turntable in my backyard. The test stand is close to 8 feet tall so I could gate the measurement to about 6.5 ms. I used these measurements to model in VituixCAD. I targeted a 4th order Linkwitz-Riley acoustic slope at 2500 Hz. After about 7 to 10 versions I had what looked like a nice frequency response. The inductor in the low pass filter is oversized to compensate for the baffle step. I used Zobel networks on both drivers to flatten the impendence curves and made additional adjustments on the tweeter Zobel to flatten its rising response.

Attachments

When I was done I had nearly enough material left to build stands but not enough ¾ plywood. I had to buy a 2 x 4 foot sheet of ¾ inch Sande plywood which is the lightest plywood I’ve ever used. I have no idea what it is made of, Balsa wood maybe, but it was fine for vertical post of a speaker stand. The top and bottom plates are made with two pieces of ¾ inch MDF laminated together and covered with the Sapele veneer. The posts are ¾ inch plywood rabbited together and laminated with matte black Formica. I put 10-32 threaded inserts in the bottoms of the speakers and used 2 inch 10-32 Allen cap screws to attach the stands to the speakers. I much prefer this method to BlueTac.

Attachments

Nice. How do they sound? Do they live up to your expectations? They should be very efficient with those drivers.

I new I forgot something, it happens every time I post.

I replaced the 3-way stand mounts in my office with these about a month ago as a test drive. I was surprised how good they sounded, very smooth and fairly deep bass. My guess the smoothness is the result of the silk dome tweeter and the paper coned woofer. The 3-ways have ceramic woofer, paper mid and a ribbon tweeter so this is a substantial change. I swapped them back yesterday and the 3-ways exhibit more detail than these. I would say they exceeded my expectations.

I replaced the 3-way stand mounts in my office with these about a month ago as a test drive. I was surprised how good they sounded, very smooth and fairly deep bass. My guess the smoothness is the result of the silk dome tweeter and the paper coned woofer. The 3-ways have ceramic woofer, paper mid and a ribbon tweeter so this is a substantial change. I swapped them back yesterday and the 3-ways exhibit more detail than these. I would say they exceeded my expectations.

Thanks Jim, I feel the same way, I always follow your posts and enjoy the very interesting engineering they contain.

- Home

- Loudspeakers

- Multi-Way

- The BRF-27B, my latest design a two-way stand mount speaker