This was asked for in another thread, so I thought I'd start it here, though it was not asked of me.

I have only really assembled one pair, which I dubbed the "Foster-Franken-Coax". This used 12" Foster woofers and 1.5" Foster dome tweeters, both from a pair of Sears-branded speakers.

I have no data or measurements, this was before I got more serious into the hobby.

The tweeter was held in place via a short length of ABS pipe, glued with epoxy to both the pole-piece and tweeter back-plate. The tweeter leads were made with solder wick going through the cone, where I made a small slit and sealed it back with glue. I briefly tried these in a Karlson 12" box, where they performed horribly, way to small Vb for the woofers. I then stuck them in a large-ish sealed box and gave them away to a buddy who I haven't heard much from in a long time. That was about 10-12 years ago.

Now, those who have handled these tweeters know they are fairly massive. I can't help but imagine that since then, the glue must have failed or is about to. Whether this happens at the pole-piece or tweeter back plate, it will brutally and irreparably take out either if not both the woofer cone and voice coil. I should check up on said buddy and see if these have met an horrible demise or if I have underestimated the strength of Lepage 20 minute epoxy.

What are your experiences with DIY coaxial drive units?

I have only really assembled one pair, which I dubbed the "Foster-Franken-Coax". This used 12" Foster woofers and 1.5" Foster dome tweeters, both from a pair of Sears-branded speakers.

I have no data or measurements, this was before I got more serious into the hobby.

The tweeter was held in place via a short length of ABS pipe, glued with epoxy to both the pole-piece and tweeter back-plate. The tweeter leads were made with solder wick going through the cone, where I made a small slit and sealed it back with glue. I briefly tried these in a Karlson 12" box, where they performed horribly, way to small Vb for the woofers. I then stuck them in a large-ish sealed box and gave them away to a buddy who I haven't heard much from in a long time. That was about 10-12 years ago.

Now, those who have handled these tweeters know they are fairly massive. I can't help but imagine that since then, the glue must have failed or is about to. Whether this happens at the pole-piece or tweeter back plate, it will brutally and irreparably take out either if not both the woofer cone and voice coil. I should check up on said buddy and see if these have met an horrible demise or if I have underestimated the strength of Lepage 20 minute epoxy.

What are your experiences with DIY coaxial drive units?

Last edited:

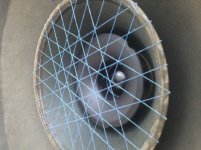

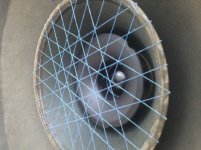

Found some photos of my attempt. I couldn’t find any measurements, but they sounded pretty good to me. Woofer was McKenzie Studio 12” 125W, tweeter was a Monacor DT-25N. Tweeter needed some trimming to fit inside the whizzer, glued a plastic post to the back and pushed it into the hole in the pole-piece. I intended to put a washer and screw in the back to hold it in place, but don’t remember if I did or not. A later mod was cotton stretched over the whizzer to stop its bell mode resonance, and this worked well

Brian

Brian

I have disassembled many of those. The tweeters are popular in Oz. I still have some 16 of the woofers. 8, along with the proper PVC pipe cut to length, and a (budget) active 4th order LR XO in the please come take away and finish projects. A very nice woofer.

dave

dave

The individual Foster drivers were all pretty good IMO, whereas the overall design of the speaker was pretty bad, also IMO.

Placing the boxes on their side was only a slight improvement, as the horizontal comb-filtering was then shifted down to the crossover frequency region. I seem to remember making the enclosures aperiodic before parting the drivers and tossing the boxes; there was an improvement in the bass IIRC. The middling Qt and somewhat large Vas of these woofers have them preferring fairly large enclosures.

Placing the boxes on their side was only a slight improvement, as the horizontal comb-filtering was then shifted down to the crossover frequency region. I seem to remember making the enclosures aperiodic before parting the drivers and tossing the boxes; there was an improvement in the bass IIRC. The middling Qt and somewhat large Vas of these woofers have them preferring fairly large enclosures.

I did not mention comment on it earlier, but brig001's "thread-damping" whizzer scheme is pretty nice - as well as novel to me - and I imagine worthwhile to tame a bit of shout. Couple this with the 98¢ trick and you'll have your driver sounding like a million bucks! 🙂

Another pseudo-coax in development, here with a Tectonic TEBM46C20N and Scan Speak 18W-8546-01.

The deveopment thread can be found in the German DIY hifi forum here. I'd post details here if anyone's interested.

The deveopment thread can be found in the German DIY hifi forum here. I'd post details here if anyone's interested.

Hello Gaga

In your picture the BMR is supported by a non-minimal baffle. I suppose x/o is 400 Hz or so to avoid diffraction issues with the woofer?

In your picture the BMR is supported by a non-minimal baffle. I suppose x/o is 400 Hz or so to avoid diffraction issues with the woofer?

Hi Boden,

Yes, you're right, I try to x/o between 400 and 500 Hz.

However, the most serious impact of the BMR-enclosure on the woofer-response is peaking at around 1.8 kHz (Helmholz-resonator between woofer membrane and enclosure-back):

The dip around 580 Hz is caused by interaction with the bass-reflex channel on the front - I have to work on that next, i.e. minimize bass reflex channel reonances. For now, up to 500Hz seems ok. If I can resolve the 580Hz-dip, the woofer may run higher though.

There is one issue with the BMR frequency response at around 1.5 kHz:

This probably caused by the enclosure front (or un-damped enclosure inside). Again something still to work on.

Beside that x/o at around 400 to 500 Hz should work fine.

Yes, you're right, I try to x/o between 400 and 500 Hz.

However, the most serious impact of the BMR-enclosure on the woofer-response is peaking at around 1.8 kHz (Helmholz-resonator between woofer membrane and enclosure-back):

The dip around 580 Hz is caused by interaction with the bass-reflex channel on the front - I have to work on that next, i.e. minimize bass reflex channel reonances. For now, up to 500Hz seems ok. If I can resolve the 580Hz-dip, the woofer may run higher though.

There is one issue with the BMR frequency response at around 1.5 kHz:

This probably caused by the enclosure front (or un-damped enclosure inside). Again something still to work on.

Beside that x/o at around 400 to 500 Hz should work fine.

Yes - however I simulated the enclosure in front of the woofer using AKABAK upfront. And I need this size in order to achive enough volume for the back of the BMR.little surprised the baffle is not more minimal

Gaga,

Given the relatively low crossover frequency of 400-500Hz, what do you see as advantageous in your co-axial scheme versus simply having the drivers on the same baffle within 90 degrees of each other, thus essentially coincident? I imagine you have something in mind to trade-off the design issues you are describing.

Given the relatively low crossover frequency of 400-500Hz, what do you see as advantageous in your co-axial scheme versus simply having the drivers on the same baffle within 90 degrees of each other, thus essentially coincident? I imagine you have something in mind to trade-off the design issues you are describing.

versus simply having the drivers on the same baffle within 90 degrees of each other, thus essentially coincident?

Criteria is quarter-wavelength at teh XO frequency, not sure where the angle citeria comes from. for 400 Hz, about 8.5”/21.5cm

dave

Hi IG81,

A fair point. I did not check the alternative/conventional approach you are suggesting and it may turn out, that the trade-off of this design finally works better. I might cross-check with a simulation. In fact I was coming from the idea constrcuting a coax-design with the advantage of a point source (regarding vertical radiation) with smooth/constant horizontal radiation over a wide frequency range.

However, I do not see too critical issues beside the dip around 580 Hz which might be still solved working on the BR-channel interaction here.

A fair point. I did not check the alternative/conventional approach you are suggesting and it may turn out, that the trade-off of this design finally works better. I might cross-check with a simulation. In fact I was coming from the idea constrcuting a coax-design with the advantage of a point source (regarding vertical radiation) with smooth/constant horizontal radiation over a wide frequency range.

However, I do not see too critical issues beside the dip around 580 Hz which might be still solved working on the BR-channel interaction here.

Lets just have a bit of this...

A bit of this...

And some of this...

A bit of this...

And some of this...

- Home

- Loudspeakers

- Multi-Way

- Show us your DIY coaxial drive units