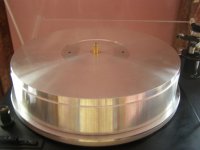

This is a third stage of upgrade process. I think what pics are able to show the process as well as final result. On the final picture the 7 kilogramm platter consisted of 8 parts has been substituted with solid 12 kilogramm one. And yes, it changed the sound signature substancially.

Attachments

Last edited:

That is very impressive - but missing the details of your design process.

I would like to know more. Did you do the machining yourself? Is the bearing of your deisgn? What are you using for a motor?

Would love to know more if you are willing to talk about this magnificent project.

I would like to know more. Did you do the machining yourself? Is the bearing of your deisgn? What are you using for a motor?

Would love to know more if you are willing to talk about this magnificent project.

Many years ago I've bought Micro Seiki MR-611 turntable in very decent condition. It had cast chassie and very big and powerfull hysteresis sinchronous AC motor together with pretty light platter of about 2,5 kilogramm. Platter bearing together with shaft was also very big and well machined. IMHO it just cried for much heavier platter. After long consideration I've decided to order six cylinders to increase platter mass, as well as one cylinder for the center of the platter together with spindle extentsion ( all of aluminum alloy). Of course, all machined on lathe. One more cylinder of stainless steel as a new tonearm base to level tonearm with new, much taller platter. All cylinders were installed and bolted on the top of original platter. Being assembled and dynamically balanced, platter went up to 7 kilos mass. Motor with a belt drive was able to speed up and reach nominal platter speed in 3-4 seconds. Sonic improvement was really noticable, no way of going back to direct drive turntables or budget belt drive ones..

And yes, I've got rid of original wooden cabinet, and ordered 4 alluminum machined feet, bolted directly to the cast chassie.

This was the first stage of upgrade, it was done at 2008, and my turntable worked in such configuration up to 2022. No any signs of motor overload, as well as no signs of increased platter bearing wear.

I do have a friend, who is a highly skilled machinist, so my part was to create drawings and assemble/adjust everything together. Original motor, as well, as platter bearings did not required any changes. Speed is very stable, and drive is very quiet.

Next stage was upgrading to the solid and even heavier platter, and the last stage- to utilize idler wheel drive instead of the belt. All of them complete last year.

And yes, I've got rid of original wooden cabinet, and ordered 4 alluminum machined feet, bolted directly to the cast chassie.

This was the first stage of upgrade, it was done at 2008, and my turntable worked in such configuration up to 2022. No any signs of motor overload, as well as no signs of increased platter bearing wear.

I do have a friend, who is a highly skilled machinist, so my part was to create drawings and assemble/adjust everything together. Original motor, as well, as platter bearings did not required any changes. Speed is very stable, and drive is very quiet.

Next stage was upgrading to the solid and even heavier platter, and the last stage- to utilize idler wheel drive instead of the belt. All of them complete last year.