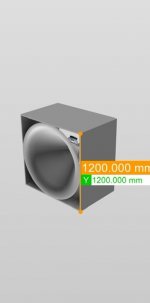

Since I saw the A For Ara H2 speakers, I feel the urge to try a better horn than the usual flat board construction for a MEH - and compare it to the prototype I am working on right now. It would be most probably a combination of CNC machined plywood and foam. My space is limited to a box of 95 x 95 cm baffle and depth of around 70 cm in total. A round mouth looks cool in a square baffle, a square/rectangular waveguide with smoot transition would also work.

The wonderful ATH tool is the natural choice, however it presents so many options, that I am a bit lost there. I would appreciate any suggestions on which profile to use as a start, with 1.4" throat, coverage angle around 85 degrees round or around 85x65 rectangular - to be comparable with the flat board prototype.

The wonderful ATH tool is the natural choice, however it presents so many options, that I am a bit lost there. I would appreciate any suggestions on which profile to use as a start, with 1.4" throat, coverage angle around 85 degrees round or around 85x65 rectangular - to be comparable with the flat board prototype.

I guess it is more like common inspiration🙂 I really dig the flat panel MEHs, if the rounded one can be even better, then I am all in!

Ha ha, Yes, I find this interesting!I guess it is more like common inspiration🙂 I really dig the flat panel MEHs, if the rounded one can be even better, then I am all in!

Have you simulated any profile yet?

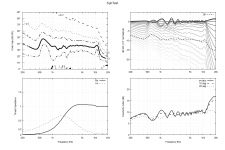

Yes, I tried one random simulation based on the CE series - in circsym as freestanding. Not sure what to think about it. It is slightly larger than available space. I would like it to be slightly smaller and maybe deeper to fit the woofers better.

Attachments

The plan is to CNC the plywood part that fits my CNC bed in whole circles, the rest with XPS in quarters.

I’ve seen and heard the H4. Amazing experience.

I’m more interested in scaling down and playing with the concept similar to the B2.

No idea what expansion formula is used on those waveguides/horns.

Since I have no CNC resources or knowledge at all I was brainstorming how to create a similar form to experiment with cheaply.

First thing that occurred to me is that the cones in my Tannoy System 15 DMTii have a very similar form.

Been looking for inexpensive 15” recone kits.

I’d probably experiment with a Celestion CDX1-1445 I bought with intentions of reproducing Waslo’s Cosyne project. May need to make a throat adapter.

I have some of the other Cosyne drivers as well…might look for something different to use for mids though.

My idea was to mount the paper cone in a square baffle and reinforce it with polyester resin.

Pick tap points for mids and mount some shaped wood or reinforced foam blocks on the back to mount them.

Hook it up with Mini DSP and play to see what happens.

Look forward to seeing where you guys go with this.

I’m more interested in scaling down and playing with the concept similar to the B2.

No idea what expansion formula is used on those waveguides/horns.

Since I have no CNC resources or knowledge at all I was brainstorming how to create a similar form to experiment with cheaply.

First thing that occurred to me is that the cones in my Tannoy System 15 DMTii have a very similar form.

Been looking for inexpensive 15” recone kits.

I’d probably experiment with a Celestion CDX1-1445 I bought with intentions of reproducing Waslo’s Cosyne project. May need to make a throat adapter.

I have some of the other Cosyne drivers as well…might look for something different to use for mids though.

My idea was to mount the paper cone in a square baffle and reinforce it with polyester resin.

Pick tap points for mids and mount some shaped wood or reinforced foam blocks on the back to mount them.

Hook it up with Mini DSP and play to see what happens.

Look forward to seeing where you guys go with this.

Yes, but why not? We do diy for a reason...

Regarding curvature, here are some thoughts too:

https://sphericalhorns.net/

Regarding curvature, here are some thoughts too:

https://sphericalhorns.net/

Last edited:

My space is limited to a box of 95 x 95 cm baffle and depth of around 70 cm in total. I would appreciate any suggestions on which profile to use as a start, with 1.4" throat, coverage angle around 85 degrees

10^6/(95*85) = ~124 Hz

34400/4/70 = ~123 Hz, so factor in a throat transition and you're good to go.

@Nissep Not that much work and weight if done partly from foam and on a CNC.

@Petter Persson Yes, that is one of the options

@GM If I understand it correctly, the first equation is related to mouth size and the second one to depth. Do you suggest a mostly conical horn with some sort of throat transition and mouth termination? Like the ones generated by ATH? To get more depth, I would need to decrease the coverage angle, maybe 60 degrees would do.

@Petter Persson Yes, that is one of the options

@GM If I understand it correctly, the first equation is related to mouth size and the second one to depth. Do you suggest a mostly conical horn with some sort of throat transition and mouth termination? Like the ones generated by ATH? To get more depth, I would need to decrease the coverage angle, maybe 60 degrees would do.

My thought experiment for/with @oLjud was a OS profile with B&C DCX464 together with larger woofers or a lot of smaller one like the Beyma 6cmv2 .

And I was thinking one can build a large frame and use stretched fabric and epoxy to make the majority of the horn body that is simply a cone.

The important throat section with the transition to straight walls would be 3D printed.

But in the end we/he came to our senses, they would simply occupy to much volume in the room.

But Peter, as a Swede we know you have some history in building huge creations.

And Palanj, https://www.desmos.com/calculator/ggzoijr0pg this would be a great start when you start to figure out size constraints.

That`s what I used but with the OS profile together with manually entering the resulting numbers in to hornresp to check the woofer performance.

And I was thinking one can build a large frame and use stretched fabric and epoxy to make the majority of the horn body that is simply a cone.

The important throat section with the transition to straight walls would be 3D printed.

But in the end we/he came to our senses, they would simply occupy to much volume in the room.

But Peter, as a Swede we know you have some history in building huge creations.

And Palanj, https://www.desmos.com/calculator/ggzoijr0pg this would be a great start when you start to figure out size constraints.

That`s what I used but with the OS profile together with manually entering the resulting numbers in to hornresp to check the woofer performance.

The driver would be DCX464 or Beyma CP755Nd, I was thinking about more smaller mids, maybe 4x Fane Sovereign 8-225 and maybe integrate some woofers to the sides, maybe slot loaded. The flat panel MEH I am slowly building now is described here: https://www.diyaudio.com/community/...d-3d-print-and-cnc.383396/page-3#post-7230365

Its external volume is ca 320 l and I can still increase the depth a bit. Intended placement is along the front wall, on a stand with wheels to be able to move them around easily.

The Desmos calculator is nice, that will definitely help. So after I find the profile that fits, I would go to ATH and try to simulate. My problem is that my knowledge is not good enough to evaluate the results. I will spend most of next week travelling, so I will have some time to play around with that.

Its external volume is ca 320 l and I can still increase the depth a bit. Intended placement is along the front wall, on a stand with wheels to be able to move them around easily.

The Desmos calculator is nice, that will definitely help. So after I find the profile that fits, I would go to ATH and try to simulate. My problem is that my knowledge is not good enough to evaluate the results. I will spend most of next week travelling, so I will have some time to play around with that.

For low frequency, how about PPSL woofer in each corner of the back chamber? Could be a fun and good way of making a single bass array configuration if you plan to have it close to the front wall . https://en.wikipedia.org/wiki/Double_bass_array

It all comes down to the size of the room/front wall and the enclosure and how high in frequency your planning to use the woofers if it fills the criteria for making a plane wave. And ultimately you add a active back wall with subs too.

In the end there is not a lot to gain from building a big low frequency horn since the room will still mess up the response.

Well there is a sensitivity gain and potential distortion reduction, but large horns and small rooms - Do They “Play Nicely” Together?..

https://kolbrek.hornspeakersystems.info/images/misc/BKHornRooms2019.pdf

It all comes down to the size of the room/front wall and the enclosure and how high in frequency your planning to use the woofers if it fills the criteria for making a plane wave. And ultimately you add a active back wall with subs too.

In the end there is not a lot to gain from building a big low frequency horn since the room will still mess up the response.

Well there is a sensitivity gain and potential distortion reduction, but large horns and small rooms - Do They “Play Nicely” Together?..

https://kolbrek.hornspeakersystems.info/images/misc/BKHornRooms2019.pdf

I have 4 pieces of 40 Hz bass horns, only two are currently used. As in the other MEH project, the goal is to keep directivity control as low as possible. The other one will use a single 18", I will test both sealed and bass reflex. The room is basically a cellar/workshop, so there is enough room for multiple subwoofer setup. I want to translate as much as possible from the old 4way horn setup to a single point source box. My midbass horns were slightly smaller than the flat panel MEH - those I am missing the most, I hope the replacement will be as nice.

Actually, the reason for going to circular/smooth rectangular transition horn is a) visual, b) maybe slightly improved performance.

Actually, the reason for going to circular/smooth rectangular transition horn is a) visual, b) maybe slightly improved performance.

- Home

- Loudspeakers

- Multi-Way

- Large circular MEH - which waveguide profile to use?