Hi,

I have Roland Cube 60 bass (orange, older version) on my bench.

Power amp is good, no noise, healthy.

Power supply caps are replaced with new, all voltages are correct.

Problems are located in preamp, scratchy pots and hum of around 150Hz.

Hum dissapear if I switch preamp off and use power amp only.

Hum is not Volume pot related, it is there after amp is ON.

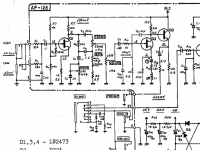

Preamp is built around three transistors (Q1,2,3).

-voltages in preamp on Q1 (2SK117) are OK

-all 4 pots in tonestack are replaced- new -no change, no DC anywhere.

(Vol pot is especially scratchy then treble and Mid + Bass less)

-all tonestack capacitors and resistors arround Q2,Q3 are new

(Q2 is 2SK117, Q3 is 2SC2240)

-voltages on Q2+Q3 are not OK, according to schematics

(Q2: G= close to 0, D= 28,2V, S= 0,33V; Q3: B= 28,2V, E=29,6V, C=37V)

-it seems there is also problem with L1 (measured 10H and 270ohm DCR)

-Q2+3 were tested outside PCB (no shorts or leakeage)

-grounding is tested and checked a few times, all OK

There isn’t any data about L1, it is marked on the body: 5R.

It looks L1 is part of series filter with R16 (1,8k) and C8 (1uF).

L1 is tied to ground with one end.

If I ground the other leg of L1, hum dissapear, sound is a bit changed.

If I ground it at the input, hum is completely gone.

Any ideas regarding scratchy pots, L1 and voltages on Q2+3?

I don’t have spare transistor Q2+3 to try, must be ordered.

What would be value of inductor at this location for bass amp?

Thanks in advance!

I have Roland Cube 60 bass (orange, older version) on my bench.

Power amp is good, no noise, healthy.

Power supply caps are replaced with new, all voltages are correct.

Problems are located in preamp, scratchy pots and hum of around 150Hz.

Hum dissapear if I switch preamp off and use power amp only.

Hum is not Volume pot related, it is there after amp is ON.

Preamp is built around three transistors (Q1,2,3).

-voltages in preamp on Q1 (2SK117) are OK

-all 4 pots in tonestack are replaced- new -no change, no DC anywhere.

(Vol pot is especially scratchy then treble and Mid + Bass less)

-all tonestack capacitors and resistors arround Q2,Q3 are new

(Q2 is 2SK117, Q3 is 2SC2240)

-voltages on Q2+Q3 are not OK, according to schematics

(Q2: G= close to 0, D= 28,2V, S= 0,33V; Q3: B= 28,2V, E=29,6V, C=37V)

-it seems there is also problem with L1 (measured 10H and 270ohm DCR)

-Q2+3 were tested outside PCB (no shorts or leakeage)

-grounding is tested and checked a few times, all OK

There isn’t any data about L1, it is marked on the body: 5R.

It looks L1 is part of series filter with R16 (1,8k) and C8 (1uF).

L1 is tied to ground with one end.

If I ground the other leg of L1, hum dissapear, sound is a bit changed.

If I ground it at the input, hum is completely gone.

Any ideas regarding scratchy pots, L1 and voltages on Q2+3?

I don’t have spare transistor Q2+3 to try, must be ordered.

What would be value of inductor at this location for bass amp?

Thanks in advance!

Attachments

L1 is 10 Henry!? Would you describe L1 physically, dimensions? Can it be reoriented to find a position with less induced hum? A picture might help. 1uF and 10H are series resonant at 50.3Hz!

Re scratchy pot, according to schematic, there's no DC across the pot, but you should confirm that's true. Contact cleaner might help.

Re scratchy pot, according to schematic, there's no DC across the pot, but you should confirm that's true. Contact cleaner might help.

I’m not in the shop right now, I attached a photo I have on the phone-you can see L1 in upper left corner.

It was measured with one leg lifted, 1H and 270ohm DCR.

It looks like it is glued to PCB originaly.

Pots are new, all was treated with Deoxit too, still scratchy.

All points in tonestack were checked, no DC measured…

It was measured with one leg lifted, 1H and 270ohm DCR.

It looks like it is glued to PCB originaly.

Pots are new, all was treated with Deoxit too, still scratchy.

All points in tonestack were checked, no DC measured…

Attachments

I would try bypassing Q2 and Q3 and connecting C10 input directly to volume pot wiper (lifting R10 and R17 one leg) - to see if it makes any change.

Last edited:

I borrowed the amp (L1 shorted) to a bass player to test it.

And also found a guy who owns the same model of Cube which is works properly.

In a day or two when I will get the other one I can open and compare both.

Will report about findings, I’m really interested what is the reason for this problem.

Thanks for suggestions!

And also found a guy who owns the same model of Cube which is works properly.

In a day or two when I will get the other one I can open and compare both.

Will report about findings, I’m really interested what is the reason for this problem.

Thanks for suggestions!

Pot noise not depends upon DC voltages. They must be dirty or weared. Try isoprophilic alcohol with the set disconnect from supply.

From initial post:Pot noise not depends upon DC voltages.

"Hum is not Volume pot related,"

And looking at the schematics - unless signal path capacitors are leaking there should be no DC voltage over volume pot.

Last edited:

The noise is when rotating them or also when quiet? I understand that usualy a scratchy pot makes visible when turning them.

Are you able to hear music even though there is hum present? Or is the input path totally blocked?

The 10H inductor is wound on a "pot core", has a plastic bobbin within containing the winding. It was likely custom wound and I doubt it needs replacement.

The 10H inductor is wound on a "pot core", has a plastic bobbin within containing the winding. It was likely custom wound and I doubt it needs replacement.

I apologise for delay in reporting.

I’ve been travelling between hospital and home all the time for a few days (first my father (flu) and then mother in law (cancer)…

So, I borrowed another Cube 60 and so compared two identical Cube 60 bass amps, actually preamps only.

One, under service is wired for 240V mains, the other one 220V.

Therefore 3V difference in power supply voltages for preamp.

Also serviced amp has 4 new power supply elko’s.

When amp is opened, there is louder hum and pots are slightly scratchy.

This is identical in both amps compared, opened and assemled.

Serviced Cube has all new pots + Deoxit, result (scratchy pots) is the same as before.

When amp is assembled into a box with alu shield, hum is less noticable, also pots are less scratchy, but you can still hear it, especially VOL pot.

If choke is shorted, hum completely dissapear.

Without choke, amp is a tiny bit louder and brighter.

I end it up with both amps assembled back and result is that serviced amp has a bit less hum, is slightly louder, otherwise sounds very similar.

Choke is reason for hum, probably need shield and better placement.

There isn’t enough space on PCB to experiment and also it is glued.

Slightly Scratchy pots are still a question not answered yet…for now it stay as is.

Thanks for your sugesstions and interest!

———————————————————

I made some measurements again in both amps:

Cube 60 - servicing, Rewired for 240V mains:

Q1- 2SK117

S=1,94

G=1,63

D=17,5

Q2- 2SK117

D=29,10

G=0,0016

S=0,32

Q3- 2SC2240

E=29

C=37

B=28,5

Choke:

L=10H (1kHz)

Z=63kOhm (1kHz)

Z=8kOhm (100Hz)

DCR=276ohm

——————————

Cube 60 - borrowed, wired for 220V, otherwise the same version:

Q1- 2SK117

S=2

G=1,74

D=20,5

Q2- 2SK117

D=29

G=0,009

S=0,49

Q3- 2SC2240

E=28,8

C=40,1

B=28,3

Choke:

L=8,8H (1kHz)

Z=55kOhm (1kHz)

Z=6kOhm (100Hz)

DCR=270Ohm

I’ve been travelling between hospital and home all the time for a few days (first my father (flu) and then mother in law (cancer)…

So, I borrowed another Cube 60 and so compared two identical Cube 60 bass amps, actually preamps only.

One, under service is wired for 240V mains, the other one 220V.

Therefore 3V difference in power supply voltages for preamp.

Also serviced amp has 4 new power supply elko’s.

When amp is opened, there is louder hum and pots are slightly scratchy.

This is identical in both amps compared, opened and assemled.

Serviced Cube has all new pots + Deoxit, result (scratchy pots) is the same as before.

When amp is assembled into a box with alu shield, hum is less noticable, also pots are less scratchy, but you can still hear it, especially VOL pot.

If choke is shorted, hum completely dissapear.

Without choke, amp is a tiny bit louder and brighter.

I end it up with both amps assembled back and result is that serviced amp has a bit less hum, is slightly louder, otherwise sounds very similar.

Choke is reason for hum, probably need shield and better placement.

There isn’t enough space on PCB to experiment and also it is glued.

Slightly Scratchy pots are still a question not answered yet…for now it stay as is.

Thanks for your sugesstions and interest!

———————————————————

I made some measurements again in both amps:

Cube 60 - servicing, Rewired for 240V mains:

Q1- 2SK117

S=1,94

G=1,63

D=17,5

Q2- 2SK117

D=29,10

G=0,0016

S=0,32

Q3- 2SC2240

E=29

C=37

B=28,5

Choke:

L=10H (1kHz)

Z=63kOhm (1kHz)

Z=8kOhm (100Hz)

DCR=276ohm

——————————

Cube 60 - borrowed, wired for 220V, otherwise the same version:

Q1- 2SK117

S=2

G=1,74

D=20,5

Q2- 2SK117

D=29

G=0,009

S=0,49

Q3- 2SC2240

E=28,8

C=40,1

B=28,3

Choke:

L=8,8H (1kHz)

Z=55kOhm (1kHz)

Z=6kOhm (100Hz)

DCR=270Ohm

Thanks Osvaldo!Best wishes for you, mum and dad!!!

1) L1 is catching ambient/surrounding Hum, nothing (practical) you can do about that.

2) L1 and C8 make a bass boosting resonant tank, common in small Bass amps to make them sound "bigger".

IF 1H then boosting ~150Hz; if 10Hy boosting about 50Hzz, both "fake" since the box IS small anyway.

2 options:

a) simple: short L1 and call it a day.

You will lose that fake boost, you will lose Hum, not bad

b) sophisticated: design a Gyrator (1 transistor 2 caps 2 or 3 resistors) plus a mini PCB to simulate a 1H (or any value you like) inductor.

It will restore original sound and not hum.

In my book, not worth it, it´s a very weak boost anyway, I´d go for the simple solution.

3) I suspect C9 is leaky, and it is supplying its own DC to pot wiper from Q2 gate bias voltage.

Replace it with a modern type quality low loss cap.

No boutique by any means, just a good commercial one. Polyster, polypropilene, teflon, any good modern commercial type.

4) for good measure, also replace C3 and C4, same considerations, you are removing all possible DC paths to pots.

5) maybe there is no leaky pot involved (replace them anyway, if anything for peace of mind) but a dirty/conductive PCB (Coke/beer spill? Mold grown in a humid environment? Very humid climate or near the beach?), I´d wash it.

Put some distilled water (sold at Service Stations for car batteries), a couple drops detergent, a squirt of Windex in a cup, wash both sides of PCB with a clean paint type brush.

Let it dry well before plugging amp in.

You might first clean the solder side with a toothbrush an alcohol to remove any solder flux residue.

2) L1 and C8 make a bass boosting resonant tank, common in small Bass amps to make them sound "bigger".

IF 1H then boosting ~150Hz; if 10Hy boosting about 50Hzz, both "fake" since the box IS small anyway.

2 options:

a) simple: short L1 and call it a day.

You will lose that fake boost, you will lose Hum, not bad

b) sophisticated: design a Gyrator (1 transistor 2 caps 2 or 3 resistors) plus a mini PCB to simulate a 1H (or any value you like) inductor.

It will restore original sound and not hum.

In my book, not worth it, it´s a very weak boost anyway, I´d go for the simple solution.

3) I suspect C9 is leaky, and it is supplying its own DC to pot wiper from Q2 gate bias voltage.

Replace it with a modern type quality low loss cap.

No boutique by any means, just a good commercial one. Polyster, polypropilene, teflon, any good modern commercial type.

4) for good measure, also replace C3 and C4, same considerations, you are removing all possible DC paths to pots.

5) maybe there is no leaky pot involved (replace them anyway, if anything for peace of mind) but a dirty/conductive PCB (Coke/beer spill? Mold grown in a humid environment? Very humid climate or near the beach?), I´d wash it.

Put some distilled water (sold at Service Stations for car batteries), a couple drops detergent, a squirt of Windex in a cup, wash both sides of PCB with a clean paint type brush.

Let it dry well before plugging amp in.

You might first clean the solder side with a toothbrush an alcohol to remove any solder flux residue.

If you can't screen the inductor then I would disconnect it , shorting it leaves C8 ( 1uF ) in circuit with the result that the gain of the preamp will increase above 88 Hz ( turning point ) which is the opposite of what it would do .

PS I think you are mixing up the base and the emitter on Q3 ( 2SC 2240 ) .

PS I think you are mixing up the base and the emitter on Q3 ( 2SC 2240 ) .

Good idea.

I would both short L1 and replace C8 1 uF by a .1uF one. Any type, even a ceramic disk will do, not critical at all.

It will leave general volume as-is but add some brightness/definition which never hurts.

Boost will reach moderate 6dB above 2-3 kHz,

I would both short L1 and replace C8 1 uF by a .1uF one. Any type, even a ceramic disk will do, not critical at all.

It will leave general volume as-is but add some brightness/definition which never hurts.

Boost will reach moderate 6dB above 2-3 kHz,

- Home

- Amplifiers

- Solid State

- Scratchy pots and hum - Roland Cube 60 bass