We discussed using CMCs with SMPS supplies in the thread on All-DHT Amplifiers, but could we continue it in more detail?

Can we also discuss using CMCs in a linear supply? Where to put them, what values, and how they help hum suppression?

Goal would be to use the supply for something like a 6B4G, 10Y, 112A stage in filament bias. Could be using Rod Coleman regs also.

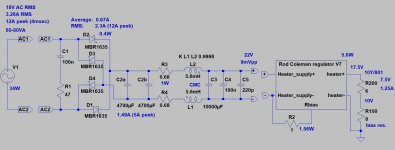

Here's a simple diagram to start with that you can analyse and pull apart and suggest modifications.

Can we also discuss using CMCs in a linear supply? Where to put them, what values, and how they help hum suppression?

Goal would be to use the supply for something like a 6B4G, 10Y, 112A stage in filament bias. Could be using Rod Coleman regs also.

Here's a simple diagram to start with that you can analyse and pull apart and suggest modifications.

CMC (Common Mode Choke) helps to reduce such disturbances, which are on both wire of secondary. It's not hum decreaser.how they help hum suppression?

Thanks Bela. Questions:

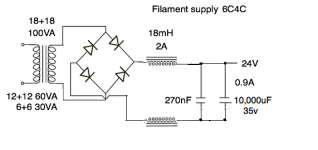

- How do I wire up my 18mH/2A Epcos CMC correctly? I see you've indicated pos and neg on your diagram.

https://www.digikey.com/en/products/detail/epcos-tdk-electronics/B82725A2202N001/1243521

- What advantages are there of putting the CMC either straight after the rectification or after the first cap?

- Presumably the resistors you indicate can be sized for dropping the voltage as required, like could be bigger?

- How do I wire up my 18mH/2A Epcos CMC correctly? I see you've indicated pos and neg on your diagram.

https://www.digikey.com/en/products/detail/epcos-tdk-electronics/B82725A2202N001/1243521

- What advantages are there of putting the CMC either straight after the rectification or after the first cap?

- Presumably the resistors you indicate can be sized for dropping the voltage as required, like could be bigger?

1.) If you see datasheet https://www.tdk-electronics.tdk.com/inf/30/db/ind_2008/b82725a.pdf the correct wiring is:Thanks Bela. Questions:

- How do I wire up my 18mH/2A Epcos CMC correctly? I see you've indicated pos and neg on your diagram.

https://www.digikey.com/en/products/detail/epcos-tdk-electronics/B82725A2202N001/1243521

- What advantages are there of putting the CMC either straight after the rectification or after the first cap?

- Presumably the resistors you indicate can be sized for dropping the voltage as required, like could be bigger?

1 -> 2

4 -> 3

2.) If you use CMC before first cap, the charging pulse passes trough the coil, so stresses it.

3.) The resistors only dropping voltage, so CMC and R.C. regulator dissipation decreases.

My rule of thumb:

Filament voltage + bias voltage on bias resistor (if it exist) + R.C. reg headroom (variable of versions) == raw DC voltage (output of raw supply).

If dropping resistors (I use its in both -positive/negative- wire) necessary, use at least 3..4x larger wattage than counted.

Andy, please locate the CMC in the position that Bela uses. Putting it at the rectifier will form an LC tank circuit that gets excited by the big current pulses from the rectifier, and a lot of noise!

THe most important thing to say about common-mode filtering in Line/mains supplies:

The chief and best common-mode filter is the mains transformer.

Excellent common-mode blocking is given by a LOW value of leakage-capacitance between the primary and secondary, and if possible, an electrostatic shield.

If you are using a filament supply PT with more than ~50pF of PRI→SEC capacitance, it would be better to concentrate on improving that, since the 50/60Hz leakage current also increases with high capacitance. Unshielded toroidals can reach up into the nF region, and this is the reason that I advise keeing away from the unshielded variety, for feeding my filament supplies.

Puny little CM chokes have no practical effect at low frequencies; commercial ones are designed to stop HF CM noise getting back into the mains from the noise created by Line→DC converters. (They don't care about spectrum below 150kHz, since most EMC testing does not need to go that low).

R-core transformers are supposed to have very small PRI→SEC capacitance, I would be interested to know if anyone has measured any commercial units. Cheap DMMs have good enough C-metering to do this, nowadays.

THe overall message should be: if you get the transformer right, you probably don't need to worry very much about CM chokes.

The chief and best common-mode filter is the mains transformer.

Excellent common-mode blocking is given by a LOW value of leakage-capacitance between the primary and secondary, and if possible, an electrostatic shield.

If you are using a filament supply PT with more than ~50pF of PRI→SEC capacitance, it would be better to concentrate on improving that, since the 50/60Hz leakage current also increases with high capacitance. Unshielded toroidals can reach up into the nF region, and this is the reason that I advise keeing away from the unshielded variety, for feeding my filament supplies.

Puny little CM chokes have no practical effect at low frequencies; commercial ones are designed to stop HF CM noise getting back into the mains from the noise created by Line→DC converters. (They don't care about spectrum below 150kHz, since most EMC testing does not need to go that low).

R-core transformers are supposed to have very small PRI→SEC capacitance, I would be interested to know if anyone has measured any commercial units. Cheap DMMs have good enough C-metering to do this, nowadays.

THe overall message should be: if you get the transformer right, you probably don't need to worry very much about CM chokes.

CM choke at the output of filament supply works to reduce crosstalk between filaments. It also works to isolate filament from detrimental sonic effects of the last capacitor.

Common Mode Chokes are used to isolate one circuit from another (isolate AC and RF; not isolate DC).

That is the reason for using a common mode choke.

One of the most used applications of the common mode choke is:

The Reduction of Conducted EMI from a product, so that it can meet European and US EMI regulations.

Millions and Millions were used on the old desktop PCs.

A common mode choke is put in the circuit between the power cord, and the switching supply of a product.

I never have heard a Hi Fi or Stereo product that only uses linear supplies that needs a common mode choke to make it meet the EMI regulations.

Well, any new regulations might find EMI signals from Stereo amplifiers with the brute force power supplies that use things like Schottky rectifiers, and huge filter capacitors that can run a Tesla car for 1 minute at 30MPH.

Now of course, if you connect a Hi Fi or Stereo system with only linear supplies, to a power mains circuit that is also powering switchers, you may need a common mode choke in the clean stereo to get rid of all the crap that those other products switchers create and put on the power mains.

Switchers introduce the kinds of interference that needs common mode chokes to pass EMI regulations.

However, just because two products pass EMI regulations, that does not mean they will not interfere with each other.

The issue is not ElectroMagnetic Interference.

The issue is EMC (ElectoMagnetic Compatibility). And EMC is an oxymoron, many systems are In-Compatible.

That above are just the opinions of someone who used to work with EMI measurement products, regulations, and practical circuits;

And with customers including Intel, etc.

If my power mains have so much interference on them, so that I need to use common mode chokes on my stereo, I will just have move to another house that does not have such interference (That means I will not use common mode chokes in my stereo).

Do not forget, using one winding of a common mode choke in the ground connections from one circuit to another, may reduce the common mode interference, but also may introduce the possibility of increasing differential mode interference that was not noticed because the grounds were not isolated by the common mode choke winding. Be careful not to make or add worse problems.

Ground Loop interference is an Art and a Science.

Have fun.

That is the reason for using a common mode choke.

One of the most used applications of the common mode choke is:

The Reduction of Conducted EMI from a product, so that it can meet European and US EMI regulations.

Millions and Millions were used on the old desktop PCs.

A common mode choke is put in the circuit between the power cord, and the switching supply of a product.

I never have heard a Hi Fi or Stereo product that only uses linear supplies that needs a common mode choke to make it meet the EMI regulations.

Well, any new regulations might find EMI signals from Stereo amplifiers with the brute force power supplies that use things like Schottky rectifiers, and huge filter capacitors that can run a Tesla car for 1 minute at 30MPH.

Now of course, if you connect a Hi Fi or Stereo system with only linear supplies, to a power mains circuit that is also powering switchers, you may need a common mode choke in the clean stereo to get rid of all the crap that those other products switchers create and put on the power mains.

Switchers introduce the kinds of interference that needs common mode chokes to pass EMI regulations.

However, just because two products pass EMI regulations, that does not mean they will not interfere with each other.

The issue is not ElectroMagnetic Interference.

The issue is EMC (ElectoMagnetic Compatibility). And EMC is an oxymoron, many systems are In-Compatible.

That above are just the opinions of someone who used to work with EMI measurement products, regulations, and practical circuits;

And with customers including Intel, etc.

If my power mains have so much interference on them, so that I need to use common mode chokes on my stereo, I will just have move to another house that does not have such interference (That means I will not use common mode chokes in my stereo).

Do not forget, using one winding of a common mode choke in the ground connections from one circuit to another, may reduce the common mode interference, but also may introduce the possibility of increasing differential mode interference that was not noticed because the grounds were not isolated by the common mode choke winding. Be careful not to make or add worse problems.

Ground Loop interference is an Art and a Science.

Have fun.

Last edited:

It is difficult to imagine a situation where a common mode choke would improve the EMC filtering performance, if the item already has a 50/60Hz power transformer.I never have heard a Hi Fi or Stereo product that only uses linear supplies that needs a common mode choke to make it meet the EMI regulations.

The PT itself deals with common mode noise, at least at to ca. 100kHz.

On the secondary side, the system EMC reference node (enslosure shield, or non-current-carrying ground plane) is almost always the power supply 0V, and often, protective earth as well. So there is not much common mode noise-current anywhere.

If the audio product has some wideband noise generators - processors, displays, oscillators - they can be addressed by local decoupling to the EMC reference node; plus ferrite beads or low-value differential mode inductors in the supply lines can keep the highest frequencies out of the mains, IO or speaker cables.

in the same situation, the CM choke can raise the impedance at the input of a amplifier or DC supply rail. Its differential impedance can react with carelessly chosen supply capacitors to cause lumps in the impedance curve at parts of the audio spectrum... This is almost always bad news!common mode choke in the ground connections from one circuit to another, may reduce the common mode interference, but also may introduce the possibility of increasing differential mode interference

Why the dots (polarity) of CMC are oriented differently in several posts ?We discussed using CMCs with SMPS supplies in the thread on All-DHT Amplifiers, but could we continue it in more detail?

Can we also discuss using CMCs in a linear supply? Where to put them, what values, and how they help hum suppression?

Goal would be to use the supply for something like a 6B4G, 10Y, 112A stage in filament bias. Could be using Rod Coleman regs also.

Here's a simple diagram to start with that you can analyse and pull apart and suggest modifications.

View attachment 1118956

Let's discuss this from a mutual inductance (M) perspective.

The dot notation:

If the two currents flow into each dot or out of each dot,

the mutual inductance M is positive.

On the other hand, if one current flows into a dotted end and the other leaves the dotted end,

then the mutual inductance M is negative.

The common mode refers to signals or noise that flow in the same direction in a pair of lines.

The differential (normal) mode refers to signals or noise that flow

in opposite directions in a pair of lines.

Referring to Fig (A) (From "Noise Reduction Techniques in Electronic Systems", by Henry W. Ott).

To the signal current I_S, the magnetic flux of each coil cancels each other out,

the mutual inductance M is negative.

V_S = s (L_1 + L_2 ) I_S - 2 s M I_S + (R_L + R_{C2}) I_S ; s=j w

Neglecting coil resistances,

since L_1 = L_2 = M, I_S = V_S / R_L ; as if the common mode choke is a pair of wires.

To the common noise (common mode noise) currents which appear in both lines of the input,

the magnetic flux of each coil adds to impede common mode current,

the mutual inductance is positive.

Total frequency dependent impedance is s (L_1 + L_2 ) + 2sM = 4 s M.

Referring to Fig (B) and figure above, the latter is from

Lundahl's /Emission Lab application note that describes improved ripple rejection

for a CLC tube power supply.

V_r is the ripple source, I_r is the ripple current.

In this case, the mutual inductance (M) wrt to I_r is positive.

The (common mode) coils are impeding the differential current I_r.

At 100Hz, assuming L_1 = L_2 = M = 5H.

The impedance to 100Hz ripple is 4sM = 100 x 20 = 2K.

Notice that this configuration does not impede common mode noise.

I hope I got this right ! Feel free to chime in.

For an R-Core power transformer, the measured capacitance between each of three secondary heater/low voltage windings and the 2 x 115V primary windings connected in series is:R-core transformers are supposed to have very small PRI→SEC capacitance, I would be interested to know if anyone has measured any commercial units. Cheap DMMs have good enough C-metering to do this, nowadays.

To the 6.3V secondary - 161pF

To the 12.6V secondary - 151pF

To the 18V secondary - 955pF

Thanks for measuring!

Curious, the values look higher than EI, I had hoped they would be lower. But it is good to have real data -- thank you!

Curious, the values look higher than EI, I had hoped they would be lower. But it is good to have real data -- thank you!

This is a for a B+ supply.Lundahl's /Emission Lab application note that describes improved ripple rejection

for a CLC tube power supply.

Maybe it gives good rejection for 100/120Hz., but the secondary and the rectifier are at a high impedance from any of the system grounds.

Many years of working in EMC chambers with my own industrial designs makes me distrust potentially-noisy circuits which are not referred to an EMC reference point (the circuit 0V). The usual differential mode choke allows the CT to be connected directly to 0V/GND, and this can reduce EM-coupling to exposed signal wiring and components.

Rod,

Glad to see you had some experience with EMC chambers.

At one of my jobs, I used a very expensive EMC chamber that i had access to.

Double sheet special material metal shields, door finger stock, and very large power mains filters of the chamber, etc.

Testing the background noise of a 20GHz to 40GHZ of an electronic countermeasures receiver was easy.

Testing the signal to noise ratio of a very low frequency receiver, that is specified at 10kHz, 0.2 uV, with 30% AM modulation was not easy.

Those very large power mains filters of the chamber, could not keep out the hash from the Welders that operated down the street, using the same open air power lines, even though they were on different poles and pole transformers.

Inside the chamber: only the signal generator, AF millivolt meter (measure AF signal and AF noise), the low frequency receiver, and . . .

"The Welder in the Chamber".

Make sure the welders are all at lunch or at break!

Everything is what it seems to be, until you find out it is different.

Glad to see you had some experience with EMC chambers.

At one of my jobs, I used a very expensive EMC chamber that i had access to.

Double sheet special material metal shields, door finger stock, and very large power mains filters of the chamber, etc.

Testing the background noise of a 20GHz to 40GHZ of an electronic countermeasures receiver was easy.

Testing the signal to noise ratio of a very low frequency receiver, that is specified at 10kHz, 0.2 uV, with 30% AM modulation was not easy.

Those very large power mains filters of the chamber, could not keep out the hash from the Welders that operated down the street, using the same open air power lines, even though they were on different poles and pole transformers.

Inside the chamber: only the signal generator, AF millivolt meter (measure AF signal and AF noise), the low frequency receiver, and . . .

"The Welder in the Chamber".

Make sure the welders are all at lunch or at break!

Everything is what it seems to be, until you find out it is different.

Many of my electronics-design colleagues thought of EMC as incomprehensible, or simply a tedious obstacle to getting product released; but I find it facsinating, and spent many hours in our in-house chamber (military, made in the 1960s; it leaked a few points of spectrum, but could still be used to figure out lower-cost ways to design our Handheld PC mainboards to be compatible with GSM, EDGE, Mobitex.. data-radios in the same plastic enclosure. In the couple of decades that I have done contract design, being able to get customers' gear through EMC testing (with in-the-chamber fixes) has made for repeat business. When R & S released a Fanless 1GHz Spectrum Analyser (the FPC), I couldn't resist having my own; & getting back to valves: it is quite amusing to see what frequency some RF triodes go off at, if not correctly arranged!Glad to see you had some experience with EMC chambers.

- Home

- Amplifiers

- Tubes / Valves

- DHT filament supplies - common mode chokes (CMCs)