I have an excellent probably 20-22 year old, 211 SE amplifier rated at 18W per channel. I use it to drive my mids/tweeter D'Appolitto speaker. The amps designer is no longer with us. In September of this year the amp developed a ticking sound in both channels, not loud but when you get close to the drivers you'll hear it. If I put my lowther PM2a in then it is loud (ticking) as expected from a 97db speaker. The odd thing, to me, is that the bass driver which is driven by a 200W solid state amp also ticks, and this stops as soon as I turn the tube amp off. I am pretty confident the source is the tube amp and probably some old, heat affected components like plate resistors, resistors in the 211 filament circuit, possibly old electrolytic caps, after all the amp is 20 years old and throws some serious heat.

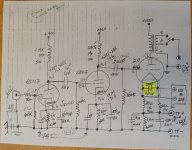

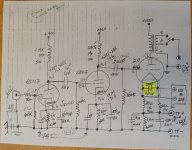

I have attached a schematic which the designer sent me a few years ago, I highlighted in yellow a capacitor in the filament circuit of the 211 which calls for a 3.5uF, 100V capacitor. In reality installed is a 1.25uf, the K I believe is 10%, 100V MPC style. I am not a technician but does that look ok to you 1.25 installed vs. 3.5 schematic. Also at the amps input I have a texas component 1K bulk metal foil resistor which connects to the grid of the 6sn7, also, according to the schematic a 200K ohm resistor runs from the grid side of the input resistor to ground. Installed in the amp is a 79K ohm resistor, not the 200K. Is that an issue?

I replaced the plate resistors (15K and 12.5K) earlier this year with mills MRA 12 resistors (15K and 12K) and earlier this week rechecked my soldering to make sure I had good joints, so hopefully these are not the cause. Visually looking over the components the 1K resistor in the 211 filament circuit looks a little heat beat up and the board below a bit brownish, I have 10W, 1K vishays on order to replace these. As stated in the title the ticking does not start until the amp has been on anywhere from 2-5 hours. You can see this 1K resistor right in front of the yellow capacitor in the attached photo.

Basically I am looking for advice on what you think could be the most likely cause of my ticking and if the 2 cases I note above are fine (they probably are) as is or should I revert back to what the schematic says. The components mount on vector boards with swaged terminal posts and these can be wired from the top or bottom. Things can get pretty tight in there, so soldering to these is not the most fun thing to do. Should I just replace some older components just because they are old and if so what priority should be given?

Thank you!!

I have attached a schematic which the designer sent me a few years ago, I highlighted in yellow a capacitor in the filament circuit of the 211 which calls for a 3.5uF, 100V capacitor. In reality installed is a 1.25uf, the K I believe is 10%, 100V MPC style. I am not a technician but does that look ok to you 1.25 installed vs. 3.5 schematic. Also at the amps input I have a texas component 1K bulk metal foil resistor which connects to the grid of the 6sn7, also, according to the schematic a 200K ohm resistor runs from the grid side of the input resistor to ground. Installed in the amp is a 79K ohm resistor, not the 200K. Is that an issue?

I replaced the plate resistors (15K and 12.5K) earlier this year with mills MRA 12 resistors (15K and 12K) and earlier this week rechecked my soldering to make sure I had good joints, so hopefully these are not the cause. Visually looking over the components the 1K resistor in the 211 filament circuit looks a little heat beat up and the board below a bit brownish, I have 10W, 1K vishays on order to replace these. As stated in the title the ticking does not start until the amp has been on anywhere from 2-5 hours. You can see this 1K resistor right in front of the yellow capacitor in the attached photo.

Basically I am looking for advice on what you think could be the most likely cause of my ticking and if the 2 cases I note above are fine (they probably are) as is or should I revert back to what the schematic says. The components mount on vector boards with swaged terminal posts and these can be wired from the top or bottom. Things can get pretty tight in there, so soldering to these is not the most fun thing to do. Should I just replace some older components just because they are old and if so what priority should be given?

Thank you!!

You could pull the 6sn7 and see if the problem still exists?

What sort of active crossover do you have between the 211 amplifier and the solid state amp? Just looking to see how the noise could couple between amps.

Is the 211 filament powered by some sort of SMPS supply? I have seen them pollute the line power with spikes that could couple with the SS amp.

What sort of active crossover do you have between the 211 amplifier and the solid state amp? Just looking to see how the noise could couple between amps.

Is the 211 filament powered by some sort of SMPS supply? I have seen them pollute the line power with spikes that could couple with the SS amp.

Not sure if I can pull the 6sn7 and power the amp up. I have tried several 6sn7's tho and the ticking still occurs after several hours as well.You could pull the 6sn7 and see if the problem still exists?

I do not use an active crossover there, just a high pass filter on the MTM to roll off lower frequencies. The only common connection between the two amps is at the preamp output. When I turn the tube amp off the SS amp stops ticking immediately and if I turn the SS amps off (with tube amp on) the ticking still continues.What sort of active crossover do you have between the 211 amplifier and the solid state amp

No the amp uses a very good power supply to isolate input from output stages, 2/3rd's of this 22 inch long amp chassis is nothing but power supply.Is the 211 filament powered by some sort of SMPS supply

Does the SS amplifier have a low pass crossover on it? I use a single capacitor high pass passive crossover just like you do.

Pulling the 6sn7 would not bother anything as long as you insert or remove with the amplifier off. Pulling the driver tubes is a common way to isolate amplifier sections.

It may be even better to disconnect the input cable again pull with the amplifier off. Just pull both sides just so you can see if the noise coupling between amplifiers ceases.

Pulling the 6sn7 would not bother anything as long as you insert or remove with the amplifier off. Pulling the driver tubes is a common way to isolate amplifier sections.

It may be even better to disconnect the input cable again pull with the amplifier off. Just pull both sides just so you can see if the noise coupling between amplifiers ceases.

yes, and before the SS amp I have a Rane PEQ55 so I can eq the bass only. So technically it is the Rane and 211 amp connected to the preamp.Does the SS amplifier have a low pass crossover on it? I use a single capacitor high pass passive crossover just like you do.

Good to know, I'll try that. I wonder once it finally starts ticking Then I'll turn amp off pull 6sn7 and IC's then amp back on will it reset, so no ticking, because of on/off cycle or because the issue is related to the 6sn7 circuit.Pulling the 6sn7 would not bother anything as long as you insert or remove with the amplifier off. Pulling the driver tubes is a common way to isolate amplifier sections.

It may be even better to disconnect the input cable again pull with the amplifier off. Just pull both sides just so you can see if the noise coupling between amplifiers ceases.

.

The coupling between the two amplifiers is the interesting part. Maybe we could start by assuming it must couple either between the paralleled inputs (unlikely but possible-ish)), between power supplies (the 211 amplifier's power supply also possibly causing the noise) or as RFI.

Input coupling could be ruled in or out by removing signal from the 211 amp. RFI is trickier and might be approached beginning with adding grid stops to the 6BX7 and especially the 211 stages. Something like 1K Ohm CC resistors mounted close as possible ti the socket pins should do it.

If the easy stuff doesn't work, you have the power supply to look forward to. Lucky you, but it's twenty years old, so maybe time anyway.

All good fortune,

Chris

Input coupling could be ruled in or out by removing signal from the 211 amp. RFI is trickier and might be approached beginning with adding grid stops to the 6BX7 and especially the 211 stages. Something like 1K Ohm CC resistors mounted close as possible ti the socket pins should do it.

If the easy stuff doesn't work, you have the power supply to look forward to. Lucky you, but it's twenty years old, so maybe time anyway.

All good fortune,

Chris

Well the coupling is interesting for sure. They are only common at the preamp outputs and even then the rane peq55 connects to the preamp and the SS amp connects to the rane. The other common point is the 120V ac. The 211 amp goes straight into the wall outlet and the SS amps and rane are in a outlet strip which connects to an isolation transformer which is plugged into the same outlet as the 211 amp, the preamp also connects to the same isolation transformer.If the easy stuff doesn't work, you have the power supply to look forward to. Lucky you, but it's twenty years old, so maybe time anyway.

I think I'll start replacing any resistors that look most worn an heat affected, see where that gets me. Those 1K resistors in the filament circuit look pretty worn. My order should arrive sometime next week.

The PSU is massive it has a lot of chokes and transformers, and in the middle of the amp a bunch of solen film capacitors which I would be surprised if they were bad. There are 4 big electrolytes in the amp. The 1200 UF in the 211 filament circuit and 2 much larger ones (not sure of the capacitance) which also seem to run to the filaments of the 211 and are not shown on the schematic.

Just curious, what's the time interval of the tick?

Also: I'd turn off the lights and run the amp in the dark while it's ticking to see if anything can be seen both above and below the top plate. Just set it up beforehand so you don't have to touch anything or even get too close while it's powered on. I've located tiny arcs that way.

You asked whether the grid resistors should be increased to meet the schematic value. I'd say no. (Somebody please correct me if I'm wrong but I don't see the merit of setting the pass down below 0.8Hz.)

Also: I'd turn off the lights and run the amp in the dark while it's ticking to see if anything can be seen both above and below the top plate. Just set it up beforehand so you don't have to touch anything or even get too close while it's powered on. I've located tiny arcs that way.

You asked whether the grid resistors should be increased to meet the schematic value. I'd say no. (Somebody please correct me if I'm wrong but I don't see the merit of setting the pass down below 0.8Hz.)

Use a scope/DMM with trigger and no music playing? (Avoid 211 anode and power for it without a proper HV probe)

Test input and power for each section systematically using the HV for mains and kV power areas.

Check heaters too.

Test input and power for each section systematically using the HV for mains and kV power areas.

Check heaters too.

It could be low frequency oscillation I built an amp that had a similar issue, though why your amp should start doing this after 20 odd years is a mystery. Pop your amp on a scope to see what's happening. In my case it was a stage before the OP stage not biasing. On power up the HT rose, current draw started to get higher but a common cathode gain stage wasn't settling,there was as mentioned LF instability, this caused the OP stage to start the same oscillation causing the HT to rise and fall, you could actually here the ticking in the OP valve.

Not saying this is the issue in your case but put a voltmeter on the HT and a scope on the OP/dummy load and hopefully it will give you a better idea,then scope each stage to see if you can narrow the fault down further.

Andy.

Not saying this is the issue in your case but put a voltmeter on the HT and a scope on the OP/dummy load and hopefully it will give you a better idea,then scope each stage to see if you can narrow the fault down further.

Andy.

Wild guess, this might be arcing. Over, around, or between high and low voltage nodes. The lights out observation might be quite revealing. Could be very subtle. Arcs produce lots of RF that can get into anything. Just agreeing with Hearinspace.

about 100-120 per minute, ticks, pretty fast.Just curious, what's the time interval of the tick?

I will do that if after replacing some resistors does not solve this. The tricky part is waiting for the amp to tick then start testing. Do you think I should disconnect the input RCA's while testing? there would be no signal either connected or not.Use a scope/DMM with trigger and no music playing? (Avoid 211 anode and power for it without a proper HV probe)

Test input and power for each section systematically using the HV for mains and kV power areas.

Check heaters too.

I'll try this when I pull out the oscilloscope. The amp will be upside down and the bottom plate removed so arcing should be pretty easy to see, of course it could arc from wires running under the boards and not be visible. There are a lot of 1250v, 450v and 400v lines there. I do own a high voltage probe, I used to use that to measure some of the very high voltages inside the Quad 63 speakers.Wild guess, this might be arcing. Over, around, or between high and low voltage nodes. The lights out observation might be quite revealing. Could be very subtle. Arcs produce lots of RF that can get into anything. Just agreeing with Hearinspace.

I'm really hoping it is just some of the older heat affected components that need replacing and close examination of all solder points for any bad ones. That amp can heat my listening room up 5-7 degrees so it puts out a lot of heat and in a lot of cases heat is the enemy of electrical components.

What about the electrolytics in the amp and their aging? Can they tick when they degrade? I know resistors can.

Keep in mind, any arcing or breakdown can occur within components. Keep an eye on components with HV across them.

After you do the lights out inspection, operate the amp with speakers disconnected (dummy load if needed). You might actually be able to hear a component cracked or tic even if you can't see an arc.

Absolutely unimportant. The filament self-resistance is far below the impedance of a uFd cap over most of the audio band.1.25 installed vs. 3.5 schematic

Turn OFF your cellphone and all WiFi devices. (Not just standby.) Is that better?a ticking sound in both channels

To answer the rca qurstion - use a shorted rca connector. I agree i would also dummy load the amp.

It sound like something thermal with the delay before it appears. Perhaps a dry solder joint, a broken resistor, shorting transformer ot cap.

At 120 hz I’d ceck the power ac line and work forward from there.

It sound like something thermal with the delay before it appears. Perhaps a dry solder joint, a broken resistor, shorting transformer ot cap.

At 120 hz I’d ceck the power ac line and work forward from there.

Cell phones can and do produce all kinds of clicking and buzzing in audio equipment. Much is immune, some are not. This is why circuits include more local bypassing than they have in the past. Overall wire dress and shielding are also factors contributing to the cell phone sensitivity.

That said, given your descriptions of symptoms, the cell phones are not likely the cause in your case. Nevertheless can't hurt to rule them out by shutting them down.

That said, given your descriptions of symptoms, the cell phones are not likely the cause in your case. Nevertheless can't hurt to rule them out by shutting them down.

My resistor order arrived so I soldered in brand new 1K 1% 10W Vishay's in the 211 filament circuit and also replaced both 25 ohm 1% 5w resistors in the same circuit, the original 1K resistors there looked a little heat beat up. I also carefully re-examined my plate resistor solder points to the terminal posts and I believe one of them was a bit suspect, so I removed the resistor, cleaned the posts and re-soldered the plate resistor back in and was satisfied with the result. Now the amp is back on and running so we'll see in a few hours if the ticking has stopped.

- Home

- Amplifiers

- Tubes / Valves

- 211 SE tube amp has developed ticking sound in both channels, after amp on 3-5 hours