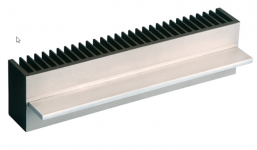

So I have this heatsink (1st image and mine is similar except I'm using an L-bracket screwed to the heatsink)

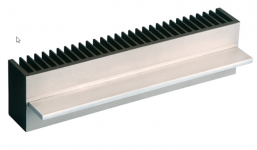

Is it ok to install a chipamp on top and bottom of the bracket? so using 1 screw, I want to connect 2 chips on the bracket (something like the second image)

Thanks

(first image)

(second image)

Is it ok to install a chipamp on top and bottom of the bracket? so using 1 screw, I want to connect 2 chips on the bracket (something like the second image)

Thanks

(first image)

(second image)

wouldn't it work like a heatpipe that draws the heat away from the source?You want to spread-out the heat, not concentrate it.

That heat-pipe you mention is the central fin/rib running horizontally along the heatsink, while fins stay vertical.

Its mission is to move heat from chipamp back (or transistors if discrete) to fins

Imagine it´s a hose moving "water" (heat) from source (hot semiconductor) to sink (fins)

And it is some kind of bottleneck in the thermal path, it is a "thin" hose.

If you mount 2 chipamps on it side by side, left one will have its own hose (left hand of rib) to its own set of fins, the left half of them, and right chipamp the same, symmetrically.

Now if you mount TWO chipamps stacked, "water" from both will have to flow through the same narrow hose, and into the same set of central fins, can you see the problem?

Will the "water" low efficiently?

No.

Will heat be dissipated into air efficiently?

No

Its mission is to move heat from chipamp back (or transistors if discrete) to fins

Imagine it´s a hose moving "water" (heat) from source (hot semiconductor) to sink (fins)

And it is some kind of bottleneck in the thermal path, it is a "thin" hose.

If you mount 2 chipamps on it side by side, left one will have its own hose (left hand of rib) to its own set of fins, the left half of them, and right chipamp the same, symmetrically.

Now if you mount TWO chipamps stacked, "water" from both will have to flow through the same narrow hose, and into the same set of central fins, can you see the problem?

Will the "water" low efficiently?

No.

Will heat be dissipated into air efficiently?

No

As yet said by the others above. Your sink is very wide, as far as I'm able to judge, and easily allows to install even multiple chips side by side. I wonder what's the motivation for your tinkering with? Just to save one screw plus nut?

Best regards!

Best regards!

Best heat transfer is not by bolting the chip with a screw through the mounting hole, but to clamp it with a bar and two screws and the bar aproximately mid-chip (no pun intended) , especially when using elastomer insulator pads as they flex a little bit.

It will. But it'll do so more efficiently if you spread out the heat sources. You can get a sense of it by playing with this heat sink calculator: https://heatscapecal.com/wouldn't it work like a heatpipe that draws the heat away from the source?

True. But bolting through the mounting hole using the appropriate torque (0.5 cNm) works just fine.Best heat transfer is not by bolting the chip with a screw through the mounting hole, but to clamp it with a bar and two screws and the bar aproximately mid-chip (no pun intended) , especially when using elastomer insulator pads as they flex a little bit.

Tom

A heat pipe is something used to convey heat from difficult places, such as in molds.

https://www.google.com/url?sa=t&rct...pplications/&usg=AOvVaw3PNZkmOAWtx1mpAZBD-nxA

I do not see one here, nor the need for it.

The early ones were fragile, and many broke because the fitter tried to force them into a slightly too small hole with a hammer.

You need slip fit, and thermal compound, that means reamer grade machining.

And you still need a heat sink or coolant flow at the other end of the heat pipe to transfer the heat.

https://www.google.com/url?sa=t&rct...pplications/&usg=AOvVaw3PNZkmOAWtx1mpAZBD-nxA

I do not see one here, nor the need for it.

The early ones were fragile, and many broke because the fitter tried to force them into a slightly too small hole with a hammer.

You need slip fit, and thermal compound, that means reamer grade machining.

And you still need a heat sink or coolant flow at the other end of the heat pipe to transfer the heat.

Be sure to use thermal compound between the bracket and the heatsink for good transfer. I've built several like this and they do work well. Used a T-Bar for the bracket instead of the L, which gives about 2X greater contact area.I'm using an L-bracket screwed to the heatsink

As for the stacking question, I agree with the others that spreading out the chips is the prefered method for best cooling.

However, stacking could still be OK but it depends on how hard you run the amp, and the heatsink size, bracket size and thickness, etc.

Consider testing a proto-type.

I see no advantage in a stacked layout, apart from complexity or possibly smaller housing.

Best put it as a nearly single mono layout on a too large heat sink.

And get some spare, just in case you blow them up.

Best put it as a nearly single mono layout on a too large heat sink.

And get some spare, just in case you blow them up.

- Home

- Amplifiers

- Chip Amps

- installing a chipamp (LM3886) to heatsink (back to back of each other