I’m going a different route on my sub woofer enclosure and building a new one .

I know they say use wood glue and clamps and there is no need for screws .

Personally I feel better using screws along with wood glue or staples brad nails . Since there is gonna be high pressure levels inside the vehicle.

Wondering will brad nails or staples works just as good as screws would ?

What’s everyone’s thoughts on this since this box is going into a SPL vehicle.

I know they say use wood glue and clamps and there is no need for screws .

Personally I feel better using screws along with wood glue or staples brad nails . Since there is gonna be high pressure levels inside the vehicle.

Wondering will brad nails or staples works just as good as screws would ?

What’s everyone’s thoughts on this since this box is going into a SPL vehicle.

When using only glue, you're only holding onto the top layer of the MDF (which can peel up).

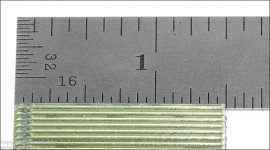

I always use fasteners. Earlier, I used screws but when building a larger number of enclosures, I used staples (below). They have adhesive on their legs that melts when driven in then holds. Wood glue is also used on all joints. As posted on the previous thread, cross bracing is also helpful. Dowels or all-thread for high SPL enclosures. The enclosure below is overkill but you get the idea.

I always use fasteners. Earlier, I used screws but when building a larger number of enclosures, I used staples (below). They have adhesive on their legs that melts when driven in then holds. Wood glue is also used on all joints. As posted on the previous thread, cross bracing is also helpful. Dowels or all-thread for high SPL enclosures. The enclosure below is overkill but you get the idea.

Attachments

Screws weaken a joint, but staples, glue coated panel (ribbed) nails is fine with glued dowels best.

For speaker cabs in general and especially SPL comp., sufficient bracing tying all six sides together to keep it from 'breathing' as PB shows is the goal to the point where the basic box joints are only there to keep it leak free.

FWIW, for subwoofers I've historically used/recommended cardboard tubes with threaded rod running through it/top plate/baffle/driver mount (within a tube in the internal section), then tightened enough to preload the cab.

Curious; does anyone in SPL comp. use cylindrical tubes or at least tried it? It's far more rigid than any box in general and especially after preloading.

For speaker cabs in general and especially SPL comp., sufficient bracing tying all six sides together to keep it from 'breathing' as PB shows is the goal to the point where the basic box joints are only there to keep it leak free.

FWIW, for subwoofers I've historically used/recommended cardboard tubes with threaded rod running through it/top plate/baffle/driver mount (within a tube in the internal section), then tightened enough to preload the cab.

Curious; does anyone in SPL comp. use cylindrical tubes or at least tried it? It's far more rigid than any box in general and especially after preloading.

I've never seen the tubes used (not questioning their use). The all-thread generally has nuts/washers inside and out.

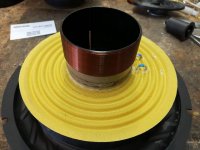

I have done it. 2 years in a row with a 10" cheap *** china subwoofer with a few customs mods. Used something like a triple front/bottom baffle of 1" MDF (so 3" baffle top and bottom) and poured over 5 pounds of polyester epoxy inside. 2/3 sheets of fiberglass outside soaked with 5 more pounds of polyester epoxy. Big 6~7" aeroport at bottom baffle. Nasty work but hey...i've kicked some big brand names in my class - 1x10". Won couple of 2nd and 3rd place.Curious; does anyone in SPL comp. use cylindrical tubes or at least tried it? It's far more rigid than any box in general and especially after preloading.

Measuring on the dash it was something like 143.6db at 41 or 43hz peak.

Keep in mind this was a cheap china knockoff sub, just with a few mods from me and my friend. I will attach some photos.

Attachments

- Home

- General Interest

- Car Audio

- Subwoofer Enclosure