Recently I made a TV stand out of wood and aluminium, and thought it would be nice if we had a pair of speakers that matched. Using T-slot extrusions would also let me avoid having to do any real joinery, which is too much effort for my lazy self. But would that really work?

To start with, the drivers: Omnes Audio CX 3.1 coaxials for the mid/tweeter, and Omnes Audio W8 Alu for the woofers (in series pairs for 8Ω total, as they are driven by an amp with a 6Ω min. load). These are nice looking aluminium cone drivers, although their matte finish doesn't quite match the silky finish of the extrusions. I chose the CX 3.1 because I wanted coax drivers, and they looked like they had less terrible frequency response than most. The woofers I chose simply because they match.

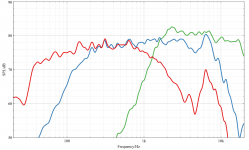

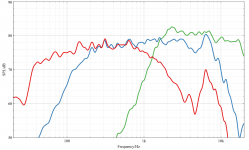

Hers's the measured frequency response of the drivers. They were mounted in the enclosure, with the mic placed 30cm from the tweeter, on-axis:

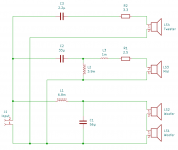

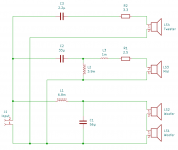

And this is the crossover:

The 1st order crossover between mid/tweeter doesn't attenuate the mid's 6.5kHz peak very much, but I decided I would accept that to make it as simple as possible, since there's (theoretically) no lobing issues from low-order crossovers with coaxial drivers.

The enclosure is made from an aluminium frame with plywood panels slotted in. The volume is 100l, with a port tuned to 33Hz.

The interior is covered with material made from recycled jeans that I had quite a lot of because it's used as packing material for some stuff that was delivered to us.

Note the enclosure for the mid/tweeter, consisting of a thick cardboard tube with a circle of plywood glued into the end.

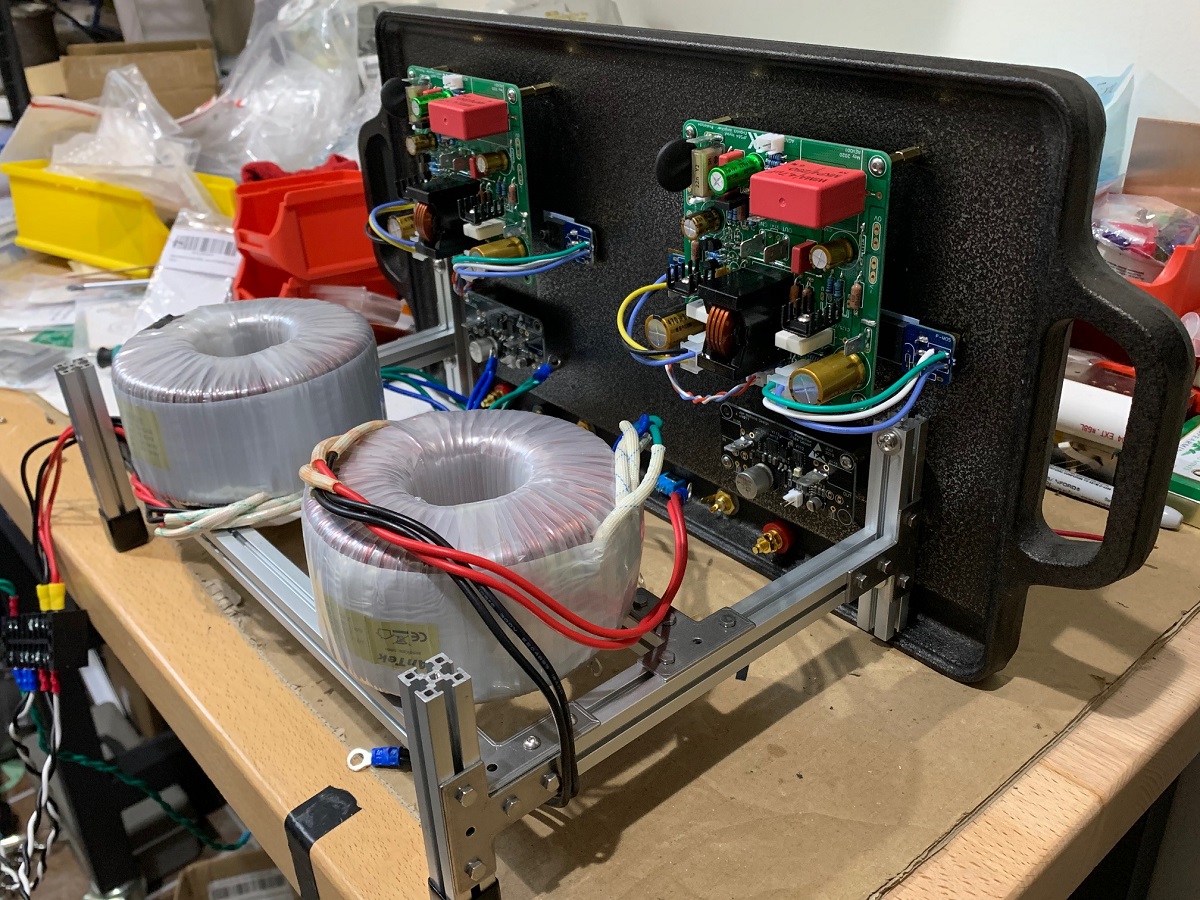

I mounted the crossover to the rear panel, using brass rod as anchors for connecting component leads and wires together, breadboard-style

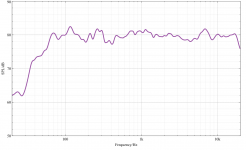

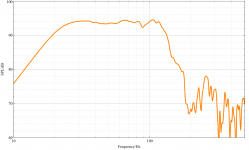

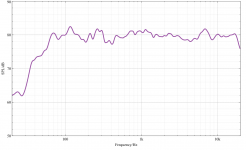

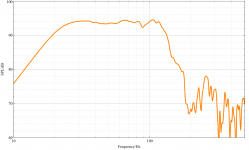

And here's the final frequency response, with one plot for the woofer/mid/tweeter combined (measured the same way as before), and one for the port (measured at a distance of 0cm from the port). I didn't attempt to combine them into a single plot, as you can get a good enough idea from just the separate plots.

And once completed and put next to the TV, they look like this:

So, it worked ok. With the panels simply slotted in, they aren't going to be fully air-tight, but it's good enough for vented speakers. If they were sealed, then I might have put some sealant or glue around the inside edges. Definitely less work than more standard construction, though routing all the rabbets took a while.

They sound great for watching films.

There are a few more images and stuff on my website.

To start with, the drivers: Omnes Audio CX 3.1 coaxials for the mid/tweeter, and Omnes Audio W8 Alu for the woofers (in series pairs for 8Ω total, as they are driven by an amp with a 6Ω min. load). These are nice looking aluminium cone drivers, although their matte finish doesn't quite match the silky finish of the extrusions. I chose the CX 3.1 because I wanted coax drivers, and they looked like they had less terrible frequency response than most. The woofers I chose simply because they match.

Hers's the measured frequency response of the drivers. They were mounted in the enclosure, with the mic placed 30cm from the tweeter, on-axis:

And this is the crossover:

The 1st order crossover between mid/tweeter doesn't attenuate the mid's 6.5kHz peak very much, but I decided I would accept that to make it as simple as possible, since there's (theoretically) no lobing issues from low-order crossovers with coaxial drivers.

The enclosure is made from an aluminium frame with plywood panels slotted in. The volume is 100l, with a port tuned to 33Hz.

The interior is covered with material made from recycled jeans that I had quite a lot of because it's used as packing material for some stuff that was delivered to us.

Note the enclosure for the mid/tweeter, consisting of a thick cardboard tube with a circle of plywood glued into the end.

I mounted the crossover to the rear panel, using brass rod as anchors for connecting component leads and wires together, breadboard-style

And here's the final frequency response, with one plot for the woofer/mid/tweeter combined (measured the same way as before), and one for the port (measured at a distance of 0cm from the port). I didn't attempt to combine them into a single plot, as you can get a good enough idea from just the separate plots.

And once completed and put next to the TV, they look like this:

So, it worked ok. With the panels simply slotted in, they aren't going to be fully air-tight, but it's good enough for vented speakers. If they were sealed, then I might have put some sealant or glue around the inside edges. Definitely less work than more standard construction, though routing all the rabbets took a while.

They sound great for watching films.

There are a few more images and stuff on my website.

Very nice job and I admire your creativity. We use a lot of T-slot framing where I work, but I never thought to use it for speaker cabinets.

You deserve an award for literally "thinking outside the box"!

You deserve an award for literally "thinking outside the box"!

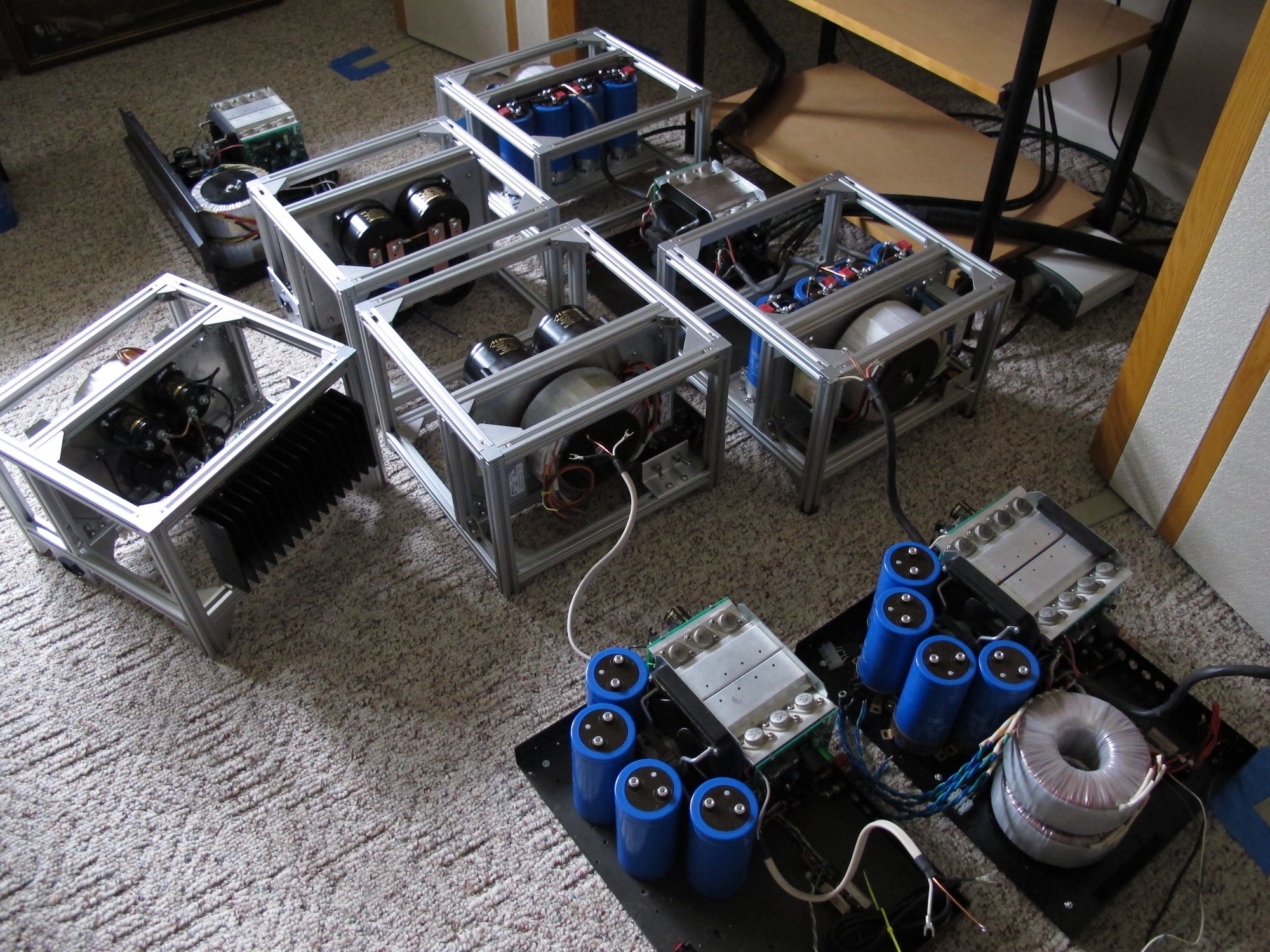

Excellent project! I’ve been daydreaming about speaker cabinet skeletons made from extruded aluminum t-slot beams since I started playing with Makerbeam for amp chassis.

Well done!

Well done!

I love aluminum and plywood, so I think they look great! But I would be worrying about some of those joints buzzing....

It's a titanium dome (not aluminum), but maybe a close enough match for your next pair of cabinets?

https://www.madisoundspeakerstore.com/hard-dome-tweeter/vifa-dq25sc16-04-1-titanium-dome-tweeter/

It's a titanium dome (not aluminum), but maybe a close enough match for your next pair of cabinets?

https://www.madisoundspeakerstore.com/hard-dome-tweeter/vifa-dq25sc16-04-1-titanium-dome-tweeter/

I love this so much.

I have a really difficult time making my projects look nice.

My 3D printers are made of aluminum extrusions and I've long wondered what else it could be used for.

I have a really difficult time making my projects look nice.

My 3D printers are made of aluminum extrusions and I've long wondered what else it could be used for.

Widely used in industry and research.

https://www.grainger.com/category/m...ystems/t-slot-framing-systems?categoryIndex=1

https://www.grainger.com/category/m...ystems/t-slot-framing-systems?categoryIndex=1

Vented boxes need to be sealed properly too. Your port response shows a really leaky box and isn't providing the low frequency boost you think it is. Sealing up the box on the inside should be pretty cheap and easy. It will also elimimate the risk of rattles.

Your construction method is otherwise great 👍 The end result matches your tv cabinet well.

Your construction method is otherwise great 👍 The end result matches your tv cabinet well.

Congratulations, they look incredibly good and modern.

I made quite a few PA mixer and instrument cases using same extrusions, but with slots holding about 4mm thick textured hardwood/Masonite sheet, never trusted them for cabinets, so happy tosee they worked for you.

What panel thickness did you use?

I made quite a few PA mixer and instrument cases using same extrusions, but with slots holding about 4mm thick textured hardwood/Masonite sheet, never trusted them for cabinets, so happy tosee they worked for you.

What panel thickness did you use?

I was careful to cut the panels as close to the thickness of the slots as possible, so they fit tightly and won't rattle. It's possible that the wood will shrink over time, but I'll deal with that if it happens.I love aluminum and plywood, so I think they look great! But I would be worrying about some of those joints buzzing....

Alas everyone in the house has decent speakers now, so I have no excuses to make any more.It's a titanium dome (not aluminum), but maybe a close enough match for your next pair of cabinets?

https://www.madisoundspeakerstore.com/hard-dome-tweeter/vifa-dq25sc16-04-1-titanium-dome-tweeter/

It's so very useful for all sorts of stuff. I've used it for speakers, several bits of furniture, and a PC case so far.Widely used in industry and research.

https://www.grainger.com/category/m...ystems/t-slot-framing-systems?categoryIndex=1

Can you tell that because the port response has wider bandwidth than it should do? I'll consider adding some sealant, but it's not convenient to work on them now.Vented boxes need to be sealed properly too. Your port response shows a really leaky box and isn't providing the low frequency boost you think it is. Sealing up the box on the inside should be pretty cheap and easy. It will also elimimate the risk of rattles.

It's nominally 18mm thick. The 30x30 extrusions have an 11mm slot, which means the panels are just shy of being flush with the frame. That's the thickest I could use without having to route both sides.What panel thickness did you use?

Nice work! I like the curved corners. Slotted rails make great amplifiers too!

My griddle amp:

https://www.diyaudio.com/community/...-a-budget-conscious-heatsink-solution.355302/

Ozark Hifi Doctor’s amps:

My griddle amp:

https://www.diyaudio.com/community/...-a-budget-conscious-heatsink-solution.355302/

Ozark Hifi Doctor’s amps:

Very nice, Mr Evil. They match the entertainment unit well, and a good example that simpler construction methods can still yield a decent result. 👍

Very nice! I was thinking of building speakers using extruded aluminum. I had the drawn out. I lucked upon a friend that has a pretty good woodworking shop and was interested so I wend with more conventional cabinets.

It wouldn't take much time or money to give the internal joins of the cabinet a coat or two of fibreglass to seal up the cab (if necessary)

Rob.

Rob.

Nice. You could seal the panels to the extrusions with silicone or construction adhesive if you desired.

Nice! Although when I read the topic title I thought this was about using the aluminum extrusions as the drivers...

Could you post a link to your T-slot source? The Grainger link has two corner side slots, but they don't have the rounded outside like yours. I also like the corner fillers. Thanks...

Since you mention Grainger I'm assuming you're in the US, so this may not be useful: I bought all the aluminium and associated hardware from KJN.Could you post a link to your T-slot source? The Grainger link has two corner side slots, but they don't have the rounded outside like yours. I also like the corner fillers. Thanks...

Google is your friend - search for aluminum extrusions. There's no shortage of sources.Could you post a link to your T-slot source? The Grainger link has two corner side slots, but they don't have the rounded outside like yours. I also like the corner fillers. Thanks...

- Home

- Loudspeakers

- Multi-Way

- Speakers made from aluminium T-slot extrusions