I am slowly building a new tube amplifier.

When ordering the power transformer, I forgot to order the negative bias winding.

I have taps for B+: 0 260 280 300 320. Can I use a 260 - 320 (delta 60V) taps for negative bias? For B+ I will use 0-280V taps.

When ordering the power transformer, I forgot to order the negative bias winding.

I have taps for B+: 0 260 280 300 320. Can I use a 260 - 320 (delta 60V) taps for negative bias? For B+ I will use 0-280V taps.

You can't, because the neg bias will be referred to ground at one side, and that will ground a tap throug a rectifier diode.

It will release the magic smoke inside the rectifier ;-).

Edit: Actually you can! If you can separate the 280V tap into the two winding halves, you can use the windings separately.

Jan

It will release the magic smoke inside the rectifier ;-).

Edit: Actually you can! If you can separate the 280V tap into the two winding halves, you can use the windings separately.

Jan

Last edited:

You can´t , because from your description you will use a bridge rectifier, to which you will feed "0" on one corner, and one of "260 280 300 320" VAC, you chose 280VAC but same applies to all others: those windings are ALWAYS positive relative to Ground, thanks to bridge rectifier diodes switching action, never a negative voltage anywhere to pull some Bias from.I am slowly building a new tube amplifier.

When ordering the power transformer, I forgot to order the negative bias winding.

I have taps for B+: 0 260 280 300 320. Can I use a 260 - 320 (delta 60V) taps for negative bias? For B+ I will use 0-280V taps.

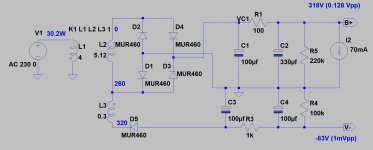

One trick often used in Guitar amps is to connect a capacitor to one winding end (either 0V or 280V AC) so you remove the positive DC component, at the other end of that cap you´ll have AC which will swing positive and negative , there you can rectify it to get negative voltage.

It will not be a sinewave but wonky rectified AC but hey, beggars are not choosers.

You can also pull out very little current, but still enough for biasing.

Look at this Marshall schematic:

key is C12, which removes positive DC inherent in a bridge rectifier, and lets the AC component through, which is then negative rectified by D1.

EDIT:

Well, technically you can,IF you open the PT and do a little neurosurgery, by separating that winding part from the rest.Edit: Actually you can! If you can separate the 280V tap into the two winding halves, you can use the windings separately.

Personally I would NOT mess with a PT ,specially the high voltage winding.

And I have no guarantee it´s easily accessible either.

Separate windings might be brought out to external tabs to be interconnected there, in which case you might melt some solder and unwind ends from around tabs (even that is iffy) , but often, specially in "classic" wound transformers, wires are scraped, twisted and soldered to wires "internally", then taped and often covered by more turns, then soaked in hard varnish ... even Epoxy ....

I would not mess with that.

Let alone it would void any warranty, big time.

Last edited: