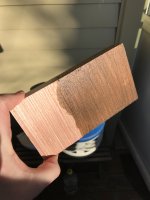

I'm in the process of assembling another project, this time in plywood which everyone claims to be the best. Ive built in MDF, pine and oak before and for the most part been happy with that, but wanted to try plywood now. But I realize ply isn't ply. Look at these pictures. What a flimsy product, impossible to stain or sand or anything. I had to double check what I actually bought. Its some Chinese ply called Red Temperate Poppel 18mm and its covered by a thin pink layer of something I struggle to understand what is. It feels light, staining doesnt work, and the quality seems bad really, the knock test also isn't good I doubt this will sound as dead as MDF or oak. What is poppel anway? I might just throw this whole build away and start over with some other materials... Any advice appreciated.

/Rant

/Rant

Attachments

'What is poppel anyway?" " thin pink layer of something"

I fear i have an answer:

https://images.app.goo.gl/Nhx78xmPMZCd3EdLA

Baltic Birch ply is the one to look for.

I fear i have an answer:

https://images.app.goo.gl/Nhx78xmPMZCd3EdLA

Baltic Birch ply is the one to look for.

I guess its popler in english but dont really know. Id love to see a comparison table showing why Baltic birch is “better”. Is it denser? From pics I find online it has the same structure, yet maybe not this pink top layer. Perhaps I can just sand the whole thing off.

Baltic birch take time to grow as there is less light in Baltic's area. The inner structure is more dense and linear.

The one i've used and see used is very consistent material.

Not cheap at all.

The one i've used and see used is very consistent material.

Not cheap at all.

Plywood, like MDF and other forms of sheet material come in quality from crap to really good.

We switched from Russian BB to Murphy[ply (still a Baltic core but much higher quality) because the BB was getting crappy.

dave

We switched from Russian BB to Murphy[ply (still a Baltic core but much higher quality) because the BB was getting crappy.

dave

Anyway not sure what to do with this box now as it seems very difficult to stain and sand especially. How to get it looking ok. I can maybe use some fake plastic wood like material and stretch around bend glue etc. not what I had in mind though.

Before commiting to a final box have you listened to it? If the material is this bad it may be awfull from an acoustic pov too. Or not.

Anyway there is as a last resort veneer. The one in melamine used for kitchen, etc,etc,.. can look very good and doesn't seems to difficult to apply.

Anyway there is as a last resort veneer. The one in melamine used for kitchen, etc,etc,.. can look very good and doesn't seems to difficult to apply.

Quality plywood is Baltic Birch, but not the junk from the big box stores. Get your materials from hardwood suppliers where cabinet makers get their materials.

I normally use plywood for very small cabinets and for large subs. Everything in the middle I use MDF. But MDF is not MDF. Again, quality can vary a lot. The big box stores stuff is junk.

The material is actually not as important as how you use it. So, the answer to the "best material" is the universal consultants report: It depends.

I also suggest reading on the woodworking forums to learn about glues and finishes. I almost never use PVA any more. More often powered resin, but I have been using super glue more and more and epoxy less. It depends.

I normally use plywood for very small cabinets and for large subs. Everything in the middle I use MDF. But MDF is not MDF. Again, quality can vary a lot. The big box stores stuff is junk.

The material is actually not as important as how you use it. So, the answer to the "best material" is the universal consultants report: It depends.

I also suggest reading on the woodworking forums to learn about glues and finishes. I almost never use PVA any more. More often powered resin, but I have been using super glue more and more and epoxy less. It depends.

Why did you made this choice about glue Tvrgeek? Could you give examples too please ( real life situation making you choose one over the other)?

As been said, there are different grades of plywood. Often they have combined grades on front/back side depending on the use, ex A and B, where A are top notch and B allows for some defects.

When cutting/sanding thru the layers there are no guarantees that there are no twig holes or other defects between the layers. And sometimes it's importnant to follow the grain of the wood or it will break or make slivers.

It's possible to repair small holes and splinters by mixing sawdust and wood glue and fill them with it. When sanding thru a ply the glue and next ply will show up, and that's inpossible to repair.

/Figge

When cutting/sanding thru the layers there are no guarantees that there are no twig holes or other defects between the layers. And sometimes it's importnant to follow the grain of the wood or it will break or make slivers.

It's possible to repair small holes and splinters by mixing sawdust and wood glue and fill them with it. When sanding thru a ply the glue and next ply will show up, and that's inpossible to repair.

/Figge

One of the biggest thigs is PVA glues shrink over time and it can creep. Resin or epoxy glue does not. I usually paint my MDF and PVA will shrink in and a year later you see the glue line. You need to pick your epoxies as they differ in hardness. I like West System epoxies mostly because I am used to them.

Even "waterproof" Titebind is not really. Resin is. I get a longer working time, but quicker fully cured. It is not about strength, as even the weakest "white" PVA glue correctly used is stronger than the wood. I use Titebond 3 for the few places where PVA is a fair choice and I don't want to mix a batch of resin. Superglue is great for repairing a splinter and no clamp time ( always use accelerator)

Cutting plywood. Score first. Often helps to tape over the cur line first. Don't try to make a perfect cut clear through. Correct blade of course. I prefer Amana blades. Top quality birch ply will not have twigs or knots and voids in it. You can always buy certified marine or aviation grade. If you were doing exposed edge plywood it is a good choice.

I found about everything I thought I knew about woodworking was wrong after hanging around on woodworking and professional cabinet makers forums. This forum has wonderful help on electronics, but for woodworking, go to woodworking!

Even "waterproof" Titebind is not really. Resin is. I get a longer working time, but quicker fully cured. It is not about strength, as even the weakest "white" PVA glue correctly used is stronger than the wood. I use Titebond 3 for the few places where PVA is a fair choice and I don't want to mix a batch of resin. Superglue is great for repairing a splinter and no clamp time ( always use accelerator)

Cutting plywood. Score first. Often helps to tape over the cur line first. Don't try to make a perfect cut clear through. Correct blade of course. I prefer Amana blades. Top quality birch ply will not have twigs or knots and voids in it. You can always buy certified marine or aviation grade. If you were doing exposed edge plywood it is a good choice.

I found about everything I thought I knew about woodworking was wrong after hanging around on woodworking and professional cabinet makers forums. This forum has wonderful help on electronics, but for woodworking, go to woodworking!

That's not really a cabinet grade plywood and is what I think of as a utility plywood that will not get finished. The red outer layer is chinese red birch. Even cabinet grades of plywood birch will have some voids in the core and birch (north american species) can be dificult to stain without blotching. IMO - birch is either a paint grade wood or a clearcoat wood using oil or polyurethane. There is no substitute for baltic birch if you want to use plywood.

https://kingsfinewoodworking.com/blogs/news/baltic-birch-plywood-what-is-it-why-is-it-better

https://kingsfinewoodworking.com/blogs/news/baltic-birch-plywood-what-is-it-why-is-it-better

I've always been led to believe "marine plywood" is the best stuff, as defects aren't tolerated and there is actually quality control and official standards for it (BS1088: https://en.wikipedia.org/wiki/BS_1088 for instance).

Apparently there are "structural" grades too which are intermediate in price. General purpose plywood is caveat emptor it seems.

Apparently there are "structural" grades too which are intermediate in price. General purpose plywood is caveat emptor it seems.

Having built cabinets

poplar wood is more considered " paint grade" wood

In other words it does not stain well.

More common for bathroom cabinets or kitchen cabinets

which are painted.

" Poppel " I never understood the name, maybe lost in translation

It basically is poplar , and poplar becomes confusing

since there is somewhat close to million species of it.

LOL just kidding, but there is a lot of species considered

" poplar"

In a nutshell it is somewhat faster growing tree

so common for more affordable plywood.

Often customers did want lower cost cabinets, basically = Poplar

But still wanted a stain finish.

You cant use common stains which need to soak into the wood.

As you found out, it is blotchy and weird.

You use a " Gel " stain

which is more designed to sit on the surface like a paint.

Basically designed for difficult to stain woods

Speaker cabinet with visible plywood edges.

Can also be considered not much different than MDF

basically you use a wood Veneer, then stain

poplar wood is more considered " paint grade" wood

In other words it does not stain well.

More common for bathroom cabinets or kitchen cabinets

which are painted.

" Poppel " I never understood the name, maybe lost in translation

It basically is poplar , and poplar becomes confusing

since there is somewhat close to million species of it.

LOL just kidding, but there is a lot of species considered

" poplar"

In a nutshell it is somewhat faster growing tree

so common for more affordable plywood.

Often customers did want lower cost cabinets, basically = Poplar

But still wanted a stain finish.

You cant use common stains which need to soak into the wood.

As you found out, it is blotchy and weird.

You use a " Gel " stain

which is more designed to sit on the surface like a paint.

Basically designed for difficult to stain woods

Speaker cabinet with visible plywood edges.

Can also be considered not much different than MDF

basically you use a wood Veneer, then stain

Poppel probally comes from the word we use here for poplar, in Dutch it's "populier", in French it's "peuplier", in German "pappel", in Danish, Swedish and Norwegian "poppel". It's the English term that for us Germanic Europeans is strange...

Well, there ya go!I'm in the process of assembling another project, this time in plywood which everyone claims to be the best. Ive built in MDF, pine and oak before and for the most part been happy with that, but wanted to try plywood now. But I realize ply isn't ply. Look at these pictures. What a flimsy product, impossible to stain or sand or anything. I had to double check what I actually bought. Its some Chinese ply called Red Temperate Poppel 18mm and its covered by a thin pink layer of something I struggle to understand what is.

Live and learn.

- Home

- Loudspeakers

- Multi-Way

- Ply isnt ply