Hi I’m a new member who is very green when it comes to the audio vocabulary, so please bare with me.

I am a drummer and was considering building a 3 way speaker. I have a few spare drum shells and was considering turning one into a woofer enclosure.

I have read some specs on a 15” woofer that said a 63 litre/16.5 gallon sealed cabinet would suit , fortunately my 18” maple drum shell fits the bill perfectly so I have a few questions.

1) Would I get the same amplitude from a 15” sealed woofer as a 12” ported but with improved sound characteristics?

2) if I heavily dampened the shell and reduced its volume considerably would I need to increase the size of the shell I use? (I hear that with a ported cabinet if you dampen the cabinet you may be able to reduce its size by up to 20%) I guess I’m also wondering if a sealed woofer requires dampening at all.

3) Would a cylinder style cabinet net me any benefits rather than going with a standard square/rectangle design?

Thankyou everyone I have so many questions but I think it’s best to go one thing at a time.

I am a drummer and was considering building a 3 way speaker. I have a few spare drum shells and was considering turning one into a woofer enclosure.

I have read some specs on a 15” woofer that said a 63 litre/16.5 gallon sealed cabinet would suit , fortunately my 18” maple drum shell fits the bill perfectly so I have a few questions.

1) Would I get the same amplitude from a 15” sealed woofer as a 12” ported but with improved sound characteristics?

2) if I heavily dampened the shell and reduced its volume considerably would I need to increase the size of the shell I use? (I hear that with a ported cabinet if you dampen the cabinet you may be able to reduce its size by up to 20%) I guess I’m also wondering if a sealed woofer requires dampening at all.

3) Would a cylinder style cabinet net me any benefits rather than going with a standard square/rectangle design?

Thankyou everyone I have so many questions but I think it’s best to go one thing at a time.

Last edited:

How big the box is depends very much on the woofers choosen.

Such an enclosure could work really well but i would strongly recommend a pair of tightly coupled drivers, mounted one on each of the flat-bits running push-push to gain active reaction force cancelation dramaitically reducing the (vibrational) energy loaded into the “box”.

The above is a simplified illustration, the coupling between the magnet snot shown.

With a woofer a sealed box will start rolling off earlier but is slower (12 dB/octave) vrs a vented box which is flatter for a while but then plunges at 24 dB/octave.

Sealed has better transient response, can be EQed more easily and tend to match room gain better.

My prefernce is sealed for this kind of application, but room, tastes and goals all play a role.

63 litres would likely work well with a pair of CSS SDX12, but there are literally tons of potentially suitable woofers.

Where you livem and what you can get plays a role.

dave

Such an enclosure could work really well but i would strongly recommend a pair of tightly coupled drivers, mounted one on each of the flat-bits running push-push to gain active reaction force cancelation dramaitically reducing the (vibrational) energy loaded into the “box”.

The above is a simplified illustration, the coupling between the magnet snot shown.

With a woofer a sealed box will start rolling off earlier but is slower (12 dB/octave) vrs a vented box which is flatter for a while but then plunges at 24 dB/octave.

Sealed has better transient response, can be EQed more easily and tend to match room gain better.

My prefernce is sealed for this kind of application, but room, tastes and goals all play a role.

63 litres would likely work well with a pair of CSS SDX12, but there are literally tons of potentially suitable woofers.

Where you livem and what you can get plays a role.

dave

Thanks Dave I will certainly consider your take on design, what do you gain out of a twin driver that you wouldn’t achieve with a passive radiator at the rear?

Thanks for replying.

Thanks for replying.

A PR is not active. Active vibration cancelation. An estimated 90% less vibrational energy loade dinto the enclosure. You gain considerably. And given the tin shell of a bass drum, likely quite important.

A PR is a vent substitutein A BR for situations where the box is small and the tuning low.

I do not like them.

dave

A PR is a vent substitutein A BR for situations where the box is small and the tuning low.

I do not like them.

dave

1) Would I get the same amplitude from a 15” sealed woofer as a 12” ported but with improved sound characteristics?a few questions.

Eh it depends. Sealed enclosures have a theoretically better transient response-in other words, the cone motion start and stop better. In reality it really depends on the woofer and the enclosure and the tuning. I like to "under-tune" ported enclosures to gain benefits of excursion reduction without a boomy sound. Very vaguely more or less kinda sorta a sealed 15" and 12" ported are about the same.

2) if I heavily dampened the shell and reduced its volume considerably would I need to increase the size of the shell I use? (I hear that with a ported cabinet if you dampen the cabinet you may be able to reduce its size by up to 20%) I guess I’m also wondering if a sealed woofer requires dampening at all.

I think you're mixed up about something. If you put stuffing* in a sealed enclosure (fiberglass, say...pillow stuffing is NOT a best material), the stuffing absorbs some energy as the woofer compresses and expands the air in the box. This makes the box appear larger to the woofer than it actually is, up to maybe 30% bigger. In a ported enclosure, the same effect can happen except you can't stuff near the port inner opening as it will interfere with the airflow.

*such as fiberglass, or Acousta-Stuff. Pillow stuffing is usually NOT so great, you won't get as much displacement bump. Also stuffing can absorb upper frequencies in the box, improving the sound. Get https://meniscusaudio.com/product/loudspeaker-design-cookbook/ which has a chapter about stuffing among a zillion other useful things.

3) Would a cylinder style cabinet net me any benefits rather than going with a standard square/rectangle design?

Cylinders are stronger in the...radial??? direction, and may resonate less, especially if made out of cardboard (like concrete formers).

I'll also note that sealed designs are less critical of enclosure size than ported enclosures are. It is much easier for a ported design to "go wrong." You need a large diameter port to flow a lot of air, which then means the port gets long, maybe too long to fit in the enclosure. And the port can resonate like an organ pipe at higher frequencies. In your situation I'd be doing the 15" sealed, with as low a resonance as I could manage, and stuffing the heck out of the enclosure.

20% is more likely.up to maybe 30% bigger.

With more degrees of freedom, it is really easy to screw up. As long as a sealed box is not to small or too large, it works.

Vented boxes unload below tuning, flapping in the wind if excited so really can’t be EQed to go lower.

Sealed on the hand only requires more power and more excirsion to EQ the response lower.

dave

Does the dual driver system change cabinet volume requirements? And i assume that amplification requirements would double?A PR is not active. Active vibration cancelation. An estimated 90% less vibrational energy loade dinto the enclosure. You gain considerably. And given the tin shell of a bass drum, likely quite important.

A PR is a vent substitutein A BR for situations where the box is small and the tuning low.

I do not like them.

dave

Thankyou for the information. Maybe there is one clarification you could make. A driver i saw had a recomendation for a sealed cabinet of 65 litre so even if i dampen it i would not have to recalculate the enclosures size?1) Would I get the same amplitude from a 15” sealed woofer as a 12” ported but with improved sound characteristics?

Eh it depends. Sealed enclosures have a theoretically better transient response-in other words, the cone motion start and stop better. In reality it really depends on the woofer and the enclosure and the tuning. I like to "under-tune" ported enclosures to gain benefits of excursion reduction without a boomy sound. Very vaguely more or less kinda sorta a sealed 15" and 12" ported are about the same.

2) if I heavily dampened the shell and reduced its volume considerably would I need to increase the size of the shell I use? (I hear that with a ported cabinet if you dampen the cabinet you may be able to reduce its size by up to 20%) I guess I’m also wondering if a sealed woofer requires dampening at all.

I think you're mixed up about something. If you put stuffing* in a sealed enclosure (fiberglass, say...pillow stuffing is NOT a best material), the stuffing absorbs some energy as the woofer compresses and expands the air in the box. This makes the box appear larger to the woofer than it actually is, up to maybe 30% bigger. In a ported enclosure, the same effect can happen except you can't stuff near the port inner opening as it will interfere with the airflow.

*such as fiberglass, or Acousta-Stuff. Pillow stuffing is usually NOT so great, you won't get as much displacement bump. Also stuffing can absorb upper frequencies in the box, improving the sound. Get https://meniscusaudio.com/product/loudspeaker-design-cookbook/ which has a chapter about stuffing among a zillion other useful things.

3) Would a cylinder style cabinet net me any benefits rather than going with a standard square/rectangle design?

Cylinders are stronger in the...radial??? direction, and may resonate less, especially if made out of cardboard (like concrete formers).

I'll also note that sealed designs are less critical of enclosure size than ported enclosures are. It is much easier for a ported design to "go wrong." You need a large diameter port to flow a lot of air, which then means the port gets long, maybe too long to fit in the enclosure. And the port can resonate like an organ pipe at higher frequencies. In your situation I'd be doing the 15" sealed, with as low a resonance as I could manage, and stuffing the heck out of the enclosure.

2 drivers require twice the volume of a single one.Does the dual driver system change cabinet volume requirements? And i assume that amplification requirements would double?

Here is one that would work. Likely vented or sealed. Abit bigger than they specify would make for better (typical) room gain.

https://www.css-audio.com/sdx12-curves

I prefer the 10” which pretty much fits the sme sealed boxes (and is not as pricey).

But there are quite a few, you need to download a modeler and start plugging their numbers in and see what is suitable.

Target a sealed Q of 0.5 to 0.707. Smaller number needs a bigger box — 26 litres net each driver to 76 litres net/driver. It can be seen that the volume, within range, of the box.

dave

Thanks again Dave.2 drivers require twice the volume of a single one.

Here is one that would work. Likely vented or sealed. Abit bigger than they specify would make for better (typical) room gain.

https://www.css-audio.com/sdx12-curves

I prefer the 10” which pretty much fits the sme sealed boxes (and is not as pricey).

But there are quite a few, you need to download a modeler and start plugging their numbers in and see what is suitable.

Target a sealed Q of 0.5 to 0.707. Smaller number needs a bigger box — 26 litres net each driver to 76 litres net/driver. It can be seen that the volume, within range, of the box.

dave

depending upon the inner diameter of your drum you could even poke an 18 inch in it and run as a "3rd" order closed box with a series capacitor.

there are probably some regular 15" which could work well enough - the tradeoff would be higher sensitivity and less low end vs subwoofer type.

the "boost" comes from an area of lower impedance with the capacitor than the driver - box combo alone so requires a low driving impedance to work. (that leaves out single ended tube amps which are generally too low in power to work in the first place.

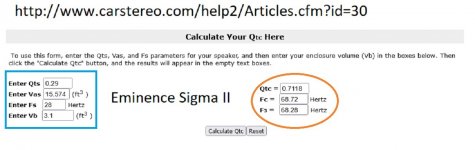

Here's an illustration using Eminence's Sigma II 18 inch woofer. It needs a 16.6" baffle hole to mount

"4 pi" is like elevated and away from boundaries - -"2 pi" loading like sitting in a big parking lot.

typically "450uF" is a good number to simulate for 8 ohm woofers in a closed box.

in this case, 350uF looks good - - - there are places which sell good motor run capacitors cheap.

"100 watts" - -~28.3v drive just about hits Sigma II's xmax rating.

there are probably some regular 15" which could work well enough - the tradeoff would be higher sensitivity and less low end vs subwoofer type.

the "boost" comes from an area of lower impedance with the capacitor than the driver - box combo alone so requires a low driving impedance to work. (that leaves out single ended tube amps which are generally too low in power to work in the first place.

Here's an illustration using Eminence's Sigma II 18 inch woofer. It needs a 16.6" baffle hole to mount

"4 pi" is like elevated and away from boundaries - -"2 pi" loading like sitting in a big parking lot.

typically "450uF" is a good number to simulate for 8 ohm woofers in a closed box.

in this case, 350uF looks good - - - there are places which sell good motor run capacitors cheap.

"100 watts" - -~28.3v drive just about hits Sigma II's xmax rating.

Attachments

Last edited:

Thankyou Freddidepending upon the inner diameter of your drum you could even poke an 18 inch in it and run as a "3rd" order closed box with a series capacitor.

there are probably some regular 15" which could work well enough - the tradeoff would be higher sensitivity and less low end vs subwoofer type.

the "boost" comes from an area of lower impedance with the capacitor than the driver - box combo alone so requires a low driving impedance to work. (that leaves out single ended tube amps which are generally too low in power to work in the first place.

Here's an illustration using Eminence's Sigma II 18 inch woofer. It needs a 16.6" baffle hole to mount

"4 pi" is like elevated and away from boundaries - -"2 pi" loading like sitting in a big parking lot.

typically "450uF" is a good number to simulate for 8 ohm woofers in a closed box.

in this case, 350uF looks good - - - there are places which sell good motor run capacitors cheap.

"100 watts" - -~28.3v drive just about hits Sigma II's xmax rating.

Just out of interest I looked up the eminence 18” driver and noticed that closed cabinet volume is N/A for this driver, are some drivers designed for closed and/or ported?depending upon the inner diameter of your drum you could even poke an 18 inch in it and run as a "3rd" order closed box with a series capacitor.

there are probably some regular 15" which could work well enough - the tradeoff would be higher sensitivity and less low end vs subwoofer type.

the "boost" comes from an area of lower impedance with the capacitor than the driver - box combo alone so requires a low driving impedance to work. (that leaves out single ended tube amps which are generally too low in power to work in the first place.

Here's an illustration using Eminence's Sigma II 18 inch woofer. It needs a 16.6" baffle hole to mount

"4 pi" is like elevated and away from boundaries - -"2 pi" loading like sitting in a big parking lot.

typically "450uF" is a good number to simulate for 8 ohm woofers in a closed box.

in this case, 350uF looks good - - - there are places which sell good motor run capacitors cheap.

"100 watts" - -~28.3v drive just about hits Sigma II's xmax rating.

In the case of Eminence's Sigma II - look at its specs. Qts (motor strength" is strong around 0.3. (over-damped for sealed box) When placed in a sealed box for maximally flat response, that box will only be about 3 cubic feet and have a half-power "F3" point near 70Hz. That's probably why the sealed box isn't mentioned by Eminence.

0.3 qts is ideal for assisted 6th order boxes where boost is applied at tuning.

Below to help in understanding are some notes regarding 6th order bass reflex from the late and great DJK (Dennis Kleitsch)

Low Qts

Posted by djk (M) on September 29, 2007 at 03:03:05

In Reply to: RE: JBL Scoop posted by Hornlover on September 28, 2007 at 08:33:11:

The optimum Qts for minimum box size and maximum bass extension is 0.312

Qts in the range of 0.25~0.40 is OK.

If much higher than 0.40 a sealed box is indicated, if much lower than 0.25 a horn is indicated.

************************************************** *********************

A little known fact is you can 'burn' Qts if it is lower than what you need(no more than 20%).Another tactic would be to use the low Qts to reduce the box size and raise the Fb to keep it flat.

The optimum Qts for an equalized 6th order Butterworth design(not to be confused with a bandpass design)is .312 .The formula for box size is Qts*Qts*4.1*Vas=Vb.The formula for Fb is (Fs/Qts)*.312 .For a Qts of .312 the Faux(eq frequency)=Fb with a Q of 2 .

************************************************** *********************

Box size is roughly proportional to the square of the Qts, so the lower the Q the smaller the box. Also the lower the Q, the higher the efficiency. Bass rolls off though if the Q is too low, the magnet can be too big for its own good.

For a vented box, the optimum Qts is 0.312

0.312 gives the best bass extension, minimum box size, and highest efficiency.

Posted by djk ( M ) on July 25, 2005 at 00:55:59

A 2 cu ft 2nd order sealed box with an F3 of 30hz can only be 0.18% efficient (84.55dB).

A 2 cu ft 4th order vented box with an F3 of 30hz can only be 0.36% efficient (87.56dB).

A 2 cu ft 6th order vented box with an F3 of 30hz can only be 0.90% efficient (91.54dB).

The correct box size for a Qts=0.312 woofer for the 6th order vented design is Vas*4.1, Fb=Fs=Faux, Q=2 for Faux.

Without the Q=2 filter the box is an SBB4 (Super Boom Box 4th order), with the best transient response of all the standard vented alignments, with the filter it is a B6(maximally flat).

0.3 qts is ideal for assisted 6th order boxes where boost is applied at tuning.

Below to help in understanding are some notes regarding 6th order bass reflex from the late and great DJK (Dennis Kleitsch)

Low Qts

Posted by djk (M) on September 29, 2007 at 03:03:05

In Reply to: RE: JBL Scoop posted by Hornlover on September 28, 2007 at 08:33:11:

The optimum Qts for minimum box size and maximum bass extension is 0.312

Qts in the range of 0.25~0.40 is OK.

If much higher than 0.40 a sealed box is indicated, if much lower than 0.25 a horn is indicated.

************************************************** *********************

A little known fact is you can 'burn' Qts if it is lower than what you need(no more than 20%).Another tactic would be to use the low Qts to reduce the box size and raise the Fb to keep it flat.

The optimum Qts for an equalized 6th order Butterworth design(not to be confused with a bandpass design)is .312 .The formula for box size is Qts*Qts*4.1*Vas=Vb.The formula for Fb is (Fs/Qts)*.312 .For a Qts of .312 the Faux(eq frequency)=Fb with a Q of 2 .

************************************************** *********************

Box size is roughly proportional to the square of the Qts, so the lower the Q the smaller the box. Also the lower the Q, the higher the efficiency. Bass rolls off though if the Q is too low, the magnet can be too big for its own good.

For a vented box, the optimum Qts is 0.312

0.312 gives the best bass extension, minimum box size, and highest efficiency.

Posted by djk ( M ) on July 25, 2005 at 00:55:59

A 2 cu ft 2nd order sealed box with an F3 of 30hz can only be 0.18% efficient (84.55dB).

A 2 cu ft 4th order vented box with an F3 of 30hz can only be 0.36% efficient (87.56dB).

A 2 cu ft 6th order vented box with an F3 of 30hz can only be 0.90% efficient (91.54dB).

The correct box size for a Qts=0.312 woofer for the 6th order vented design is Vas*4.1, Fb=Fs=Faux, Q=2 for Faux.

Without the Q=2 filter the box is an SBB4 (Super Boom Box 4th order), with the best transient response of all the standard vented alignments, with the filter it is a B6(maximally flat).

Attachments

there's a mistake above with the line:

"The correct box size for a Qts=0.312 woofer for the 6th order vented design is Vas*4.1"

That should read "The correct box size for a Qts=0.312 woofer is ~0.4X Vas"

as Qts^2 (0.312x0.312) * 4.1 = 0.3991104

so the optimum size for Eminence Sigma II whose Qes hasn't been raised significantly by additional series resistance or amplifier output impedance ia around 6 cubic feet including driver displacement.

"The correct box size for a Qts=0.312 woofer for the 6th order vented design is Vas*4.1"

That should read "The correct box size for a Qts=0.312 woofer is ~0.4X Vas"

as Qts^2 (0.312x0.312) * 4.1 = 0.3991104

so the optimum size for Eminence Sigma II whose Qes hasn't been raised significantly by additional series resistance or amplifier output impedance ia around 6 cubic feet including driver displacement.

Last edited:

Nah. Sealed designs are pretty forgiving. It would just lower the "Q" in other words tighten the response, rarely a bad thing. However we'd like the know the specific driver make and model number, and link if you have it, to see what the Thiele-Small parameters are. Some "recommendations" are based on what they think customers want to hear and not actual calculation at all.A driver i saw had a recomendation for a sealed cabinet of 65 litre so even if i dampen it i would not have to recalculate the enclosures size?

Back to this-the shell is fairly thin, right? And the inside surface, is it slick? Can you apply anti-vibration compound or will it just fall off? I'd want to stiffen this thing with some bracing likely. In a wood box I cut dowels or 1x2 to length where with some sanding I can barely jam them in between opposing walls, then wood glue all around where the ends touch the wood. I don't think that would work with your shell???18” maple drum shell

Doesn't the woofer impedance peak at resonance do screwy things? I mean I guess not looking at the simulation-hornresp appears to calculate the voltage division at each frequency? I had to redesign an existing passive highpass satellite crossover, worked but only crudely due to the impedance at resonance. Different use case though."3rd" order closed box with a series capacitor.

The swayback in the response makes me feel the time response could be a bit negative. Can hornresp simulate response to tone bursts? THAT is what I've been wanting to do for the longest time.

What happens then? Can you model say an Eminence Sigma II 15 (if that exists)? What I recall from my time working on subs is it seemed like the key to low frequency sensitivity was keeping the resonance in the box low, because below resonance you are rolling off and the magnet just controls the Q/bump/peak. Hmmm...that would indicate you need a high mass, soft suspension animal, unless you have a quite large box. Then maybe a huge magnet to keep the Q down.some regular 15"

prices for raw loudspeakers have risen a good 40% in some case from a year or two ago. Parts Express sells a 15" with low qts and relatively high mass for about $120. Its a bit heavier than Sigma II and to get the low Q from a small motor, has 4.12 milliHenries voice coil inductance. It could be used ported in your drumshell. You will have to ask users on how to cross it over to a midrange.. The Dayton PA310 12" speaker has more midrange (less than Kappa 12 but quite extended on-axis.

Is this going to be a music playback speaker ? - or say playback for electronic drums?

Is this going to be a music playback speaker ? - or say playback for electronic drums?

Yes it is , I was going to put a product called dynamat extreme on the inside of the shell. Then I have a friend who can access industrial pipe insulation it’s basically rock wool approx 150mm thick. I’m not sure if I should go with one more layer of something between the fore mentioned materials. The dynamat is adhesive and the Rockwool is preformed. On each end I was going to use the thickest marine ply I can find.Back to this-the shell is fairly thin, right? And the inside surface, is it slick? Can you apply anti-vibration compound or will it just fall off? I'd want to stiffen this thing with some bracing likely. In a wood box I cut dowels or 1x2 to length where with some sanding I can barely jam them in between opposing walls, then wood glue all around where the ends touch the wood. I don't think that would work with your shell???

Hopefully that is enough

- Home

- General Interest

- Everything Else

- 12” ported cabinet or 15” sealed cabinet?