Hi all,

What do you consider a "normal" level of mismatch between two new unmatched KT88's from the same Russian manufacturer (EHX)?

Maybe I've just been lucky, but to date most pairs of EL34's and KT88's I have used have biased within a volt or two of each other. Measured THD between channels is typically equal to within fractions of a percent.

The other day I installed a brand new pair of unmatched Electro-Harmonix KT88's which were purchased from the same store. One of them self biased at -46V and one at -50V. One channel displayed 1.2% THD @ 1W, the other more than double at 3-4%. Swapping the tube positions confirmed it was the tubes, and another set of JJ tubes self biased nicely at -45V with near identical THD figures (1.2%).

Maybe I have just been lucky, but to date the difference between the two EHX tubes far exceeds the variability I have become used to. I suspect the high THD tube may be faulty or damaged in transport.

Any thoughts?

What do you consider a "normal" level of mismatch between two new unmatched KT88's from the same Russian manufacturer (EHX)?

Maybe I've just been lucky, but to date most pairs of EL34's and KT88's I have used have biased within a volt or two of each other. Measured THD between channels is typically equal to within fractions of a percent.

The other day I installed a brand new pair of unmatched Electro-Harmonix KT88's which were purchased from the same store. One of them self biased at -46V and one at -50V. One channel displayed 1.2% THD @ 1W, the other more than double at 3-4%. Swapping the tube positions confirmed it was the tubes, and another set of JJ tubes self biased nicely at -45V with near identical THD figures (1.2%).

Maybe I have just been lucky, but to date the difference between the two EHX tubes far exceeds the variability I have become used to. I suspect the high THD tube may be faulty or damaged in transport.

Any thoughts?

Last edited:

I think the general rule of thumb is tubes have a 10% tolerance on parameters. That may or may not translate into 10% variance in the things you measure.

Cheers

Ian

Cheers

Ian

Thanks for the replies.

So from what you two are saying this is normal level of variation and I should not be seeking a replacement from the store?

So from what you two are saying this is normal level of variation and I should not be seeking a replacement from the store?

They may be at the edges of the distribution, what's left after all the matched sets are sold. Maybe you clod trade the -50V one for a "colder" one, or a pair at -50V would likely be fine too.

Most parameters will vary +-25% , with current production AND was the same in the 1960Hi all,

What do you consider a "normal" level of mismatch between two new unmatched KT88's from the same Russian manufacturer (EHX)?

Maybe I've just been lucky, but to date most pairs of EL34's and KT88's I have used have biased within a volt or two of each other. Measured THD between channels is typically equal to within fractions of a percent.

The other day I installed a brand new pair of unmatched Electro-Harmonix KT88's which were purchased from the same store. One of them self biased at -46V and one at -50V. One channel displayed 1.2% THD @ 1W, the other more than double at 3-4%. Swapping the tube positions confirmed it was the tubes, and another set of JJ tubes self biased nicely at -45V with near identical THD figures (1.2%).

Maybe I have just been lucky, but to date the difference between the two EHX tubes far exceeds the variability I have become used to. I suspect the high THD tube may be faulty or damaged in transport.

Any thoughts?

Therefor it's important to get matched tubes in positions where it is needed. Power tubes is one.

That is an interesting comment. How did you arrive at the 25% figure? Is that just for power tubes or is it generally applicable?Most parameters will vary +-25% , with current production AND was the same in the 1960

Therefor it's important to get matched tubes in positions where it is needed. Power tubes is one.

Cheers

ian

It's general.That is an interesting comment. How did you arrive at the 25% figure? Is that just for power tubes or is it generally applicable?

Cheers

ian

Read for instance comers book ( or other from the old time)

The 25% is an estimate of what i have seen.

Hi all

Please also note that a tube needs to run several dozen hours before its properties get stable. Some manufacturer therefore offer already burnt tubes, but this is not for free. However, it is not comlicated to do the burnin procedure yourself. Easiest way is to burnin just in your amp, and readjust the bias after 48h non-stop running time. Perhaps this needs to be repeated a second time after 96h. Tubes which had to be quite stable for its application (like DC-amplifier) were typically burnt from the manufacturer for 150h.

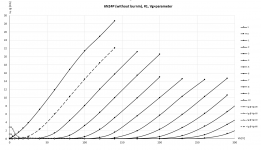

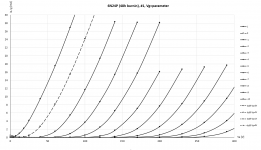

However, it is quite impressive how strong the curves of a tube may change during burnin. As an example, see the attached curves of a 6N24P, measured before and after 48h of burnin with 2/3 of the allowed plate power.

BR Adrian

Please also note that a tube needs to run several dozen hours before its properties get stable. Some manufacturer therefore offer already burnt tubes, but this is not for free. However, it is not comlicated to do the burnin procedure yourself. Easiest way is to burnin just in your amp, and readjust the bias after 48h non-stop running time. Perhaps this needs to be repeated a second time after 96h. Tubes which had to be quite stable for its application (like DC-amplifier) were typically burnt from the manufacturer for 150h.

However, it is quite impressive how strong the curves of a tube may change during burnin. As an example, see the attached curves of a 6N24P, measured before and after 48h of burnin with 2/3 of the allowed plate power.

BR Adrian

Attachments

It's general.

Read for instance comers book ( or other from the old time)

Do you mean Tomer?

Cheers

Ian

If a triode's mu, u, is 10% high, and its transconductance, Gm, is 10% low, then . . .

The plate impedance, rp, will be 20% high.

u = Gm x rp

rp = u/Gm

The plate impedance, rp, will be 20% high.

u = Gm x rp

rp = u/Gm

For several decades I had a VTVM with a 12AU7. If I turned it off, I had to chase the zero calibration all day. If I left it on, less drift. So I left it on. For 20 years. It got as good as my new FET-VM, dozen mV per day, much of it city power variation.burnt from the manufacturer for 150h. However, it is quite impressive how strong the curves of a tube may change during burnin.

I've never obsessed about "matching" power tubes. I even had a mule-amp I rigged with 1950 metal 6L6 or 1969 Tungsol 6550 or 1980 GE 6550 on one side and an old EL34 on the other side. Assuming the tubes were not "dead" (I had a very sick 7027), the amp played fine, no glitch on 'scope. There would be THD differences but I had a Fisher which would be adjusted 10 or 12 ways and the only "better" I found was biased red-hot (it was a cold design).

Thanks all. Sounds like it is normal variation, although far worse than I have ever seen in the numerous unmatched tubes I have run in it.

10% tolerance for a complex variable that involves difficult dimensions like cathode to grid distance and flatness, for a randomly selected pair, seems amazingly close. We're spoiled. Semiconductors like JFETs with similar dimensional issues are tested to group into 100% tolerance groups, and ya just gotta live with it.

All good fortune,

Chris

All good fortune,

Chris

I agree, this kind of tube variation is quite normal. If your amp has trouble with such variations, I'd say that's a design flaw of the amp. Don't blame the tubes!

Yes you are right. Tomer "Mostvacuumtubes"Do you mean Tomer?

Cheers

Ian

Have you never seen a tube tester? A bit less than half the meter is green, a tiny bit of yellow and the lower ~half is red. That means that a tube is considered OK if it conducts just over 50% of what it did new. So, yes +/-25% is normal. Tube circuits were never precision for long, hence the need for frequent instrument calibration. And the designs were damn sloppy. I once changed a resistor in a driver tube circuit and moved the undistorted power from 60W to 100W, because the quiescent point was way off. How many remember that unbanded resistors meant 20% tolerance, and carbon resistors drifted almost as much as the tubes.

https://en.wikipedia.org/wiki/Tube_tester#/media/File:Vacuum_tube_multimeter.jpg

https://en.wikipedia.org/wiki/Tube_tester#/media/File:Vacuum_tube_multimeter.jpg

In addition one could mention that the designers of the time knew this and design the circuitsHave you never seen a tube tester? A bit less than half the meter is green, a tiny bit of yellow and the lower ~half is red. That means that a tube is considered OK if it conducts just over 50% of what it did new. So, yes +/-25% is normal. Tube circuits were never precision for long, hence the need for frequent instrument calibration. And the designs were damn sloppy. I once changed a resistor in a driver tube circuit and moved the undistorted power from 60W to 100W, because the quiescent point was way off. How many remember that unbanded resistors meant 20% tolerance, and carbon resistors drifted almost as much as the tubes.

https://en.wikipedia.org/wiki/Tube_tester#/media/File:Vacuum_tube_multimeter.jpg

accordingly. Thus NFB was used together with well centered workingpoints to copy with varying

tubes and also to cope with aging. Design this way the amps was insensitive of tube parameters

and "tube rolling" was an unknown (and unneeded) activity.

This is what is says on the subject from my Funke W20 valve tester manual (written in 1959) ...

There are still no standards for the quality assessment of tubes. Until 1945, it was common practice for tubes manufactured in Germany to calculate the good value of a tube from 70% of the nominal value, e.g. 70% of the anode quiescent current value. The value between 50% and 70% was designated as “still usable” and the value below 50% as “unusable”. With some special tubes, these areas were different. With American and other foreign tubes it was customary to designate the range from 60% as "good", the range from 40% - 60% of the nominal value with "?", That means "doubtful", can also mean "still usable", and the range below 40% with "used" or with "unusable". Because of the small size of today's tubes, the tolerances in production have improved and so, since 1945, calculations have been made in Germany for the tube types that have come onto the market since 1945 for the range

New tubes cannot be objected to as long as they are above 60% of the nominal value. In the case of new tubes, the tolerances are higher the more complicated the internal structure is. If you measure several factory-made tube types of the same type, the tolerances for the octodes will be higher than for simpler tubes such as triodes.

The % information from the measurement result could be unwise to be given to a tube buyer, since he does not know about this matter. If he has this pre-measured when buying a new tube, and if only 75% were displayed, he would certainly ask for a 100%. It can happen that none of the existing ones reach this value, nevertheless all those over 60% are considered brand new and cannot be complained about. In the opposite case, too, he would not be satisfied if, for example, a brand new RE134 was measured with 130%, which is not uncommon for this type, he would complain about the 130%. For this reason,% information is missing from the test cards.

There are no standards for the quality assessment of tubes. The differences in the anode current in small tubes are not only determined by the ability of the cathode to output current, but also by the dimensional tolerances of the materials used for the system. With these types of tubes, the range of 40-60% cannot always be described as "still usable". While a tube that works with resistance amplification will still work adequately in this area, difficulties can arise with output tubes and oscillator tubes. According to the specifications of the tube factories, the range 40-60% is indicated with "?" which, as explained above, means "doubtful".

Measurement result - evaluation.

There are still no standards for the quality assessment of tubes. Until 1945, it was common practice for tubes manufactured in Germany to calculate the good value of a tube from 70% of the nominal value, e.g. 70% of the anode quiescent current value. The value between 50% and 70% was designated as “still usable” and the value below 50% as “unusable”. With some special tubes, these areas were different. With American and other foreign tubes it was customary to designate the range from 60% as "good", the range from 40% - 60% of the nominal value with "?", That means "doubtful", can also mean "still usable", and the range below 40% with "used" or with "unusable". Because of the small size of today's tubes, the tolerances in production have improved and so, since 1945, calculations have been made in Germany for the tube types that have come onto the market since 1945 for the range

- 60%-100% of the setpoint with "good"

- 40%-60% of the setpoint with "?" (Still usable or doubtful)

- Below 40% of the target value with "used up" (unusable).

New tubes cannot be objected to as long as they are above 60% of the nominal value. In the case of new tubes, the tolerances are higher the more complicated the internal structure is. If you measure several factory-made tube types of the same type, the tolerances for the octodes will be higher than for simpler tubes such as triodes.

The % information from the measurement result could be unwise to be given to a tube buyer, since he does not know about this matter. If he has this pre-measured when buying a new tube, and if only 75% were displayed, he would certainly ask for a 100%. It can happen that none of the existing ones reach this value, nevertheless all those over 60% are considered brand new and cannot be complained about. In the opposite case, too, he would not be satisfied if, for example, a brand new RE134 was measured with 130%, which is not uncommon for this type, he would complain about the 130%. For this reason,% information is missing from the test cards.

There are no standards for the quality assessment of tubes. The differences in the anode current in small tubes are not only determined by the ability of the cathode to output current, but also by the dimensional tolerances of the materials used for the system. With these types of tubes, the range of 40-60% cannot always be described as "still usable". While a tube that works with resistance amplification will still work adequately in this area, difficulties can arise with output tubes and oscillator tubes. According to the specifications of the tube factories, the range 40-60% is indicated with "?" which, as explained above, means "doubtful".

- Home

- Amplifiers

- Tubes / Valves

- Tube to tube variability