Hey there guys, I bought a house (!) about a year ago and have a small workshop in the back that I spend a good bit of time doing woodworking projects in. The outbuilding is not insulated, and is basically bare stud walls at this time- I'm slowly adding power outlets, and plan to insulate and put up sheetrock walls over the summer. In the meantime I wanted to throw together a pair of cheap, quick speakers to set on a shelf to run some music while working on projects.

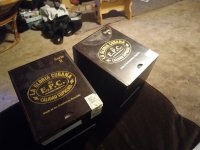

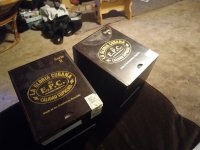

I have a pair each of TC9FD19-08, and Fountek FE85 on hand that I can use, and have some relatively nice little cigar boxes that I was planning to use to make a couple super simple, easy bookshelf types of speakers that wont hurt my feelings if they fall over or get covered in dust. I ran a couple simulations on the speaker DB site simply because it took only a few minutes, and it looks like sealed may not be terrible, even if I am not likely to get any low bass from them- which is perfectly fine for the intended use. Cigar boxes internal dimensions are 5.5 x 4.25 x 7.125" and volume comes out to .0964 cubic feet. Walls are about 5mm. I figure that these will not be super strong, but I can add some braces and they will never need to play very loud.

Here's a quick Speaker DB sim for each in a sealed box they look like some stuffing and back wall lining may be enough to make these servicable. The TC9FD looks to have a better response off the bat, but I almost want to use the FE85 for this project just to use them up, and maybe since the round frame may look a little less janky from a front mount perspective, just for the sake of easy assembly. Also thinking of saving the TC9's for a set of Nola Brio clones in hardwood 🙂

Anybody have any input here? I think sealed is a nice simple way to go, and I'm not equipped to do any simulations on my own. I'm not opposed to a vented box with a simple port cut in, or a section of PVC pipe for an internal port. Maybe add a baffle inside and make a bootleg uFonken out of them?

I have a pair each of TC9FD19-08, and Fountek FE85 on hand that I can use, and have some relatively nice little cigar boxes that I was planning to use to make a couple super simple, easy bookshelf types of speakers that wont hurt my feelings if they fall over or get covered in dust. I ran a couple simulations on the speaker DB site simply because it took only a few minutes, and it looks like sealed may not be terrible, even if I am not likely to get any low bass from them- which is perfectly fine for the intended use. Cigar boxes internal dimensions are 5.5 x 4.25 x 7.125" and volume comes out to .0964 cubic feet. Walls are about 5mm. I figure that these will not be super strong, but I can add some braces and they will never need to play very loud.

Here's a quick Speaker DB sim for each in a sealed box they look like some stuffing and back wall lining may be enough to make these servicable. The TC9FD looks to have a better response off the bat, but I almost want to use the FE85 for this project just to use them up, and maybe since the round frame may look a little less janky from a front mount perspective, just for the sake of easy assembly. Also thinking of saving the TC9's for a set of Nola Brio clones in hardwood 🙂

Anybody have any input here? I think sealed is a nice simple way to go, and I'm not equipped to do any simulations on my own. I'm not opposed to a vented box with a simple port cut in, or a section of PVC pipe for an internal port. Maybe add a baffle inside and make a bootleg uFonken out of them?

Last edited:

I think these are better as cigar boxes than speakers, if you are going to the trouble and money you might as well come up with a better enclosure, imo. I like small sealed boxes better than small ported..

I mean, they will literally cost me nothing. 😉

I plan to make something nicer soon, but a quick simple build is all I need in here for now.

I plan to make something nicer soon, but a quick simple build is all I need in here for now.

Fair enough, those are nice ones though, I've seen them before. Handy for items floating round the place. You could really just throw the drivers in there, put them against the wall and you won't have to mess around with bsc..

Looks like I fudged the dimensions a bit on the online sim earlier but re-plugging in the numbers doesn't change much. I think I'll try to dig out a circle cutting jig and pop the drivers in there and go from there with some simple stuffing and lining. Worst case I end up with some simple speakers for testing amps later on.

I had a set of foamcore Karlsonators in the shop but the heat of the summer delaminated the glue joints on one of them, and these should do just fine in their stead.

I had a set of foamcore Karlsonators in the shop but the heat of the summer delaminated the glue joints on one of them, and these should do just fine in their stead.

Well, I said this would cost me nothing, I lied 😉 I picked up a Dremel circle cutting jig so now I've paid about $12 for a new tool. Figured this was a good practice project before I tried it on anything fancy.

The jig worked well, I was able to cut out the holes for the Parts Express speaker terminal cups just a hair undersized and fitted them to a nice snug push fit. The cutouts for the drivers also were cut easily, although I encountered some splintering on the back side of the cut. Next time I'll attach a piece of scrap wood behind to support the backside of the cut to prevent that. I put some tee nuts into some scrap mahogany straps to act as support for the mounting screws. I considered flush mounting these from inside but was planning to glue the side panels on and wanted access inside so went with face mounting. It also hides the edges of the cutouts.

I figure a buck each for the terminal cups, free cigar boxes, a handful of hardware, and a pair of $12 drivers is plenty for a pair of dirty dusty workshop speakers.

Next up is lining the back wall with dense stuffing or foam, and some loose polyfill.

The jig worked well, I was able to cut out the holes for the Parts Express speaker terminal cups just a hair undersized and fitted them to a nice snug push fit. The cutouts for the drivers also were cut easily, although I encountered some splintering on the back side of the cut. Next time I'll attach a piece of scrap wood behind to support the backside of the cut to prevent that. I put some tee nuts into some scrap mahogany straps to act as support for the mounting screws. I considered flush mounting these from inside but was planning to glue the side panels on and wanted access inside so went with face mounting. It also hides the edges of the cutouts.

I figure a buck each for the terminal cups, free cigar boxes, a handful of hardware, and a pair of $12 drivers is plenty for a pair of dirty dusty workshop speakers.

Next up is lining the back wall with dense stuffing or foam, and some loose polyfill.

Hey, cool! I made some small ported boxes for the TC9FD at one point. They sounded so good at low volume that I kept wanting to turn them up, and then they would start to become confused sounding. Too much excursion, I expect, so sealed is probably the better call. They do sound good with some LF support. I have a 3" hole saw that does a good job for mounting that driver, but you're already there. I suggest black screws for aesthetic purposes. Cool little cigar boxes, enjoy!

Last shot before the side is glued up-

Some loosely stuffed polyfill and some medium-ish density junk foam. Gave them a quick listen and they sound great, very clean and detailed being driven by my flea amp in my small space. I have an old home theater sub I can use with them, I just need to make a simple line level crossover to split them off appropriately.

I'll probably screw some quick shelves up in the corners of the room to mount them up out of the way and they'll do nicely.

I agree on the screws, next time I'm at the hardware store I'll grab some black socket cap screws to put in.

For the time and effort invested I'm very happy with them. Good placeholders until the shop is nice enough to deserve better!

Some loosely stuffed polyfill and some medium-ish density junk foam. Gave them a quick listen and they sound great, very clean and detailed being driven by my flea amp in my small space. I have an old home theater sub I can use with them, I just need to make a simple line level crossover to split them off appropriately.

I'll probably screw some quick shelves up in the corners of the room to mount them up out of the way and they'll do nicely.

I agree on the screws, next time I'm at the hardware store I'll grab some black socket cap screws to put in.

For the time and effort invested I'm very happy with them. Good placeholders until the shop is nice enough to deserve better!

I've been using these in the shop for a while now while I organize and unpack from our move into this house last year, and they have been great. Other than the fact that they don't reach very low into the bass region they are excellent, clear sounding speakers for a small space with light background music. I'm loving that they are compact enough to set pretty much anywhere as I rearrange the shelving and stuff in the room.

I like them a great deal, very handy. I think I'll put some home theater speaker wall mount arms in the upper corners of the room once it's finished more to keep them up out of the way, and I can run a simple subwoofer in a cabinet somewhere to augment the low end.

I like them a great deal, very handy. I think I'll put some home theater speaker wall mount arms in the upper corners of the room once it's finished more to keep them up out of the way, and I can run a simple subwoofer in a cabinet somewhere to augment the low end.

If you haven't already glued them together, I would be tempted to go down the thin wall but well damped route, use contact adhesive to glue some rubber/cork/carpet panels inside, I'd also keep to sealed boxes as I believe ported boxes have to be stiffer. I'd also go for a 100 Hz hump in the response to give an " illusion " af bass.

They're glued, but I can reach in to make adjustments inside the boxes through the speaker opening... I think my next variant on something like this will have panelbond adhesive holding some sheets of foamcore board or something similar inside. For this project some leftover foam works well.

I would rather make some boxes from scratch if going through the trouble to do constrained layer damping, that way the whole thing can be optimised.

I'm not unhappy at all so I wouldn't really wish to artificially pump up the bass with a bump in the curve. I have a thrift store home theater sub to fill in the low end later.

I would rather make some boxes from scratch if going through the trouble to do constrained layer damping, that way the whole thing can be optimised.

I'm not unhappy at all so I wouldn't really wish to artificially pump up the bass with a bump in the curve. I have a thrift store home theater sub to fill in the low end later.

Last edited:

Update on these.

The workshop is a mess during its remodel into a home office. They now live in the upper corners of my master bedroom, and are driven by a small class D amp for sleep aid (rain sounds, light music) or for, ahem, sexy time music.

They are unobtrusive, sound clean, and up in the corners of the room have plenty of low end from corner loading for their use.

Still happy, and the other users of the bedroom are delighted at how they are working out.

The workshop is a mess during its remodel into a home office. They now live in the upper corners of my master bedroom, and are driven by a small class D amp for sleep aid (rain sounds, light music) or for, ahem, sexy time music.

They are unobtrusive, sound clean, and up in the corners of the room have plenty of low end from corner loading for their use.

Still happy, and the other users of the bedroom are delighted at how they are working out.

- Home

- Loudspeakers

- Full Range

- Simple cigar box shop speakers with TC9FD or FE85?