One of my generators has died. It is an old beast from the eighties, a HP3335A. I salvaged it from the scrap heap ~15 years ago, and with time, care, love and patience, I managed to restore it to its former glory.

It had suffered water damage.

Now, when I power it up, everything looks normal at first: the turn-on display indicates the correct 1MHz frequency, but as soon as I hit a key, any key, the display goes blank and the front-panel becomes unresponsive, completely dead.

Clearly something to do with the controller.

I made the basic checks: supply voltages, clock and reset signals, etc., but found no anomaly.

Looking deeper, I can see that the MPU remains alive, even after the display has gone blank: the bus signals are active, the decoding seems to happen normally, and no line remains stuck. The scanning of the keyboard and display stops completely.

The troubleshooting procedure is centred on signature analysis, but I don't have an analyser.

I can however enter the various test modes:

-Test 1 (PIA) is OK

-Test 2 (ROM C) fails

-Test 3 (ROM B) is OK

-Test 4 (ROM A) is OK

-Test 5 (RAM A) fails

-Test 6 (RAM B) is OK

-Test 7 (HP IB) is OK

-Test 8 (display, keyboard) fails

I do not take these tests at their face value: for example, I tried replacing and swapping the chips of RAM A, but the diagnostic didn't change. The keyboard/display test fails, but in fact the µP has no way of knowing: it can only send stimuli signals, but if no key is depressed, there is no response possible.

I don't have a ROM C unfortunately, as it looks like a plausible cause.

I have checked the truth tables of the address decoders and glue-logic gates, as they would also be plausible causes, but I found no anomaly.

Currently, the hypothesis I find the most probable are the failure of ROM C or an internal bad contact somewhere in the controller's PCB: the humidity might have infiltrated inside the internal layers and corroded a connection after many years.

The service manual is available on the keysight website, or here:

https://elektrotanya.com/hp_3335a_synthesizer-generator_sm.pdf/download.html

Any other ideas?

It had suffered water damage.

Now, when I power it up, everything looks normal at first: the turn-on display indicates the correct 1MHz frequency, but as soon as I hit a key, any key, the display goes blank and the front-panel becomes unresponsive, completely dead.

Clearly something to do with the controller.

I made the basic checks: supply voltages, clock and reset signals, etc., but found no anomaly.

Looking deeper, I can see that the MPU remains alive, even after the display has gone blank: the bus signals are active, the decoding seems to happen normally, and no line remains stuck. The scanning of the keyboard and display stops completely.

The troubleshooting procedure is centred on signature analysis, but I don't have an analyser.

I can however enter the various test modes:

-Test 1 (PIA) is OK

-Test 2 (ROM C) fails

-Test 3 (ROM B) is OK

-Test 4 (ROM A) is OK

-Test 5 (RAM A) fails

-Test 6 (RAM B) is OK

-Test 7 (HP IB) is OK

-Test 8 (display, keyboard) fails

I do not take these tests at their face value: for example, I tried replacing and swapping the chips of RAM A, but the diagnostic didn't change. The keyboard/display test fails, but in fact the µP has no way of knowing: it can only send stimuli signals, but if no key is depressed, there is no response possible.

I don't have a ROM C unfortunately, as it looks like a plausible cause.

I have checked the truth tables of the address decoders and glue-logic gates, as they would also be plausible causes, but I found no anomaly.

Currently, the hypothesis I find the most probable are the failure of ROM C or an internal bad contact somewhere in the controller's PCB: the humidity might have infiltrated inside the internal layers and corroded a connection after many years.

The service manual is available on the keysight website, or here:

https://elektrotanya.com/hp_3335a_synthesizer-generator_sm.pdf/download.html

Any other ideas?

Hi,

you may have a look over at the eevblog forum.

There are certainly more specialized-on-measurement-devices guys around than here.

see for example : https://www.eevblog.com/forum/repair/hp-3335a-level-generator-repair/msg2504352/#msg2504352

jauu

Calvin

you may have a look over at the eevblog forum.

There are certainly more specialized-on-measurement-devices guys around than here.

see for example : https://www.eevblog.com/forum/repair/hp-3335a-level-generator-repair/msg2504352/#msg2504352

jauu

Calvin

I remember a fix up by Signal Path which traced a partial failure down to shared tracks and the power regulation on those tracks. What could be happening is a short, pulling down the power for the display and the ROMs causing the system to crash.

have you put a probe on the address line strobe?

have you put a probe on the address line strobe?

Yeah, I tried to search the net, and I found that one too, but the ROM image link is dead.Hi,

you may have a look over at the eevblog forum.

There are certainly more specialized-on-measurement-devices guys around than here.

see for example : https://www.eevblog.com/forum/repair/hp-3335a-level-generator-repair/msg2504352/#msg2504352

jauu

Calvin

You are probably right: if I join the forum, and post my problem, I may have more information. One more site, identity, password to handle, but if I have no other option I will probably do it.

I tested practically every line for conflict, and I found none, thus this is probably not happening

Can you connect and control using GPIB? EEVblog forum has become an essential tool for serious troubleshooting. There is a lot of experiece to tap into and potentially a designer will pop up.

I used one of those a generation ago testing a hard disk trackwriter design. Unfortunately it was not good enough/too good and we switched to a Heathkit RC oscillator. The machine had to write exactly 4+ million transitions +/- 1/4 (clock track) in one turn and its a mechanical setup. It could take an hour to get the right number of transitions.

I used one of those a generation ago testing a hard disk trackwriter design. Unfortunately it was not good enough/too good and we switched to a Heathkit RC oscillator. The machine had to write exactly 4+ million transitions +/- 1/4 (clock track) in one turn and its a mechanical setup. It could take an hour to get the right number of transitions.

I have repaired/attempted tp repair several 3335A's over the years, with only about a 50% success rate (not good). I have a few carcasses laying around if you need any parts. They're a unique beastie still in demand as a wideband level generator with high-precision attenuator. With no currently-made equivalent, they're still sought after if working properly.

I recall encountering similar symptoms on one of them, powered up but keypresses made it go berserk. Ended up being a bad electrolytic on the front panel pcb, where most of the keypad logic is (DC measured fine but lots of AC across it), and connectors which needed to be reseated.

They run quite hot inside and so are hard on 'lytics.

I recall encountering similar symptoms on one of them, powered up but keypresses made it go berserk. Ended up being a bad electrolytic on the front panel pcb, where most of the keypad logic is (DC measured fine but lots of AC across it), and connectors which needed to be reseated.

They run quite hot inside and so are hard on 'lytics.

Thanks for your advices and your generous offer.

The E-caps on the controller and front panel are solid tantalum, metal-glass case types, so no likely problem there. The layout/design of the boards is completely non-sensical and atrocious (daisy-chained GND tracks), which means that different ground points have a significant amount of crap between them, but this didn't cause troubles for decades, thus it should not matter: the TTL and µP circuits have enough noise immunity to cope with it.

If you have a ROM C available, I would be glad to test it. I can probably transfer it on an EPROM and send the original back to you (I don't know which format it is: 2716, 2708? I can adapt anyway)

The E-caps on the controller and front panel are solid tantalum, metal-glass case types, so no likely problem there. The layout/design of the boards is completely non-sensical and atrocious (daisy-chained GND tracks), which means that different ground points have a significant amount of crap between them, but this didn't cause troubles for decades, thus it should not matter: the TTL and µP circuits have enough noise immunity to cope with it.

If you have a ROM C available, I would be glad to test it. I can probably transfer it on an EPROM and send the original back to you (I don't know which format it is: 2716, 2708? I can adapt anyway)

But TTL has lacklustre noise immunity of 0.4V, I'd seriously consider improving the decoupling and ground network to see if it was borderline since the layout is clearly Kirchhoff-inspired, not Maxwell-inspired, and early TTL circuitry was often subject to pattern-sensitive failures due to being designed in ignorance of high-speed design principles.

Also there's more RFI around today - might be as simple as some 2.4GHz getting in the wrong place.

But the first thing to check is hairline cracks in the front panel PCB and solder joints on anything that emerges through the front panel, these get mechanical forces which overtime can fatique and crack things. Until that display/keyboard failure goes away I'd suspect that first and foremost.

Things drift over time, PCBs might become a little more capacitive due to moisture, or a bit more lossy at RF, etc etc. PSUs and decoupling caps might change gradually in their impedance at HF.but this didn't cause troubles for decades, thus it should not matter

Also there's more RFI around today - might be as simple as some 2.4GHz getting in the wrong place.

But the first thing to check is hairline cracks in the front panel PCB and solder joints on anything that emerges through the front panel, these get mechanical forces which overtime can fatique and crack things. Until that display/keyboard failure goes away I'd suspect that first and foremost.

I can try to reinforce the GND network with a mesh of additional connections, and also add a few bypass caps. It should be relatively quick and easy to do.

I do not think it has to do with RFI or other external causes: one day, it simply stopped to work properly, and from then on it never changed again despite the numerous tests and manipulations I made.

I do not think it has to do with RFI or other external causes: one day, it simply stopped to work properly, and from then on it never changed again despite the numerous tests and manipulations I made.

That is exactly where I concentrated my investigations: I examined, tested, retested, and I didn't simply check the continuity of each connection, I also measured their actual resistance, to make sure it was low enoughBut the first thing to check is hairline cracks in the front panel PCB and solder joints on anything that emerges through the front panel, these get mechanical forces which overtime can fatique and crack things. Until that display/keyboard failure goes away I'd suspect that first and foremost.

If it helps, I can lend you a Prologix GPIB/USB controller for some tests,At home, I have no GPIB interface (I am retired). The EEvblog is the next obvious step

but I'll need it back to integrate my sampling scope.

That a RAM, a ROM and the display fail at the same time does not look

like a defective ROM. More like address decoder / bus system.

But the decoder may be a fast TTL prom, too.

You should also check for empty Li batteries. The 54750A scope

failed to boot last year, just needed a new battery and then it

absolutely wanted a new mainframe calibration. But that was easy.

My SNA-33 spectrum analyzer has the same problem and it lost

some buffered ramdisk contents. Still unresolved. :-(

Cheers, Gerhard

Last edited:

Thanks for your kind offer, but I don't think it is worth the trouble: the keyboard/display assemblies are essentially dumb devices, with data flowing in a single direction except if a key is depressed, which means that the actual culprit is the controller and I need to find what's wrong with it: even if by some miracle the GPIB operation was unaffected (which I doubt), it would be unpractical for me to use it that way, and it wouldn't help either in locating the problem sourceIf it helps, I can lend you a Prologix GPIB/USB controller for some tests,

but I'll need it back to integrate my sampling scope.

I don't think the RAM has a problem: in fact I made sure it hasn't by replacing them. It is just a quirk of the self-test system, but ROM C looks more plausible: it is the first memory test to be done according to the HP service manual, probably for good reasons. It probably stores critical routines for the rest of the operations.That a RAM, a ROM and the display fail at the same time does not look

like a defective ROM. More like address decoder / bus system.

But the decoder may be a fast TTL prom, too.

I scrutinized the address decoding, as it looked like a very probable cause, but I couldn't find any anomaly: I checked the truth-table of the decoders and small gates logic, but they were OK.

This instrument has no PROM for decoding.

It does have lousy one-shots used for dubious reasons, but I also checked them

No Li battery on an instrument of that era: they weren't invented yet.You should also check for empty Li batteries. The 54750A scope

failed to boot last year, just needed a new battery and then it

absolutely wanted a new mainframe calibration. But that was easy.

My SNA-33 spectrum analyzer has the same problem and it lost

some buffered ramdisk contents. Still unresolved. :-(

There is no NiCad memory protection either: no data needs to safeguarded.

Sort of thing you want a RPi in between on a rom and socket - let it read the data read from which location. That provides the data that could be rerun.

Not sure on the legalities given you have the ROM C of a discontinued product it’s contents are just corrupt.

Not sure on the legalities given you have the ROM C of a discontinued product it’s contents are just corrupt.

No problem, thanks for trying anyway.Well I'm sorry to say, both of my parts units are missing that board.

If I have a model, I can probably dump its contents into an EPROM, maybe with a few tweaks on the address or CS lines. No need for great sophistication, the contents is all that is needed.

I just came across this searching for something else, but if anyone is still interested:

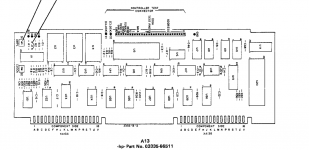

When troubleshooting 3335A's the problem almost always winds up being the power supply, either it directly or with a shorted tantalum decoupling card on one of the boards. The 3335A's power supply runs very hot during operation which really takes it's toll after 30 years or so the capacitors on boards A14 and A15 very often fail. First off, check the ripple on the power rails - anything over 50 mv or so is a Bad Thing. If one or more rails is low, the first check should be to pull all the cards and see if the voltages recover. If so, replace the cards one by one and see which one(s) cause it to drop. More than likely it will be a shorted tantalum capacitor used to locally decouple the rails - this is far more likely on later units that used the mustard-yellow T322 series tantalums. Note: The electrolytic appearing silver axial capacitors with "150D" are Sprague (now Vishay) hi-rel and spec'd tantalums - you will probably win the lottery before one of these fails. If you replace any of the tantalums, use ones with a higher rated voltage - de-rate by at least 50%

Notes:

To access the cards, the large aluminum unit containing them must be removed. First carefully remove the hardline coax between the attenuator and the card cage then remove the three long screws through the metal plate spanning the two halves. The card cage will lift out and can be set along side the unit with the card front covers facing up.

Important: When handling the hardline coax, be extremely careful - DO NOT bend and it is well worth it to get a special torque wrench to use when reattaching it. One of the main features of the 3335A is the extreme flatness and accuracy of it's output and any changes to this line will ruin that.

There are four 10uf 50V axial electrolytics on A15 (C1-C4). Replace them. If they are not bad now, they will be soon. As always, use a reputable brand and NEVER ePay specials.

I use:

https://www.mouser.com/ProductDetail/647-UPM1J120MDD

There are four 50uF axial electrolytics on the back of the card cage immediately under the voltage test points - best to replace these as well (I use polymer here, just be sure to stand them off enough not to short the leads to the board.)

I use:

https://www.mouser.com/ProductDetail/667-EEH-AZA1J560B

There are two 12,000uF and three 15,000uf screw mount can capacitors. More than likely these have started losing capacitance and are getting leaky. They can be replaced with snap-in capacitors if desired (lot cheaper than new screw mounts) but probably stay away from wire leaded ones as they won't hold up to the required dissipation and ripple rating.

I use:

https://www.mouser.com/ProductDetail/871-B41252A7129M000

https://www.mouser.com/ProductDetail/871-B41252C5159M000

Anyway, hope this helps...

Hal

When troubleshooting 3335A's the problem almost always winds up being the power supply, either it directly or with a shorted tantalum decoupling card on one of the boards. The 3335A's power supply runs very hot during operation which really takes it's toll after 30 years or so the capacitors on boards A14 and A15 very often fail. First off, check the ripple on the power rails - anything over 50 mv or so is a Bad Thing. If one or more rails is low, the first check should be to pull all the cards and see if the voltages recover. If so, replace the cards one by one and see which one(s) cause it to drop. More than likely it will be a shorted tantalum capacitor used to locally decouple the rails - this is far more likely on later units that used the mustard-yellow T322 series tantalums. Note: The electrolytic appearing silver axial capacitors with "150D" are Sprague (now Vishay) hi-rel and spec'd tantalums - you will probably win the lottery before one of these fails. If you replace any of the tantalums, use ones with a higher rated voltage - de-rate by at least 50%

Notes:

To access the cards, the large aluminum unit containing them must be removed. First carefully remove the hardline coax between the attenuator and the card cage then remove the three long screws through the metal plate spanning the two halves. The card cage will lift out and can be set along side the unit with the card front covers facing up.

Important: When handling the hardline coax, be extremely careful - DO NOT bend and it is well worth it to get a special torque wrench to use when reattaching it. One of the main features of the 3335A is the extreme flatness and accuracy of it's output and any changes to this line will ruin that.

There are four 10uf 50V axial electrolytics on A15 (C1-C4). Replace them. If they are not bad now, they will be soon. As always, use a reputable brand and NEVER ePay specials.

I use:

https://www.mouser.com/ProductDetail/647-UPM1J120MDD

There are four 50uF axial electrolytics on the back of the card cage immediately under the voltage test points - best to replace these as well (I use polymer here, just be sure to stand them off enough not to short the leads to the board.)

I use:

https://www.mouser.com/ProductDetail/667-EEH-AZA1J560B

There are two 12,000uF and three 15,000uf screw mount can capacitors. More than likely these have started losing capacitance and are getting leaky. They can be replaced with snap-in capacitors if desired (lot cheaper than new screw mounts) but probably stay away from wire leaded ones as they won't hold up to the required dissipation and ripple rating.

I use:

https://www.mouser.com/ProductDetail/871-B41252A7129M000

https://www.mouser.com/ProductDetail/871-B41252C5159M000

Anyway, hope this helps...

Hal

Thanks for your advices. The PSU was one of the first checks I made, and it looked perfectly healthy. However, I am going to check it again very carefully, in case I missed something earlier

One place you might to try is: https://groups.io/g/HP-Agilent-Keysight-equipment

One of the designers of the 3335A is a member as well as a lot of other very knowledgeable people.

One of the designers of the 3335A is a member as well as a lot of other very knowledgeable people.

- Home

- Design & Build

- Equipment & Tools

- HP 3335A woes