Hey guys,

I wanted to share my experience with you. Translam usually means wasting material. Recently we built some pairs of speakers by using the waste BB plywood parts of proaudio loudspeakers production. 15" and 18" woofers in speakers will leave ~37-45 cm circle parts that we used to burn during cold seasons till we got natural gas pipeline in our facility, so we didn't need to burn wood to stay alive! Afterwards we sold some o the circles with natural coating from Monocoat as pizza serving dish, but hundreds and hundreds of dishes soon saturated the local market.

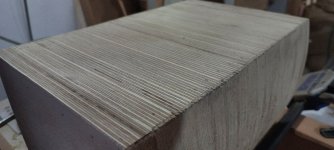

We used these parts to make some kinda translam cabinets, but each layer consists of three pieces. After all, it turned out good. Acceptable. Adequate.

I wanted to share my experience with you. Translam usually means wasting material. Recently we built some pairs of speakers by using the waste BB plywood parts of proaudio loudspeakers production. 15" and 18" woofers in speakers will leave ~37-45 cm circle parts that we used to burn during cold seasons till we got natural gas pipeline in our facility, so we didn't need to burn wood to stay alive! Afterwards we sold some o the circles with natural coating from Monocoat as pizza serving dish, but hundreds and hundreds of dishes soon saturated the local market.

We used these parts to make some kinda translam cabinets, but each layer consists of three pieces. After all, it turned out good. Acceptable. Adequate.

Attachments

-

21.jpg44.5 KB · Views: 150

21.jpg44.5 KB · Views: 150 -

20.jpg68.7 KB · Views: 167

20.jpg68.7 KB · Views: 167 -

19.jpg32 KB · Views: 154

19.jpg32 KB · Views: 154 -

18.jpg44.1 KB · Views: 163

18.jpg44.1 KB · Views: 163 -

17.jpg53.8 KB · Views: 192

17.jpg53.8 KB · Views: 192 -

17.jpg53.8 KB · Views: 171

17.jpg53.8 KB · Views: 171 -

16.jpg52.6 KB · Views: 166

16.jpg52.6 KB · Views: 166 -

15.jpg99.3 KB · Views: 157

15.jpg99.3 KB · Views: 157 -

14.jpg80.5 KB · Views: 145

14.jpg80.5 KB · Views: 145 -

13.jpg54.9 KB · Views: 139

13.jpg54.9 KB · Views: 139 -

12.jpg51.8 KB · Views: 155

12.jpg51.8 KB · Views: 155

Neat idea. I've sometimes wondered if some of the wastage of translam could be mitigated by kind of a "lincoln logs" approach where no single layer needs to be a single piece, but the joints in different layers are staggered at different locations, so that any given layer's joint laps the others. A simple layout could repeat in staggered alternating layers with sort of a dovetail effect; if someone wanted to get more complex the design could randomize the joints vertically, or have them occurring in some staircase pattern other than alternating layers