Hi,

I was thinking about whether it would make sense to design a power supply for plate voltage using batteries (LiIo, LiPo, LiFePo...).

I Know battery supply is a thing with solid state preamps especially high-gain phono stages. But I have not seen much in this regard with tubes.

I also know there are some types of tubes that were specifically designed for battery based operation in portable units back in the day. Here I'm more thinking about using our standard 12AX7, 6DJ8, etc... so B+ in the 100-200 V range.

We could design a power supply that manages the indivudual cells in a smart way (using a micro controller) and decides which cells to charge and which cells to use for power supply. So we need to put in more cells than we need for the maximum B+ Volatge that we want so we could always re-charge some of the cells while we use the others to supply volatage. We would need to have somthing that evens out the output volatge when a re-charged cell is brought "on-line" and a discharged cell is then taken of-line for re-charging.

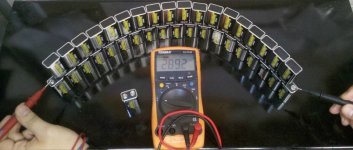

So my theory is that this could yield an almost perfect DC voltage source using ca. 45 Lithium cells (for 3.6V each) in series for 160V. We can cluster them together in groups of 4 and hook those up to individual charging controllers. Given that that amounts to a huge capacity (assuming around 2000 mAh per cell) we probably don't even need to think about a scheme for charging some batteries while discharging others. 45 cells would combine to

90,000 mAh and if we power 4 double-triodes that maybe draw 20 mA each those cells will last for more than 1000 hous.

So the question is just , is it worth it for a high-gain phono stage? I'd say we wouldn't be powering the heaters from the batteries just B+ and maybe a CCS if we want that for our design.

Thoughts?

Cheers,

Lars

I was thinking about whether it would make sense to design a power supply for plate voltage using batteries (LiIo, LiPo, LiFePo...).

I Know battery supply is a thing with solid state preamps especially high-gain phono stages. But I have not seen much in this regard with tubes.

I also know there are some types of tubes that were specifically designed for battery based operation in portable units back in the day. Here I'm more thinking about using our standard 12AX7, 6DJ8, etc... so B+ in the 100-200 V range.

We could design a power supply that manages the indivudual cells in a smart way (using a micro controller) and decides which cells to charge and which cells to use for power supply. So we need to put in more cells than we need for the maximum B+ Volatge that we want so we could always re-charge some of the cells while we use the others to supply volatage. We would need to have somthing that evens out the output volatge when a re-charged cell is brought "on-line" and a discharged cell is then taken of-line for re-charging.

So my theory is that this could yield an almost perfect DC voltage source using ca. 45 Lithium cells (for 3.6V each) in series for 160V. We can cluster them together in groups of 4 and hook those up to individual charging controllers. Given that that amounts to a huge capacity (assuming around 2000 mAh per cell) we probably don't even need to think about a scheme for charging some batteries while discharging others. 45 cells would combine to

90,000 mAh and if we power 4 double-triodes that maybe draw 20 mA each those cells will last for more than 1000 hous.

So the question is just , is it worth it for a high-gain phono stage? I'd say we wouldn't be powering the heaters from the batteries just B+ and maybe a CCS if we want that for our design.

Thoughts?

Cheers,

Lars

As you say, in some ways this is going full circle, back to the days when people did not have reliable or standardised electricity supplies.

However when I see 'microcontroller' I balk. The beauty of tube electronics in my opinion is that every problem *can* have a simple solution. What is more elegant than a tube amplifiers, with transformers and a handful of passive components?

However when I see 'microcontroller' I balk. The beauty of tube electronics in my opinion is that every problem *can* have a simple solution. What is more elegant than a tube amplifiers, with transformers and a handful of passive components?

Hi,

I was thinking about whether it would make sense to design a power supply for plate voltage using batteries (LiIo, LiPo, LiFePo...).

I Know battery supply is a thing with solid state preamps especially high-gain phono stages. But I have not seen much in this regard with tubes.

I also know there are some types of tubes that were specifically designed for battery based operation in portable units back in the day. Here I'm more thinking about using our standard 12AX7, 6DJ8, etc... so B+ in the 100-200 V range.

We could design a power supply that manages the indivudual cells in a smart way (using a micro controller) and decides which cells to charge and which cells to use for power supply. So we need to put in more cells than we need for the maximum B+ Volatge that we want so we could always re-charge some of the cells while we use the others to supply volatage. We would need to have somthing that evens out the output volatge when a re-charged cell is brought "on-line" and a discharged cell is then taken of-line for re-charging.

So my theory is that this could yield an almost perfect DC voltage source using ca. 45 Lithium cells (for 3.6V each) in series for 160V. We can cluster them together in groups of 4 and hook those up to individual charging controllers. Given that that amounts to a huge capacity (assuming around 2000 mAh per cell) we probably don't even need to think about a scheme for charging some batteries while discharging others. 45 cells would combine to

90,000 mAh and if we power 4 double-triodes that maybe draw 20 mA each those cells will last for more than 1000 hous.

So the question is just , is it worth it for a high-gain phono stage? I'd say we wouldn't be powering the heaters from the batteries just B+ and maybe a CCS if we want that for our design.

Thoughts?

Cheers,

Lars

It's certainly doable (almost anything is), but it is a lot of effort and cost and I am not sure what the advantage would be? A well designed regulator like the T-reg in the diyaudo.com store is simpler, cheaper and delivers a more 'ideal DC' than all those batteries.

Then again it may be just down to personal preference.

Jan

The available energy in 45 lithium cells is enough to create a serious fireball if anything went wrong. Multiple fuses should be in the plan if you go this route. Series connected lithium cells can fail spectacularly if they are not all charged to the same capacity, as one could be reversed polarized during discharge if it was undercharged. This is why multiple cell packs have a BMS. A BMS for 45 cells would be complicated. Obviously it can be done, and from the teardown videos it appears that Tesla cars use several small BMS chips all controlled by a master chip.

Series connected 9 volt batteries are a cheaper and probably more appropriate for a preamp. I have seen rechargeable lithium 9V batteries on Amazon, but have not tried them. Some even have a USB charging port on the side.

Note, dumm blonde experiments many years ago proved that a box full of series connected 9 volt alkaline batteries can be a dangerous toy as well. Attempting to make a pencil lead arc lamp resulted in an exploding battery.

Series connected 9 volt batteries are a cheaper and probably more appropriate for a preamp. I have seen rechargeable lithium 9V batteries on Amazon, but have not tried them. Some even have a USB charging port on the side.

Note, dumm blonde experiments many years ago proved that a box full of series connected 9 volt alkaline batteries can be a dangerous toy as well. Attempting to make a pencil lead arc lamp resulted in an exploding battery.

I did 😱

Not 2700V but 220V to 350V many many times.

One of my customers was Les Luthiers, based in Buenos Aires, famous for using WEIRD musical instruments (a ham can violin, a multi coconut marimba, a musical typewriter hitting test tubes with letter hammers, filled with various amounts of water, etc.) and they used *all* Radio Microphone channels available, so some 14 each from Sennheiser, Shure, etc.

All powered from 9V alkalines (I´m talking the late 70s to mid 90s here) which were religiously disposed of after each show, so I had TONS of lightly used (oh,some 4 hours into each one) to play with.

It was trivial to plug them into each other to get high voltages.

Not 2700V though 😱

As of ´powering Tube amps , we are going back to the early days of Electronics.

In fact, that´s where current voltage source names come from 😱

* "A" batteries were for filament, and given high consumption typically from lead-acid rechargeable cells, that´s where early 2V to 2.5V filaments come from, from a single cell, then most popular 6,3V from three cells,and some 12.6V ones from 6 cells.

Also 1.5V in portables to use light zinc-carbon cells but in general in lowish consumption tubes (or else).

* "B" batteries (we still call HV "+B" 🙂 ) were zinc carbon, 45V was very popular, many "modern" 🙄 tubes show curves for 90V +B , both because of using two 45V batteries in series, OR easy to get from 110V DC mains.

* "C" batteries were used for biasing.

Special very stable, extended life, but almost zero current available were designed for that.

Bias is often called "-C" in up to 40s and 50s schematics.

Not 2700V but 220V to 350V many many times.

One of my customers was Les Luthiers, based in Buenos Aires, famous for using WEIRD musical instruments (a ham can violin, a multi coconut marimba, a musical typewriter hitting test tubes with letter hammers, filled with various amounts of water, etc.) and they used *all* Radio Microphone channels available, so some 14 each from Sennheiser, Shure, etc.

All powered from 9V alkalines (I´m talking the late 70s to mid 90s here) which were religiously disposed of after each show, so I had TONS of lightly used (oh,some 4 hours into each one) to play with.

It was trivial to plug them into each other to get high voltages.

Not 2700V though 😱

As of ´powering Tube amps , we are going back to the early days of Electronics.

In fact, that´s where current voltage source names come from 😱

* "A" batteries were for filament, and given high consumption typically from lead-acid rechargeable cells, that´s where early 2V to 2.5V filaments come from, from a single cell, then most popular 6,3V from three cells,and some 12.6V ones from 6 cells.

Also 1.5V in portables to use light zinc-carbon cells but in general in lowish consumption tubes (or else).

* "B" batteries (we still call HV "+B" 🙂 ) were zinc carbon, 45V was very popular, many "modern" 🙄 tubes show curves for 90V +B , both because of using two 45V batteries in series, OR easy to get from 110V DC mains.

* "C" batteries were used for biasing.

Special very stable, extended life, but almost zero current available were designed for that.

Bias is often called "-C" in up to 40s and 50s schematics.

Last edited:

Thanks for the comments. It really comes down to whether any advantage over a well good regulated DC source can be had.

I think there are two factors to consider:

1. Behavior of the DC: From your comments, it looks like good regulators can be just as good. So here, the effort would not pay off.

2. Mains transformer and rectifier that we need to be running. Those can be a source of considerable source of EMF that could cause noise/hum in the amplifier. Even we manage to supply a perfectly flat B+ there is still the possibility of EMF messing things up.

(It might be that #2 is not even worth considering if we are sitting next to a power amp thats running a big mains transformer+rectifier of its own)

I think there are two factors to consider:

1. Behavior of the DC: From your comments, it looks like good regulators can be just as good. So here, the effort would not pay off.

2. Mains transformer and rectifier that we need to be running. Those can be a source of considerable source of EMF that could cause noise/hum in the amplifier. Even we manage to supply a perfectly flat B+ there is still the possibility of EMF messing things up.

(It might be that #2 is not even worth considering if we are sitting next to a power amp thats running a big mains transformer+rectifier of its own)

I made a small amplifier (for headphones or line drive) using Subminiature russian rod pentodes, which have a very low current requirement for filament and HT.

I chained together 10 PP3 batteries for 90V give or take.

It worked well enough, but I found performance better at more elevated HT, and did not relish having to chain another 10 PP3s!

Rechargeable or not, 20 PP3 get expensive (since the tubes were costing less than 1 PP3 battery to buy)

I chained together 10 PP3 batteries for 90V give or take.

It worked well enough, but I found performance better at more elevated HT, and did not relish having to chain another 10 PP3s!

Rechargeable or not, 20 PP3 get expensive (since the tubes were costing less than 1 PP3 battery to buy)

Analog Devices sells a development board for the LT3751, a high voltage photo-flash charger. It would need a maida or T-Reg follower linear regulator if you need "quiet". Patrick started a thread on it: LT3751 Driven, +/-400V Shunt Regulated Supply

Its a great thought experiment I think, but practicalities are very much against this.Hi,

I was thinking about whether it would make sense to design a power supply for plate voltage using batteries (LiIo, LiPo, LiFePo...).

I Know battery supply is a thing with solid state preamps especially high-gain phono stages. But I have not seen much in this regard with tubes.

A highly complicated BMS like this is a massive project in itself - you might require quite a costly switching fabric to do this.We could design a power supply that manages the indivudual cells in a smart way (using a micro controller) and decides which cells to charge and which cells to use for power supply. So we need to put in more cells than we need for the maximum B+ Volatge that we want so we could always re-charge some of the cells while we use the others to supply volatage. We would need to have somthing that evens out the output volatge when a re-charged cell is brought "on-line" and a discharged cell is then taken of-line for re-charging.

Things like a switch-mode boost supply with decent output filtering look pretty simple and economic by comparison!

Hi,

...45 cells would combine to

90,000 mAh and if we power 4 double-triodes that maybe draw 20 mA each those cells will last for more than 1000 hous.

Lars

Just pointing out that 45 cells in PARALLEL gives 90,000mAh at 3.6 volts; in SERIES they are 90 volts at 2000mAH.

:^)

When I first started this hobby I had thoughts of doing this with power tool batteries in a pack on the floor. Id use the tool mfg charger to recharge them every so often. Lithium batteries scare the hell out of me making my own charger. Power tool batteries have their own BMS built into each pack because of the abuse, freezing, heat, vibration, shorts, etc. Since all my tools are DeWalt Id use those batteries. There is a guy on ebay that sells 3d printed sockets for all the major power tool batteries. Just wire the sockets in series. A 6 Amp hour battery pack may go a year between charges.

Cordless Power Tool Batteries | DEWALT

Cordless Power Tool Batteries | DEWALT

Last edited:

Once I tried 32x12V lead acid battery (replaced UPS accumulators -before transporting to recycle company-) as my 300B amplifier HT.

It was the most "dead" voice that I heard. :-(

It was the most "dead" voice that I heard. :-(

I have seen rechargeable lithium 9V batteries on Amazon, but have not tried them. Some even have a USB charging port on the side.

These are actually a pair of Lithium rechargeable batteries and the output is 7.6V, not 9V.

But because they have the same form factor (PPS3) they are sold as '9V batteries'. 😡

Jan

Another thought about this... The DeWalt batteries above are 20V they also have 12V and 18V versions. 6 in series gives you 120V add the 12V = 132. The 12V tap can go to the filaments and automatically be elevated depending on the position of the 12V battery in the stack. Using 8,000 maH batteries in series it will last long before a recharge. I run my chop saw on a double 20V pair, I've trimmed out entire houses without a recharge. So a battery preamp is nowhere near this drain rate.

Last edited:

45 2000mAh Li Ion is still just 2000mAh, not 90,000mAh as you stated, this would be true only for cells in parallel. The Wh rating of this pack would be 340Wh which is substantial.

I design Lithium Ion battery packs for a living, and I'd like to discourage you from following this path, the odds of you doing this safely are not good. The BMS to manage 45 cells simultaneously would be difficult to design and test.

You would have to monitor the voltage across each cell individually, you would need to monitor cell temperatures at multiple locations during charging and discharge, you would need to use cell balancing during charge. You would need to provide protection against overcharging (OVP) which is critical, over discharge (UVP) which will shorten the cell life and may be hazardous, short circuit/over current protection (not just fuses!) and with that many cells there is always going to be risk of malfunction in a cell with potentially serious consequences.

The source impedance depending on cells would be around 700mR which is OK, but IMO not worth the effort.

You can't solder the cells, you'd need to use holders which are potentially unreliable over time. The cells have connecting straps welded to them for interconnection in all packs I have examined.

I've overseen the development of at least 8 Li packs from 1 - 8 cells at as much as 3.0Ah capacity and there are millions of these packs in use today. I have never considered designing a G job pack for a home project even though I definitely could. (I don't have the ability to self certify safety or completely assure myself that something dire couldn't go wrong.)

I haven't talked about fast charging and problems with cells at low temperatures.

It is probably not that unlikely that your home owners policy would refuse to cover the aftermath of a diy pack mishap if something were to go seriously wrong.

Take a look at what happened with the Chevy Bolt for an idea of what can happen even when people know what they are doing.

I design Lithium Ion battery packs for a living, and I'd like to discourage you from following this path, the odds of you doing this safely are not good. The BMS to manage 45 cells simultaneously would be difficult to design and test.

You would have to monitor the voltage across each cell individually, you would need to monitor cell temperatures at multiple locations during charging and discharge, you would need to use cell balancing during charge. You would need to provide protection against overcharging (OVP) which is critical, over discharge (UVP) which will shorten the cell life and may be hazardous, short circuit/over current protection (not just fuses!) and with that many cells there is always going to be risk of malfunction in a cell with potentially serious consequences.

The source impedance depending on cells would be around 700mR which is OK, but IMO not worth the effort.

You can't solder the cells, you'd need to use holders which are potentially unreliable over time. The cells have connecting straps welded to them for interconnection in all packs I have examined.

I've overseen the development of at least 8 Li packs from 1 - 8 cells at as much as 3.0Ah capacity and there are millions of these packs in use today. I have never considered designing a G job pack for a home project even though I definitely could. (I don't have the ability to self certify safety or completely assure myself that something dire couldn't go wrong.)

I haven't talked about fast charging and problems with cells at low temperatures.

It is probably not that unlikely that your home owners policy would refuse to cover the aftermath of a diy pack mishap if something were to go seriously wrong.

Take a look at what happened with the Chevy Bolt for an idea of what can happen even when people know what they are doing.

I design Lithium Ion battery packs for a living, and I'd like to discourage you from following this path, the odds of you doing this safely are not good. The BMS to manage 45 cells simultaneously would be difficult to design and test...... short circuit/over current protection (not just fuses!)

I mentioned fuses as a minimum needed just to keep your wiring from catching fire. The common 18650 cell can source 20 amps or so if shorted. It may also vent or violently decompose in the process. A lithium ion cell needs to be treated right, or it can burst into flames. A LIPO is even worse. Both use inherently unstable chemistry.

I have built a couple 18650 based battery packs for my projects using Samsung cells. The big one is a 7S2P for about 5 AH. It is current limited to 3 amps total in or out, and fused between each cell at 7 amps in case of physical damage. It goes in a portable computer.

I learned that some of the BMS and chargers found on Ebay and Amazon are junk. They will not balance the cells, and may or may not shut down when operated out of range. I did find a good one on my third try, but Amazon doesn't have it any longer. They had some BMS boards that "work with LIPO, Lithium Ion and Lithium Iron Phosphate cells." There were no jumpers since detection is "automatic." Of course they didn't work, the cell voltages are different. If you don't understand this, or don't know how to test a BMS, or completed pack, don't play with lithium.

Good points all in above ^^^ post from tubelab. Short circuit current in a typical single fully charged Samsung 20R or 25R 18650 cell is > 100A. (I've measured it) Most of my pack designs are designed for up to 20A continuous output current with "industrial cells"

The comment on BMS boards available from Amazon and eBay is on point, almost all are rubbish and are not safe.

LG, the people being sued by GM for $1.9 billion USD over battery fires in the Chevy Bolt now include warnings in their battery specifications that the industrial cells are only for sale to customers that will build them into certified packs with proper BMS and that have been approved to purchase cells from them.

I can think of many uses for diy packs here at home, and I even have the knowledge, experience and skill set to do it safely and yet I haven't despite the obvious temptation.

The comment on BMS boards available from Amazon and eBay is on point, almost all are rubbish and are not safe.

LG, the people being sued by GM for $1.9 billion USD over battery fires in the Chevy Bolt now include warnings in their battery specifications that the industrial cells are only for sale to customers that will build them into certified packs with proper BMS and that have been approved to purchase cells from them.

I can think of many uses for diy packs here at home, and I even have the knowledge, experience and skill set to do it safely and yet I haven't despite the obvious temptation.

Thanks again for all the insights. (And of course, if we put cells in series to get more voltage we cannot add up the capacity... I need to think before I type...)

Building something like this up from individuals Lithium-Whatever cells and trying to build the required management capability around that clearly seems a much too hazardous path. Just too many things that can go wrong.

We could design something around commercial battery packs (like the 20V dewalt packs mentioned) and use dedicated charging stations but that isn't really practical.

Given that weight and space are not so much constrained (we're not building a tube based mobile phone 🙂 in this hypothetical situation, one should probably look at other types of batteries that use more stable chemistry... (and are also much easier to charge and manage in general)

Building something like this up from individuals Lithium-Whatever cells and trying to build the required management capability around that clearly seems a much too hazardous path. Just too many things that can go wrong.

We could design something around commercial battery packs (like the 20V dewalt packs mentioned) and use dedicated charging stations but that isn't really practical.

Given that weight and space are not so much constrained (we're not building a tube based mobile phone 🙂 in this hypothetical situation, one should probably look at other types of batteries that use more stable chemistry... (and are also much easier to charge and manage in general)

Once I tried 32x12V lead acid battery (replaced UPS accumulators -before transporting to recycle company-) as my 300B amplifier HT.

It was the most "dead" voice that I heard. :-(

You mean it sounded "dead"? Can you elaborate? What do you think would cause that?

- Home

- Amplifiers

- Tubes / Valves

- Using batteries for plate voltage