dear experts from diyaudio,

After a long pause in speaker building I've started the design of a new speaker, I will open a separate threat for the speaker project.

At this moment in time I have some questions on how to design a throat adapter.

I bought two big old cast biradial horns, brand is unknown, size is 62x24x30cm.

These have a totally weird un-standard throat size of 41mm.

Inspired by the "Shadow of The Colossus" build thread of forum member Legis I decided to go with Faital Pro HF108 drivers, which of course have a 1" throat.

I plan to have adapters 3D printed but I'm stuck at how I should make the mechanical design.

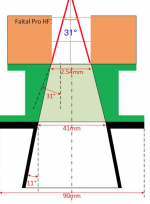

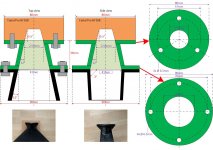

According to the datasheet of the HF108 it has an exit angle of 31 degrees.

The horn has a 13 degrees entrance angle looking from the top, and a -3 degrees entrance angle looking from the side, see the attached sketch (black = horn, green = adapter, orange = HF108).

There are several ways to design the adapter (assuming the adapter will be a simple conical design):

1 - Extend the 31 degrees of the driver to go the 41mm opening of the horn --> one sharp corner to the entrance of the horn

2 - Find some kind of average angle between the driver and the horn?? --> two corners that are less sharp.

3 - other smart idea?

3D printing would of course enable non-conical shapes but my 3D CAD skills are rather under developed 🙂

Can anybody give my some advice?

thanks, kind regards,

Peter

the Netherlands

After a long pause in speaker building I've started the design of a new speaker, I will open a separate threat for the speaker project.

At this moment in time I have some questions on how to design a throat adapter.

I bought two big old cast biradial horns, brand is unknown, size is 62x24x30cm.

These have a totally weird un-standard throat size of 41mm.

Inspired by the "Shadow of The Colossus" build thread of forum member Legis I decided to go with Faital Pro HF108 drivers, which of course have a 1" throat.

I plan to have adapters 3D printed but I'm stuck at how I should make the mechanical design.

According to the datasheet of the HF108 it has an exit angle of 31 degrees.

The horn has a 13 degrees entrance angle looking from the top, and a -3 degrees entrance angle looking from the side, see the attached sketch (black = horn, green = adapter, orange = HF108).

There are several ways to design the adapter (assuming the adapter will be a simple conical design):

1 - Extend the 31 degrees of the driver to go the 41mm opening of the horn --> one sharp corner to the entrance of the horn

2 - Find some kind of average angle between the driver and the horn?? --> two corners that are less sharp.

3 - other smart idea?

3D printing would of course enable non-conical shapes but my 3D CAD skills are rather under developed 🙂

Can anybody give my some advice?

thanks, kind regards,

Peter

the Netherlands

I don't know how great it's ever going to be with those differing angles, but it will certainly work.

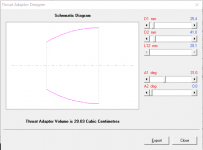

Hornresp has a throat adapter calculator that is easy to use. Have you tried that? You can specify diameters and angles.

Hornresp has a throat adapter calculator that is easy to use. Have you tried that? You can specify diameters and angles.

Just do the best you can, maybe try a couple of your options.

A radial horn isn't going to fit a round compression driver properly. The designers of this one decided to pinch the throat to make it work (probably also following an expansion target). So there is no correct option to begin with.

A radial horn isn't going to fit a round compression driver properly. The designers of this one decided to pinch the throat to make it work (probably also following an expansion target). So there is no correct option to begin with.

Yep, what Allen said.

Since you provided all the dimensions I'll finish my coffee and run the adapter wizard in Hornresp.

Since you provided all the dimensions I'll finish my coffee and run the adapter wizard in Hornresp.

Here you go. I've done both top and side views, as they are different. Obviously one is longer than the other, because of the exit angles. So as Allen said, you just have to do the best you can. I hope that these will be of some help.

Attachments

Maybe try doing like Altec did for the 5/811; severely 'pinch' it, then rapid flare to conical with it + driver conical 'pushing' its HF corner pattern control lower.

IMHO + (IME ) this "custom" adapter thing is really being over-thought ( + for no known benefit ).

FYI, I consistently get good imaging ( + loading ) from radials ( like the Emilar EH500 or NorthWest 340 ) when mated to an Altec 288 with a 1.4"-2" straight ( conical ) adapter .

- Both horns mentioned have a quick 2" entrance into the bell.

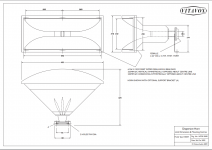

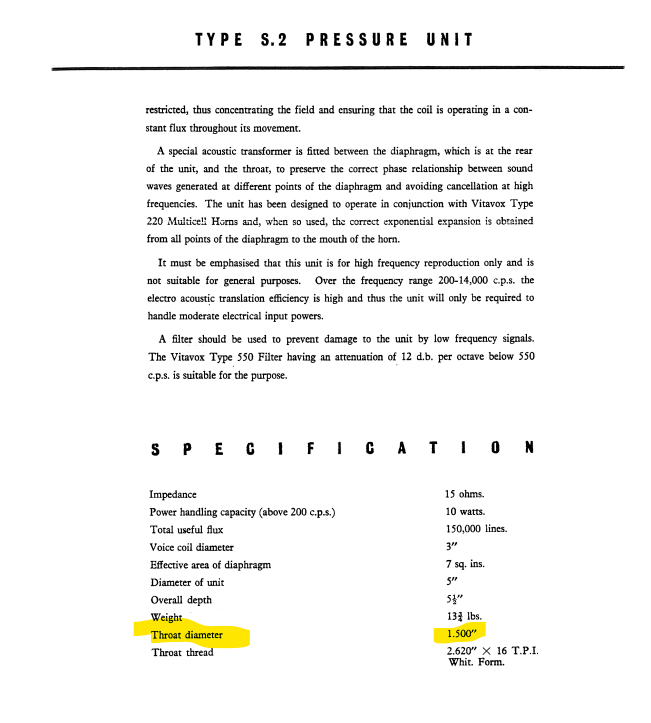

The original driver for the horn in question is the VitaVox S2.

The S2 has a throat exit of 1.5" // 38.1mm ( reduced from a 3" diaphragm, just like the earlier JBL Vertec drivers ) .

Personally, I suspect the OP has measured a really early example that's sporting a very "rough" casting. There were a handful of different castings made for this horn over the years.

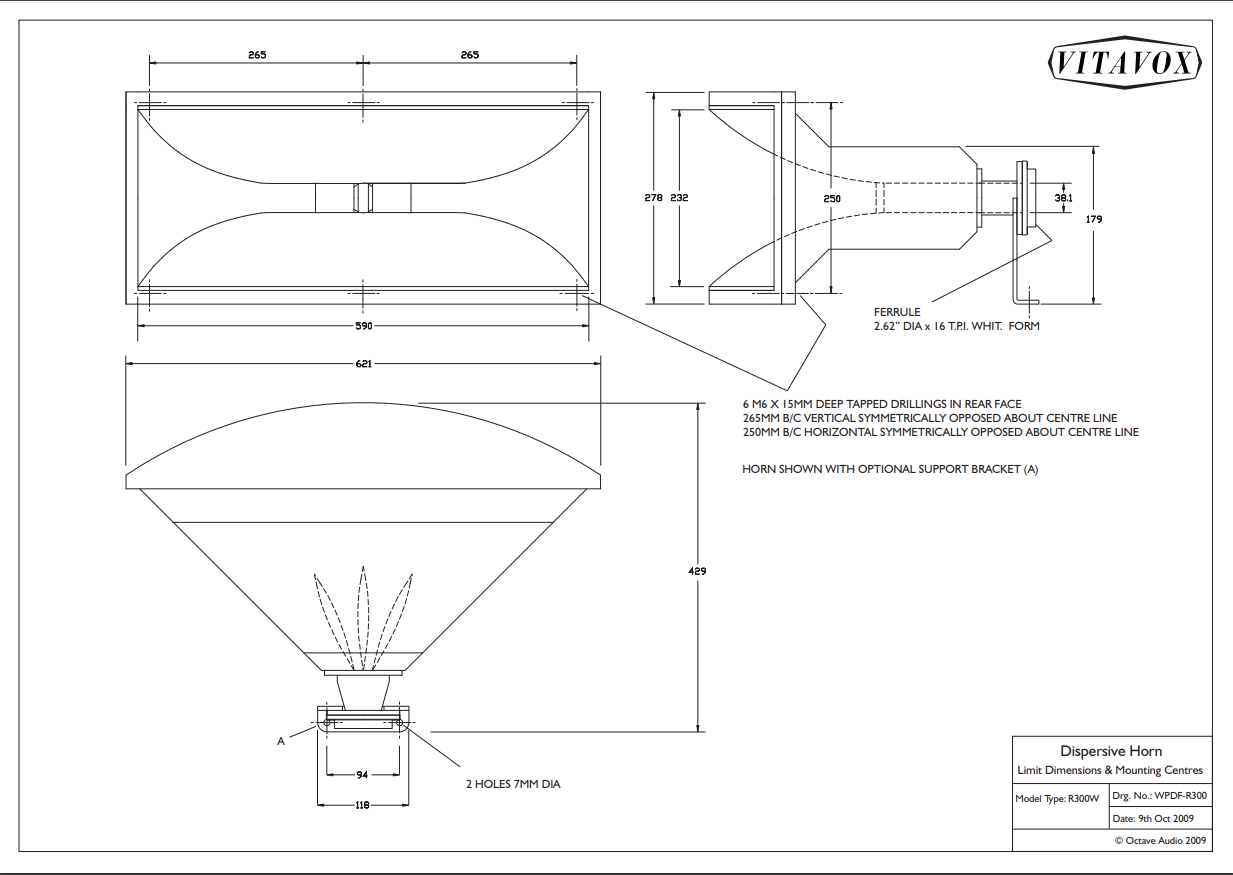

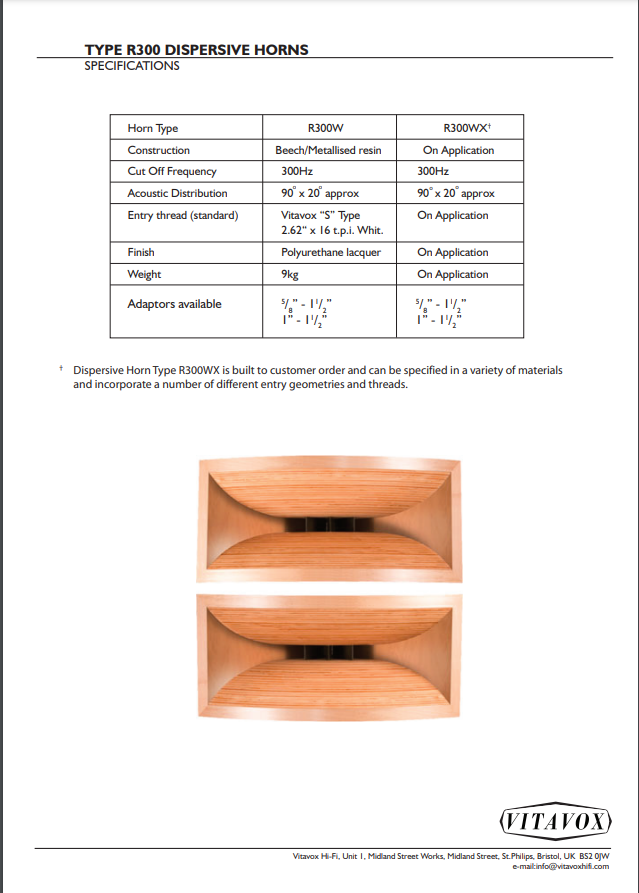

Here's a look at the modern VitaVox ( wooden ) version of that horn ( also meant to mate with an S2 ).

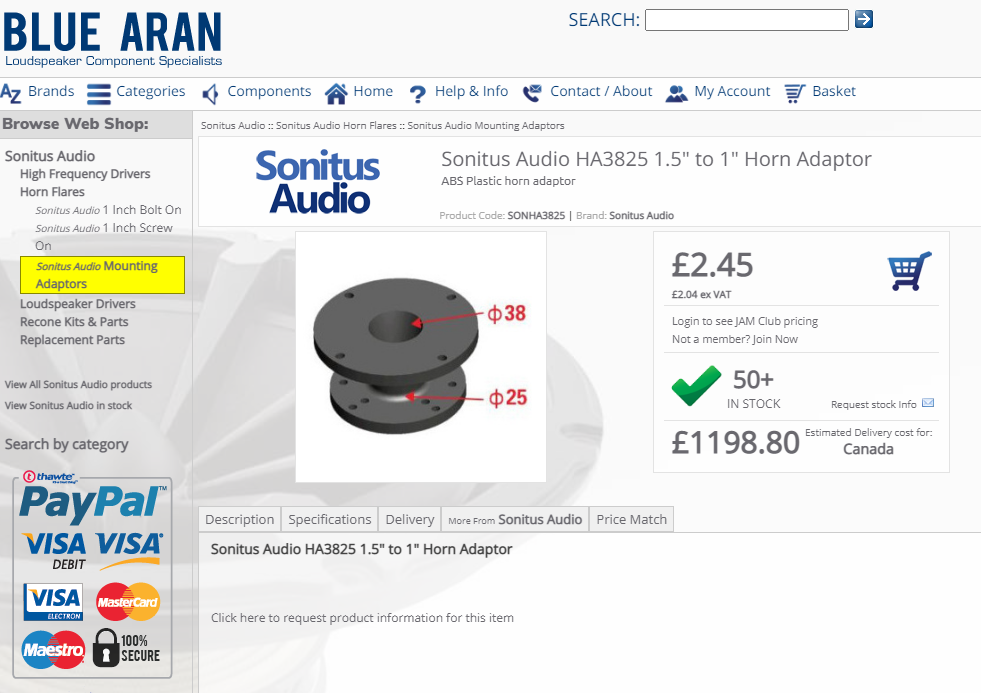

No matter, I would simply buy a 1" to 1.5" diameter adapter ( P-Audio PC-3825 used to make one ) and then add an enlargement spacer//washer to go from 38.1mm to 40 mm ( if it's necessary ). That spacer would be a breeze to design & print.

I have quite a few pics of these radials ( collected over the last 20 years of eBay sales ) and I don't see within any of them a horn-bell squeeze ( such is found in the Emilar EH500 radial ) .

- IOW, they all look like somewhat primitive examples//inspirations for the TAD TH4001.

🙂

FYI, I consistently get good imaging ( + loading ) from radials ( like the Emilar EH500 or NorthWest 340 ) when mated to an Altec 288 with a 1.4"-2" straight ( conical ) adapter .

- Both horns mentioned have a quick 2" entrance into the bell.

The original driver for the horn in question is the VitaVox S2.

The S2 has a throat exit of 1.5" // 38.1mm ( reduced from a 3" diaphragm, just like the earlier JBL Vertec drivers ) .

Personally, I suspect the OP has measured a really early example that's sporting a very "rough" casting. There were a handful of different castings made for this horn over the years.

Here's a look at the modern VitaVox ( wooden ) version of that horn ( also meant to mate with an S2 ).

No matter, I would simply buy a 1" to 1.5" diameter adapter ( P-Audio PC-3825 used to make one ) and then add an enlargement spacer//washer to go from 38.1mm to 40 mm ( if it's necessary ). That spacer would be a breeze to design & print.

I have quite a few pics of these radials ( collected over the last 20 years of eBay sales ) and I don't see within any of them a horn-bell squeeze ( such is found in the Emilar EH500 radial ) .

- IOW, they all look like somewhat primitive examples//inspirations for the TAD TH4001.

🙂

Attachments

Last edited:

hi guys,

Thanks for the advice, especially Pano for running the hornresp tool.

I didn't know hornresp has this tool, I will download it and play a bit with it myself.

It's obvious there is no perfect adapter for this situation. I will think about it a bit more and then make a first prototype and measure the response.

I will post my results, can take same time 🙂

Kind regards, Peter

Thanks for the advice, especially Pano for running the hornresp tool.

I didn't know hornresp has this tool, I will download it and play a bit with it myself.

It's obvious there is no perfect adapter for this situation. I will think about it a bit more and then make a first prototype and measure the response.

I will post my results, can take same time 🙂

Kind regards, Peter

IMHO + (IME ) this "custom" adapter thing is really being over-thought ( + for no known benefit ).

The main reason is to minimize reflections back to the driver throat, which has been known to make for a [much] smoother HF response, which may/may not be audible due to the usual caveats. 🙁

Peter,hi guys,

Thanks for the advice, especially Pano for running the hornresp tool.

I didn't know hornresp has this tool, I will download it and play a bit with it myself.

It's obvious there is no perfect adapter for this situation. I will think about it a bit more and then make a first prototype and measure the response.

I will post my results, can take same time 🙂

To minimize reflections back to the driver throat, I would advise against a parabolic throat adapter as Pano depicted in post #4, and would go with EarlK's advice, using a conical adapter.

Also, a 31 degree throat angle is total, each side 15.5 degrees, close to the 11 degree horn diffraction throat casting horizontal angle- assuming you measured that angle correctly 😉

Cheers,

Art

Attachments

Yeah, I wondered about that 31 degrees as it seems very wide.

But running the sim was interesting because it showed me different the two profiles are. It does seem that just a conical is going to be the best bet.

I can vouch for HF problems if the adapter is weird. I had to use a 1.4" to 2" backward to get a 2" driver onto a 1.4" horn. Sure does kill the high end.

But running the sim was interesting because it showed me different the two profiles are. It does seem that just a conical is going to be the best bet.

I can vouch for HF problems if the adapter is weird. I had to use a 1.4" to 2" backward to get a 2" driver onto a 1.4" horn. Sure does kill the high end.

Peter,

Here's a plastic adapter piece that'll get you started ( + should save you a bunch of sanding time ). You'll still need to make the final 38mm to 41mm spacer.

Taking response measurements as you go along is key here ( to learning how much effort to put into this custom-design project ).

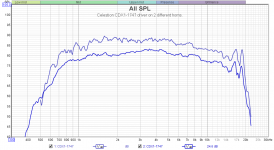

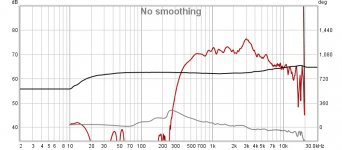

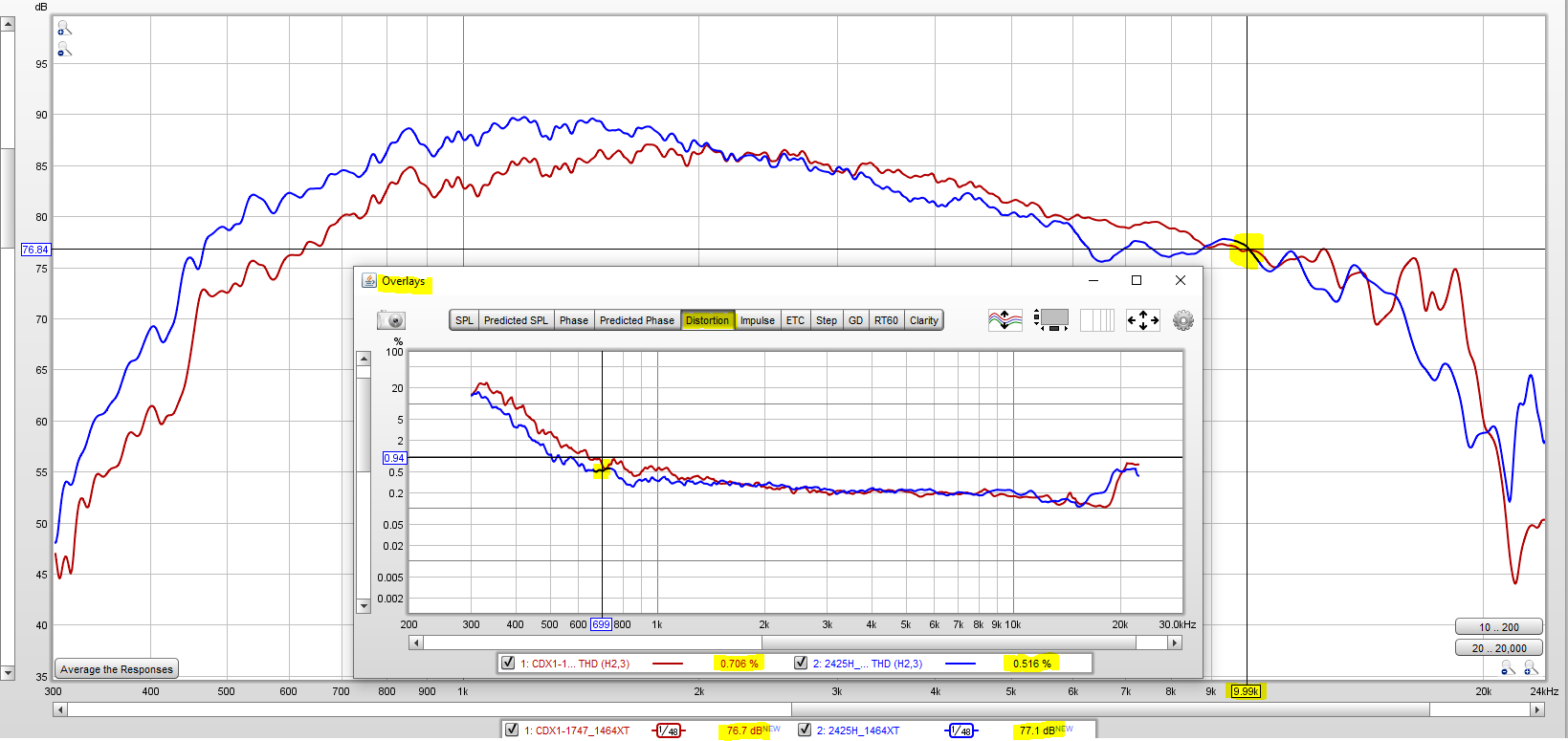

Here's a comparison of two (1" exit ) drivers mounted onto an 18-Sound XT1464 with an Eminence HA1-14 adapter. Both drivers will have mis-matched flair rates between their exits > adapter > horn entrance .

🙂

With enough study of the squiggles one will eventually see that the horn dominates the FR curve, along with the drivers response ( notice how the tiny ripples match-up to each other ) .

- HF reflections from flare rate mismatches are all over 10K here and become near impossible to identify when compared to the drivers own rough response up there.

A bit more opinion on the subject ;

Mismatched Horn Throats 2 CD Exits

🙂

PS; please choose the curve that has the Eminence HA1-14 involved.

Here's a plastic adapter piece that'll get you started ( + should save you a bunch of sanding time ). You'll still need to make the final 38mm to 41mm spacer.

Taking response measurements as you go along is key here ( to learning how much effort to put into this custom-design project ).

Here's a comparison of two (1" exit ) drivers mounted onto an 18-Sound XT1464 with an Eminence HA1-14 adapter. Both drivers will have mis-matched flair rates between their exits > adapter > horn entrance .

🙂

With enough study of the squiggles one will eventually see that the horn dominates the FR curve, along with the drivers response ( notice how the tiny ripples match-up to each other ) .

- HF reflections from flare rate mismatches are all over 10K here and become near impossible to identify when compared to the drivers own rough response up there.

A bit more opinion on the subject ;

Mismatched Horn Throats 2 CD Exits

🙂

PS; please choose the curve that has the Eminence HA1-14 involved.

Attachments

Peter,

To minimize reflections back to the driver throat, I would advise against a parabolic throat adapter as Pano depicted in post #4, and would go with EarlK's advice, using a conical adapter.

Also, a 31 degree throat angle is total, each side 15.5 degrees, close to the 11 degree horn diffraction throat casting horizontal angle- assuming you measured that angle correctly 😉

Cheers,

Art

hi Art,

Thank you very much, I wondered about the 31 degrees myself because it didn't look that wide too me, forgot to add this question to my first email.

Conical seems the way to go!

kind regards, Peter

Peter,

Here's a plastic adapter piece that'll get you started ( + should save you a bunch of sanding time ). You'll still need to make the final 38mm to 41mm spacer.

Taking response measurements as you go along is key here ( to learning how much effort to put into this custom-design project ).

Here's a comparison of two (1" exit ) drivers mounted onto an 18-Sound XT1464 with an Eminence HA1-14 adapter. Both drivers will have mis-matched flair rates between their exits > adapter > horn entrance .

🙂

With enough study of the squiggles one will eventually see that the horn dominates the FR curve, along with the drivers response ( notice how the tiny ripples match-up to each other ) .

- HF reflections from flare rate mismatches are all over 10K here and become near impossible to identify when compared to the drivers own rough response up there.

A bit more opinion on the subject ;

Mismatched Horn Throats 2 CD Exits

🙂

PS; please choose the curve that has the Eminence HA1-14 involved.

Thanks Earl,

The adapter you mention is difficult to get in Netherlands/Europe, I did find a Eminence 1"-1.4" adapter which is a good alternative.

I will first get a quote for a 3D printed adapter, one transition less, and less work for me.

kind regards, Peter

Thanks for all the responses!

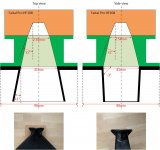

I re-measured the entrance angle of the horn, it's closer to 12 degrees instead of my earlier 11 degrees.

Plan is to make the adapter 12 degrees also, this will position the 15.5-->12 degrees edge at the driver, pushing the possible effects to higher frequency range, is my theory correct?

I will ask for a quote for 3D printed adapters, if it's somewhat acceptable I will go this route. If not Earl's idea with the HA114 and a additional filler ring might be the second best option.

kind regards, Peter

I re-measured the entrance angle of the horn, it's closer to 12 degrees instead of my earlier 11 degrees.

Plan is to make the adapter 12 degrees also, this will position the 15.5-->12 degrees edge at the driver, pushing the possible effects to higher frequency range, is my theory correct?

I will ask for a quote for 3D printed adapters, if it's somewhat acceptable I will go this route. If not Earl's idea with the HA114 and a additional filler ring might be the second best option.

kind regards, Peter

Attachments

Peter,I re-measured the entrance angle of the horn, it's closer to 12 degrees instead of my earlier 11 degrees.

Plan is to make the adapter 12 degrees also, this will position the 15.5-->12 degrees edge at the driver, pushing the possible effects to higher frequency range, is my theory correct?

I will ask for a quote for 3D printed adapters, if it's somewhat acceptable I will go this route. If not Earl's idea with the HA114 and a additional filler ring might be the second best option.

The small angle difference effects will be very high frequency regardless of which end of the adapter they are on.

If you are going to make the adapter, match the driver angle, the area where no transition must (has to) occur.

Whether you use the Eminence 1"-1.4" adapter with a filler ring, or make one from scratch, first attach the adapter to the horn, file the transition area smooth, then paint, then attach the driver.

Actually, before the above make sure the driver end lines up perfectly- I have had to re-drill bolt holes on both ends of some adapters to allow them to fit properly..

The rest of the throat casting looks like it could benefit from smoothing too.

There is science in horn and throat design, but what you are doing is more plumbing- make sure the flow is smooth and there will be less "gurgling".

Art

Attachments

Last edited:

Pffttt! Easy when you got from small driver to larger horn throat. Try that backwards and let's see what you get. 😀PS; please choose the curve that has the Eminence HA1-14 involved.

Update, adapters have been printed, horn throats epoxied and filed into shape, horns spray painted and damped.

Attachments

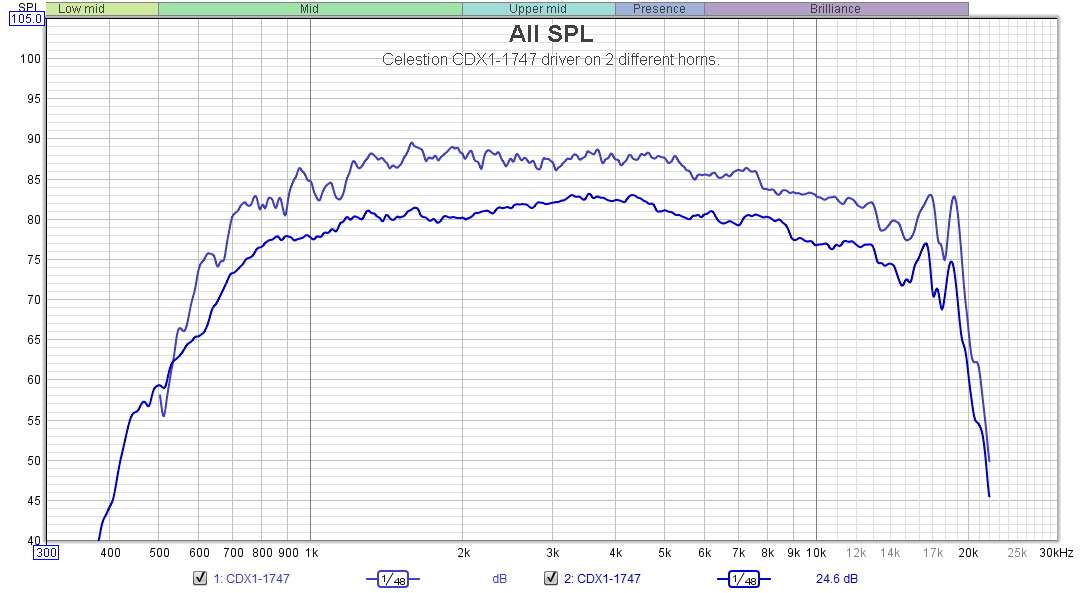

Below is the measured response, not really flat but it looks usable with some dsp, response drops around 500Hz.

More measurements of the complete speaker in the other thread: New project: 15PR400+HF108+BigOldRadial+HypexFA123

kind regards, Peter

More measurements of the complete speaker in the other thread: New project: 15PR400+HF108+BigOldRadial+HypexFA123

kind regards, Peter

Attachments

- Home

- Loudspeakers

- Multi-Way

- Need help with designing a throat adapter for HF108 to big old Vitavox(?) biradial