My next project was in building an over the top (bordering silly) big P/S to run a Hafler 500/600 modeled amp and eventually use the Exicon T0-264 dual die MOSFETS or possibly 2 pairs per chassis, of Hypex UCD 400/700 or ICE500/1000a power modules to build mono blocks for bi-amping my Maggies. A whole other post and topic [later this year]

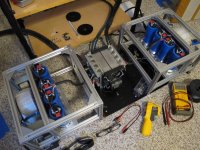

I chose to layout the amps differently due to using a larger 1000va toroid and the huge United Chemi Con electrolytics. This supply will drive the "Hafler 500 or 600" with great reserve and will (eventually) easily have dual amplifier modules per chassis. At this point I still consider these proof of concept builds... as I am experimenting with parts and wiring layout. I have listened to the 500 heatsink with Musical Concepts PA7 driver boards for about 3 weeks and am very happy with results, it is amazing. *I chose these large 39,000 mfd caps, in that *IF* I did not like the result, I could repurpose them in a "stock chassis" of a 500 or 600 amp...

In the meantime, while I re-built the chassis pan of my XL600, using Cardas RCAs and 5 way binding posts, along with heavier gauge wiring, cleaned up the AC wiring layout and installed an IEC jack. I stripped the amp down exactly like the 500 to keep everything the same... for easy comparison. Right now the XL600 is powered by the Franken'Amp CLC supplies... I have only taken a few pictures... too busy listening. This 3 piece Franken' amp is a monster, frankly I am nearly surprised I have not popped fuses in the Maggies, not by abuse or clipping... simply putting humongous amounts of power into them. I never heard any Maggies or my Maggies play like this... I doubt the I would ever need a subwoofer... they do ~ big ~ tight ~ bass. This amp configuration exerts incredible bass control over the panels...

The vertical layout created room for the audio circuit (in the back 1/3 of the amps) and I was feeling driven to isolate the magnetics of the toroid and inductors from the audio circuitry... I pondered the parts in various layouts for over a month and finally resolved all of my goals with this layout. I wanted to keep the wiring paths short, symmetrical and tidy [rats nests make me crazy] not judging anyone else's work, I am my own worst critic.

This power supply driving "Hafler 500 and 600" has ridiculous clarity, sense of finesse and effortless ease. The Macro and micro dynamics are unparalleled, compared to any amp that I have built in 40 years...

My reference for sound has been the Futterman OTL4 sitting in the middle of the frame... I have only powered it up ~once~ the past 2 months of being blown away by the CLC designs. I wish my OTL tube amps could play like these... there are ways that I prefer the solid state (yes, I said that).

I chose to layout the amps differently due to using a larger 1000va toroid and the huge United Chemi Con electrolytics. This supply will drive the "Hafler 500 or 600" with great reserve and will (eventually) easily have dual amplifier modules per chassis. At this point I still consider these proof of concept builds... as I am experimenting with parts and wiring layout. I have listened to the 500 heatsink with Musical Concepts PA7 driver boards for about 3 weeks and am very happy with results, it is amazing. *I chose these large 39,000 mfd caps, in that *IF* I did not like the result, I could repurpose them in a "stock chassis" of a 500 or 600 amp...

In the meantime, while I re-built the chassis pan of my XL600, using Cardas RCAs and 5 way binding posts, along with heavier gauge wiring, cleaned up the AC wiring layout and installed an IEC jack. I stripped the amp down exactly like the 500 to keep everything the same... for easy comparison. Right now the XL600 is powered by the Franken'Amp CLC supplies... I have only taken a few pictures... too busy listening. This 3 piece Franken' amp is a monster, frankly I am nearly surprised I have not popped fuses in the Maggies, not by abuse or clipping... simply putting humongous amounts of power into them. I never heard any Maggies or my Maggies play like this... I doubt the I would ever need a subwoofer... they do ~ big ~ tight ~ bass. This amp configuration exerts incredible bass control over the panels...

The vertical layout created room for the audio circuit (in the back 1/3 of the amps) and I was feeling driven to isolate the magnetics of the toroid and inductors from the audio circuitry... I pondered the parts in various layouts for over a month and finally resolved all of my goals with this layout. I wanted to keep the wiring paths short, symmetrical and tidy [rats nests make me crazy] not judging anyone else's work, I am my own worst critic.

This power supply driving "Hafler 500 and 600" has ridiculous clarity, sense of finesse and effortless ease. The Macro and micro dynamics are unparalleled, compared to any amp that I have built in 40 years...

My reference for sound has been the Futterman OTL4 sitting in the middle of the frame... I have only powered it up ~once~ the past 2 months of being blown away by the CLC designs. I wish my OTL tube amps could play like these... there are ways that I prefer the solid state (yes, I said that).

Attachments

An Exicon MOSFET based amp is next

I chose to associate this post with the CLC supply commentary, as the comparison of the CLC 500 Franken'amp and the Exicon 500 I just rebuilt for a friend was a complete surprise. I only had a few days to test and listen to his amp. I am rebuilding the other 500, part of the abused pair of my buddies that both had blown output transistors... these are the first Hafler amps that I have ever touched (in 40 years) of working on, that had blown output devices. In the 80's I used to sell DH500s to customers that would blow up any amps we sold them... They never came back in for repairs.

These DH500 mono amps were purchased from another friend that had them bridged, running a 2ohm subwoofer stack... UNBELIEVABLE... 10 amp slow blow! fuses on the B+ rails, and 30 amp slow blow! fuses in the speaker "protection" gave indication of what was 'done to' these amps, they were a mess... I digress...

The Exicon fitted amp exceeded the power and control (of the Franken'amp powered vintage Hitachi MOSFET amp) you could clearly hear the power and authority and even see the differences in cone movement / excursion in my test speakers. When I hooked it up to the Maggies, my mind was blown. It had a greater sense of power and authority than even the Franken'amp.

The Hafler 500 had stock heatsinks, with Exicon MOSFETS, Musical Concepts PA4 driver cards, dual toroids, dual HEXFREDS and 4 of the big United Chemi Con caps. Very beefy compared to stock... Its power supply was able to deliver on the power of the dual die Exicons... Needless to say I am building another one exactly like this one, as shown. But, I will first power with the CLC supplies, compare and contrast to the stock Hitachi MOSFETS.

My dilemma is whether to use (older) PA4 boards that sounded so good in my buddies amp, the top amp, as shown, or to use the newer PA7... I want to build exactly like his... the output module sit on my workbench while I make up my mind. Meanwhile I am listening to the XL600, which is at home (and shall remain for a wile) while I re-build the next Exicon powered 500. There is a linear path to my madness, it is all good...

I really want to put Exicons in the XL600... (another post and story, I dream)

I think that (stock 600) is a notch above the Excion 500 amp (as shown), but the jury is still out... Time will tell...

I chose to associate this post with the CLC supply commentary, as the comparison of the CLC 500 Franken'amp and the Exicon 500 I just rebuilt for a friend was a complete surprise. I only had a few days to test and listen to his amp. I am rebuilding the other 500, part of the abused pair of my buddies that both had blown output transistors... these are the first Hafler amps that I have ever touched (in 40 years) of working on, that had blown output devices. In the 80's I used to sell DH500s to customers that would blow up any amps we sold them... They never came back in for repairs.

These DH500 mono amps were purchased from another friend that had them bridged, running a 2ohm subwoofer stack... UNBELIEVABLE... 10 amp slow blow! fuses on the B+ rails, and 30 amp slow blow! fuses in the speaker "protection" gave indication of what was 'done to' these amps, they were a mess... I digress...

The Exicon fitted amp exceeded the power and control (of the Franken'amp powered vintage Hitachi MOSFET amp) you could clearly hear the power and authority and even see the differences in cone movement / excursion in my test speakers. When I hooked it up to the Maggies, my mind was blown. It had a greater sense of power and authority than even the Franken'amp.

The Hafler 500 had stock heatsinks, with Exicon MOSFETS, Musical Concepts PA4 driver cards, dual toroids, dual HEXFREDS and 4 of the big United Chemi Con caps. Very beefy compared to stock... Its power supply was able to deliver on the power of the dual die Exicons... Needless to say I am building another one exactly like this one, as shown. But, I will first power with the CLC supplies, compare and contrast to the stock Hitachi MOSFETS.

My dilemma is whether to use (older) PA4 boards that sounded so good in my buddies amp, the top amp, as shown, or to use the newer PA7... I want to build exactly like his... the output module sit on my workbench while I make up my mind. Meanwhile I am listening to the XL600, which is at home (and shall remain for a wile) while I re-build the next Exicon powered 500. There is a linear path to my madness, it is all good...

I really want to put Exicons in the XL600... (another post and story, I dream)

I think that (stock 600) is a notch above the Excion 500 amp (as shown), but the jury is still out... Time will tell...

Attachments

Thermal coupling options

Thanks von Ah. I used the Bergquist Sil-Pads SP600-05, part number BER100-ND, purchased from Digi-Key as well. Yes, I happy with them...

I have been going a little crazy with a Fluke I/R thermometer measuring and trying to wrap my mind around the temperature gradients among the output devices... output devices coupled to the heatsink... and the temperatures across the entire heatsink. There appears to be greater variation than I would like and it makes me question the thermal coupling of the outputs to the heatsink... to early to say... too much on my mind...

I just got the I/R device, so it is new to me. I am trying to establish some sort of baseline. We for the most part "know what to expect" of MICA and Silicone for therm-coupling. But the properties of the Sil-Pads are new to me... I had an engineer buddy / mentor of mine highly recommend them and frankly, I am tired of the silicone mess... As you said it was easy and straight forward...

Nice looking build! What TO3 insulator pads did you use? Are you pleased with them?

I used these in my DH-220 rebuild with Exicons:

T-500

They've been working fine and were of course a breeze to use.

Thanks von Ah. I used the Bergquist Sil-Pads SP600-05, part number BER100-ND, purchased from Digi-Key as well. Yes, I happy with them...

I have been going a little crazy with a Fluke I/R thermometer measuring and trying to wrap my mind around the temperature gradients among the output devices... output devices coupled to the heatsink... and the temperatures across the entire heatsink. There appears to be greater variation than I would like and it makes me question the thermal coupling of the outputs to the heatsink... to early to say... too much on my mind...

I just got the I/R device, so it is new to me. I am trying to establish some sort of baseline. We for the most part "know what to expect" of MICA and Silicone for therm-coupling. But the properties of the Sil-Pads are new to me... I had an engineer buddy / mentor of mine highly recommend them and frankly, I am tired of the silicone mess... As you said it was easy and straight forward...

Admittedly, a little "over built"

I built them to be able to use any power amp combinations imaginable... and I simply wanted to try this exact parts combination...

These power supplies are loafing... transformers barely get warm, run about 85F, the 68 amp / 600 volt HEXFRED rectifiers (part number VBE55-06NO7-ND) are running a 76F.

I am tempted to try some of the 800va Anteks in another build... though I already another pair of the 1000va toroids from my 3rd pair of chassis, to be used with the 100v / 22,000mfd Mundorfs (a project that's a few weeks out)

Truth be told... (mainly) this Goldmund Telos 5500 (left image) was stuck in my head...

The Mark Levinson No. 33 (right image) both having massive power supplies.

*this audio obsession thing...

Those things would put most arc welders to shame, love it 🙂

I built them to be able to use any power amp combinations imaginable... and I simply wanted to try this exact parts combination...

These power supplies are loafing... transformers barely get warm, run about 85F, the 68 amp / 600 volt HEXFRED rectifiers (part number VBE55-06NO7-ND) are running a 76F.

I am tempted to try some of the 800va Anteks in another build... though I already another pair of the 1000va toroids from my 3rd pair of chassis, to be used with the 100v / 22,000mfd Mundorfs (a project that's a few weeks out)

Truth be told... (mainly) this Goldmund Telos 5500 (left image) was stuck in my head...

The Mark Levinson No. 33 (right image) both having massive power supplies.

*this audio obsession thing...

Attachments

The work continues... (XL600 tested)

I finally had an opportunity to experience the "XL600" 16 output power module on the CLC power supplies... It is astoundingly powerful, refined with incredible finesse and sense of power. I drove the Maggies in ways that I have never heard from them.

The classic *bang - blur* fast leading edge, slow trailing edge, (to me) typical of Magnepan's even on world class, monster power amps... was virtually absent. The sound of the 600 power module, driven by Franken-amp CLC power supply transformed the nature of the "XL600" and the Maggies... I struggled to take it out of the circuit ~ to hear the "DH500" power module with the Exicon MOSFETS.

The improvements and refinement continues in a very linear and meaningful ways... AS WE KNOW ~ THE AMP IS THE POWER SUPPLY ~ it's abilities and/or limitations... The beefy supply helps to better hear the refinements in the amp module (the circuit) and the better circuit helps to better understand the improvements in the power supply. The lens of truth and understanding lays everything out very clearly.

Going step, by step through the various build stages of the power module... without limitations of the power supply (unregulated power supply sag) noise, etc., has been vital to linear understanding.

The DH500 shown, in the foreground now gets converted "back to normal" with integrated internal power supply after experimenting with the CLC supply.

~ to be continued ~

I finally had an opportunity to experience the "XL600" 16 output power module on the CLC power supplies... It is astoundingly powerful, refined with incredible finesse and sense of power. I drove the Maggies in ways that I have never heard from them.

The classic *bang - blur* fast leading edge, slow trailing edge, (to me) typical of Magnepan's even on world class, monster power amps... was virtually absent. The sound of the 600 power module, driven by Franken-amp CLC power supply transformed the nature of the "XL600" and the Maggies... I struggled to take it out of the circuit ~ to hear the "DH500" power module with the Exicon MOSFETS.

The improvements and refinement continues in a very linear and meaningful ways... AS WE KNOW ~ THE AMP IS THE POWER SUPPLY ~ it's abilities and/or limitations... The beefy supply helps to better hear the refinements in the amp module (the circuit) and the better circuit helps to better understand the improvements in the power supply. The lens of truth and understanding lays everything out very clearly.

Going step, by step through the various build stages of the power module... without limitations of the power supply (unregulated power supply sag) noise, etc., has been vital to linear understanding.

The DH500 shown, in the foreground now gets converted "back to normal" with integrated internal power supply after experimenting with the CLC supply.

~ to be continued ~

Attachments

The Exicon's tested with CLC supply.

I have got to say, I am astounded by the attributes of the Exicon MOSFETS with Musical Concepts PA-7 driver card... driven by the Franken'amp CLC power supply. [I think] that it outperforms the XL600 power module with PA-7 and stock Hitachi MOSFETS. It is still early to make that comparison...

This is the best that I have ever heard my Magnepans sound... Among the best I have ever heard *any* Magnepans ~ ever sound ~ The classic panel / diaphragm "coloration" in the upper mid-range and mid-range is gone... The Franken'amp exerts such incredible control over the speakers, they are tighter than tight, have the cone driver speed and neutrality, without any enclosure sound and will play super loud... it is nearly scary...

(Image 2) I built the loading around the Exicons a little differently than any amp that I have done prior, based on numerous conversations with John Hillig (of Musical Concepts) and to contrast the performance to the 'other' Exicon equipped DH500, I just built and tested for a buddy... I hated to give it up...

It took me (several months) reasoning this layout, which was 3 layered layered and congested, along with retaining 220 mfd caps, I had to do it in a way to work with existing component lead lengths, 3 pieces were a real challenge (getting them to reach) I had to use a 5 lug terminal strip to help and to segregate the devices with Teflon tubes to limit contact with critical parts ~and~ then make sure and trim several through hole component leads on the bottom of the driver PCB, checking for clearance. As simple as it looks, it was a real challenge to do correctly. Sensibly. Safely.

It was one of those... It took me 4.5 hours to wire this up. 3.5 on the first heatsink and 1 hour on the 2nd (after I figured it out) Now the challenge will be remembering (all this) for the next 500 chassis that I do. I like adding the source resistors... the result in a simple word / expression ~ refinement ~ greater clarity in complex musical passages... of extreme listening levels and transients. Improvements in macro and micro detail...

It (admittedly) has been dizzying to try the many comparisons all using or involving the CLC supply as the basis for the best possible performance model or as my reference...

~ more to come ~

I have got to say, I am astounded by the attributes of the Exicon MOSFETS with Musical Concepts PA-7 driver card... driven by the Franken'amp CLC power supply. [I think] that it outperforms the XL600 power module with PA-7 and stock Hitachi MOSFETS. It is still early to make that comparison...

This is the best that I have ever heard my Magnepans sound... Among the best I have ever heard *any* Magnepans ~ ever sound ~ The classic panel / diaphragm "coloration" in the upper mid-range and mid-range is gone... The Franken'amp exerts such incredible control over the speakers, they are tighter than tight, have the cone driver speed and neutrality, without any enclosure sound and will play super loud... it is nearly scary...

(Image 2) I built the loading around the Exicons a little differently than any amp that I have done prior, based on numerous conversations with John Hillig (of Musical Concepts) and to contrast the performance to the 'other' Exicon equipped DH500, I just built and tested for a buddy... I hated to give it up...

It took me (several months) reasoning this layout, which was 3 layered layered and congested, along with retaining 220 mfd caps, I had to do it in a way to work with existing component lead lengths, 3 pieces were a real challenge (getting them to reach) I had to use a 5 lug terminal strip to help and to segregate the devices with Teflon tubes to limit contact with critical parts ~and~ then make sure and trim several through hole component leads on the bottom of the driver PCB, checking for clearance. As simple as it looks, it was a real challenge to do correctly. Sensibly. Safely.

It was one of those... It took me 4.5 hours to wire this up. 3.5 on the first heatsink and 1 hour on the 2nd (after I figured it out) Now the challenge will be remembering (all this) for the next 500 chassis that I do. I like adding the source resistors... the result in a simple word / expression ~ refinement ~ greater clarity in complex musical passages... of extreme listening levels and transients. Improvements in macro and micro detail...

It (admittedly) has been dizzying to try the many comparisons all using or involving the CLC supply as the basis for the best possible performance model or as my reference...

~ more to come ~

Attachments

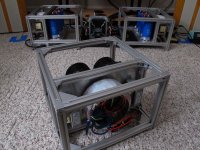

Building the 3rd CLC chassis

I had to try this CLC supply using the exemplary $$$$! Mundorf MLyticHC caps, they are such incredible components. About 4 times the cost and ~1/2 of the capacitance (88,000 -vs- 156,000 per side) compared to "the other" CLC supply... I have said it elsewhere / before ~ they are a break-through ~ in performance, in 4 other amps that I have built and tested, using them... We will see.

The Mundorfs are much larger, which required a different chassis layout to fit them and to get the lead lengths of the toroid and the inductors to reach. I wanted to retain the magnetic isolation of prior build, with the transformers in the front of the chassis. I still have 1/3 of the rear of the chassis to place the driver board and heatsinks, that will eventually be used (in place of the "Hafler" power modules.

I wanted a sound comparison of United Chemi Con caps and the Mundorfs to determine which I will use in my final amps design / build. I have included the commentary about various power amp configurations that I have used so far to test these Power Supplies... as a very critical part of the overall equation

I have been starring at the 3rd supply trying to reason how I want to wire it. I am very happy with the UCC capped supply... but there is not way to duplicate it with this layout, everything is different, even with 2 inches of additional (interior) chassis height... I am still somehow a bit cramped.

The massive - fat caps dictated many layout options, working with inductor lead lengths and a tidy ground buss / ground set-up... Still working to figure it out... Mean-while the UCC franken'amp is serving well with the Maggies and I have "a spare" 500 and 600 heat-sink assembly to work on... I am *completely* rebuilding the chassis pans on both amps...

~ decisions - decisions ~

I had to try this CLC supply using the exemplary $$$$! Mundorf MLyticHC caps, they are such incredible components. About 4 times the cost and ~1/2 of the capacitance (88,000 -vs- 156,000 per side) compared to "the other" CLC supply... I have said it elsewhere / before ~ they are a break-through ~ in performance, in 4 other amps that I have built and tested, using them... We will see.

The Mundorfs are much larger, which required a different chassis layout to fit them and to get the lead lengths of the toroid and the inductors to reach. I wanted to retain the magnetic isolation of prior build, with the transformers in the front of the chassis. I still have 1/3 of the rear of the chassis to place the driver board and heatsinks, that will eventually be used (in place of the "Hafler" power modules.

I wanted a sound comparison of United Chemi Con caps and the Mundorfs to determine which I will use in my final amps design / build. I have included the commentary about various power amp configurations that I have used so far to test these Power Supplies... as a very critical part of the overall equation

I have been starring at the 3rd supply trying to reason how I want to wire it. I am very happy with the UCC capped supply... but there is not way to duplicate it with this layout, everything is different, even with 2 inches of additional (interior) chassis height... I am still somehow a bit cramped.

The massive - fat caps dictated many layout options, working with inductor lead lengths and a tidy ground buss / ground set-up... Still working to figure it out... Mean-while the UCC franken'amp is serving well with the Maggies and I have "a spare" 500 and 600 heat-sink assembly to work on... I am *completely* rebuilding the chassis pans on both amps...

~ decisions - decisions ~

Attachments

- Home

- Amplifiers

- Power Supplies

- 85/90 volt CLC supplies (Hafler 500/600)