Just a quick one, what's the best stuffing to go from adiabatic to isothermal compression? It's for a second chamber of an aperiodic enclosure, so sound absorbing is of no importance. I just presume high specific heat, high density and high thermal conductivity would be desirable. Would copper wire ( screening from old coax? ) have any worthwhile advantage over polyester?

I've heard of distributing thin copper strands throughout the stuffing material in order to produce equal temperature conditions.

Worth experimenting with no doubt.

Worth experimenting with no doubt.

What's that look like? I usually think of "aperiodic" as either a membrane behind the woofer (car audio) or a very stuffed box with a leak (like a VarioVent). And why aperiodic? Not against the idea, just curious....for a second chamber of an aperiodic enclosure...

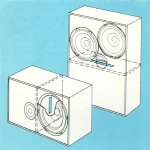

Also, see Fig. 1 in this patent: https://patentimages.storage.googleapis.com/62/98/78/6176b06154093c/US2065751.pdf

And the purpose of the second chamber is described here under the heading 'MAPD (Multichamber Aperiodic Progressive Damping).

North Creek Music's new MAPD driver loading

North Creek Music's new MAPD driver loading

- Home

- Loudspeakers

- Multi-Way

- stuffing.