Ok, I see it if I download the PDF just not in the image in the post. The dimensions are very close to what I ended up at for the foam core homage.

http://www.diyaudio.com/forums/atta...ore-mini-build-fh3-inspired-foamcore-plan.jpg

http://www.diyaudio.com/forums/atta...ore-mini-build-fh3-inspired-foamcore-plan.jpg

Last edited:

http://www.diyaudio.com/forums/full...pired-foam-core-mini-build-3.html#post3339779

And it looks like this:

And it looks like this:

Last edited:

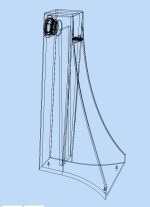

Beautiful design, I modeled up with a little larger horn back and slender curve.

Tony

Tony

Attachments

-

frugal lite.jpg73.2 KB · Views: 114

frugal lite.jpg73.2 KB · Views: 114 -

58708BB1-3225-4324-BFFB-673AD7F5E956.jpeg26 KB · Views: 111

58708BB1-3225-4324-BFFB-673AD7F5E956.jpeg26 KB · Views: 111 -

D03CE0D7-834B-4DB7-A3FD-6A51A5F23B45.jpeg25.3 KB · Views: 94

D03CE0D7-834B-4DB7-A3FD-6A51A5F23B45.jpeg25.3 KB · Views: 94 -

1A3CC9DE-7D71-4EC1-AA0D-528946643FB7.jpeg25.8 KB · Views: 91

1A3CC9DE-7D71-4EC1-AA0D-528946643FB7.jpeg25.8 KB · Views: 91 -

DFED426E-CB8A-420E-843C-92FC0CF1FC0E.jpeg22 KB · Views: 93

DFED426E-CB8A-420E-843C-92FC0CF1FC0E.jpeg22 KB · Views: 93 -

CB7E5CC7-633A-4AC2-8585-5C5776B2E878.jpeg24.1 KB · Views: 105

CB7E5CC7-633A-4AC2-8585-5C5776B2E878.jpeg24.1 KB · Views: 105

Last edited by a moderator:

Hi Tony,Beautiful design, I modeled up with a little larger horn back and slender curve.

Tony

That’s superb modeling you did there to get compound curves like that - was that done using a “swept curve” approach?

A curved plywood implementation would look fantastic.

Thanks for looking into this. I really like the organic shape - like a sail on a boat filled with wind.

Other than looks, would you gain anything sonically over the FH-Lite? Because it would be quite a bit harder to build!

Last edited by a moderator:

Depends over what. The FH series have a specific set of alignments & the dimensions are functional (it's not designed using plane-wave assumptions); the above is X's design, so I don't know what his alignment goals etc. were or how they compare.

Thanks X, here is pictures of the 3d print of the model.Hi Tony,

That’s superb modeling you did there to get compound curves like that - was that done using a “swept curve” approach?

A curved plywood implementation would look fantastic.

Thanks for looking into this. I really like the organic shape - like a sail on a boat filled with wind.

View attachment 1204827

View attachment 1204828

Attachments

Looks great! Have you started playing music through them yet? How many days did the print job take?

I was going to wait to play music until I got the pair done but been having a little trouble with my printer for my last piece. The bottom part took 10 day to print. The top half took 6 days. I may plug the on in this weekend. Inhale the two pieces clamped together and have acoustic stuffing in place.here is a picture of two pieces looking at the joint.

Attachments

I hope not! I would use something like 20% infill. Those are crazy long print times! It’s amazing you don’t have a filament jam, etc.

- Home

- Loudspeakers

- Full Range

- XRK Homage tp the Frugel-Horn but for 3" drivers