I recently acquired a Sony 227ESD CDP from Germany via eBay.

Although the player initially worked it now refuses to track discs most of the time.

I've been pulling my hair out over the last couple of weeks trying to diagnose the problem and tonight after removing and examining the transport carefully I finally found the problem.....and it's not good news. 🙁

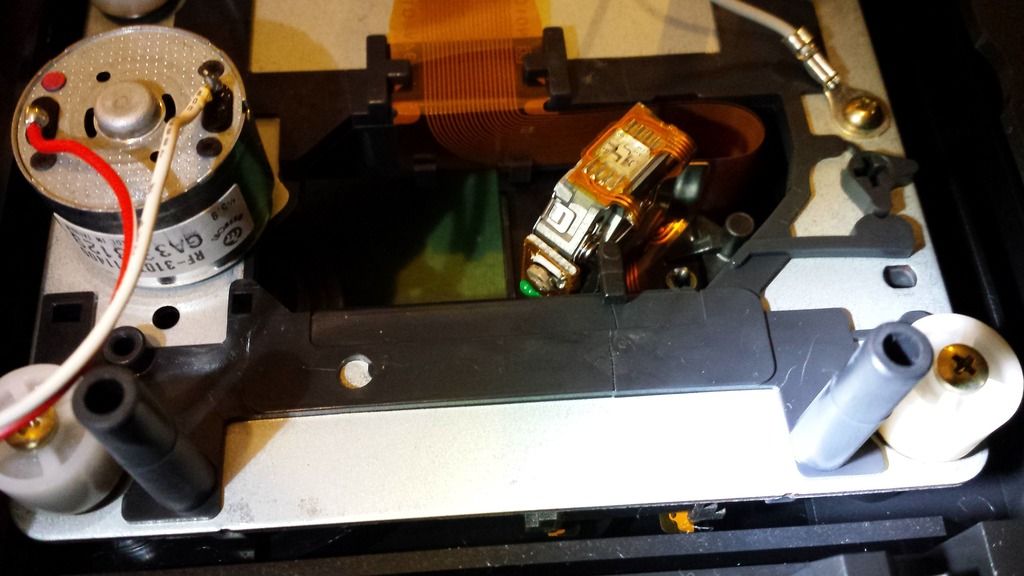

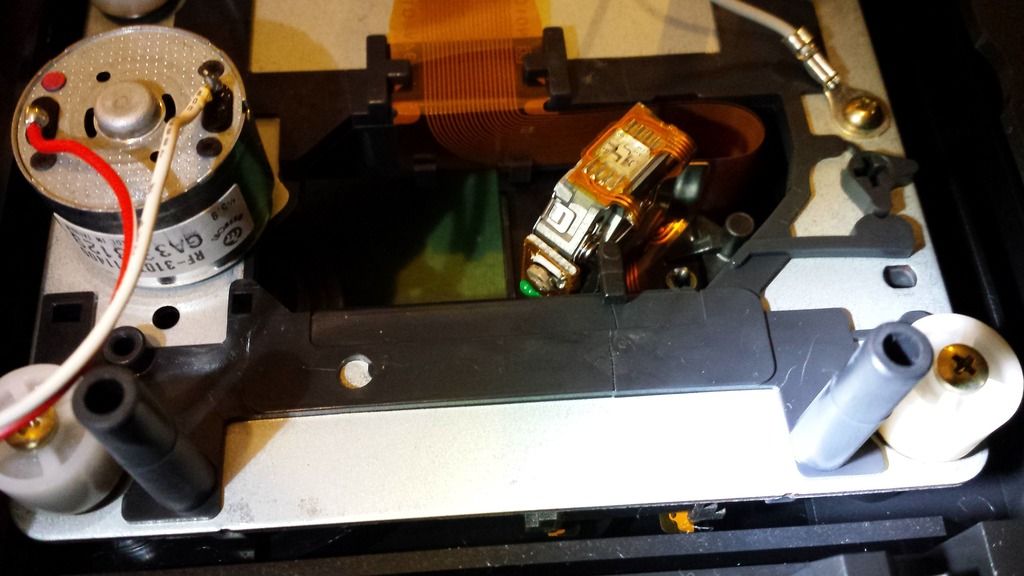

The KSS-151A uses a linear motor for the tracking and I've found that the plastic guide rails are cracked/fractured in several places. As the optical pick-up unit tries to slide of this rails it catches on the cracks and and prevents the laser from tracking properly.

In the photos below you can just see the fracture lines.

I wonder what has caused this? Ageing of the plastic? Mechanical damage in transit? The wrong lubricant? Has anyone seen this problem before?

If anyone has a KSS-151A with a dead laser they would let me have/buy for parts I'd be very grateful.

Although the player initially worked it now refuses to track discs most of the time.

I've been pulling my hair out over the last couple of weeks trying to diagnose the problem and tonight after removing and examining the transport carefully I finally found the problem.....and it's not good news. 🙁

The KSS-151A uses a linear motor for the tracking and I've found that the plastic guide rails are cracked/fractured in several places. As the optical pick-up unit tries to slide of this rails it catches on the cracks and and prevents the laser from tracking properly.

In the photos below you can just see the fracture lines.

An externally hosted image should be here but it was not working when we last tested it.

I wonder what has caused this? Ageing of the plastic? Mechanical damage in transit? The wrong lubricant? Has anyone seen this problem before?

If anyone has a KSS-151A with a dead laser they would let me have/buy for parts I'd be very grateful.

Just an update to let you know that I managed to fix my 227ESD.

I used a two part expoxy glue to fill in the cracks in the plastic. After the glue had dried I carefully trimmed of the excess with a razor blade. Using rifler files and abrasive paper I then managed to get the plastic rail nice and smooth.

The player is now 95% fixed, much better than it was before. It still occasionally struggles going from reading playing the first track on a CD after reading the TOC but will now play the rest of a full CD flawlessly. With a little more fine tuning a reckon I will be able to get it 100%.

I hope this might be useful to other forum members.

I used a two part expoxy glue to fill in the cracks in the plastic. After the glue had dried I carefully trimmed of the excess with a razor blade. Using rifler files and abrasive paper I then managed to get the plastic rail nice and smooth.

The player is now 95% fixed, much better than it was before. It still occasionally struggles going from reading playing the first track on a CD after reading the TOC but will now play the rest of a full CD flawlessly. With a little more fine tuning a reckon I will be able to get it 100%.

I hope this might be useful to other forum members.

I have had a few plastic and wrong lubricant issues with the KSS range and Grundig/Panasonic equivalent. Clean thoroughly and lubricate the slide with dry graphite or Mr Sheen silicone polish. They are both dry lubricants that do not attract dust to clog up the moving parts or attack the plastic.

Hi Jon, thanks for dry graphite lube tip.

On reflection I don't think the fractures in the plastic will have been caused by the use of an inappropriate lubricant. The entire plastic molding has fractures on it, even parts which should never have had any lubricant near them. I think it's more likely that the plastic has just aged and perished over time (loss of plasticiser?). It's a bit surprising though as it really doesn't get very warm in there and it's obviously not in direct sunlight or anything.

I have lubed the metal guide rod with a light synthetic oil but I didn't put any lube on the plastic rail which had cracked. the Laser pick-up rolls along the plastic track on a little plastic wheel, I so I don't think it'll need any lube.

I've just won an eBay auction for another old Sony with the higher spec KSS-190A mechanism, it'll be interesting to see how they compare in terms of build quality.

On reflection I don't think the fractures in the plastic will have been caused by the use of an inappropriate lubricant. The entire plastic molding has fractures on it, even parts which should never have had any lubricant near them. I think it's more likely that the plastic has just aged and perished over time (loss of plasticiser?). It's a bit surprising though as it really doesn't get very warm in there and it's obviously not in direct sunlight or anything.

I have lubed the metal guide rod with a light synthetic oil but I didn't put any lube on the plastic rail which had cracked. the Laser pick-up rolls along the plastic track on a little plastic wheel, I so I don't think it'll need any lube.

I've just won an eBay auction for another old Sony with the higher spec KSS-190A mechanism, it'll be interesting to see how they compare in terms of build quality.

A little more fettling has now got it 100% fixed and the 227ESD now reads anything I feed it very quickly.

When I thought this player was dead I purchased another 227ESD from a forum member on here (thanks Josch). This too has cracks in the plastic molding but fortunately not any of the sliding surfaces so it doesn't affect performance.

I suspect this is a common problem with the KSS-151A on old Sony players, hopefully other owners can do the same DIY repair. Interestingly I notice Denon used their own superior looking base plate/chassis on which the Sony laser head is mounted.

When I thought this player was dead I purchased another 227ESD from a forum member on here (thanks Josch). This too has cracks in the plastic molding but fortunately not any of the sliding surfaces so it doesn't affect performance.

I suspect this is a common problem with the KSS-151A on old Sony players, hopefully other owners can do the same DIY repair. Interestingly I notice Denon used their own superior looking base plate/chassis on which the Sony laser head is mounted.

Successor Diodes for KSS-151A

From China there is since longer time a supplier of new laser diodes for this model and some other from Sony's KSS series - go to

2pcs SONY KSS-151A 3mw-5mW 780nm 5.6mm TO18 Infrared IR Laser/Lazer Diode LD | eBay

This is the Link from German. To open ebay insight of an individual country, please fill in the item No from ebay in eBay's search engine as follow: 120946832767

The actually question from me now is follow:

Who is able to replace this three pin laser diode in the KSS-block to get refurbish resp. new condition for a proper operating?

Probably on HIFI????? - ?????????????? there are mentioned some companies or guys, which are able to do this.

Thank you very much for advices.

From China there is since longer time a supplier of new laser diodes for this model and some other from Sony's KSS series - go to

2pcs SONY KSS-151A 3mw-5mW 780nm 5.6mm TO18 Infrared IR Laser/Lazer Diode LD | eBay

This is the Link from German. To open ebay insight of an individual country, please fill in the item No from ebay in eBay's search engine as follow: 120946832767

The actually question from me now is follow:

Who is able to replace this three pin laser diode in the KSS-block to get refurbish resp. new condition for a proper operating?

Probably on HIFI????? - ?????????????? there are mentioned some companies or guys, which are able to do this.

Thank you very much for advices.

I have had a few plastic and wrong lubricant issues with the KSS range and Grundig/Panasonic equivalent. Clean thoroughly and lubricate the slide with dry graphite or Mr Sheen silicone polish. They are both dry lubricants that do not attract dust to clog up the moving parts or attack the plastic.

Have a Denon DN-1200F with bumpy crusty stuff on the KSS-151A magnetic rail. Presumably hardened dried grease. I suppose clean it off and use dry lubricant as suggested?

Yes, that looks like dried grease. IPA and a few cotton buds will clean it and I would use a dry lubricant on the slider.

Plastic self lubricates as a rule. Silicone based dry lube is OK to use if needed.Hi Jon, thanks for dry graphite lube tip.

On reflection I don't think the fractures in the plastic will have been caused by the use of an inappropriate lubricant. The entire plastic molding has fractures on it, even parts which should never have had any lubricant near them. I think it's more likely that the plastic has just aged and perished over time (loss of plasticiser?). It's a bit surprising though as it really doesn't get very warm in there and it's obviously not in direct sunlight or anything.

I have lubed the metal guide rod with a light synthetic oil but I didn't put any lube on the plastic rail which had cracked. the Laser pick-up rolls along the plastic track on a little plastic wheel, I so I don't think it'll need any lube.

I've just won an eBay auction for another old Sony with the higher spec KSS-190A mechanism, it'll be interesting to see how they compare in terms of build quality.

Plastic will fall to bits if mineral based lubricant gets anywhere near it, even migration from an inch away will affect the plastic.

Philips supplied red silicone based grease for the lubrication of their planet and ring gear in some VHS recorders as the sun, planet and ring gear, were all plastic.

Yes, that looks like dried grease. IPA and a few cotton buds will clean it and I would use a dry lubricant on the slider.

Thanks. Got 2x of these DN-1200F for free. Both skips and both shows dried grease on the laser head rails. The one pictured actually is bumpy. Manually sliding laser assembly feels smooth.

KSS-151A is buried in this unit (200 CD changer) and looks challenging to remove. Perhaps Grease is under the laser assembly above the greased rails as well but hard to get to.

After going to see the photo more closely, I have the impression that it is glue to stick the magnetic masses, but I could be wrong (photo) try rubbing with a cotton swab and a little WD40 or IPA on the cotton to see if it comes off and if not, it's glue.

@huggygood

I think you are right, barely stains q-tip with IPA. Had to scrap it off with finger nail (took awhile, very hard) Maybe its excess glue oozed out onto the top of the rails.

Now where to lube with dry graphite? First, I guess have to understand how this sliding mechanism works.. Here is a guess based on pictures. This video is helpful (26s mark)

So I guess in my labeled picture below

So C and maybe A5 side are the only surfaces needing lube?

I think you are right, barely stains q-tip with IPA. Had to scrap it off with finger nail (took awhile, very hard) Maybe its excess glue oozed out onto the top of the rails.

Now where to lube with dry graphite? First, I guess have to understand how this sliding mechanism works.. Here is a guess based on pictures. This video is helpful (26s mark)

So I guess in my labeled picture below

- C has physical contact (pickup assembly sliding over metal tube)

- Pickup assembly has 2 electromagnets? Left and right of the laser head in video @ 27s mark

- Not really sure where perm magnets are (A2 & A5?)

- A5 side surface looks like it has contact with white plastic rail

- B1 is another perm magnet on the other end of pickup assembly?

So C and maybe A5 side are the only surfaces needing lube?

Used graphite lubricant on all the rails and IPA cleaned the laser lens. Still skips at about 5th song in (same as before). I guess weakening laser power is the next guess? Unfortunately no scope to help diagnose further...

Looked at this a year later and found the problem and fix. The problem likely 2 different areas. Some maybe Denon specific..

Since I have 2 DN-1200Fs, did the same cleaning of the 2nd one. Forgot to attach pickup assembly flex on reassembly and powered up. Obviously didn't work. Reconnected the flex and still doesn't work. Hopefully didn't kill the pickup assembly or maybe just need some cryptic initialization sequence.

- The laser pickup moves magnetically. I found small flakes of magnets that chipped off the corners and metal specks (probably from somewhere in the changer CD loader assembly) These easily contaminates the metal rails and permanent magnet surfaces. Cleaned it off with ISO Q-Tip and airgun.

- The pickup assembly glides along a stainless track rod with a pair of brass bushings. The fit is tight and dirt accumulates. I may have added to the problem by using graphite lubricant.

Since I have 2 DN-1200Fs, did the same cleaning of the 2nd one. Forgot to attach pickup assembly flex on reassembly and powered up. Obviously didn't work. Reconnected the flex and still doesn't work. Hopefully didn't kill the pickup assembly or maybe just need some cryptic initialization sequence.

Last edited:

Update on the the failed Denon DN-1200F unit post cleaning. It appears I might have killed the optical unit (incl KSS 151A) accidentally while cleaning. The optical unit is adding about 30mV of noise onto the ground. This is enough to cause the wrong coil slide sensor readings. Many components shares ground including a couple optical diodes. Perhaps those got damaged from not doing the solder drop protective link (against static electricity?) safety on the KSS-151A flex. Pulled the flex to access the sliding rod and bushing for cleaning.

Alternatively, when I initially assembled the unit post cleaning. Forgot to connect the optical unit flex. Powered up and wasn't working. Then powered down and reconnected the optical flex. Probably should have let the unit idle for awhile and drain all residual energy.

I guess an amateur mistake 🙁

I guess the wisdom is do that solder drop safety step first and gentle handling. Or avoid disconnecting the KSS-151A flex and just do the best cleaning possible on the glide rod/bushing.

Alternatively, when I initially assembled the unit post cleaning. Forgot to connect the optical unit flex. Powered up and wasn't working. Then powered down and reconnected the optical flex. Probably should have let the unit idle for awhile and drain all residual energy.

I guess an amateur mistake 🙁

I guess the wisdom is do that solder drop safety step first and gentle handling. Or avoid disconnecting the KSS-151A flex and just do the best cleaning possible on the glide rod/bushing.

Last edited:

The mentioned magnet flakes on this kind of transport mechanism are often an issue while troubleshooting procedure, especially if one don't immediately think of this kind of deficiency.Looked at this a year later and found the problem and fix. The problem likely 2 different areas. Some maybe Denon specific..

Require full removal of the pickup assembly and track rod for cleaning. ISO cleaned rod, brass bushing, and various rails. Removed any magnet flakes. When finished, KSS-151A pickup will slide effortlessly with gravity as you tilt the pickup assembly. Now the unit played perfectly.

- The laser pickup moves magnetically. I found small flakes of magnets that chipped off the corners and metal specks (probably from somewhere in the changer CD loader assembly) These easily contaminates the metal rails and permanent magnet surfaces. Cleaned it off with ISO Q-Tip and airgun.

- The pickup assembly glides along a stainless track rod with a pair of brass bushings. The fit is tight and dirt accumulates. I may have added to the problem by using graphite lubricant.

Since I have 2 DN-1200Fs, did the same cleaning of the 2nd one. Forgot to attach pickup assembly flex on reassembly and powered up. Obviously didn't work. Reconnected the flex and still doesn't work. Hopefully didn't kill the pickup assembly or maybe just need some cryptic initialization sequence.

View attachment 1350486View attachment 1350487View attachment 1350497View attachment 1350496View attachment 1350493View attachment 1350489

- Home

- Source & Line

- Digital Source

- Strange KSS-151A failure