I'm lazy , so there are excerpts from my correspondence on Tannoy Yahoo group; all quotes - Mighty ZM

I'm putting this here as future reference for some other desperate Tanner ; I must admit ( or I'm just boasting ) - I'm always having serius backup for all things speakers - from Aleksandar RAAL ....... even if I'm always stubborn and I'm bugging him only post hoc ..... to be sure that I didn't blew something

of course - "Danish guy " wasn't prepared to share his recipe ; I don't blame him 😉

that's why I'm sharing mine

then one guy is saying that Mouse Glue is forbidden in some EU countries ; my reply :

then guy asked where to search for surround impregnation goop ;

my reply :

then guy asked for difference sound-wise , pre and post procedure ; my reply :

I hope you enjoyed little story

In case that I remember to get cam to my workshop tomorrow , I'll make few pics and put it here , along with few pics of same drivers prior to fun procedure

I'm putting this here as future reference for some other desperate Tanner ; I must admit ( or I'm just boasting ) - I'm always having serius backup for all things speakers - from Aleksandar RAAL ....... even if I'm always stubborn and I'm bugging him only post hoc ..... to be sure that I didn't blew something

K3809 - cloth surround impregnation solvent ?

as I wrote - pair of K3809

cloth surround , no back cone ribs

Fs is high - around 70Hz on both drivers

I contacted Tannoy Support , but they can't help - all they can recommend is

reconing , which is out of possibility , counting on fact that drivers are in

excellent condition and just slightly used (well - same as they aren't used at

all )

so - anyone having real life experience , regarding solvent for surround

impregnation ?

whatever , guy at Hasling Audio Systems Denmark is doing exactly the same for SH

Altec's , so I think same is possible for Tanns

TIA

Tnx for reply ;

There is no particular info on Altec related link , but point was that planned

procedure was implemented ...... I sent e-mail to Danish guy , asking for his

recipe , if nothing else , as starting point .

Whatever - K3808 (3809) are having impregnated cloth surround , not paper ;

that's visible on many pictures on net , and "cloth surround" is having exactly

that name in related info

In any case , if I succeed in "operation" , I'll share my findings

of course - "Danish guy " wasn't prepared to share his recipe ; I don't blame him 😉

that's why I'm sharing mine

besides Sam R's problem with teared surround ......... and strictly speaking of hardened cloth surround - I'm stubborn and there is no way I'm going to change them .....

I would go to generic soft (probably acquired from Sonido guys in Hungary )

cloth surround , but will ever never invest money in new cones or - God forbid!

- neoprene surrounds 😉

I remember some guys at Diyaudio speaking of

2-Butoxyethanol - Wikipedia, the free encyclopedia

so I plan to start with that

Hardened cloth surround problem solved !!

soaking both sides of surround , using small brush , with plain Ethanol 95-96% ,

brought Fs from 71Hz to 29Hz .

I'm expecting that Fs will rise to spec. 35Hz , when solvent evaporate

That's what we are calling just Pure Alcohol , and you can buy it in every

drugstore.

So much speaking of recone and surround replacement 😉

I'll keep you informed , of course ;

even in case that Fs start rising again , I'll just repeat procedure , removing

old impregnation as much I can , and brush new tacky layer above it

then it will permanent solution

no damage , certainly ;

I'll post few pics in few days , after having definitive conclusion about

longevity of cure

Update : after 24h rest and solvent evaporated - two steps forward , one step back 😉

steps forward are :

1 - impregnate is not brittle and cracked (inducing noise , especially

detectable at Fs)

2 - everything looks just nice , almost as new

step back - Fs is back on 71Hz 😉)

whatever , I'll proceed with more cleaning of old impregnate , and then try to

seal it with tacky surround goo , which will (hopefully) prevent repeated

hardening

will keep you informed

OK

K3809 - cloth surround impregnation solvent ; hardened cloth surround - high Fs

- issue SOLVED

procedure finished and confirmed

after 24h (and more ) of solvents evaporating , Fs is still good : 33-35Hz

RECIPE

what you need :

1.small brush , semi hard m ~8mm wide , same as kids are using for painting in

school

2.Ethanol 95% (pure alcohol)

3.Acetone with oil ( nothing else than nail polish remover )

4.mouse glue (yes , that organic everlasting sticky goo)

5.Vaseline

6.cotton cloth ( old T shirt or whatever)

brush - buy it anywhere , mouse glue - anywhere , everything else - nearest drugstore

important to say - surround was originally threated from upper side , mostly ;

just slight residue of original rubbery impregnate is visible from bottom side

of surround

procedure for upper side of surround:

using brush - from upper side - soak surround with ethanol ; it's best to soak

it in parcels of 10cm , then rub it with same brush ; whenever you fill brush

with residue , wipe it on cloth

repeat procedure until you make two full circles (so entire surround perimeter

is twice treated)

move to second speaker ,same procedure , again two circles ;

repeat same soak-rub-wipe-soak-rub-wipe procedure on both speakers , until you can see clear fabric of cloth , without any trace of rubber

it's fun , but only if you have some muzak and coffee 😉

after few steps in procedure you'll see what's happening ; if you think that

you'll gain anything with another soak-rub-wipe circle , just do it

leave speakers 12h , to let Ethanol to evaporate

now - put some mouse glue on small (coffee cup) plate , add acetone and dissolve it to something liquid as milk

using brush - put that mixture on upper side of surround ; if you see that your

mixture on plate is going firmer , add acetone and mix ; when you treat entire

surround , take just acetone with brush and treat entire ( already impregnated )

area with it , to make it more uniform

leave it for 12h

now - bottom side of surround :

soak brush in acetone , rub it firmly in Vaseline , then put that mixture on

entire bottom side area ; goal is to have tiny layer of vaseline on bottom side

leave it 12h

measure Fs

easiest way of measuring Fs - use sine signal generator with 50R output

impedance , connect it to bass terminals , put CRO probes on terminals

sweep frequency from 100Hz down ; when you see biggest sine amplitude , there is Fs

another possibility for measuring - instead of sig gene - use Sig Jenny program

( wave gene with counter ) , sound card to small amp , amp to bass terminals ,

AC voltmeter to terminals

put few volts of sine to bass , sweep from 100Hz down , when you see biggest

reading on Vac meter , that is it

mine are at 31 and 33 Hz , I'm not loosing sleep because of using mouse glue and

vaseline on piece of cloth 😉

then one guy is saying that Mouse Glue is forbidden in some EU countries ; my reply :

in that case - just buy softest surround impregnation goop ; easy to do on line

, if living in Europe

unfortunately - Serbia , where I'm living - somehow isn't in Europe , so I'm

Paypal-less 😉

that means that I'm just lazy to chase soft surround impregnation goop from

Europe , taking in account that there is no domestic one

then guy asked where to search for surround impregnation goop ;

my reply :

sorry - just google ;

search for something like this : Speaker Repair Adhesive, Sealer, Cloth Surrounds, Foam Surrunds, MI-1291

but , it's wise to buy only after confirmation from seller that really soft

thing is in question

Zen Mod

then guy asked for difference sound-wise , pre and post procedure ; my reply :

sound-wise - taking in account that my pair is most mint pair I ever had

opportunity to even see (except surround condition - most probably as result of

no-usage for all long years ), I'm eager to say that they're sounding just as

proper pair of K3809 😉

right now being in stage of preparation of making boxes for them , I'm having

fresh experience just listening them in bafle-less iteration ; even like that ,

there is proper difference in bass , comparing to prior (surround treatment )

performance

whatever , fact that plain and common Ethanol is sufficiently good as solvent

for old impregnation , was nice surprise ....

Zen Mod

I hope you enjoyed little story

In case that I remember to get cam to my workshop tomorrow , I'll make few pics and put it here , along with few pics of same drivers prior to fun procedure

Last edited:

Hi Zen Mod,

My 3808's have hardened surrounds and I've been looking for a solution. Found the Tannoy Yahoo group discussion - and, surprise, it’s you. 🙂

This must certainly be worth a try. I think I'll go with 'normal' goop.

Has fs stabilised now, i.e. not climbing again?

Thanks for sharing!

My 3808's have hardened surrounds and I've been looking for a solution. Found the Tannoy Yahoo group discussion - and, surprise, it’s you. 🙂

This must certainly be worth a try. I think I'll go with 'normal' goop.

Has fs stabilised now, i.e. not climbing again?

Thanks for sharing!

pics are tellin' everything 😉

feel free to use mouse glue

so called original thing is worse than that - butyl based goop vs. organic goop

whatever - if you want regular (commercial) thingie - try it first on piece of cloth

after few days check compliance

feel free to use mouse glue

so called original thing is worse than that - butyl based goop vs. organic goop

whatever - if you want regular (commercial) thingie - try it first on piece of cloth

after few days check compliance

Zen Mod,

Not yet.

I'm in 'electronics mode' right now so it will take a while.

Yours still down low?

Not yet.

I'm in 'electronics mode' right now so it will take a while.

Yours still down low?

what can I say ...... drool 😉

even if I would never choose these cabs , they're simply gorgeous looking

even if I would never choose these cabs , they're simply gorgeous looking

OK , just for the record ; as known - rest of pics on my blog

same : prior to procedure , after procedure upper side , after procedure bottom side

same : prior to procedure , after procedure upper side , after procedure bottom side

zen mod

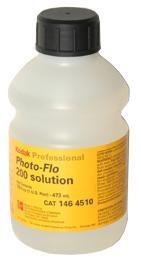

the next time you have a driver with a stiff surround or spider assembly try using Kodak photoflow diluted 8:1 with water.i've used this time and again on old stiff drivers with excellent results.and unlike solutions with volatiles that evaporate you don't need to consequently re-apply.

i'm currently doing this to a batch of HX-125 drivers out of a pair of Biffrons Hox 05's

the next time you have a driver with a stiff surround or spider assembly try using Kodak photoflow diluted 8:1 with water.i've used this time and again on old stiff drivers with excellent results.and unlike solutions with volatiles that evaporate you don't need to consequently re-apply.

i'm currently doing this to a batch of HX-125 drivers out of a pair of Biffrons Hox 05's

tnx for tip !

I hope that I'll not need that in future ....

not for my K3809 ( I'm not doubting durability of my tweaks) , but for any other ...... 😉

edit : just to be sure - you meant this ?

Kodak Photo-Flo 200 Solution should be added to the final wash when processing black & white films. It acts as a wetting agent by foaming up and protecting the film from dust and scratches while hanging to dry.

Decreases the water-surface tension on the emulsion.

Minimizes water marks and streaks on film.

Promotes faster, more uniform drying.

I hope that I'll not need that in future ....

not for my K3809 ( I'm not doubting durability of my tweaks) , but for any other ...... 😉

edit : just to be sure - you meant this ?

Kodak Photo-Flo 200 Solution should be added to the final wash when processing black & white films. It acts as a wetting agent by foaming up and protecting the film from dust and scratches while hanging to dry.

Decreases the water-surface tension on the emulsion.

Minimizes water marks and streaks on film.

Promotes faster, more uniform drying.

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Tannoy K3809 - hardened cloth surround issue - solved