Very good posting a video. The left channel is working? and other than the hum do they sound the same.

Appears it is a bad capacitor. I switched them and the hum switched channels. I reversed the offending capacitor and the hum is still there.

Here is the cap I'll need to replace:

F1773-410-2000MKT

0.1ufX2 SH 250VAC

I know what 0.1uf means......but not familiar with the "X2"

Can someone explain?

Here is the cap I'll need to replace:

F1773-410-2000MKT

0.1ufX2 SH 250VAC

I know what 0.1uf means......but not familiar with the "X2"

Can someone explain?

Ebay offers this:

ERO Roederstein F1773 X2 Type RFI MKT Film Capacitors 1.0uf / 250vac X 2pcs

Two for $8 shipped. Would these be OK for replacement?

I just realized these at 1uf and not 0.1uf......

ERO Roederstein F1773 X2 Type RFI MKT Film Capacitors 1.0uf / 250vac X 2pcs

Two for $8 shipped. Would these be OK for replacement?

I just realized these at 1uf and not 0.1uf......

Last edited:

and other than the hum do they sound the same.

Both channels are working and they sound the same. The preamplifier actually sounds fantastic! And with music playing, my ears can't hear the hum......But I know it's there!

In the video is is IMO quite clear that PE is only connected to the transformers screen. PE should of course (*certainly in a tube device) be connected to the casing. This is mandatory for safety as well. Then a reference of 100 Ohm from Audio GND to PE can be made. Of course also the screen of the transformer should be connected to the same PE point. I would choose a location close to the IEC inlet and use the regular stuff for a safe and sturdy connection so with washers etc.

Your casing is floating......

Your casing is floating......

Correct! This is another conversation.....But should there be a simple connection from the Line Ground to the chassis? While it was playing I ran a test lead from that Line Ground to chassis with no negative effect. Should I make it permanent?PE is only connected to the transformers screen.

No this is not another conversation, it starts with the basics and safety.

1. A floating metal casing with even higher voltages than mains voltage is incompetent and dangerous. Your casing and transformer screen should both be connected to PE. Those should be very permanent and carried out the usual way. This is the minimum standard so to speak.

2. If the mandatory things did not solve matters completely try to temporarily connect Audio GND to PE via a 100 Ohm resistor. This is step 2 and follows only after 1. Try again if it is solved.

Please try to imagine what the transformers do to a metal chassis/metal covers when these are floating.

1. A floating metal casing with even higher voltages than mains voltage is incompetent and dangerous. Your casing and transformer screen should both be connected to PE. Those should be very permanent and carried out the usual way. This is the minimum standard so to speak.

2. If the mandatory things did not solve matters completely try to temporarily connect Audio GND to PE via a 100 Ohm resistor. This is step 2 and follows only after 1. Try again if it is solved.

Please try to imagine what the transformers do to a metal chassis/metal covers when these are floating.

Last edited:

X2 is a safety rating and unimportant in this usage.Appears it is a bad capacitor. I switched them and the hum switched channels. I reversed the offending capacitor and the hum is still there.

Here is the cap I'll need to replace:

F1773-410-2000MKT

0.1ufX2 SH 250VAC

I know what 0.1uf means......but not familiar with the "X2"

Can someone explain?

Here is a much better replacement cap than the stock ones. Replace both left and right channel caps as a pair.

https://www.digikey.ca/en/products/...BVIQF2AHkUAFkcNCwAVz4cUJAAWmjreX5B5UcyJOZxFaA

Measure the size of the current one to make sure they will fit...

It can very well be that one of the caps is mounted with the outer foil reverse so not to the lowest potential. It can then pick up induced hum as its shielding function is then not OK.

Edit: I see this was already mentioned in post #19. BTW not all manufacturers mark the outer foil and some... mark it even wrongly 🙂

X2 is meant for mains use not as coupling cap. Rbertaletto, if you have a schematic please first check what this cap does. if it is a coupling cap you can use fine MKP or the like as long as the voltage ratings are OK. It is important to use caps that fit physically so with the right pitch. If the cap in the video is meant that you touch with the pencil then it likely is an input cap and no X2 rating is needed.

As a chain is as strong as its weakest link you'll notice some things should be done not just replacing caps.

Edit: I see this was already mentioned in post #19. BTW not all manufacturers mark the outer foil and some... mark it even wrongly 🙂

X2 is meant for mains use not as coupling cap. Rbertaletto, if you have a schematic please first check what this cap does. if it is a coupling cap you can use fine MKP or the like as long as the voltage ratings are OK. It is important to use caps that fit physically so with the right pitch. If the cap in the video is meant that you touch with the pencil then it likely is an input cap and no X2 rating is needed.

As a chain is as strong as its weakest link you'll notice some things should be done not just replacing caps.

Last edited:

I connected a 100ohm resistor from Line Ground (PE) to the RCA input ground (Audio GND)........no change in hum.

For safety , If I connect the line ground to chassis (casing), do I need a resistor in the line? Or just simply ground the chassis (casing)

For safety , If I connect the line ground to chassis (casing), do I need a resistor in the line? Or just simply ground the chassis (casing)

Well, I tried. First step 1 then step 2 as in post #28. Reread my previous posts if you like, it makes no sense repeating stuff as it will only make one insecure.

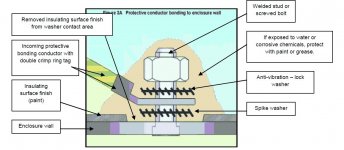

I attached a wrong picture of the right practice 🙂. Use an M4 nut and bolt and use the ring type connectors with the "toothed" washers. Most will use a bolt and nut so the bolts head should have a "toothed" washer as well.

I attached a wrong picture of the right practice 🙂. Use an M4 nut and bolt and use the ring type connectors with the "toothed" washers. Most will use a bolt and nut so the bolts head should have a "toothed" washer as well.

Attachments

Last edited:

I ordered the DigiKey caps......

Can't thank all of you enough. I keep learning more and more about the electronics side of the hobby every day!

Can't thank all of you enough. I keep learning more and more about the electronics side of the hobby every day!

So you don't do stuff safe/right nor do you try and report back if your issue is solved? Your issue might be a combination of factors (it is) in an unsafe device.

Not sure what you mean by this. I did what you suggested and it did not change the hum. And I understand your concern for safety and not having the chassis grounded. I'm only asking if the resistor is necessary for a chassis ground.....Or just ground the chassis to the line ground with a piece of wire.Well, I tried.

So you don't do stuff safe/right nor do you try and report back if your issue is solved? Your issue might be a combination of factors (it is) in an unsafe device.

Are you not seeing post #31?

No you did not do what was suggested. Yes I did read post #31 and it is a question.

1. The casing and the transformers screen must be connected directly to PE. Period. That is the first step which is permanent for your and others safety. Use 1.5 or 2.5 mm2 stranded green/yellow wire and ring type connectors so you can add stuff later.

2a. Only then one can reference Audio GND to PE with a 100 Ohm 2W resistor. Please mind that this one is not mandatory but it may solve your troubles completely.

2b. In some areas on this planet only direct connections of Audio GND to PE are done in every device in the chain. This is getting ground loops for free. Advice is to only do so in the power amplifier.

3. And... then you could try to reverse the cap that is sensitive. Explanation was already given what may be the cause.

1. The casing and the transformers screen must be connected directly to PE. Period. That is the first step which is permanent for your and others safety. Use 1.5 or 2.5 mm2 stranded green/yellow wire and ring type connectors so you can add stuff later.

2a. Only then one can reference Audio GND to PE with a 100 Ohm 2W resistor. Please mind that this one is not mandatory but it may solve your troubles completely.

2b. In some areas on this planet only direct connections of Audio GND to PE are done in every device in the chain. This is getting ground loops for free. Advice is to only do so in the power amplifier.

3. And... then you could try to reverse the cap that is sensitive. Explanation was already given what may be the cause.

Last edited:

That's amazing. I have never seen such a thing happen before, and I've seen a lot.Appears it is a bad capacitor. I switched them and the hum switched channels. I reversed the offending capacitor and the hum is still there.

See the benefits of a methodical troubleshooting process? If you had only "reversed" that capacitor,

the hum would still have been there, and then you might have looked elsewhere for the problem,

and wasted a lot of time and patience.

- Home

- Amplifiers

- Tubes / Valves

- Strange Tube Preamp Hum Issue..Help