Just for educational purposes (and because of the excellent results of this one) a picture of a custom built Noratel Imed medical isolation transformer.

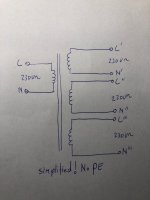

This one has something non standard. It comes with 2 primary 115V windings (for 230V in series) and 3 separate secondary windings 2 x 115V/230V so 3 galvanic separated groups. The device of course has electronic slow start as it is 1000VA (no power saving techniques found for the bypass relay). It also has a PE leakage test circuit with test and reset button. So in effect this device functions more or less like 3 transformers in 1 casing. Also nice is the built in mains filter which is lacking in other models of this brand.

Everything is double pole so 2 mains fuses and a double pole mains switch. It was meant to be used with endoscopes.

The rule of thumb with audiophiles seems to be the higher the voltages the smaller the chance of finding PE in the installations and/or DIY devices. Please see the meticulous wiring of PE.

This one has something non standard. It comes with 2 primary 115V windings (for 230V in series) and 3 separate secondary windings 2 x 115V/230V so 3 galvanic separated groups. The device of course has electronic slow start as it is 1000VA (no power saving techniques found for the bypass relay). It also has a PE leakage test circuit with test and reset button. So in effect this device functions more or less like 3 transformers in 1 casing. Also nice is the built in mains filter which is lacking in other models of this brand.

Everything is double pole so 2 mains fuses and a double pole mains switch. It was meant to be used with endoscopes.

The rule of thumb with audiophiles seems to be the higher the voltages the smaller the chance of finding PE in the installations and/or DIY devices. Please see the meticulous wiring of PE.

Attachments

Last edited:

Looks like there are multiple, looks like 4, chassis ground points. Why is that? As you say, I'm just trying to learn.

Correct, it also has the external hardsilver PE connectors as usual with medical equipment (upper left corner).

All in all an excellent piece of equipment. I like the multiple secondary 230V windings but I suppose having such a transformer wound is not affordable. A 500 VA version combined with group distribution would be nice for audio. This one is quite large. I have smaller ones but these lack a front mains switch, mains filter and the multiple windings. The 2 kVA version is unusable for audio as it hums severely and also lacks all the mentioned features. Weighs a ton too 🙂

All in all an excellent piece of equipment. I like the multiple secondary 230V windings but I suppose having such a transformer wound is not affordable. A 500 VA version combined with group distribution would be nice for audio. This one is quite large. I have smaller ones but these lack a front mains switch, mains filter and the multiple windings. The 2 kVA version is unusable for audio as it hums severely and also lacks all the mentioned features. Weighs a ton too 🙂

Last edited:

Three phase to 230volts seems a good use for it. L1, L2 and L3 to Neutral as there is little call for a multiple winding single transformer. The regulation will be closely coupled and may cause voltage drop on all windings when only one winding draws current.

It is single phase input as can be seen. It has 3 separate output windings which is probably its added value for audio. It is 1000 VA so little chance it will sag with the 2 x 3W amp + Elac Discovery I am using with it 🙂

As these are in use with very expensive power demanding medical stuff without any issue I trust the quality. They feed the various sections of endoscope systems with high res video systems etc.

As these are in use with very expensive power demanding medical stuff without any issue I trust the quality. They feed the various sections of endoscope systems with high res video systems etc.

Attachments

Last edited:

Any idea what they cost new? I doubt its anywhere near reasonable for us, but since i doubt theres a secondary market for medical use, there may be one for non-medical uses?.

Expensive 😉 The simple 1kVA version is affordable but it does not have all the features. It is about 400 Euro.

https://www.noratel.com/products/product/imed-1000/

https://www.noratel.com/products/product/imed-1000/

You could ask but do so before the camera goes where the sun doesn't shine. BTW using a mains isolation transformer is one of the best upgrades in audio systems. In my experience they offer immediate improvement certainly when a good mains filter is also used. Probably food for endless debate but every time I take one out of my setup I regret it directly.

A middle way is to use a small one for only the sources. Like an IMEDe150 (just below 190 Euro). Point to use a medical version is because of the tight specifications and very low leakage.

* Example of one of the benefits/design features: one can touch the output L with one hand and PE with the other hand without dangerous consequences. Don't do this of course. For audio the lower noise is a benefit.

A middle way is to use a small one for only the sources. Like an IMEDe150 (just below 190 Euro). Point to use a medical version is because of the tight specifications and very low leakage.

* Example of one of the benefits/design features: one can touch the output L with one hand and PE with the other hand without dangerous consequences. Don't do this of course. For audio the lower noise is a benefit.

Last edited:

I admire those medical grade cardboard insulators. Especially the one at lower right which hovers above the slow start resistance elements.

Yes it looks odd at first but apparently no risk of wires/cables coming loose and making things dangerous or malfunctioning is accepted.

During production/testing of high power DC systems normal corrugated cardboard is also still temporarily used as isolator despite all modern plastic sheet etc.

During production/testing of high power DC systems normal corrugated cardboard is also still temporarily used as isolator despite all modern plastic sheet etc.

Last edited:

That looks expensive, but nice if you can find one.

I have had one at work under my desk for about ten years now, 1kva, is probably 40-50 years old, found it in a scrap bin. I have a 500va one there also, but it has a slight hum, was probably abused.

I was pleasantly surprised at the improvement it made with my headphone rig.

The one at home is made from two identical 800va transformers in a case. I put a CLCLC line filter between them.

I have had one at work under my desk for about ten years now, 1kva, is probably 40-50 years old, found it in a scrap bin. I have a 500va one there also, but it has a slight hum, was probably abused.

I was pleasantly surprised at the improvement it made with my headphone rig.

The one at home is made from two identical 800va transformers in a case. I put a CLCLC line filter between them.

Decided to sell the 1 kVA. As nice as it is it is slightly overrated for my use and it looks out of place being several factors larger than all other devices. There are some others who do fit in.

The one at home is made from two identical 800va transformers in a case. I put a CLCLC line filter between them.

Two isolation transformers in series is an excellent idea, congratulations!

Why not deploy them with three line filters? mains-->F1-->Trafo1-->F2-->Trafo2-->F3-----> output

Seen it before also with plain 230V/xV transformer followed by an identical xV/230V transformer used "in reverse" which broadens the choice as long as they are identical. Will it bring any benefit compared to extremely low leakage medical gear? I mean, is the means not worse than the issue? Twice the losses too.

BTW I recently got a schematic of a device built/sold commercially where the secondary middle point was coupled to the N of the primary winding...

BTW I recently got a schematic of a device built/sold commercially where the secondary middle point was coupled to the N of the primary winding...

Last edited:

I recall that the one at work sounded better with the mains filter after the isolation transformer.

Not sure if the is any electrical/perceived audio benefit to having the filter between the two, but packaging-wise, it worked well. Actually have another line filter after the transformer/filter/transformer setup…

Not sure if the is any electrical/perceived audio benefit to having the filter between the two, but packaging-wise, it worked well. Actually have another line filter after the transformer/filter/transformer setup…

One would think (experiences with medical transformers also point that way) that having garbage not entering, so filtering before the transformer, is most effective.

Now devices with those wonderful SMPS tend to feedback garbage so these are also equipped with a mains filter. Well, there things start to become complicated when an isolation transformer with built in mains filter is feeding such devices.

Now devices with those wonderful SMPS tend to feedback garbage so these are also equipped with a mains filter. Well, there things start to become complicated when an isolation transformer with built in mains filter is feeding such devices.

The one at home is made from two identical 800va transformers in a case. I put a CLCLC line filter between them.

pictures, please!

- Home

- Design & Build

- Construction Tips

- Isolation/safety transformer built (professional)