I don`t have a Facebook account,Nor do I want one.

So Matthew unfortunately i cant see what you have to offer.

So Matthew unfortunately i cant see what you have to offer.

might "this" general arrangement {to preserve K-fetish) be in anyways worthwhile vs using a simple vented rear chamber?

(aperture would be on the 18" wide front"

(aperture would be on the 18" wide front"

Last edited:

I wouldn't see why not. It's still a form of a BP6S enclosure. That K slot is hard to calculate though. I like the simplicity of a square or rectangular exit. Technically, it's still a simple vented rear chamber with a long folded port. Basically, it's a TH with a compression chamber.

Attachments

so for PA310 a sim might be like so ? Do I have the compression chamber "right" ? - would it make more sense to sim that with segments since this tunnel has no taper ?

Attachments

Last edited:

You converted a BP6S to a BP4 by sealing off the back of the speaker with Vrc & Lrc.

Use Vtc & Atc for the compression chamber or add Ap & Lpt to your current model.

Use Vtc & Atc for the compression chamber or add Ap & Lpt to your current model.

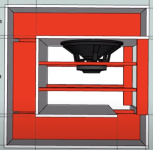

Making reasonable progress on one of the Type C cabs I'm building.

Quick question--I haven't build a cab this powerful before. Would 16AWG wiring be acceptable for the wiring from the speakon input to the driver? The actual cable powering these cabs will be significantly thicker.

Quick question--I haven't build a cab this powerful before. Would 16AWG wiring be acceptable for the wiring from the speakon input to the driver? The actual cable powering these cabs will be significantly thicker.

Attachments

Sure it works, but going larger certainly won't hurt .

Ziggurat,

As BP1Fan said 12AWG if possible (if it isn't too late for that) , but 16AWG will get you by if necessary .........

I have two of the Paraflex Type "C" Classic 1x18 subwoofers built for me (by my friend Pete) and he used 16AWG in these ..... I have the cabinets stacked in my living room right now and I use them daily here for music, movies and video games .........

This is a crazy amount of headroom for my living room but i am really enjoying it and these sound a heck of a lot better than the FLH i was using previously ..... If i were to turn them up loudly i would have neighbors and the police beating on my door long before that 16AWG wire ever began to approach even remotely warm

Would 16AWG wiring be acceptable for the wiring from the speakon input to the driver? The actual cable powering these cabs will be significantly thicker.

Ziggurat,

As BP1Fan said 12AWG if possible (if it isn't too late for that) , but 16AWG will get you by if necessary .........

I have two of the Paraflex Type "C" Classic 1x18 subwoofers built for me (by my friend Pete) and he used 16AWG in these ..... I have the cabinets stacked in my living room right now and I use them daily here for music, movies and video games .........

This is a crazy amount of headroom for my living room but i am really enjoying it and these sound a heck of a lot better than the FLH i was using previously ..... If i were to turn them up loudly i would have neighbors and the police beating on my door long before that 16AWG wire ever began to approach even remotely warm

Last edited:

Making reasonable progress on one of the Type C cabs I'm building.

Ziggurat,

Looks like your Paraflex build is coming along nicely

, but i noticed that some of your plywood panels are the type with a finished surface ..... Be sure to sand or route the surface of those panels where there will be a joint otherwise you may not have a good bond and the joint will be weak .....

, but i noticed that some of your plywood panels are the type with a finished surface ..... Be sure to sand or route the surface of those panels where there will be a joint otherwise you may not have a good bond and the joint will be weak .....I thought i should mention it since some of our other Paraflex builders have had this issue with that type of plywood ...

Assuming amplifier damping factor of 800:

Damping indicates the amplifier's ability to control the driver's diaphragm. The higher this value, the better.

4mm2 cable gives you max handling 3205w handling at 8Ohm. total damping system >400

4mm2 cable gives you max handling 1603w handling at 4Ohm. total damping system > 300

2.5mm2 cable gives you max handling 2253w handling at 8Ohm. total damping system > 300

2.5mm2 cable gives you max handling 1127w handling at 4Ohm. total damping system > 200

1.5mm2 cable gives you max handling 1536w handling at 8Ohm. total damping system > 250

1.5mm2 cable gives you max handling 768w handling at 4Ohm. total damping system > 140

Loss is calculated by cable length. 1m to 10m has minimal loss.

Damping indicates the amplifier's ability to control the driver's diaphragm. The higher this value, the better.

4mm2 cable gives you max handling 3205w handling at 8Ohm. total damping system >400

4mm2 cable gives you max handling 1603w handling at 4Ohm. total damping system > 300

2.5mm2 cable gives you max handling 2253w handling at 8Ohm. total damping system > 300

2.5mm2 cable gives you max handling 1127w handling at 4Ohm. total damping system > 200

1.5mm2 cable gives you max handling 1536w handling at 8Ohm. total damping system > 250

1.5mm2 cable gives you max handling 768w handling at 4Ohm. total damping system > 140

Loss is calculated by cable length. 1m to 10m has minimal loss.

Ziggurat,

Looks like your Paraflex build is coming along nicely, but i noticed that some of your plywood panels are the type with a finished surface ..... Be sure to sand or route the surface of those panels where there will be a joint otherwise you may not have a good bond and the joint will be weak .....

I thought i should mention it since some of our other Paraflex builders have had this issue with that type of plywood ...

As always, thanks for the expert guidance!

I found some 12 gauge wire and swapped it in, no problem.

Fortunately, those plywood panels are just pieces that I sanded, painted and finished before gluing them in simply because I didn't want to reach my torso into the cab to do it on those hard-to-reach surfaces later! The glued ajoints were all bare wood, so no worries there. I may chisel away some of the purple paint to add bracing between the sides and the back wall, though.

Ran the first unfinished cab last night with an 18DS115-8 and it sounded incredible.

Any general advice regarding bracing in the mouth (that cavity is the higher-tuned resonator, right)? I've seen a few different bracing schemes used on this design.

Heck yes!

Ziggurat,

Looking good!

How would you describe the sound?

If the cabinet's upper response sounds a bit too resonant then you always have the option to stick a 2" thick square piece of open-cell acoustic foam on the panel at the back (closed-end) of the High-Tuned resonator section, and that will tighten things up for you 🙂

Ziggurat,

Looking good!

How would you describe the sound?

If the cabinet's upper response sounds a bit too resonant then you always have the option to stick a 2" thick square piece of open-cell acoustic foam on the panel at the back (closed-end) of the High-Tuned resonator section, and that will tighten things up for you 🙂

That's super helpful and thanks for the illustration. How useful would it be to add lateral braces that run perpendicular to the mouth?

There was a sketchup model online that suggested this (attached).

I'm taking my sweet time building these because my day job has been overwhelming but I plan on having them finished by mid June.

There was a sketchup model online that suggested this (attached).

I'm taking my sweet time building these because my day job has been overwhelming but I plan on having them finished by mid June.

Attachments

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Compound loading 6th order quarterwave "Super Planar" horns and pipes concepts/builds