Not yet. I don't like the burned kerf on wood.

My friend has one, I think it's a 50 watt. He uses it for glass etching, woodburning pictures, even putting a picture on slate.

I understand it is great for acrylic.

We seem to be complementing our tools, our tool purchase venn diagram overlaps roughly 50%, which works for both of us. I just finished 6 kilograms of 3d printed bins for his parts drawer cabinets. He is making a 2 by 72 sander, to use for prepping parts for his tig welder. I'm making a flip table for a bandsaw/drill press, he made a large workbench using the dogs I turned/milled to print.

We are considering the design of an underwater drone to move a 20 foot diameter metal detector loop to look for an airplane that went down outside the harbor here decades ago. Silt shifted over the years, so it may be up to 50 feet under the bottom, so a search coil has to be at least one fifth the diameter of the distance you want to detect. Current towed detectors have loops closer to a meter diameter, so can't find metal buried more than 15 feet. My only real challenge is how to run a search pattern, I don't think GPS works in salt water, was thinking about three acoustic pingers the drone can hear to calculate position. Oh, almost forgot..an absolute must is a heartbeat circuit monitoring the system...something hiccups, it blows the ballast and surfaces.

A fun thought experiment for now, some of the other guys are looking through sonar plots that can find buried objects, and scouring underwater floor maps for changes over the years.

jn

My friend has one, I think it's a 50 watt. He uses it for glass etching, woodburning pictures, even putting a picture on slate.

I understand it is great for acrylic.

We seem to be complementing our tools, our tool purchase venn diagram overlaps roughly 50%, which works for both of us. I just finished 6 kilograms of 3d printed bins for his parts drawer cabinets. He is making a 2 by 72 sander, to use for prepping parts for his tig welder. I'm making a flip table for a bandsaw/drill press, he made a large workbench using the dogs I turned/milled to print.

We are considering the design of an underwater drone to move a 20 foot diameter metal detector loop to look for an airplane that went down outside the harbor here decades ago. Silt shifted over the years, so it may be up to 50 feet under the bottom, so a search coil has to be at least one fifth the diameter of the distance you want to detect. Current towed detectors have loops closer to a meter diameter, so can't find metal buried more than 15 feet. My only real challenge is how to run a search pattern, I don't think GPS works in salt water, was thinking about three acoustic pingers the drone can hear to calculate position. Oh, almost forgot..an absolute must is a heartbeat circuit monitoring the system...something hiccups, it blows the ballast and surfaces.

A fun thought experiment for now, some of the other guys are looking through sonar plots that can find buried objects, and scouring underwater floor maps for changes over the years.

jn

Last edited:

I only ask as SWMBO has recently got addicted to laser cut wooden jigsaw puzzles. These are some sort of MDF but I have yet to see any burn marks.

Of course I still have the wooden jigsaw from childhood that the sproglets play with as I did.

Of course I still have the wooden jigsaw from childhood that the sproglets play with as I did.

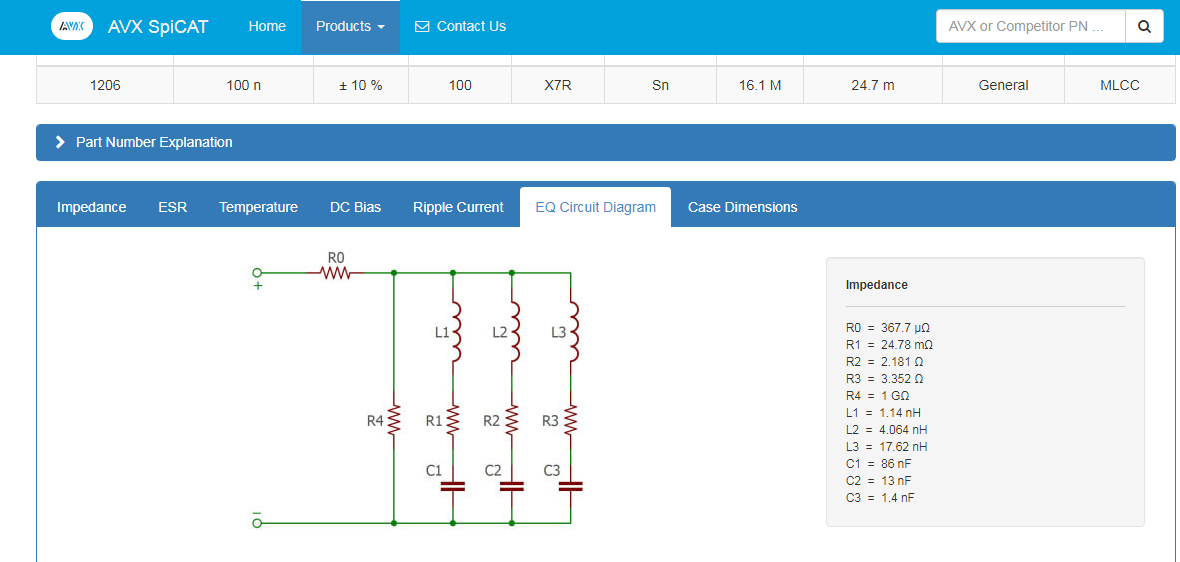

Vendor supplied equivalent circuit model of capacitor with ELEVEN elements

I'm fiddling around with an AVX ceramic capacitor, part number 12061C104KAT2A, when I get the bright idea to visit the manufacturer's website and look around. To my surprise, AVX has a very detailed set of modeling software that's free to use, which gives an astonishing amount of information on second- , third- , and fourth-order effects. Including everyone's good friend, dielectric soakage.

Here is (the web page) -- click on all of the tabs across the top and especially the Equivalent Circuit diagram. You'll see this monster, and more. (Click on image to see it full size and free of foreshortening distortion):

_

I'm fiddling around with an AVX ceramic capacitor, part number 12061C104KAT2A, when I get the bright idea to visit the manufacturer's website and look around. To my surprise, AVX has a very detailed set of modeling software that's free to use, which gives an astonishing amount of information on second- , third- , and fourth-order effects. Including everyone's good friend, dielectric soakage.

Here is (the web page) -- click on all of the tabs across the top and especially the Equivalent Circuit diagram. You'll see this monster, and more. (Click on image to see it full size and free of foreshortening distortion):

_

Attachments

Look at all that stuff hidden inside an otherwise innocent-looking capacitor! If this isn't a government plot, I don't know what is!

(Sorry, heh.) 🙄

P.S. Thanks for the link.

(Sorry, heh.) 🙄

P.S. Thanks for the link.

I had to look up SWMBO...😀. These are some sort of MDF but I have yet to see any burn marks.

.

With the pin router and a climb cut, I can get darn near polished surfaces, an important thing for gear teeth. Wooden teeth don't work well if they are coated with any finish. Not sure why.

The laser kerf is not "clock" quality finish, so I'd probably have to put some 1000 grit on my spindle sander, but first I'd have to make a hardened spindle 1/8th inch diameter to fit in the teeth. I've done it on my drill press, but it is a pita.

My next iteration will be to make pallets out of lignum vitae (brazilian), as that is self lubricating and harder than all getout. Harrison used it for his gears, they were rollers instead of teeth. I got some good pictures when I was there.

jn

Thanks Mark.

Didn't Pease have a model something like that?

I don't think he had the inductances, but I haven't seen in in decades. I can definitely see the need for inductances nowadays with high frequency SMPS.

Ed, you talkin 6L6, or 6L6GC?? I used lots of 6V6 back in the day, pushed 2 speakerlab K knockoffs in my 12 by 12 bedroom.

jn

Didn't Pease have a model something like that?

I don't think he had the inductances, but I haven't seen in in decades. I can definitely see the need for inductances nowadays with high frequency SMPS.

Ed, you talkin 6L6, or 6L6GC?? I used lots of 6V6 back in the day, pushed 2 speakerlab K knockoffs in my 12 by 12 bedroom.

jn

Yup we did the contact explosives. They never locked the windows to the chem lab prep room and the keys were always in the same place. Mind you my science teachers generally encouraged that sort of thing. These days science teaching is far too safe for my liking.

I am fortunate to have survived.

Back in High School days I made my own still, black powder in my mother’s blender and fulminate of mercury tipped homemade rockets. I created a crater in the neighbor’s orchard. I am lucky to be alive and out of jail.

My father was a rocket scientist at Aero-Jet Corp. and encouraged my experimentation. My dad would take the family out the Rancho Cordova back roads, to watch the rocket engine test burns. If the test burn lasted two minutes it was a success.

Today it is audio analyzers and GRAS microphones.

I'm fiddling around with an AVX ceramic capacitor, part number 12061C104KAT2A, when I get the bright idea to visit the manufacturer's website and look around. To my surprise, AVX has a very detailed set of modeling software that's free to use, which gives an astonishing amount of information on second- , third- , and fourth-order effects. Including everyone's good friend, dielectric soakage.

Here is (the web page) -- click on all of the tabs across the top and especially the Equivalent Circuit diagram. You'll see this monster, and more. (Click on image to see it full size and free of foreshortening distortion):

_

Great link! Thanks.

I had to look up Kerf so makes us even 🙂I had to look up SWMBO...😀

Ah. Sounds like an excuse to get one of those vibration polishing setups (don't even know if you can polish wood with them).With the pin router and a climb cut, I can get darn near polished surfaces, an important thing for gear teeth. Wooden teeth don't work well if they are coated with any finish. Not sure why.

Is that legal to buy any more or do you have to chop up something existing? I know in the good/bad old days when Britannia ruled the waves that it was used for bearings in ships rudders.My next iteration will be to make pallets out of lignum vitae

I just remembered, I did a fractal puzzle that was laser cut.

The top and bottom surfaces are clean as a whistle, no evidence of burn. But the cut edges are much darker.

I suspect they may have coated the top surface with something that they cleaned off to prevent burn byproducts from coating the top edge.

As to excuses to buy new tools...my gf always says go for it...The odds of me using a new tool to do something for her is 100%.

jn

The top and bottom surfaces are clean as a whistle, no evidence of burn. But the cut edges are much darker.

I suspect they may have coated the top surface with something that they cleaned off to prevent burn byproducts from coating the top edge.

As to excuses to buy new tools...my gf always says go for it...The odds of me using a new tool to do something for her is 100%.

jn

Attachments

Last edited:

That looks like a fairly nasty puzzle.

You've just reminded me of the episode of 'home improvement' where the wife does an impression of Tim doing a job. She says 'I'll need more tools, just going to the hardware store'.

You've just reminded me of the episode of 'home improvement' where the wife does an impression of Tim doing a job. She says 'I'll need more tools, just going to the hardware store'.

It actually wasn't too bad. I realized that the library loans it out exactly as seen, just inside a zippered carrier bag. So I made a carrier for them using Baltic birch and acrylic sheet. The parts are way too delicate to survive transport if they fall out of the puzzle.

Jn

Jn

DAC comparison

So I have been doing casual A-B comparisons between the two best D>As I have, an Auralic Vega and the RME ADI-2 Pro FS. I fed them both via USB2 and tried swapping ports to see if that made any difference (it did not).

First off, I will state to me they are both indistinguishable from each other with most program material. With some true 24-bit pristine files it sounds to me as if the RME has slightly more edginess with HF dynamics (transient overshoot by the RME, or undershoot by the Auralic?), but the difference is so subtle as to be unnoticeable without a comparison.

Basically what I am saying is they are both so good I just had fun listening to the music instead of finding anything annoying or odd.

I would unhesitatingly recommend either, indeed the RME represents a particularly good value given it also has an excellent equalizer and high power headphone amp built in. It's HP amp rivals >$1k HP amps I have listened to...

Cheers,

Howie

So I have been doing casual A-B comparisons between the two best D>As I have, an Auralic Vega and the RME ADI-2 Pro FS. I fed them both via USB2 and tried swapping ports to see if that made any difference (it did not).

First off, I will state to me they are both indistinguishable from each other with most program material. With some true 24-bit pristine files it sounds to me as if the RME has slightly more edginess with HF dynamics (transient overshoot by the RME, or undershoot by the Auralic?), but the difference is so subtle as to be unnoticeable without a comparison.

Basically what I am saying is they are both so good I just had fun listening to the music instead of finding anything annoying or odd.

I would unhesitatingly recommend either, indeed the RME represents a particularly good value given it also has an excellent equalizer and high power headphone amp built in. It's HP amp rivals >$1k HP amps I have listened to...

Cheers,

Howie

I just remembered, I did a fractal puzzle that was laser cut.

The top and bottom surfaces are clean as a whistle, no evidence of burn. But the cut edges are much darker.

I suspect they may have coated the top surface with something that they cleaned off to prevent burn byproducts from coating the top edge.

As to excuses to buy new tools...my gf always says go for it...The odds of me using a new tool to do something for her is 100%.

jn

The laser cut creates a plasma which in turn oxidizes the metal in the cut lane. On the surface you might get slag or sputtered metal if the laser wasn't configured right ( energy and mabe pulse duration ).

- Home

- Member Areas

- The Lounge

- The Black Hole......