Good side about balanced input is that the 'even harmonics' are dominant.

Hello

I am surprised !

Best regards

Roger

D

Deleted member 148505

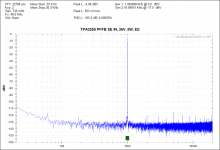

It's weird, I'm getting better measurements on 450kHz + 10uH inductors (in orig module, no modifications).

Attached 5W at 8 ohms 0.0005% THD, I removed THD+N because noise floor of my QA400+interface setup is unreliable.

5W at 4 ohms is 0.002%, so I'm expecting 95dB SINAD only.

5th harmonic on my qa400 + interface setup is naturally high even without DUT.

Attached 5W at 8 ohms 0.0005% THD, I removed THD+N because noise floor of my QA400+interface setup is unreliable.

5W at 4 ohms is 0.002%, so I'm expecting 95dB SINAD only.

5th harmonic on my qa400 + interface setup is naturally high even without DUT.

Attachments

Last edited by a moderator:

D

Deleted member 148505

D

Deleted member 148505

Hello

I am surprised !

Best regards

Roger

I'd take it back, when I changed the wiring, the result is the same be it BAL or SE. I will get BNC to alligator clips so that the result will be consistent.

SMPS300RS has arrived, It's tiny, I can use smaller chassis for this.

Not that it matters but the caps on the primary side of the psu look crappy physically. Easily mistaken for an old , used unit. Can't believe this is direct from factory for the kind of money they are asking for.

I'd take it back, when I changed the wiring, the result is the same be it BAL or SE. I will get BNC to alligator clips so that the result will be consistent.

Lester, do u think there is any advantage to drive the inputs in differential mode? Have u tried to compare the sound?

D

Deleted member 148505

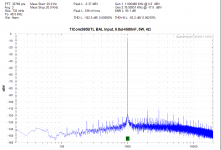

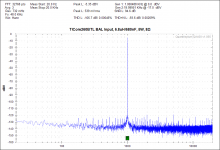

Alright, I found out the culprit of inconsistent and poor THD measurements.

When the opamp of my soundcard interface is heating up, I'm getting higher THD.

When the opamp is cool, I'm getting the best measurements.

So I cooled down the opamp of my soundcard interface, the result of my 'ASR' entry module at 5W, 4Ω is 0.0008% !!!

If the noise floor is good, this will get around ~101dB SINAD.

If the noise floor is more or less the same, I assume the module will get 0.0017% THD+N or 95dB SINAD.

This is exciting 😀, I might just rent an AP if ASR is full jammed with queue for reviews.

When the opamp of my soundcard interface is heating up, I'm getting higher THD.

When the opamp is cool, I'm getting the best measurements.

So I cooled down the opamp of my soundcard interface, the result of my 'ASR' entry module at 5W, 4Ω is 0.0008% !!!

If the noise floor is good, this will get around ~101dB SINAD.

If the noise floor is more or less the same, I assume the module will get 0.0017% THD+N or 95dB SINAD.

This is exciting 😀, I might just rent an AP if ASR is full jammed with queue for reviews.

Attachments

D

Deleted member 148505

Not that it matters but the caps on the primary side of the psu look crappy physically. Easily mistaken for an old , used unit. Can't believe this is direct from factory for the kind of money they are asking for.

Actually the whole unit looks crappy because the whole module was dipped into 'insulating varnish'. So the bubble wrap plastics 'sticked' into the components, and when I removed the bubble wrap, the letterings on the primary capacitors were erased.

And when I touch the module, it still has a sticky feeling so until now it hasn't been fully cured yet.

They should have dipped it on insulating varnish when the through hole parts are not yet assembled. Advanced manufacturing uses conformal coating spray with targeted parts on the PCB.

Also it doesn't have an LED indicator so I might mistakenly touch it while it's LIVE.

Last edited by a moderator:

D

Deleted member 148505

Lester, do u think there is any advantage to drive the inputs in differential mode? Have u tried to compare the sound?

I think it will depend on your 'source'. With my measurements, it's more or less the same.

Yikes. Horrible quality control but hopefully it's not a typical example. I have an SMPS800RS that doesn't have those issues and I know Tom Christensen, and others, have had a decent experience. Have you reached out to Cristi? He's banned from this forum (lol) but should still be responding to emails.Actually the whole unit looks crappy because the 'insulating varnish' is not yet cured. So the bubble wrap plastics 'sticked' into the components, when I removed the bubble wrap, the letterings on the capacitors were erased.

And when I touch the module, it still has a sticky feeling so until now it hasn't been fully cured yet.

Also it doesn't have an LED indicator so I might mistakenly touch it while it's LIVE.

Re: the results, great work! The graph title still says TICore260BTL, will that be the same name even with the TPA3251 board?

D

Deleted member 148505

Yikes. Horrible quality control but hopefully it's not a typical example. I have an SMPS800RS that doesn't have those issues and I know Tom Christensen, and others, have had a decent experience. Have you reached out to Cristi? He's banned from this forum (lol) but should still be responding to emails.

Re: the results, great work! The graph title still says TICore260BTL, will that be the same name even with the TPA3251 board?

I'm ok with this unit, I'll replace the caps anyway.

I'm using the same PCB and TPA3255, I just changed the buffer gain to 1.5x, changed osc freq to 650kHz, changed feedback parts, and used VER2923-682KL + 680nF for the output filter.

D

Deleted member 148505

What impact does (changing) oscillation frequency have on performance / stability?

Should you be sticking a heat sink onto the opamps? 🙂

Should you be sticking a heat sink onto the opamps? 🙂

Hello

The results are very good, it may be necessary to improve the wiring, shielding, partitioning, mains filter etc.

The heating of the AOP of the interface may be due to the absence of a 200kHz filter used during AP class D measurements.

Roger

The results are very good, it may be necessary to improve the wiring, shielding, partitioning, mains filter etc.

The heating of the AOP of the interface may be due to the absence of a 200kHz filter used during AP class D measurements.

Roger

Last edited:

D

Deleted member 148505

What impact does (changing) oscillation frequency have on performance / stability?

Should you be sticking a heat sink onto the opamps? 🙂

Impact of osc frequency depends on class-d design/architecture.

We can change the TPA325X operating frequency for AM avoidance as stated in the datasheet. I've used 650kHz, same as PFFB slaa788a manual, It will have higher idle losses. Higher operating frequency also reduces residual/ripple from the output filter, specially that we've used lower L output inductors.

Yes I will place a heatsink on the opamp.

D

Deleted member 148505

Hello

The results are very good, it may be necessary to improve the wiring, shielding, partitioning, mains filter etc.

Roger

Chassis work + modules placement inside + reducing mains interference is difficult.

Yes probably, the interface doesn't have a steep filter.Hello

The heating of the AOP of the interface may be due to the absence of a 200kHz filter used during AP class D measurements.

Roger

D

Deleted member 148505

Update: Verifying stability of our TICore260BTL (orig schematic) 51V DC rails module with VER2923-682KL. Inductor temp will not be a problem since the dissipation factor of it is low.

As pointed out by pppp, the 682KL has an ultra linear response which I already verified using THD measurements.

If proven stable. We will change the default inductor to VER2923-682KL 🙂

As pointed out by pppp, the 682KL has an ultra linear response which I already verified using THD measurements.

If proven stable. We will change the default inductor to VER2923-682KL 🙂

Does the 682kl have same footprint as 103kl?

I had the 103 sat in my Mouser cart but have just gone out of stock. The 6.8uH is in stock however. Would you recommend get the 6.8 for my recently ordered Ticore260?

I had the 103 sat in my Mouser cart but have just gone out of stock. The 6.8uH is in stock however. Would you recommend get the 6.8 for my recently ordered Ticore260?

D

Deleted member 148505

Does the 682kl have same footprint as 103kl?

I had the 103 sat in my Mouser cart but have just gone out of stock. The 6.8uH is in stock however. Would you recommend get the 6.8 for my recently ordered Ticore260?

Yes they have the same footprint, only different inductance. I will check after stability tests, although theoretically it should run good without any modifications. Output ripple current (carrier residual) will be higher, and the inductors will have a slightly higher idle temp.

Last edited by a moderator:

Is the 682KL very far along on the path of diminishing returns? Quantitatively, what's the impact of using 682KL vs 103KL on higher harmonics (HD4+) and IMD? And would there be anything to gain by using air core inductors?

Jantzen Audio 0.010mH 20 AWG Air Core Inductor Crossover Coil

Jantzen Audio 0.010mH 20 AWG Air Core Inductor Crossover Coil

Last edited:

- Status

- Not open for further replies.

- Home

- Vendor's Bazaar

- Amplifier Modules and PCBs For Sale