Hi,

in my previous thread (My new stats, model #4) I measured the frequency response of my fourth set of DIY esl's. Compared to my previous panels (set #3), by adding a damping screen I managed to substantially reduce resonance, approximately by around 12 dB.

But +12dB @18 Hz is still problematic with some recordings (only a very few, but still I don't like the fact that I can't play all music without problems).

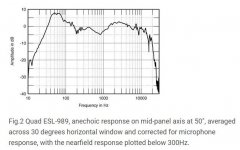

When comparing to a commercial esl like the Quad esl 989, this loudspeaker has an + 8dB resonance peak in a dead-room @ 50 inch mic distance from the loudspeaker. I'm wondering how much this peak would be when measuring close to the loudspeaker (< 10 cm / 4 inch)?

I'm interested in this topic as, as far as I'm aware, Quad loudspeakers don't suffer from severe resonance problems like my own DIY panels do. What did they do to overcome this difficult problem? I've read about felt damping screen for their tweeter panels (esl 57), but I'm curious how bass-resonance is dampened in their current models? Do they use something like a silk mesh screen like I did in my DIY panels? If so, do they apply it on one or both sides? I tried to find more information about this, but was not able to find much about this topic.

in my previous thread (My new stats, model #4) I measured the frequency response of my fourth set of DIY esl's. Compared to my previous panels (set #3), by adding a damping screen I managed to substantially reduce resonance, approximately by around 12 dB.

But +12dB @18 Hz is still problematic with some recordings (only a very few, but still I don't like the fact that I can't play all music without problems).

When comparing to a commercial esl like the Quad esl 989, this loudspeaker has an + 8dB resonance peak in a dead-room @ 50 inch mic distance from the loudspeaker. I'm wondering how much this peak would be when measuring close to the loudspeaker (< 10 cm / 4 inch)?

I'm interested in this topic as, as far as I'm aware, Quad loudspeakers don't suffer from severe resonance problems like my own DIY panels do. What did they do to overcome this difficult problem? I've read about felt damping screen for their tweeter panels (esl 57), but I'm curious how bass-resonance is dampened in their current models? Do they use something like a silk mesh screen like I did in my DIY panels? If so, do they apply it on one or both sides? I tried to find more information about this, but was not able to find much about this topic.

Last edited:

Close to the loudspeaker you get exaggerated bass due to proximity effect.

I've never seen the inside of an ESL-989, but in the ESL-63, there are woven screens at the inside of both stators. According to a chapter that Peter Baxandall wrote about the ESL-63s, the resonance is damped to a Q of about 2. That would normally result in a peak of about 6 dB, but it is compensated for by rolling off the driving current with a first-order slope below about 1 octave above the resonance frequency. All in all, you have a kind of third-order Chebyshev alignment.

If you haven't done so already, you should have a look at Elektrostatic Loudspeakers

I've never seen the inside of an ESL-989, but in the ESL-63, there are woven screens at the inside of both stators. According to a chapter that Peter Baxandall wrote about the ESL-63s, the resonance is damped to a Q of about 2. That would normally result in a peak of about 6 dB, but it is compensated for by rolling off the driving current with a first-order slope below about 1 octave above the resonance frequency. All in all, you have a kind of third-order Chebyshev alignment.

If you haven't done so already, you should have a look at Elektrostatic Loudspeakers

I've never seen the inside of an ESL-989, but in the ESL-63, there are woven screens at the inside of both stators.

The dirty secret is all the modern quads are effectively identical (Don't believe the marketing hype), so if you've seen the workings of one, you've seen the workings of all of them.

Yes, there is a fine mesh screen (silkscreening screen I believe)glued to the rear stator of each panel. It does damp out the resonance nicely, but as noted, not completely. The rise in response combined with the dropping drive level extends the bass response and then it falls rapidly below resonance.

Sheldon

Here's a picture of the stator/damping screen I took a while back. It's an old ESL-63 panel, but as Sheldon said, the basics of these bits have been mostly constant.

Attachments

Last edited:

And here's a Quad ESL-989 frequency response plot from Stereophile that uses nearfield measurement below 300 Hz.

Quad ESL-989 electrostatic loudspeaker Measurements | Stereophile.com

Quad ESL-989 electrostatic loudspeaker Measurements | Stereophile.com

Attachments

Last edited:

Hi, thanks for your insightful replies!

Is the mesh on both front and rear stator, or rear stator only? (one or two screens per channel / esl?)

Is the mesh on both front and rear stator, or rear stator only? (one or two screens per channel / esl?)

On the panel I have, the screen/mesh is only on one stator.

Sheldon's post also says the damping screen is on the rear stator only.

This rebuild shows the same:

Quad ESL repair by Hey You

Sheldon's post also says the damping screen is on the rear stator only.

This rebuild shows the same:

Quad ESL repair by Hey You

I thought it was on both, but it has been years since I last saw an ESL-63 panel, so I probably misremembered.

By the way, according to Baxandall, it was a deliberate choice to damp to a Q of 2 rather than the Q of 1 that would be needed for a third-order Butterworth alignment. With a Q of 2, the current could be rolled off an octave higher which resulted in a better sensitivity (86 dB for 2.83 V, extrapolated to 1 m rather than only 80 dB). So it's a compromise between ripple in the frequency response and sensitivity.

By the way, according to Baxandall, it was a deliberate choice to damp to a Q of 2 rather than the Q of 1 that would be needed for a third-order Butterworth alignment. With a Q of 2, the current could be rolled off an octave higher which resulted in a better sensitivity (86 dB for 2.83 V, extrapolated to 1 m rather than only 80 dB). So it's a compromise between ripple in the frequency response and sensitivity.

The bass panels are driven from series resistors: the smaller the resistors, the higher the current, the higher the sound pressure level but also the higher the cut-off frequency. The story was a bit more complicated for the centre panels with the concentric circles that are driven from a damped transmission line. Anyway, see Baxandall.

like quad you can use a mesh, or felt. the HUGE peak seems to be measured nearby.

when you measure at 1 or 2 meter will give you a better image on how high it actually is you have to compensate or damp

when you measure at 1 or 2 meter will give you a better image on how high it actually is you have to compensate or damp

Hi,

thanks again for your helpful replies. I'm aware that the peak is at maximum closer to the diaphragm.

Could someone tell if the Quad esl plays all music (also music that contains musical information at resonance frequency) without any audible resonance problems?

thanks again for your helpful replies. I'm aware that the peak is at maximum closer to the diaphragm.

Could someone tell if the Quad esl plays all music (also music that contains musical information at resonance frequency) without any audible resonance problems?

I don't mean to hijack your thread, but am curious about the nature of your resonance problem. Are you dealing with muddiness/excess output in the low bass range or is it more of a distortion issue where the diaphragm is hitting the stators?

And what sort of solutions are you willing to entertain? Something as simple as 30 Hz highpass Harrison Labs FMODs might alleviate the issue. They are a cheap thing to try if you don't have other crossover options handy. If successful, you could implement a high quality filter a different way longer term.

Or are you more interested in figuring out how to address the resonance issue from an acoustic/ESL design standpoint?

Sorry for the detour.

And what sort of solutions are you willing to entertain? Something as simple as 30 Hz highpass Harrison Labs FMODs might alleviate the issue. They are a cheap thing to try if you don't have other crossover options handy. If successful, you could implement a high quality filter a different way longer term.

Or are you more interested in figuring out how to address the resonance issue from an acoustic/ESL design standpoint?

Sorry for the detour.

I don't mean to hijack your thread, but am curious about the nature of your resonance problem. Are you dealing with muddiness/excess output in the low bass range or is it more of a distortion issue where the diaphragm is hitting the stators?

No problem - fair question! It's not muddiness or excess of bass output. It sounds good / tight enough to my taste. But I think (this is an assumtion) the diaphragm is hitting the (wire) stators as I do hear a distortive sound, "mylar like". In my previous stats this problem was more frequent, but I still have a few recordings that trigger the mylar-slapping-the-stators-problem.

And what sort of solutions are you willing to entertain? Something as simple as 30 Hz highpass Harrison Labs FMODs might alleviate the issue. They are a cheap thing to try if you don't have other crossover options handy. If successful, you could implement a high quality filter a different way longer term.

I'm not sure about this one. Yesterday I did an expermiment by building a simple wooden frame and stretching antother silk mesh screen and attach it to the outside of the front stator of one esl. I measured a -2.3 dB difference in resonance damping. I was able to hear a very small difference in mid / high sound quality. I will post the results soon in this topic.

But the resonance - problematic recordings were still problematic. I own a MiniDSP 2x4HD so right now I use a 48 dB/oct highpass filter at 20 Hz which practially solves the problem. Thanks for the Harrison Labs FMO suggestion. In the long term I would be interested in a passive filter solution, if this doesn't introduce too many drawbacks.

Or are you more interested in figuring out how to address the resonance issue from an acoustic/ESL design standpoint?

Sorry for the detour.

Yes even though I think my stats are quite ok now, I keep questioning how to get rid of the resonance without being reliant on external devices like a DSP. If I'm correct, a second damping screen won't solve the problem completely. I will experiment with the mentioned felt on the rear stator (bass stator area only), but it seems like a difficult compromise between mid / high soundquality and resonance control.

Last edited:

See the note at the bottom of page 9 (a.k.a. page 7) of https://www.quadesl.com/modernRefs/ESL63_service_manual2.pdf I never heard any rattling when playing music, though.

Obviously you already know a lot of what's in this post, but I'm trying to be thorough for future readers.

From a general design standpoint, diaphragm resonance can be handled a few different ways, and mixing the approaches is common.

You can resistively damp it.

You can stagger multiple resonance frequencies.

You can make the resonance low, then use a high-pass filter to eliminate its excitation. While more common on midrange/tweeter ESLs, if done carefully it can work for full-range designs as well, as your miniDSP solution shows.

You can make the resonance frequency as high as is practically possible. While excursion increases at resonance, the roll-off below that point limits excursion. So the Quad ESL-989 has significantly lower excursion requirements than your design, since the 989's resonance is over an octave higher. My guess is this is likely the biggest difference between your current speaker and Quad's subjective bass performance at higher drive levels. Stator open area, the inclusion of a tensioned membrane dust cover, and any mesh differences are likely smaller contributors, since you describe the rest of your speaker's performance as very good, and your measurements don't seem to indicate that your resonance is more poorly damped than Quad's. The Quads do have a bit more spacing also (2.5 mm).

Another related topic is whether your transformers are saturating at very low frequencies. That can sound similar to a speaker that has run out of travel. If you are using a large amplifier and driving to high levels, it's another possibility. I'm not familiar with Audiostatic transformers, so don't know their capabilities. If Quad's transformer cores are significantly larger than yours, that's another indicator that it might be worth checking. A short-term test with a bunch of extra felt on your speaker would also help determine which issue is at play. If you damp resonance into oblivion, but still have distorted sound at the same drive level, the transformers become more likely.

It's also worth noting that the Quads have a limiter circuit that prevents very high drive levels. You may be pushing harder than is possible with factory Quads.

From a general design standpoint, diaphragm resonance can be handled a few different ways, and mixing the approaches is common.

You can resistively damp it.

You can stagger multiple resonance frequencies.

You can make the resonance low, then use a high-pass filter to eliminate its excitation. While more common on midrange/tweeter ESLs, if done carefully it can work for full-range designs as well, as your miniDSP solution shows.

You can make the resonance frequency as high as is practically possible. While excursion increases at resonance, the roll-off below that point limits excursion. So the Quad ESL-989 has significantly lower excursion requirements than your design, since the 989's resonance is over an octave higher. My guess is this is likely the biggest difference between your current speaker and Quad's subjective bass performance at higher drive levels. Stator open area, the inclusion of a tensioned membrane dust cover, and any mesh differences are likely smaller contributors, since you describe the rest of your speaker's performance as very good, and your measurements don't seem to indicate that your resonance is more poorly damped than Quad's. The Quads do have a bit more spacing also (2.5 mm).

Another related topic is whether your transformers are saturating at very low frequencies. That can sound similar to a speaker that has run out of travel. If you are using a large amplifier and driving to high levels, it's another possibility. I'm not familiar with Audiostatic transformers, so don't know their capabilities. If Quad's transformer cores are significantly larger than yours, that's another indicator that it might be worth checking. A short-term test with a bunch of extra felt on your speaker would also help determine which issue is at play. If you damp resonance into oblivion, but still have distorted sound at the same drive level, the transformers become more likely.

It's also worth noting that the Quads have a limiter circuit that prevents very high drive levels. You may be pushing harder than is possible with factory Quads.

Hi Mattstat, thanks for your insightful reply, I think you are right about the subjective bass performance at higher drive levels / lower excursion requirements.

Damping low frequency resonances, such a filter can clearly do more good than harm.

Adding a (punchy) subwoofer is difficult because of the much longer response time and the much higher distortion.

Is not the method of printing the conductive coil on the diaphragm important?

Adding a (punchy) subwoofer is difficult because of the much longer response time and the much higher distortion.

Is not the method of printing the conductive coil on the diaphragm important?

Is not the method of printing the conductive coil on the diaphragm important?

It sounds like you are describing planar magnetics. Those have low resistance metallic layers that are often patterned to maintain the proper induced field orientation. It is basically a flattened voice coil operating in a permanent magnetic field. The mass of the coil is significant in these designs.

In electrostatic speakers, a very high resistance coating is typically applied uniformly to the diaphragm. The mass of the conductive layer on the diaphragm is low enough to be insignificant in most cases. As the name implies, electrostatic fields are used to move the diaphragm in this type of speaker.

- Home

- Loudspeakers

- Planars & Exotics

- Quad esl resonance damping: how?