I have a couple of E-core transformers. My Kill-O-Watt meter shows 121.5V, .34 Amp. 13.5 Watt & 40.5vA. This is a lot higher than most of my Toroidal transformers of the same size. Any ideas what may be causing this?

Thanks, Terry

Thanks, Terry

Last edited:

In a word, cheap design, skimping on core area or copper turns (or both). A cheaply designed transformer will have high exciting current (that's what you're seeing on the meter - that's the current it takes to magnetize the core). It may also have a low tolerance for higher primary voltage. Silicon steel has a very square hysteresis loop, and it doesn't take a lot of extra volt-seconds to drive it around the bend into saturation, especially if the design is marginal.

Oh dear! If a transformer's core saturates, the primary's impedance essentially becomes resistive with the result of overheating and burning. The core necessarily must never reach magnetic saturation. The fluxes generated by the primary and secondary coils oppose each other according to Lenz's Law. The difference is what causes transformer action and can never reach saturation for correct functioning.Vrystaat said:Lots of transformers runs into saturation with open secondaries.That is what I have read.

Most likely primary inductance is too low. Good 120 VAC 50 VA torrid transformer has primary inductance of about 30H and will draw only few milliamps unloaded. But budget transformers of this size could be only 1-3 H.

Very much depends on the absolute size of the transformer: 13.5W of real, no load losses is substantial, and if it is a 50VA size, it is clearly excessive, but for 500VA, it could be acceptable.I have a couple of E-core transformers. My Kill-O-Watt meter shows 121.5V, .34 Amp. 13.5 Watt & 40.5vA. This is a lot higher than most of my Toroidal transformers of the same size. Any ideas what may be causing this?

Thanks, Terry

The active to reactive power ratio looks reasonable anyway (there are large, yet normal variations).

Another possibility: if the transformers are old, the core may have begun to delaminate which increases the hysteresis and eddy current losses. Over time the insulating adhesive holding the laminations together, starts to break apart, the transformer emits an audible hum. The increasing losses causes the core to heat up and this accelerates the delamination with eventual failure of the transformer as the insulation coating of the windings breaks down under thermal stress.

A properly impregnated transformer shouldn't have this problem. A poorly designed transformer is bad from the git-go.

To Edbarx -

A transformer can and will saturate if it encounters too many volt-seconds because of poor design. This can be caused by insufficient primary turns, insufficient core area, or a combination of both.

Bp = 10^8* Vin/4.44*Np*Ae*f

The above is the classic transformer equation for sine input, rearranged to calculate flux density rather than primary turns. It's easy to see that a varied combination of factors can cause excessive flux density (saturation), including too high input voltage, too low frequency, insufficient primary turns, or insufficient core area.

Another factor that might cause excessive excitation current would be if the core was butt-stacked, and the I-bars shifted in construction or handling such that the core was inadvertently gapped. This would not be the case for interleaved laminations, leaving poor design as the deciding factor. A really cheeseparing design will push the flux density up just short of saturation, resulting in a hot, possibly buzzy transformer with no capacity for withstanding higher line voltage.

A transformer can and will saturate if it encounters too many volt-seconds because of poor design. This can be caused by insufficient primary turns, insufficient core area, or a combination of both.

Bp = 10^8* Vin/4.44*Np*Ae*f

The above is the classic transformer equation for sine input, rearranged to calculate flux density rather than primary turns. It's easy to see that a varied combination of factors can cause excessive flux density (saturation), including too high input voltage, too low frequency, insufficient primary turns, or insufficient core area.

Another factor that might cause excessive excitation current would be if the core was butt-stacked, and the I-bars shifted in construction or handling such that the core was inadvertently gapped. This would not be the case for interleaved laminations, leaving poor design as the deciding factor. A really cheeseparing design will push the flux density up just short of saturation, resulting in a hot, possibly buzzy transformer with no capacity for withstanding higher line voltage.

These transformers were pulled from multi channel amps. They have 4 or 5 different windings. Output are 45/0/45, 17/0/17, 12v/0v, 5v/0v. I bought them for bench testing and they have worked OK but using a light bulb tester it lights the light bulb without any bias dialed into amp itself. I did install one of these in an amp and I am hearing buzzing. I'm thinking that is coming from the transformer. Looks like I need to replace it with something else.

Do you have tools to mesure angle betwen mains voltage and current ??

It should be close to 90 .... if it is not close to 90 the transformer may be defective ... short betwen winding or some other defect

It should be close to 90 .... if it is not close to 90 the transformer may be defective ... short betwen winding or some other defect

You didn´t answer transformer power rating 🙂

In any case,leave the suspect one connected to mains for a couple hours, all secondaries open.

It heats up too much, uncomfortable to the touch, then you may have a problem.

If just warm, but you can wrap your hand around it, no big deal.

In any case,leave the suspect one connected to mains for a couple hours, all secondaries open.

It heats up too much, uncomfortable to the touch, then you may have a problem.

If just warm, but you can wrap your hand around it, no big deal.

I betcha those transformer probably get hot just sitting unloaded on the bench with line voltage applied to the primary and no load. A transformer on the verge of saturation might buzz because of magnetostriction of the core, or the increased current due to saturation might cause the windings to rattle as well.

I have a couple of E-core transformers. My Kill-O-Watt meter shows 121.5V, .34 Amp. 13.5 Watt & 40.5vA. This is a lot higher than most of my Toroidal transformers of the same size. Any ideas what may be causing this?

Thanks, Terry

looks normal to me....what is the VA rating?

although that can use more primary turns by the looks of it...

look at microwave oven traffos, they are worse...

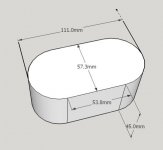

if you can give me dimensions, i can estimate VA..

looks normal to me....what is the VA rating?

although that can use more primary turns by the looks of it...

look at microwave oven traffos, they are worse...

if you can give me dimensions, i can estimate VA..

Here are the dimensions of the copper coil.

Attachments

You didn´t answer transformer power rating 🙂

In any case,leave the suspect one connected to mains for a couple hours, all secondaries open.

It heats up too much, uncomfortable to the touch, then you may have a problem.

If just warm, but you can wrap your hand around it, no big deal.

I left them connected to mains for about an hour

Ambient temp is 32.4C

The yellow trafo is 43.4C and the white trafo is 40.9c measured at the top of the iron. The yellow trafo has a slight hum when it is plugged in. The white one is silent.

OP, you really should have provided photos for starters and indicated that you don't have primary winding voltage spec.

If you have a variac, you can plot the magnetising current versus voltage.

To me, the cores look like they are least 100VA and likely 150 or more.

The core laminations are also not interleaved, and simply butted with weld lines for mass manufacture, so will inherently have lowish primary inductance.

You can also measure primary DCR, and I'd guess that the resistive loss is benign for that size transformer.

If you have a variac, you can plot the magnetising current versus voltage.

To me, the cores look like they are least 100VA and likely 150 or more.

The core laminations are also not interleaved, and simply butted with weld lines for mass manufacture, so will inherently have lowish primary inductance.

You can also measure primary DCR, and I'd guess that the resistive loss is benign for that size transformer.

Here are the dimensions of the copper coil.

not that one....i mean the dimensions of the core, length, width, and stack depth.....

if those were japanese traffo, the cores may not be exactly as per standard, they have their own standards...

The core laminations are also not interleaved, and simply butted with weld lines for mass manufacture, so will inherently have lowish primary inductance.

that is how MOT's are done...this method is quick, and since time is money, they save money by not interleaving laminations...

butt jointing helps in preventing saturation better than if interleaved...

- Home

- Amplifiers

- Power Supplies

- E-core tranformers draw a lot of current with open secondaries.