In-floor subwoofers - 8x8" drivers each, highest WAF factor, lowest THD

I built in-floor sealed subwoofers consisting of 8 x 8" drivers each (Dayton Audio DCS 205-4). Those were the only 8" drivers which I found to fit in the subfloor cavity with a box built around them. Each sub has the cone surface area of 2 x 15" subs and 1 x 15" sub displacement. The drivers were not the reference type but I had to compromise since they were the only ones which would fit. The whole build was designed around the subfloor cavity restriction.

The purpose of the subs was to use them below 40Hz. The box size gives each driver Qtc=0.9, Vb=5 Ltr, , Fb=82Hz .

When the house was still renovated and did not have the drywall installed yet I tested them both with 120Hz x-over at full displacement and they played really loud - I would say around 120dB at 120Hz. The garage floor concrete slab was shaking 🙂.

Each subwoofer has 2 boxes - the first one is the "drivers head", the second box is the "cavity box". Assembled total length is 10.5ft, height 9.25", width 14".

The subwoofer boxes are bolted together and have a removable cover for bolts access. They were installed in the basement ceiling - between the floor joists. The boxes are separated from the floor structure and don't transfer vibrations to the house. The drivers are mounted opposed to each other to cancel any vibrations too. The boxes are suspended by multiple metal straps (like a swing cradle). For safety there are aircraft cables spun across the bottom too (not tensioned, slightly loose and taped to the boxes to prevent rattling).

The subwoofer ports are covered with the same covers used for the heating ducts in the house and you can't tell that they are there.

When there was no furniture in the house yet you could feel the floor bending from the air pressure whenever the subs played.

Now when I have them set up below 40Hz they are enough for movie playing. For this open floor plan and the music levels I enjoy occasionally though I would need 4x that displacement. That's why there is another project on the go for few years already - but that's another topic altogether 🙂.

I built in-floor sealed subwoofers consisting of 8 x 8" drivers each (Dayton Audio DCS 205-4). Those were the only 8" drivers which I found to fit in the subfloor cavity with a box built around them. Each sub has the cone surface area of 2 x 15" subs and 1 x 15" sub displacement. The drivers were not the reference type but I had to compromise since they were the only ones which would fit. The whole build was designed around the subfloor cavity restriction.

The purpose of the subs was to use them below 40Hz. The box size gives each driver Qtc=0.9, Vb=5 Ltr, , Fb=82Hz .

When the house was still renovated and did not have the drywall installed yet I tested them both with 120Hz x-over at full displacement and they played really loud - I would say around 120dB at 120Hz. The garage floor concrete slab was shaking 🙂.

Each subwoofer has 2 boxes - the first one is the "drivers head", the second box is the "cavity box". Assembled total length is 10.5ft, height 9.25", width 14".

The subwoofer boxes are bolted together and have a removable cover for bolts access. They were installed in the basement ceiling - between the floor joists. The boxes are separated from the floor structure and don't transfer vibrations to the house. The drivers are mounted opposed to each other to cancel any vibrations too. The boxes are suspended by multiple metal straps (like a swing cradle). For safety there are aircraft cables spun across the bottom too (not tensioned, slightly loose and taped to the boxes to prevent rattling).

The subwoofer ports are covered with the same covers used for the heating ducts in the house and you can't tell that they are there.

When there was no furniture in the house yet you could feel the floor bending from the air pressure whenever the subs played.

Now when I have them set up below 40Hz they are enough for movie playing. For this open floor plan and the music levels I enjoy occasionally though I would need 4x that displacement. That's why there is another project on the go for few years already - but that's another topic altogether 🙂.

Attachments

Last edited:

More pictures

Attachments

I'm left with these questions:

Why did you not just go with an IB assembly when you have all of the room below available?

Is it to make it self-contained and not bother the room below?

Why did you not wire to one set of posts instead of making it all individually wired? This will allow fewer than all of the drivers to be wired up, and could be devastating to the unconnected woofers should someone else own your home in the future. It would have been more fool-proof if it was pre-wired.

Still- I admire your gumption, and this is impressive to say the least!

Wolf

Why did you not just go with an IB assembly when you have all of the room below available?

Is it to make it self-contained and not bother the room below?

Why did you not wire to one set of posts instead of making it all individually wired? This will allow fewer than all of the drivers to be wired up, and could be devastating to the unconnected woofers should someone else own your home in the future. It would have been more fool-proof if it was pre-wired.

Still- I admire your gumption, and this is impressive to say the least!

Wolf

I did not go to IB since the room below is a functional one.

The drivers are wired to separate connector posts so I can bypass a driver in case one fails and continue using the rest (it's better than loosing the whole subwoofer).

Currently there are jumpers installed across the connector posts and only 1 wire goes to the amplifier.

Once the rooms were finished (main floor and basement) the subwoofers are not accessible anymore.

The drivers are wired to separate connector posts so I can bypass a driver in case one fails and continue using the rest (it's better than loosing the whole subwoofer).

Currently there are jumpers installed across the connector posts and only 1 wire goes to the amplifier.

Once the rooms were finished (main floor and basement) the subwoofers are not accessible anymore.

Cool! Beautiful flooring/grills! Did you post it over on the Cult of the Infinitely Baffled, home of the Twelve Dancing Shivas vertical array?

GM

GM

Thanks GM! The floor grills were installed by the hardwood floor guy and got finished at the same time the floor got finished. All the floor grills in the house are the same so no one can tell that those 2 are the subwoofers ports.

I knew from the get go that the displacement won't be enough for what I ultimately needed but that was a too good opportunity to pass - installing in-floor sealed subwoofers while the house was renovated.

Right after the subs got installed I started using them along with a small i-pod portable speaker while working on the rest of the house construction. I had few good laughs when some of the contractors coming to the house saw the portable speaker alone and could not believe that the i-pod speaker could sound and shake the house like that 🙂

I knew from the get go that the displacement won't be enough for what I ultimately needed but that was a too good opportunity to pass - installing in-floor sealed subwoofers while the house was renovated.

Right after the subs got installed I started using them along with a small i-pod portable speaker while working on the rest of the house construction. I had few good laughs when some of the contractors coming to the house saw the portable speaker alone and could not believe that the i-pod speaker could sound and shake the house like that 🙂

GM,

The IB subs would be the ultimate in low distortion but they require access to large and unused space in the house, the attic or crawl space which none of those I currently have.

I checked the " Cult of the Infinitely Baffled" website you asked about. I did not post it there. That's a really cool site for IB subs install though!

The IB subs would be the ultimate in low distortion but they require access to large and unused space in the house, the attic or crawl space which none of those I currently have.

I checked the " Cult of the Infinitely Baffled" website you asked about. I did not post it there. That's a really cool site for IB subs install though!

Understood, just thought Thomas might let your merely sealed line array be posted as a horizontal IB concept 'wannabe' as opposed to an actual IB.

GM

GM

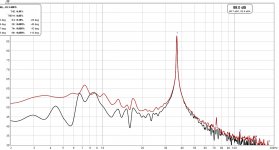

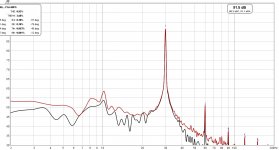

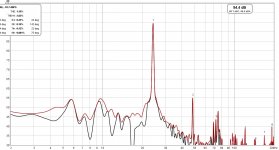

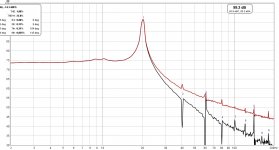

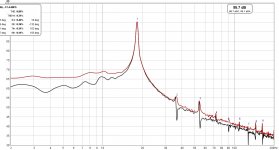

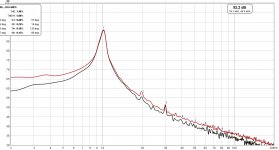

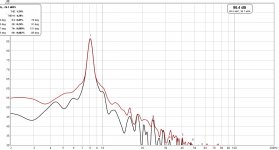

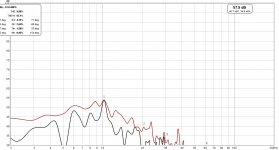

Today I did some THD measurements of the in-floor subs using REW and calibrated UMIC. The readings were taken in the Listening Position which is 12ft away from either sub.

The room is open concept, 45ft deep, 28ft wide, 10ft ceilings. Open to both basement and second floor through stairs. No treatments on walls, lots of hard surfaces, very little furniture, lots of windows. There is a horizontal bass trap in the back upper corner.

The normal listening level peak is 105dB Pink Noise (2Hz-20Hz noise spectrum) in Listening Position.

That is the max level before LF starts rattling the windows, patio door, floor, walls.

Any louder than that and it gets too much LF and the room can not take it.

There is no EQ on the subs.

The subs are xovered at 40Hz.

The subs were drawing no more than 400W each side (-20dB LED on CROWN XLS1500 is solid on; -10dB LED never came on; subs drivers wired for 8 Ohm)

I measured THD starting with the Noise Floor and then continued with the 8Hz - 37Hz band.

I knew the subs were clean sounding even before I started.

The THD measurements really surprised me though. THD% was around 1% anywhere in the 8Hz-37Hz band.

That is a mid-bass driver THD territory, not a subwoofer THD territory.

That shows the advantages of using multiple smaller subs vs one single sub even when the displacement is equal.

Some of the advantages are increased sensitivity (add extra +3dB each time number of subs is doubled; here that means 9dB more sensitivity - which means the total power for all 8 subs is 1/8 of the power needed for 1 large sub if big and small driver sensitivities are equal), reduced thermal compression (the 1/8 power is further dived between the individual drivers - in my case that's about 40W/driver; heat dissipation is a lot easier when the heat load is spread out to multiple drivers) , reduced THD.

The room is open concept, 45ft deep, 28ft wide, 10ft ceilings. Open to both basement and second floor through stairs. No treatments on walls, lots of hard surfaces, very little furniture, lots of windows. There is a horizontal bass trap in the back upper corner.

The normal listening level peak is 105dB Pink Noise (2Hz-20Hz noise spectrum) in Listening Position.

That is the max level before LF starts rattling the windows, patio door, floor, walls.

Any louder than that and it gets too much LF and the room can not take it.

There is no EQ on the subs.

The subs are xovered at 40Hz.

The subs were drawing no more than 400W each side (-20dB LED on CROWN XLS1500 is solid on; -10dB LED never came on; subs drivers wired for 8 Ohm)

I measured THD starting with the Noise Floor and then continued with the 8Hz - 37Hz band.

I knew the subs were clean sounding even before I started.

The THD measurements really surprised me though. THD% was around 1% anywhere in the 8Hz-37Hz band.

That is a mid-bass driver THD territory, not a subwoofer THD territory.

That shows the advantages of using multiple smaller subs vs one single sub even when the displacement is equal.

Some of the advantages are increased sensitivity (add extra +3dB each time number of subs is doubled; here that means 9dB more sensitivity - which means the total power for all 8 subs is 1/8 of the power needed for 1 large sub if big and small driver sensitivities are equal), reduced thermal compression (the 1/8 power is further dived between the individual drivers - in my case that's about 40W/driver; heat dissipation is a lot easier when the heat load is spread out to multiple drivers) , reduced THD.

Attachments

The subs were drawing no more than 400W each side (-20dB LED on CROWN XLS1500 is solid on; -10dB LED never came on; subs drivers wired for 8 Ohm)

Given that the XLS1500 is capable of 300w/ch into 8ohm, -10dB would be 30w/ch and -20dB would be 3w/ch.

Looks like your subs are very efficient!

Chris

Hello, could you tell me what is the blue syrup on the bolts please ?Now you got me thinking.. That setup could work as "convertible sealed subwoofer -to - IB subwoofer". All I have to do is remove the flange bolts access cover and the sub would turn into IB one vented into the basement.

Given that the XLS1500 is capable of 300w/ch into 8ohm, -10dB would be 30w/ch and -20dB would be 3w/ch.

Looks like your subs are very efficient!

Chris

Yes, the sub drivers would start hitting hard limits "Xmech" before the -10dB LED goes solid.

Hello, could you tell me what is the blue syrup on the bolts please ?

That's a threadlocker compound.

It prevents the bolts from loosening themselves up.

"https://www.loctiteproducts.com/en/products/specialty-products/specialty/loctite_threadlockerblue242.html"

Attachments

That's a threadlocker compound.

It prevents the bolts from loosening themselves up.

"https://www.loctiteproducts.com/en/products/specialty-products/specialty/loctite_threadlockerblue242.html"

You should remove all the product on the outside of the threaded parts, it cures anaerobically in consequence the product d'ont dry in the air and therefore will stay liquid and could be projected everywhere with the vibrations. This one is toxic and dangerous for the eyes, do you have a pet ?

I wiped the threads clean before closing the box. They are on the box sealed side too so there is no exposure.

Thanks

Thanks

Attachments

Last edited:

- Home

- Loudspeakers

- Subwoofers

- In-floor subwoofer s- 8x8" drivers each, highest WAF factor