Hi,

I'm working on a tube pre amp and it is ready for test and adjustment. However everytime i switch on the power the fuse blows.

I triple checked wiring etc, tested with all secondary's disconnected but everytime the fuse goes blown. When wired up out of the case and out of circuit no prob and voltages at ac are ok. When mounted inside the chassis with nothing connected the fuse blows.

I know the center mounting bolt and thus the mounting plates (toroidal) is connecting to earth/ ground but would that be enough to blow the fuse? if so, is it safe to just isolate that center bolt and be done? ie no short winding to the trannie?

I've tried and used the mounting materials provided and have not seen this behaviour from this supplier (Amplimo, 4n183) before on other trannie types from this supplier.

Should i just isolate the center bolt and thus the mounting structure, from earth and be done with it or do I need to do something extra?

Just checking, normally i isolate the center bolt and one of the mounting plates thus preventing the short. but I have not experienced fuses blowing when not doing this before.

thanks for answers in advance.

Kind regards,

Joris

I'm working on a tube pre amp and it is ready for test and adjustment. However everytime i switch on the power the fuse blows.

I triple checked wiring etc, tested with all secondary's disconnected but everytime the fuse goes blown. When wired up out of the case and out of circuit no prob and voltages at ac are ok. When mounted inside the chassis with nothing connected the fuse blows.

I know the center mounting bolt and thus the mounting plates (toroidal) is connecting to earth/ ground but would that be enough to blow the fuse? if so, is it safe to just isolate that center bolt and be done? ie no short winding to the trannie?

I've tried and used the mounting materials provided and have not seen this behaviour from this supplier (Amplimo, 4n183) before on other trannie types from this supplier.

Should i just isolate the center bolt and thus the mounting structure, from earth and be done with it or do I need to do something extra?

Just checking, normally i isolate the center bolt and one of the mounting plates thus preventing the short. but I have not experienced fuses blowing when not doing this before.

thanks for answers in advance.

Kind regards,

Joris

Last edited by a moderator:

Do you have 2X110V primaries to be connected in series in order to make 1X220V one? If yes, please check not to have one of the primary shorted, and the other one connected to 220V. If you somehow make a metallic ring (or circuit) through the toroid, you will create a shorted secondary.

Please check all the secondary coils for shorts.

This can be of help

https://www.tubecad.com/2015/12/blog0334.htm

Please check all the secondary coils for shorts.

This can be of help

https://www.tubecad.com/2015/12/blog0334.htm

Last edited:

Should i just isolate the center bolt and thus the mounting structure, from earth.

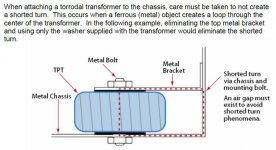

You may have a shorted turn from the mounting bolt. Are both ends of the mounting bolt

directly connected to the chassis? If so, one end needs to be isolated to avoid a shorted turn.

See fig. 9.4 here. http://www.edn.com/design/audio-des...wer-supply-types---transformer-considerations

Last edited:

Transformer manufacturers usually supply their toroids with the mounting hardware, ie. bolt, nut, one (or 2) big steel washer(s), two rubber washers. Did you mount your toroid lying flatly on the chassis? Then the sequence must be (from bottom to top): Chassis - 1st rubber washer - toroid - 2nd rubber washer - steel washer, with the bolt through the center holes. As said before, the top steel washer mustn't be connected electrically to the chassis or something else. Are both rubber washers intact?

Or did you decide to mount the toroid vertically, by means of a U-shaped support? Then you need to isolate one end of the central bolt from the support to prevent a short turn.

Best regards!

Or did you decide to mount the toroid vertically, by means of a U-shaped support? Then you need to isolate one end of the central bolt from the support to prevent a short turn.

Best regards!

Last edited:

I triple checked wiring etc, tested with all secondary's disconnected but everytime the fuse goes blown. When wired up out of the case and out of circuit no prob and voltages at ac are ok. When mounted inside the chassis with nothing connected the fuse blows.

Shorted turn, or damage to the windings that only show up when pressure is applied through mounting

Hi,

thanks for the replies. yes the mounting supplies where used and in the correct way. the trannie is used on 230v mains so primaries in series, ie black and white together. I'm gonna try and reconnect it in circuit, connecting the secondaries one by one. If it passes that I'm gonna remount it isolated from the chassis with light tightning. if it passes that I'll tighten the mounting to see if it is a short that only shows with pressure. Was just wondering if any of you had experienced this behaviour (fuse blowing) with the center bolt not isolated from the chassis and the mounting plate neither, thus indeed creating the short.

regards

Joris

thanks for the replies. yes the mounting supplies where used and in the correct way. the trannie is used on 230v mains so primaries in series, ie black and white together. I'm gonna try and reconnect it in circuit, connecting the secondaries one by one. If it passes that I'm gonna remount it isolated from the chassis with light tightning. if it passes that I'll tighten the mounting to see if it is a short that only shows with pressure. Was just wondering if any of you had experienced this behaviour (fuse blowing) with the center bolt not isolated from the chassis and the mounting plate neither, thus indeed creating the short.

regards

Joris

Last edited:

The short is only going to be created if the top mounting plate or bolt is also making contact with the chassis at the top end

Attachments

Last edited:

Have you used the Mains Bulb Tester to power ON your transformer?Hi,

thanks for the replies. yes the mounting supplies where used and in the correct way. the trannie is used on 230v mains so primaries in series, ie black and white together. I'm gonna try and reconnect it in circuit, connecting the secondaries one by one. If it passes that I'm gonna remount it isolated from the chassis with light tightning. if it passes that I'll tighten the mounting to see if it is a short that only shows with pressure. Was just wondering if any of you had experienced this behaviour (fuse blowing) with the center bolt not isolated from the chassis and the mounting plate neither, thus indeed creating the short.

regards

Joris

Hi,

No i do not use a light bulb. I've got a power cord i use for testing which has some high resistance ntc's. Using this gives me time to see how voltages are coming up. I use multiple multimeters when powering up first time and that is done with me at a distance and a remote controlled on/off switch. That said, i almost never have problems when first checking.

Did the controlled connecting en measuring sequence. Isolating the top mounting plate from the center bolt and thus preventing the shorted turn did it. everything fine now.

A bit puzzled still cause I never experienced this without isolating the mounting structure before. I do wonder however why manufacturers do supply mounting materials but no means to prevent this shorted turn.

greetz,

Joris

No i do not use a light bulb. I've got a power cord i use for testing which has some high resistance ntc's. Using this gives me time to see how voltages are coming up. I use multiple multimeters when powering up first time and that is done with me at a distance and a remote controlled on/off switch. That said, i almost never have problems when first checking.

Did the controlled connecting en measuring sequence. Isolating the top mounting plate from the center bolt and thus preventing the shorted turn did it. everything fine now.

A bit puzzled still cause I never experienced this without isolating the mounting structure before. I do wonder however why manufacturers do supply mounting materials but no means to prevent this shorted turn.

greetz,

Joris

Isolating the top mounting plate from the center bolt and thus preventing the shorted turn did it. everything fine now.

That is interesting, but, to my knowledge, the shorted turn should only be happening if the top of the bolt or mounting plate is in contact with the chassis.

Hi,

The center bolt is still in contact with the chassis and thus safety ground. To my experience you either isolate the bolt from the chassis and leave it connectd to the top plate, or isolate the top plate from the center bolt. Both defeat the shorted turn. Isolating the bolt from both the chassis and the top mounting plate brings no benefits as far as I know.

Regards,

Joris

The center bolt is still in contact with the chassis and thus safety ground. To my experience you either isolate the bolt from the chassis and leave it connectd to the top plate, or isolate the top plate from the center bolt. Both defeat the shorted turn. Isolating the bolt from both the chassis and the top mounting plate brings no benefits as far as I know.

Regards,

Joris

Yes, bolt is in contact with chassis at the bottom, but shorted turn only happens when it is also in contact at the top, as in the diagram I posted. I've never had a problem and needed to isolate the bolt or the mounting plate. This is why I find your experience interesting.

As mentioned above by me, no short turn will be expected it a toroid is mounted flat on the chassis. So there's no need for the manufacturer to supply isolating material additionally. A short turn only happens if you mount the toroid in a manner Scottjoplin has shown in the drawing in post #7 - electric connection from top to bottom outside the toroid.

Btw, something to guess: If we stack three identical toroids, produce a short turn around all of them, and supply them from a three phase mains, nothing happens. Why?

Btw (2): This ain't no joke, as I've seen something like this in 3-phase variacs with the central shaft going through all three toroids and being supported to the Chassis by non-isolated bearings at both of it's ends.

Best regards!

Btw, something to guess: If we stack three identical toroids, produce a short turn around all of them, and supply them from a three phase mains, nothing happens. Why?

Btw (2): This ain't no joke, as I've seen something like this in 3-phase variacs with the central shaft going through all three toroids and being supported to the Chassis by non-isolated bearings at both of it's ends.

Best regards!

Last edited:

Just out of interest, I'm sure I remember a post somewhere on DIY Audio describing how a commercial amplifier had the central ground star-point mounted at the top end of the transformer mounting bolt (with bottom of bolt firmly against chassis). I never understood how that wouldn't cause problems.

Just out of interest, I'm sure I remember a post somewhere on DIY Audio describing how a commercial amplifier had the central ground star-point mounted at the top end of the transformer mounting bolt (with bottom of bolt firmly against chassis). I never understood how that wouldn't cause problems.

Problems only would be expected if there were a second connection to the chassis.

Best regrads!

"Problems only would be expected if there were a second connection to the chassis."

I think that was the point - there was/were at least one other connection - possibly signal earth and/or mains ground. I can't recall the details now, but I remember that commenters were perplexed by the design and why it worked unproblematically.

I think that was the point - there was/were at least one other connection - possibly signal earth and/or mains ground. I can't recall the details now, but I remember that commenters were perplexed by the design and why it worked unproblematically.

Interesting. One reason I've never bought a toroid, they don't list these parts on the web page. Plus capturing between rubber washers encloses the heat.Transformer manufacturers usually supply their toroids with the mounting hardware, ie. bolt, nut, one (or 2) big steel washer(s), two rubber washers.

Commercial toroids like TV's & industrial switcher supplies always have a plastic cradle holding the toroid vertical. No cradle on web page, no toroid purchased by me.

- Home

- Amplifiers

- Power Supplies

- toroidal transformer mounting, insulated?