Hi i have the following problem. i made a small test element to use as tweeter.

but after apllying coating. a transparant glue waterbased from the company HEMA. i dont know if it is exactly the same as the velpon used by so many but it does work. only down side i noticed is this.

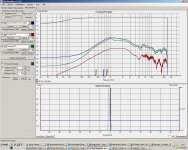

after aplying and when its dry i assemble the element en give it a go, pretty high efficiency and after a while it drops. first the membrane only needed half the voltage to be sucked to one stator after an hour i needed the full 4500 volt, and it wont stuck to membrane. and this is a picture of what happens tot the output, first reading (blue) is a reading after 2 hours on full voltage because output dropped to much already. second reading is green and measured after 3.5 hours last but not least, well it is least but ok (red) after 10 hours, its almost to soft to make a decent measurement.

any ideas ?? looks like when its still is a bit wet it works like a charm but fails after it completly dries. or something

but after apllying coating. a transparant glue waterbased from the company HEMA. i dont know if it is exactly the same as the velpon used by so many but it does work. only down side i noticed is this.

after aplying and when its dry i assemble the element en give it a go, pretty high efficiency and after a while it drops. first the membrane only needed half the voltage to be sucked to one stator after an hour i needed the full 4500 volt, and it wont stuck to membrane. and this is a picture of what happens tot the output, first reading (blue) is a reading after 2 hours on full voltage because output dropped to much already. second reading is green and measured after 3.5 hours last but not least, well it is least but ok (red) after 10 hours, its almost to soft to make a decent measurement.

any ideas ?? looks like when its still is a bit wet it works like a charm but fails after it completly dries. or something

Attachments

Hi WrineX,

Do you keep your diaphragm charged at all the time, or do you charge and measure?

Wachara C.

Do you keep your diaphragm charged at all the time, or do you charge and measure?

Wachara C.

Have you tried inserting a small neon indicator lamp in series with the diaphragm charging circuit so you can monitor the charging rate of the diaphragm? (Faster blinking means a larger charging current.) Perhaps the charge is migrating off your diaphragm via a path that is, for some reason, growing more conductive with time.

Few

Few

yeha have one, but not blinking verry often, also when the glue alcohol solution is still fresh i works like a charm after it completly dries out its going down the drane. going to get me some real velpon glue and test again maybe more thinner layers willl do the trick. or aybe the glue has diferent mixture of ingredients

Calvin suggests adding a couple of drops of black ink to the glue to raise the conductivity (IIRC).

Take a breath and aspirate onto the membrane. If efficiency raise up, your coating just works with a certain kind of humidity layer (as most DIY coatings do).

Capaciti

Capaciti

hmm nice info. by the way wich kind of ink ? suppose the one with carbon black , but i also posted a thread about that where to find stuff with carbon black in it to include in the mix 🙂 exactly what you say. im really curious if that might do the trick. because just ink is like uh there are 3000 sorts of inks🙂

Hi,

i am wondering people telling you about just using some black ink to dope. There is no carbon black in black ink used for writing !! I measured several types of black ink, and never were able to measure some conductivity.

Possibly people dope for having a "good feeling" , but nobody here has proven, means provided measurement readings of black ink.

Folks, before going on suggesting any black ink, tell us about the specific brand, for which you were able to confirm conductivity !

BTW: You can try out different kind of PVA glue. All of them need humidity to work. It depends on the final surface roughness how much water molecules are attracted by the PVA-Layer. Possibly there are types of PVA glue which provide an appropriate layer to attract enough Water, while others dont do. PVA is not conductive.

Capaciti

i am wondering people telling you about just using some black ink to dope. There is no carbon black in black ink used for writing !! I measured several types of black ink, and never were able to measure some conductivity.

Possibly people dope for having a "good feeling" , but nobody here has proven, means provided measurement readings of black ink.

Folks, before going on suggesting any black ink, tell us about the specific brand, for which you were able to confirm conductivity !

BTW: You can try out different kind of PVA glue. All of them need humidity to work. It depends on the final surface roughness how much water molecules are attracted by the PVA-Layer. Possibly there are types of PVA glue which provide an appropriate layer to attract enough Water, while others dont do. PVA is not conductive.

Capaciti

Last edited:

yeah thats the question really 🙂 but i did a little test yesterday with ink from my printer refill kit in combination with the velpon stuff, although i could not measure it the way the mebrane sucked to one stator does say me there is something different with this mix compared to the glue and water only formula. blinking light whas going beserk.

Absolutely,Hi,

i am wondering people telling you about just using some black ink to dope. There is no carbon black in black ink used for writing !! I measured several types of black ink, and never were able to measure some conductivity.

Possibly people dope for having a "good feeling" , but nobody here has proven, means provided measurement readings of black ink.

Folks, before going on suggesting any black ink, tell us about the specific brand, for which you were able to confirm conductivity !

BTW: You can try out different kind of PVA glue. All of them need humidity to work. It depends on the final surface roughness how much water molecules are attracted by the PVA-Layer. Possibly there are types of PVA glue which provide an appropriate layer to attract enough Water, while others dont do. PVA is not conductive.

Capaciti

in order to get conductivity in non-conductive matrix, the amount of carbon black shall be... substantial...

Most printer inks use coated carbon particles - simpiest way to check it is to measure resistance of the printed line - no luck so far.

Quite expensive china (indian) writing ink did not work either

Use graphite or specifically designed dissipative coatings. The latter ones are pricey, shelf life is limited; resistance, however is reproducible,

adhesion is proven and specified in tds by manufacturer.

The one I've got is based on polyanilin (my guess): resistance depends on temperature - measured the value during heat treatment.

Sincerely,

Alex

i am wondering people telling you about just using some black ink to dope. There is no carbon black in black ink used for writing !! I measured several types of black ink, and never were able to measure some conductivity.

I have tried 6 different black inks, including the often recommended India Ink. None seem to improve or change the conductivity of a coating once dry. As a final test, I drew thick black lines on mylar with each of the undiluted inks and let them dry completely with the help of some warm air from a small personal heater. Once dried, none of the black inks were conductive at all. Of course, before the ink was completely dry there is some conductivity.

Perhaps there was one particular black ink that someone found that DID have conductive properties and that was the root of the recommendation for black ink doping.

Last edited:

well i finally after 2 days of aplying and removing caotings, i ended up with a coating with wich sucked my membrane to the stator,

this are the mixtures i tried.

- velpon glue and water, works but not that good whas not able to suck my membrane to one side.

- Ink velpon and water. my experience whas after mesearuments a bit higher output but still not that high.

- ink and velpon no water. did increase output but looks black and verry ugly end gets messy.

- velpon water aplyd after that rubbed in graphite. if people like graphite this is the way to go to applly need almost no graphite sticks verry wel and after rubbin in ytou get some silver mirror, but for me way to low resistance of 300 ohm happens to be the resistance of the earlier solosound panels.

- and now the mixture that worked best for me is

think there is room to bumb up the water so it will get a thinner layer. but for now it workes for me.

velpon , water, and washing soap used 10ml water 3 drops velpon and 4 drops dreft.

only one layer whas enough, if its complete dry it does not stick and its transparant, only from side you see in direct light rainbow colors . sucked my membrane to stator directly (to low res freq for small pannel) so lowerd voltage but got more output then any other solution used by me.

this are the mixtures i tried.

- velpon glue and water, works but not that good whas not able to suck my membrane to one side.

- Ink velpon and water. my experience whas after mesearuments a bit higher output but still not that high.

- ink and velpon no water. did increase output but looks black and verry ugly end gets messy.

- velpon water aplyd after that rubbed in graphite. if people like graphite this is the way to go to applly need almost no graphite sticks verry wel and after rubbin in ytou get some silver mirror, but for me way to low resistance of 300 ohm happens to be the resistance of the earlier solosound panels.

- and now the mixture that worked best for me is

think there is room to bumb up the water so it will get a thinner layer. but for now it workes for me.

velpon , water, and washing soap used 10ml water 3 drops velpon and 4 drops dreft.

only one layer whas enough, if its complete dry it does not stick and its transparant, only from side you see in direct light rainbow colors . sucked my membrane to stator directly (to low res freq for small pannel) so lowerd voltage but got more output then any other solution used by me.

yeah that remains a thing here as well, i leave my setup for now, and measure everyday to look what happens. for now past 5 hours, it just goes a little up and one minute later a little down. stays pretty stable

i figured the ink thing was a farse.as i have yet to find one that is conductive unless it stated as such,including ones that were metalic.i must have spent a small fortune on different kinds of inks.

the only thing that i have found to readily work as a conductive paint is graphite, as i don't have a source for super extra finely ground powdered metal.

I'm wondering if another type of metal oxide could be used such as iron oxide.it is conductive,easy to make and not so poisenous as tin oxide or indium oxide and dissolves in water easily. jer

the only thing that i have found to readily work as a conductive paint is graphite, as i don't have a source for super extra finely ground powdered metal.

I'm wondering if another type of metal oxide could be used such as iron oxide.it is conductive,easy to make and not so poisenous as tin oxide or indium oxide and dissolves in water easily. jer

Hi,

It's interesting to hear from many of you that you can't measure the resistance from the dried black ink. I'll try to make some measurements and report back by tonight.

Wachara C.

It's interesting to hear from many of you that you can't measure the resistance from the dried black ink. I'll try to make some measurements and report back by tonight.

Wachara C.

the reason why i cant measure is just i can only measure up to 2M this is ofcoourse far more, if its conductive at all. for now i forget about the ink stuf. measures my new mix today with mic and its exactly the same output as yesterday .

Hi,

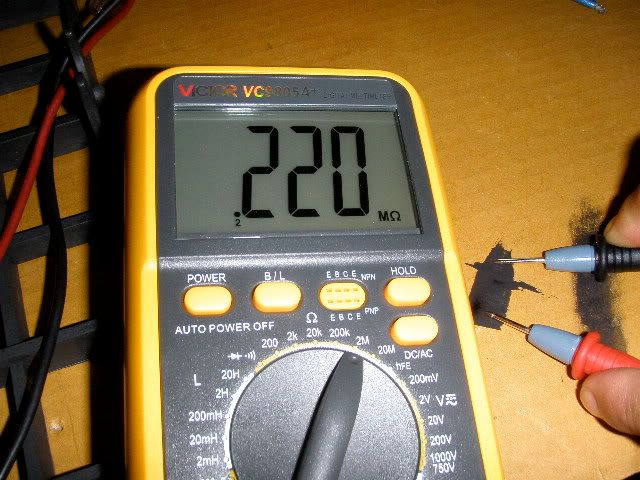

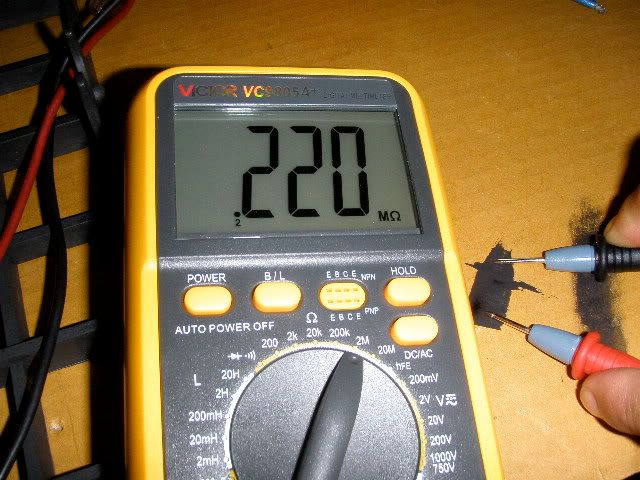

I make two small samples to measure the conductivity (resistivity) of the black poster ink I used. They all show some conductivities as shown.

The first paint sample is thicker (darker) than the second and its resistivity corresponds to that. I get 220K ohm from the first and 4.8M ohm from the second.

The measurements are measured by a cheap multimeter.

I'm quite sure that black ink contains carbon.

Wachara C.

I make two small samples to measure the conductivity (resistivity) of the black poster ink I used. They all show some conductivities as shown.

The first paint sample is thicker (darker) than the second and its resistivity corresponds to that. I get 220K ohm from the first and 4.8M ohm from the second.

The measurements are measured by a cheap multimeter.

I'm quite sure that black ink contains carbon.

Wachara C.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Dropping efficiency coating ?