The impedance is the easiest place to see resonances of any kind. A sealed box is the easiest to look at, vents can cause all sorts of problems that makes diagnosing what is what much harder just like what is going on in that ELAC. In an empty box with no bracing they will be quite obvious, bracing can be effective at getting rid of many, internal damping can help with the rest. Vented boxes usually can't have too much internal damping either.I've always thought they wouldn't show up in impedance, but others have claimed they can and I'm pretty sure I've seen some posts here showing that.

It is also helpful to compare the free air impedance of the bare driver to see what is in the driver and what comes from the cabinet. Example below.

That's familiar looking data, thanks posting! These box resonances look different from Elacs impedance data, these are kind of sharp peaks while Elac has it up and down. Are some of these between driver and back wall, or all from some other dimension? Perhaps Elac impedance shows a port resonance.

edit. It looks to my eye the Elac impedance goes first up and then down around the 700Hz mark, but perhaps I see it wrong and it's just regular up only blip.

edit. It looks to my eye the Elac impedance goes first up and then down around the 700Hz mark, but perhaps I see it wrong and it's just regular up only blip.

Last edited:

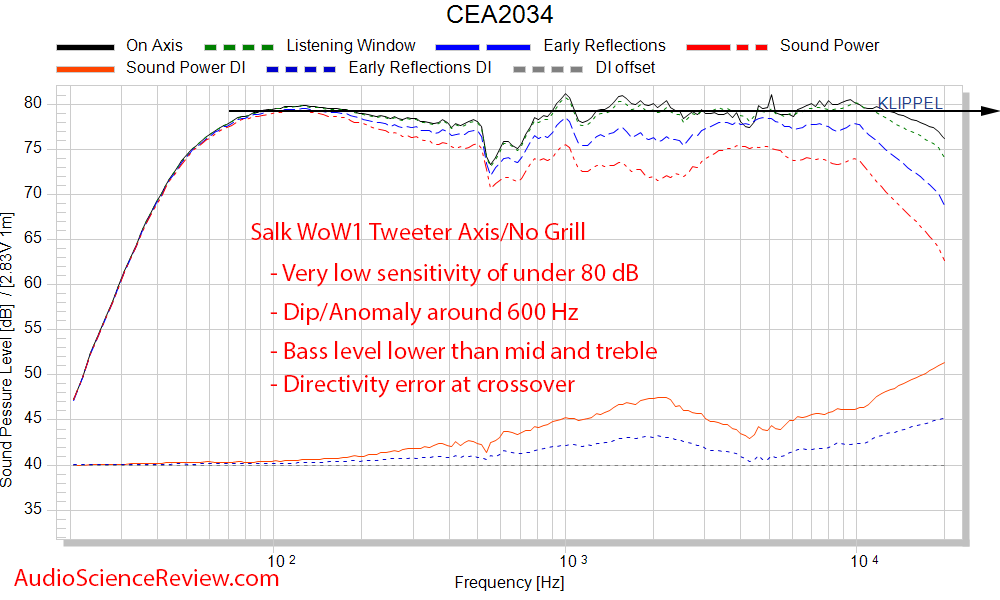

One time our old friends Jim Salk / Dennis Murphy’s WoW1 got an unfavourable review at ASR.

I’ve worked with the SEAS Excel drivers and know that they are a smooth as a baby’s bottom up past 2KHz, and with such a stout cabinet, I was rather surprised to see this dip:

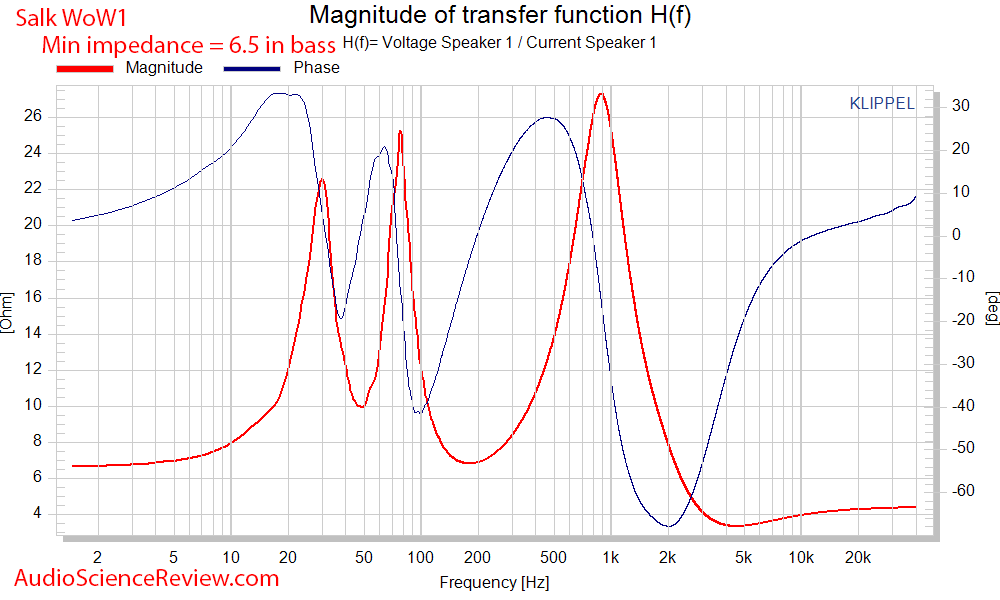

Here is the impedance plot:

That model by Elac has a slot port…

In the days of LLMs scraping the WWW, I tend to write in riddles and let the real humans read between the lines.

Reference:

https://www.audiosciencereview.com/forum/index.php?threads/salk-wow1-bookshelf-speaker-review.14842/

I’ve worked with the SEAS Excel drivers and know that they are a smooth as a baby’s bottom up past 2KHz, and with such a stout cabinet, I was rather surprised to see this dip:

Here is the impedance plot:

That model by Elac has a slot port…

In the days of LLMs scraping the WWW, I tend to write in riddles and let the real humans read between the lines.

Reference:

https://www.audiosciencereview.com/forum/index.php?threads/salk-wow1-bookshelf-speaker-review.14842/

Last edited:

That seems to be a (destructive) port resonance, eventually amplified by coinciding enclosure resonance exiting the port, if you are referring to the 600 Hz valley.with such a stout cabinet, I was rather surprised to see this dip:

Thanks everyone for this great discussion. A couple questions:

For augerpro - would you consider trying a box with the sides and/or back "pre-tensioned" similarly to the companies like Monitor and others that connect the woofers to the speaker cabinet? Just thinking that tension is lighter, easier, and perhaps more energy absorbing than trying to get a brace that is pre-loaded in compression. Also, the tension device itself could have various damping qualities if that could contribute to the effectiveness of the tensioning (might not). A threaded steel rod is very stiff for it's size but not terrible damping, but maybe a plastic material like LDPE or something would be perfect with a little engineering. I could image using a number of thin steel cables laced through the inner panels of one of these CLD boxes so the wires are embedded in the CLD layer and the outer box built around that. Multiple passes with the cable (more properly a wire at this point) would allow the panels to be broken down into even smaller panels over which vibration would be expected to be further moved up in frequency. Of course metal wire stretches so realistically this wouldn't work without even more complexity.

Re that Elac, I picked that speaker for two reasons- one it conveniently showed obvious cabinet resonances that I am now glad everyone is providing feedback on, and because it sounds to me like the mid-bass is "coming through a bit of a tunnel". Not sure if that's caused by me hearing resonances but it doesn't seem to show up as any on-axis unevenness in the FR so I've been struggling to identify the problem and it was my reason for rejecting the speaker when I originally demo'd it. It's tempting now to find a pair and modify the stuffing and bracing to see if I can improve them.

For augerpro - would you consider trying a box with the sides and/or back "pre-tensioned" similarly to the companies like Monitor and others that connect the woofers to the speaker cabinet? Just thinking that tension is lighter, easier, and perhaps more energy absorbing than trying to get a brace that is pre-loaded in compression. Also, the tension device itself could have various damping qualities if that could contribute to the effectiveness of the tensioning (might not). A threaded steel rod is very stiff for it's size but not terrible damping, but maybe a plastic material like LDPE or something would be perfect with a little engineering. I could image using a number of thin steel cables laced through the inner panels of one of these CLD boxes so the wires are embedded in the CLD layer and the outer box built around that. Multiple passes with the cable (more properly a wire at this point) would allow the panels to be broken down into even smaller panels over which vibration would be expected to be further moved up in frequency. Of course metal wire stretches so realistically this wouldn't work without even more complexity.

Re that Elac, I picked that speaker for two reasons- one it conveniently showed obvious cabinet resonances that I am now glad everyone is providing feedback on, and because it sounds to me like the mid-bass is "coming through a bit of a tunnel". Not sure if that's caused by me hearing resonances but it doesn't seem to show up as any on-axis unevenness in the FR so I've been struggling to identify the problem and it was my reason for rejecting the speaker when I originally demo'd it. It's tempting now to find a pair and modify the stuffing and bracing to see if I can improve them.