Unfortunately, adding taps to an OPT is a compromise to the winding geometry, because a tap increases the distance between the coils, hence a higher leakage inductance.

I guess might be easier and more universal with a C-core, two bobbin transformer (Lundahl style). Naturally such transformer has the option to be connected with the primaries in series/parallel, as the secondaries.

Unfortunately for a such 4 Ohm tap transformer with the secondaries connected in parallel, their series connection will result in 16 Ohms for the same primary impedance.

I guess might be easier and more universal with a C-core, two bobbin transformer (Lundahl style). Naturally such transformer has the option to be connected with the primaries in series/parallel, as the secondaries.

Unfortunately for a such 4 Ohm tap transformer with the secondaries connected in parallel, their series connection will result in 16 Ohms for the same primary impedance.

Last edited:

I guess might be easier and more universal with a C-core, two bobbin transformer (Lundahl style).

That's is not true a priori. One friend of mine here knows one thing or two about it. A much cheaper transformer with EI core can do much better. Lundahls apparently work fine in low impedance mode (which for some is low loss and others is higher power loss) otherwise have poor high frequency response. Transformers like the Tango U808 are much better, getting to 100 KHz, despite of the taps at both primary and secondary and EI core!

That's is not true a priori. One friend of mine here knows one thing or two about it. A much cheaper transformer with EI core can do much better. Lundahls apparently work fine in low impedance mode (which for some is low loss and others is higher power loss) otherwise have poor high frequency response. Transformers like the Tango U808 are much better, getting to 100 KHz, despite of the taps at both primary and secondary and EI core!

I'm not trying to generalize, I'm saying that a double bobbin transformer can be built with less additional secondary wires, because there are more wiring combinations possible with two bobbins.

Because Lundahls have poor HF response, it doesn't mean a double bobbin transformer cannot be built for a better one. The ones I have on my amplifier for example (DIY, SE, 2,4k to 8R, 120mA DC), have a high cut-off frequency at 105kHz (-3dB), 9.5cm2 core and even better can be done.

EI or double bobbin C-core, each has its advantages and disadvantages. I've started winding OPTs a year ago and although I learned a lot, there is still a lot more to learn. The greatest teachers are failures from unusable transformers because of a Cp/Ls resonance in the audio range.

Last edited:

It's not true. The number of windings can be whatever one wants regardless of one or two bobbins.I'm not trying to generalize, I'm saying that a double bobbin transformer can be built with less additional secondary wires, because there are more wiring combinations possible with two bobbins.

No it means that the design is not good enough. It is independent of of the number of bobbins. I can do on one bobbin both vertical and horizontal sectioning.Because Lundahls have poor HF response, it doesn't mean a double bobbin transformer cannot be built for a better one.

It's not true. The number of windings can be whatever one wants regardless of one or two bobbins.

I suspect you misunderstood me, or I did not use the correct expression. I meant additional output wires from the bobbins. For example if you're winding a single bobbin, you'll have to alter its geometry much more times as opposed to double bobbins, in case of course you have to take a lead from the inside of the coils.

But it really depends of the design. If you take the magnet wire end of each secondary layer outside the coil, you can do lots of combinations - a DIY friendly transformer.

No it means that the design is not good enough. It is independent of of the number of bobbins. I can do on one bobbin both vertical and horizontal sectioning.

There are drawbacks of single bobbins although. They result in a bigger height that makes the coil layers being more far away from the core, resulting in further leakage inductance. Two coils permit a better core length utilization, splitting the layers in half, so they can be much closer to the core.

Also two coils have the advantage to have a better symmetry, especially useful for SE to PP transformers designs. A single coil will always have a certain asymmetry, even when wound with vertical sectioning.

Have your have made any transformer? I do. There is no practical advantage. There are so many solutions for geometry and wires that you can do whatever you want even with one bobbin. And it can be perfectly symmetric.

The drawback you talk about is inexistent. The height is not a problem for the single bobbin because the magnetic flux has two closed magnetic paths to flow around external to the coil on both left and right hand sides before returning back to the center. It can be problem for the two bobbins arrangement.

The drawback you talk about is inexistent. The height is not a problem for the single bobbin because the magnetic flux has two closed magnetic paths to flow around external to the coil on both left and right hand sides before returning back to the center. It can be problem for the two bobbins arrangement.

Have your have made any transformer? I do.

About 20 OPTs, excluding the PT and chokes. Not so much, but I still learned a lot from it

There is no practical advantage. There are so many solutions for geometry and wires that you can do whatever you want even with one bobbin. And it can be perfectly symmetric.

Can you explain me how you are going to wind two perfectly symmetric secondaries for a SE to PP application that will have the same Rdc and parasitic Lp and Cs to the primary?

The drawback you talk about is inexistent. The height is not a problem for the single bobbin because the magnetic flux has two closed magnetic paths to flow around external to the coil on both left and right hand sides before returning back to the center. It can be problem for the two bobbins arrangement.

And these two closed paths are close to the sides of the bobbin and do not surround the whole bobbin. So they are partially helpful, as opposed to the option to have two bobbins with less height, surrounding the whole core leg.

Double bobbin is closer to the advantages of the toroid transformer.

Last edited:

The shell type (i.e. 4C with one bobbin) and core type (2C with two bobbins) with same total windings and geomtry show no practical difference at high frequency. The 3D field around the core has not a cylindrical geometry so the core type transformer hasn't got any advantage. The leakage path is just different but equivalent for audio purpose. The difference is that for the same basic core the core type transformer is more compact, average turn lenght is about 22% less and the height for EACH bobbin is about 1/2. However, in order to have the same inductance, you MUST have 41% more turns because the cross-section is 1/2. This means that copper loss will be higher and that's the price for a smaller overall volume occupied by the transformer.

If you view a coil from the top view, the magnetic flux is quite cylindrical - reference from the Transformer and inductor design handbook, 3rd edition. It is only when contained in the core that it travels along the core length. The outer legs of a double - C core or EI are far away from the perpendicular side of the bobbin.

Not practical difference at high frequency, because the magnetic coupling is mostly directly between the primary and secondary interleaving, but at the low frequencies the core starts to play its role.

The relation between 4C and 2C and cross section is not an excuse. You have to get a 2C core with a larger cross section and that's it.

You didn't answer my question about the symmetrical winding, so I'll give you the answer myself. It can be done using a split coil where the primaries and secondaries are split in half. It is literally two bobbins into one.

A double C-core single bobbin gapped SE transformer has also problems around the outer air gaps. The later are not covered by coils the cancel the radiated fringing flux from the gaps due to their natural low permability.

Another advantage of double bobbins is the better cooling factor that can be relevant for high power, PP amplifiers.

And two bobbins have the radiated flux canceling mechanism, because they're located in opposing directions. Just like a twisted pair of wires.

Not practical difference at high frequency, because the magnetic coupling is mostly directly between the primary and secondary interleaving, but at the low frequencies the core starts to play its role.

The relation between 4C and 2C and cross section is not an excuse. You have to get a 2C core with a larger cross section and that's it.

You didn't answer my question about the symmetrical winding, so I'll give you the answer myself. It can be done using a split coil where the primaries and secondaries are split in half. It is literally two bobbins into one.

A double C-core single bobbin gapped SE transformer has also problems around the outer air gaps. The later are not covered by coils the cancel the radiated fringing flux from the gaps due to their natural low permability.

Another advantage of double bobbins is the better cooling factor that can be relevant for high power, PP amplifiers.

And two bobbins have the radiated flux canceling mechanism, because they're located in opposing directions. Just like a twisted pair of wires.

Last edited:

C core transformers have 100% grain oriented cores and the fringing flux around the air gap is near zero if the spacer area is just a tiny bit smaller than the core area. Small practical trick!

You can't design a proper audio transformer ignoring what it does at low frequency! If you use a larger core for core-type transformer to avoid winding more turns then you increase the size which will be worse for both leakage inductance and capacitance.

I did give the answer to your question before you asked the question in post n.15!!! Do you know the meaning of vertical and horizontal sectioning?

The reality is the for the 2C using the same basic core number is actually a bit worse. The two coils only cancel partially because the outer parts are too far away and their leakage path goes OUTSIDE the core while the leakage path in 4C core is shorter. This plus the shorter average turn lenght and lower height are not enough to compensate for the additional 41% number of turns (which brings a factor of 2 into the leakage computation). Most manufaturers of high quality audio transformers use the shell type and getting well beyond 100KHz is not a problem. It's not a problem even with EI cores that suffer more leakage.

So please bring this transformer of yours made with 2C's and two bobbins and I will make the equivalent with 4C's. Then we measure them. No practical difference. More copper loss for the 2C type if the basic core is the same. End.

You can't design a proper audio transformer ignoring what it does at low frequency! If you use a larger core for core-type transformer to avoid winding more turns then you increase the size which will be worse for both leakage inductance and capacitance.

I did give the answer to your question before you asked the question in post n.15!!! Do you know the meaning of vertical and horizontal sectioning?

The reality is the for the 2C using the same basic core number is actually a bit worse. The two coils only cancel partially because the outer parts are too far away and their leakage path goes OUTSIDE the core while the leakage path in 4C core is shorter. This plus the shorter average turn lenght and lower height are not enough to compensate for the additional 41% number of turns (which brings a factor of 2 into the leakage computation). Most manufaturers of high quality audio transformers use the shell type and getting well beyond 100KHz is not a problem. It's not a problem even with EI cores that suffer more leakage.

So please bring this transformer of yours made with 2C's and two bobbins and I will make the equivalent with 4C's. Then we measure them. No practical difference. More copper loss for the 2C type if the basic core is the same. End.

Last edited:

EASYCan you explain me how you are going to wind two perfectly symmetric secondaries for a SE to PP application that will have the same Rdc and parasitic Lp and Cs to the primary?

You just get a nice split bobbin and wind exactly the same on both halves

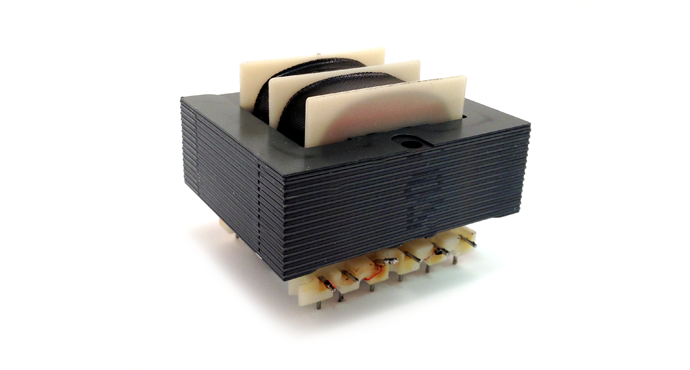

Similar to:

An externally hosted image should be here but it was not working when we last tested it.

EASY

You just get a nice split bobbin and wind exactly the same on both halves

Yes, that's the one. Thanks for sharing. I was expecting the same from 45.

C core transformers have 100% grain oriented cores and the fringing flux around the air gap is near zero if the spacer area is just a tiny bit smaller than the core area. Small practical trick!

I said nothing against the grain orientation. Can you elaborate further about the spacer area please, it didn't make sense to me?

You can't design a proper audio transformer ignoring what it does at low frequency! If you use a larger core for core-type transformer to avoid winding more turns then you increase the size which will be worse for both leakage inductance and capacitance.

When going for a core with a bigger surface area, this is correct for any type of core geometry. And it is where a single bobbin transformer will be worse than a double bobbin one with the same core cross section and tongue dimensions, because it won't have twice the core filling as double bobbin transformers have. Thanks for the s splitting into two bobbins, you're dividing the needed turns in half and that will result in less wire length per turn needed and resulting in less Rdc, but also in less Cs as well due to the lower surface area between windings. Do you doubt it? Do the math. A single bobbin with the same turns and the same height will have larger Rdc and interwinding surface area compared to the sum of the ones from two bobbins.

I did give the answer to your question before you asked the question in post n.15!!! Do you know the meaning of vertical and horizontal sectioning?

I'm sorry, I was expecting the kind of answer that JMFahey gave.

The reality is the for the 2C using the same basic core number is actually a bit worse. The two coils only cancel partially because the outer parts are too far away and their leakage path goes OUTSIDE the core while the leakage path in 4C core is shorter. This plus the shorter average turn lenght and lower height are not enough to compensate for the additional 41% number of turns (which brings a factor of 2 into the leakage computation). Most manufaturers of high quality audio transformers use the shell type and getting well beyond 100KHz is not a problem. It's not a problem even with EI cores that suffer more leakage.

Shorter turn length is a benefit, not a drawback, resulting in less Rdc per turn.

Additional number is needed for a smaller core for less AC flux density. I thought we were comparing 2C and 4C with the same SURFACE area, so that Ac2C = Ac4C

So please bring this transformer of yours made with 2C's and two bobbins and I will make the equivalent with 4C's. Then we measure them. No practical difference. More copper loss for the 2C type if the basic core is the same. End.

I won't be able to move from here from a while, but I can accept another kind of challenge. I can make a 2C transformer with approximately the same basic parameters as you can make one with 4C (core surface area and material, primary inductance, max AC amplitude swing before saturation at 10Hz, Dc current (or not), impedance ratio). The we measure both. If there are doubts in the measurements, we can arrange a third party to measure both transformers for us, possible.

Last edited:

Sorry I am not going to repeat the same things forever. You do not seem to understand simple things like the one related to average turn lenght. If the average turn lenght is just 22% shorter but you must have 41% more turns to match the low frequency performance it is obvious that is not a good thing at all because the copper loss is going to be higher.

I was comparing trnasformers with same basic core. In fact I did say that you must use a bigger core with 2C's to match the cross section in case you want to use the same turns and match the copper loss. In that case capacitance will be worse for sure. Any core you choose with 2C's if I double it with 4C's it will be more efficient and won't be worse in terms of high frequency performance. That's the challenge.

You can use split bobbins also with a core type transformer (on each bobbin) if you like but why? As you say that you have made 20 transformers so I assume you know. I am not going any further. So choose a specific transformer for a specific case and let's see. I will wait....no problem.

I was comparing trnasformers with same basic core. In fact I did say that you must use a bigger core with 2C's to match the cross section in case you want to use the same turns and match the copper loss. In that case capacitance will be worse for sure. Any core you choose with 2C's if I double it with 4C's it will be more efficient and won't be worse in terms of high frequency performance. That's the challenge.

You can use split bobbins also with a core type transformer (on each bobbin) if you like but why? As you say that you have made 20 transformers so I assume you know. I am not going any further. So choose a specific transformer for a specific case and let's see. I will wait....no problem.

Sorry I am not going to repeat the same things forever. You do not seem to understand simple things like the one related to average turn lenght. If the average turn lenght is just 22% shorter but you must have 41% more turns to match the low frequency performance it is obvious that is not a good thing at all because the copper loss is going to be higher.

But WHY? What does the average turn length have to do with the LF response?

Inductance is square dependent of the turns number.

AC flux density at a frequency decreases with the increasing number of turns.

DC flux density increases with the increasing number of turns and can be decreased by lowering the core's permeability by artificially increasing the MPL using an air gap.

I suspect you're talking about air core inductors, where doubling the core height results half decreasing of the inductance value and then it needs ~41% more windings. But this isn't so relevant for magnetic core inductor. Take a 2C. Put one bobbin with x numbers of turns on one of its tongues and measure. Then put two types of the same bobbin on both legs, where their sum of windings is equal to the amount on the first bobbin. Measure again.

But WHY? What does the average turn length have to do with the LF response?

Inductance is square dependent of the turns number.

AC flux density at a frequency decreases with the increasing number of turns.

DC flux density increases with the increasing number of turns and can be decreased by lowering the core's permeability by artificially increasing the MPL using an air gap.

You ask too many questions for someone that claims he can design a transformer.

Is frequency response everything?

Yes, DC induction decreases with the turns that's why with a smaller core area you need more turns. You cannot play with air gap too much because at some point, i.e. above a certain H field, permeability will drop steeply already for 1-2% increase in DC current. You can do that with chokes you CANNOT do that with audio transformers. So if I maximize inductance for the shell type at the max DC current I want use you have no choice with 2C's other than increase the turns.

Wrong.I suspect you're talking about air core inductors, where doubling the core height results half decreasing of the inductance value and then it needs ~41% more windings. But this isn't so relevant for magnetic core inductor. Take a 2C. Put one bobbin with x numbers of turns on one of its tongues and measure. Then put two types of the same bobbin on both legs, where their sum of windings is equal to the amount on the first bobbin. Measure again.

You ask too many questions for someone that claims he can design a transformer.

That's not an excuse, I can still design transformers and ask for further knowledge if I have the desire to be enlightened. Do you have the answers to my questions?

Is frequency response everything?

Well, is there something else? I'm talking about LF response

Yes, DC induction decreases with the turns that's why with a smaller core area you need more turns. You cannot play with air gap too much because at some point, i.e. above a certain H field, permeability will drop steeply already for 1-2% increase in DC current. You can do that with chokes you CANNOT do that with audio transformers. So if I maximize inductance for the shell type at the max DC current I want use you have no choice with 2C's other than increase the turns.

DC induction is not always welcome, because it leaves less AC induction headroom.

Wrong.

Wrong? Why don't you do measurements and post them here?

Here are mine I just did AGAIN, hopefully not to waste my time:

1. I'm measuring the inductance of a single coil with 3840 turns of 0.35mm wire and a height of 82mm on a 2C core. Remember that the coil is located on only one tongue of the core. The later has an area is 6.5cm2. No DC current is present.

2. The measurement result is 106H. The measuring methodology is done using a known capacitor value, forming a parallel LC resonant tank being fed from a high impedance frequency generator and the resonant frequency is measured using a true RMS multimeter. The capacitor's value is 184nF. The resulting resonant frequency Fres=27Hz

3. Then I'm installing two bobbins of the same height on each leg of the same 2C core and each bobbin has 1920 turns. Connected in series and properly oriented, they result in 3840 turns and are measured again.

4. The measurement gives me the same resonant frequency (27Hz) that results in the same inductance value of 106H.

5. My question to you is - where is the difference you claimed that is related to 41% more turns?

Last edited:

First, wrong was referred to the fact that I am not thinking about air cores to do extrapolations.

Second, I define what I need for the amp, select the core, limit the induction (AC + DC) for max Pout, decide a target inductance (as high as I would like) and THEN I find how many turns and the air gap! If losses are not satisfying I decide what to do. It depends on the specific case. So compromises can be different

I think I have already answered several times to your last question: if you have 1920x2=3840 turns on a 2C transformer with a core area A then I only need 2716 with a double core are I get the same inductance, less copper loss and equivalent high frequency performance. If use the same core area with 2C you loose the advantage of size and get worse high frequency performance. If you keep the 1/2 core area and have 2715 turns then your low freuqency performance is A LOT worse. No escape. The shell type transformer is more common for a reason.....

If I wanted a core type transformer where I can improve in high frequency performance without comprising the low frequency performance I would not go for a 2Cs and two coils. I would go for a proper toroidal like a Plitron.

Unfortunately I am not equipped for winding toroidal so I have to buy it. Not interested in doing myself as the shell type transformers I have done so far are good more than enough. As far as I am concerned 200-250 KHz bandwidth makes no difference in practice respect to 100-125 KHz bandwidth....

Having said that I also have Lundahl transformers but they are not better at all. They are compact though and that's why I bought them....

Second, I define what I need for the amp, select the core, limit the induction (AC + DC) for max Pout, decide a target inductance (as high as I would like) and THEN I find how many turns and the air gap! If losses are not satisfying I decide what to do. It depends on the specific case. So compromises can be different

I think I have already answered several times to your last question: if you have 1920x2=3840 turns on a 2C transformer with a core area A then I only need 2716 with a double core are I get the same inductance, less copper loss and equivalent high frequency performance. If use the same core area with 2C you loose the advantage of size and get worse high frequency performance. If you keep the 1/2 core area and have 2715 turns then your low freuqency performance is A LOT worse. No escape. The shell type transformer is more common for a reason.....

If I wanted a core type transformer where I can improve in high frequency performance without comprising the low frequency performance I would not go for a 2Cs and two coils. I would go for a proper toroidal like a Plitron.

Unfortunately I am not equipped for winding toroidal so I have to buy it. Not interested in doing myself as the shell type transformers I have done so far are good more than enough. As far as I am concerned 200-250 KHz bandwidth makes no difference in practice respect to 100-125 KHz bandwidth....

Having said that I also have Lundahl transformers but they are not better at all. They are compact though and that's why I bought them....

Last edited:

That's is not true a priori. One friend of mine here knows one thing or two about it. A much cheaper transformer with EI core can do much better. Lundahls apparently work fine in low impedance mode (which for some is low loss and others is higher power loss) otherwise have poor high frequency response. Transformers like the Tango U808 are much better, getting to 100 KHz, despite of the taps at both primary and secondary and EI core!

C-CORE with tow bobbin is gift for people who makes amps for hifi .for last 5 years i buy c-core and winding in tow bobbin. from 10hz to 40khz .so i am happy with tow bobbin.why use ei ?

tango is good in distortion and fervency resonance but how abut character in audio ?how abut money ?

I'm not trying to generalize, I'm saying that a double bobbin transformer can be built with less additional secondary wires, because there are more wiring combinations possible with two bobbins.

Because Lundahls have poor HF response, it doesn't mean a double bobbin.

i am working with 2 bobbin c-core ...and ....yes

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Yet More Discussion on Winding Output Transformers