I am building a CCDA stereo 9-Pin valve pre-amp and looking for a power

transformer to work with.

http://tubecad.com/Product_PDFs/CCDA_9-Pin

The following is quoted from the document:

“ The CCDA PCB requires a power transformer(s) to energize its two power supplies.

The heater power supply power transformer must offer at least 1.8 times more current than the heaters will draw. For example, two 12FQ7s will draw 0.6A @12.6v, so the heater power transformer must be able to sustain an AC 1.08A current draw. In addition, with sine waves, the AC voltage equals the peak voltage divided by the square root of 2, i.e. 1.414. Thus, a 10Vac sine wave peaks at 14.14V; a 6.3Vac, 8.9V.

In other words, a sine wave that peaks at 14.14V will produce the same amount of heat in a resistance as a 10Vdc voltage source would produce in the same resistance; thus, we label the 14.14Vpk sine wave as being 10Vac. Thus, in order to get the 16Vdc raw DC voltage that a 12.6V heater voltage regulator requires an input voltage equal to remainder of 16V minus the rectifier loss (about 2V) divided by 1.414, which is roughly 12.6Vac.

The high voltage power transformer must also follow the same rules. Thus, to achieve 300V of raw DC voltage, the transformer secondary must deliver (300V +2V) / 1.414, or about 214Vac. And if 50mA is required, the power transformer must be rated for 50mA x 1.8 (in a full-wave bridge rectifier circuit), or 90mA. Thus, such a transformer VA rating would be rated about 20VA, as 0.9 x 214 =19.71. "

I have very limited knowledge and understanding on the power

transformer and seek your help to work out the spec on the Heater and HV.

The following is my understanding for the secondaries of the main transformer

HV 300 VDC (300v + 2v / 1.414) = 214 VAC, 20VA

Heater 17.8 VDC (16v + 2v / 1.414) = 12.6 VAC

I’m going to use 6DJ8 x 2. The heater voltage is 6.3v and heater current is 365ma.

Correct me if I’m wrong. The heater requires 12.6VAC at 1.3A (365ma x 2 =730ma x 1.8 =1.314A x 12.6VAC) = 16.6 VA.

I have looked at the Sowter’s Website Custom Designed Mains Transformers. Its price depends on total power in watts. It says: To obtain the total power in Watts (VA) simply multiply the voltage and current rating of each secondary winding and add them together.

Does it mean: HV = 20(VA) Watts + Heater 16.6(VA) Watts = Total 36.6 Watts? Should I choose the transformer from 35W or 40W?

SOWTER CUSTOM MAINS TRANSFORMERS

I am using solid-state diode for rectification and prefer the centre-tape version for the PT. The transformer main can be used either 120v or 240v. I appreciate your advice on the spec and if you know where to source the power transformer.

Arron

transformer to work with.

http://tubecad.com/Product_PDFs/CCDA_9-Pin

The following is quoted from the document:

“ The CCDA PCB requires a power transformer(s) to energize its two power supplies.

The heater power supply power transformer must offer at least 1.8 times more current than the heaters will draw. For example, two 12FQ7s will draw 0.6A @12.6v, so the heater power transformer must be able to sustain an AC 1.08A current draw. In addition, with sine waves, the AC voltage equals the peak voltage divided by the square root of 2, i.e. 1.414. Thus, a 10Vac sine wave peaks at 14.14V; a 6.3Vac, 8.9V.

In other words, a sine wave that peaks at 14.14V will produce the same amount of heat in a resistance as a 10Vdc voltage source would produce in the same resistance; thus, we label the 14.14Vpk sine wave as being 10Vac. Thus, in order to get the 16Vdc raw DC voltage that a 12.6V heater voltage regulator requires an input voltage equal to remainder of 16V minus the rectifier loss (about 2V) divided by 1.414, which is roughly 12.6Vac.

The high voltage power transformer must also follow the same rules. Thus, to achieve 300V of raw DC voltage, the transformer secondary must deliver (300V +2V) / 1.414, or about 214Vac. And if 50mA is required, the power transformer must be rated for 50mA x 1.8 (in a full-wave bridge rectifier circuit), or 90mA. Thus, such a transformer VA rating would be rated about 20VA, as 0.9 x 214 =19.71. "

I have very limited knowledge and understanding on the power

transformer and seek your help to work out the spec on the Heater and HV.

The following is my understanding for the secondaries of the main transformer

HV 300 VDC (300v + 2v / 1.414) = 214 VAC, 20VA

Heater 17.8 VDC (16v + 2v / 1.414) = 12.6 VAC

I’m going to use 6DJ8 x 2. The heater voltage is 6.3v and heater current is 365ma.

Correct me if I’m wrong. The heater requires 12.6VAC at 1.3A (365ma x 2 =730ma x 1.8 =1.314A x 12.6VAC) = 16.6 VA.

I have looked at the Sowter’s Website Custom Designed Mains Transformers. Its price depends on total power in watts. It says: To obtain the total power in Watts (VA) simply multiply the voltage and current rating of each secondary winding and add them together.

Does it mean: HV = 20(VA) Watts + Heater 16.6(VA) Watts = Total 36.6 Watts? Should I choose the transformer from 35W or 40W?

SOWTER CUSTOM MAINS TRANSFORMERS

I am using solid-state diode for rectification and prefer the centre-tape version for the PT. The transformer main can be used either 120v or 240v. I appreciate your advice on the spec and if you know where to source the power transformer.

Arron

A couple of questions -

What HT voltage do you want? (I.E., what B+ voltage, 200v? 250v? 300v? something else?)

And do you know of any local (well, Australia, for your purposes) distributor of DIY parts and such? A link would be very helpful.

There has to be an off the shelf transformer that is close enough, or perhaps even perfect. You are not needing anything particularly special or strange. A custom xfmr at that power level will be quite expensive for it's size.

What HT voltage do you want? (I.E., what B+ voltage, 200v? 250v? 300v? something else?)

And do you know of any local (well, Australia, for your purposes) distributor of DIY parts and such? A link would be very helpful.

There has to be an off the shelf transformer that is close enough, or perhaps even perfect. You are not needing anything particularly special or strange. A custom xfmr at that power level will be quite expensive for it's size.

The B+ is 300v.

The CCDA xfmr requires the HV 214V at 90 mA = 19.26 VA or 20 Watts and the heater requires 17.8 VDC (16v + 2v / 1.414) = 12.6 VAC.

I’m not sure the heater VA calculation if I use 6DJ8/6922 x 2. The 6DJ8/6922heater voltage is 6.3v and heater current is 365ma.

Correct me if I’m wrong. The heater requires 12.6VAC at 1.3A (365ma x 2 =730ma x 1.8 =1.314A x 12.6VAC) = 16.6 VA or 17 Watts?

Don't have the link for the supply of a quality xfmr for audio here in Australia.

The CCDA xfmr requires the HV 214V at 90 mA = 19.26 VA or 20 Watts and the heater requires 17.8 VDC (16v + 2v / 1.414) = 12.6 VAC.

I’m not sure the heater VA calculation if I use 6DJ8/6922 x 2. The 6DJ8/6922heater voltage is 6.3v and heater current is 365ma.

Correct me if I’m wrong. The heater requires 12.6VAC at 1.3A (365ma x 2 =730ma x 1.8 =1.314A x 12.6VAC) = 16.6 VA or 17 Watts?

Don't have the link for the supply of a quality xfmr for audio here in Australia.

You don't need to run a 6DJ8 with a 12v heater, a 6.3v heater winding will be fine.

They draw about .4A each, or .8A in total, and with rectification losses you will find that a 1.5A winding will be fine, and 2A will be better.

You could choose to run them on 12v, but finding a single transformer with B+ and a 12v heater winding will be difficult.

Also, 300v is really quite hot for a 6DJ8, if you look at page 13 of the CCDA manual you will see a suggested range of 100-240v B+, with the given resistor values centered on 200v B+ .

SO, now knowing that you will be needing about 200v B+ and a suitable winding to run the heaters, we can look at this page - Power Transformer and Choke Prices

And we see that the model "368BX" is awfully close to ideal. It's 150-0-150 (giving about 210v B+, perfect!) at 75ma, which will be fine for the current required. The filament winding is 6.3v 2A, which is more than enough.

If you would be interested in overkill, then look to this - EDCOR - XPWR196-240

It's the same voltage range, just much more current. Underrating a transformer has very little downside, and it's chief advantages are that it will run quiet (low mechanical hummm) and cool. Ignore the 5v winding, it being there will cause no harm to anything.

I have no idea what the Import duty and shipping costs would be to OZ, but it's worth a look. Also know that Edcor makes everything to order, and usually take 4-5 weeks before shipping.

They draw about .4A each, or .8A in total, and with rectification losses you will find that a 1.5A winding will be fine, and 2A will be better.

You could choose to run them on 12v, but finding a single transformer with B+ and a 12v heater winding will be difficult.

Also, 300v is really quite hot for a 6DJ8, if you look at page 13 of the CCDA manual you will see a suggested range of 100-240v B+, with the given resistor values centered on 200v B+ .

SO, now knowing that you will be needing about 200v B+ and a suitable winding to run the heaters, we can look at this page - Power Transformer and Choke Prices

And we see that the model "368BX" is awfully close to ideal. It's 150-0-150 (giving about 210v B+, perfect!) at 75ma, which will be fine for the current required. The filament winding is 6.3v 2A, which is more than enough.

If you would be interested in overkill, then look to this - EDCOR - XPWR196-240

It's the same voltage range, just much more current. Underrating a transformer has very little downside, and it's chief advantages are that it will run quiet (low mechanical hummm) and cool. Ignore the 5v winding, it being there will cause no harm to anything.

I have no idea what the Import duty and shipping costs would be to OZ, but it's worth a look. Also know that Edcor makes everything to order, and usually take 4-5 weeks before shipping.

Aarrgh... I can't type today. The Hammond I'm talking about is the 369BX. Sorry if there was confusion.

good choice, i also make power traffos and for that kind of circuit, an EI-66 will be very adequate....

Thanks 6L6 for your very helpful info.

I should use the 150vac to get the 200vdc to run the 6DJ8. The Edcor XPWR196-240 looks good for my application.

From the schematic it has two 150V points and a CT in the middle. The CCDA B+ PCB has two connection points for the AC and one for the CT. Could you please let me know how to wire the XPWR196-240 to get the 150V.

Thanks and regards.

I should use the 150vac to get the 200vdc to run the 6DJ8. The Edcor XPWR196-240 looks good for my application.

From the schematic it has two 150V points and a CT in the middle. The CCDA B+ PCB has two connection points for the AC and one for the CT. Could you please let me know how to wire the XPWR196-240 to get the 150V.

Thanks and regards.

Of course.

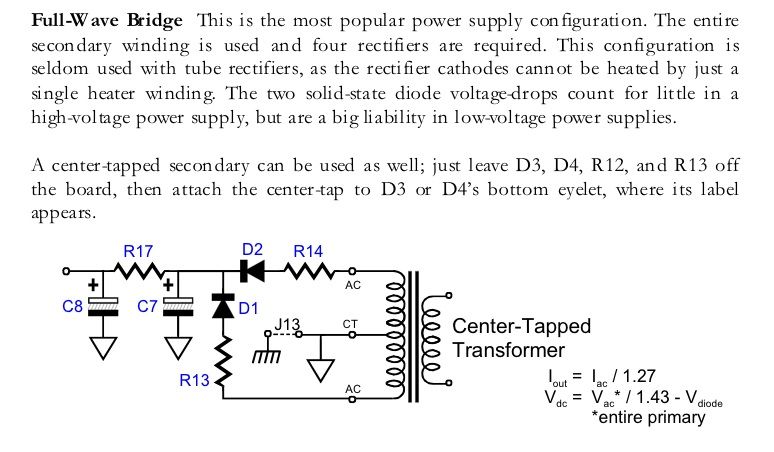

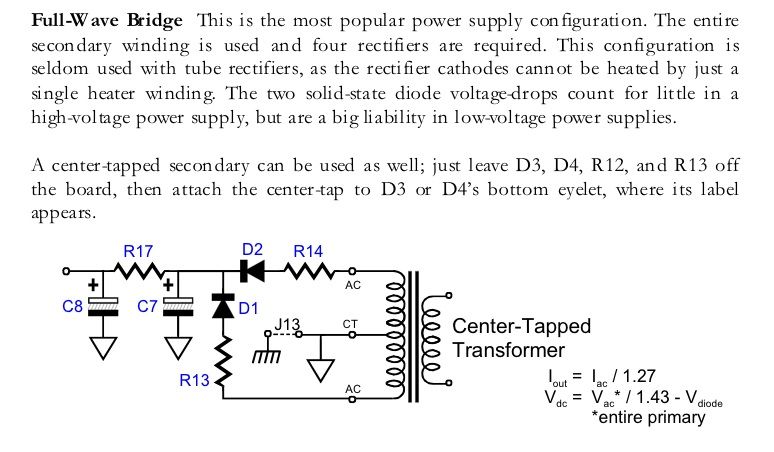

Read page 7 and 8 of the manual, and then build it as in this diagram - -

(Image taken from 9-pin CCDA manual, Tubecad.com)

Hook up the HV wires as above.

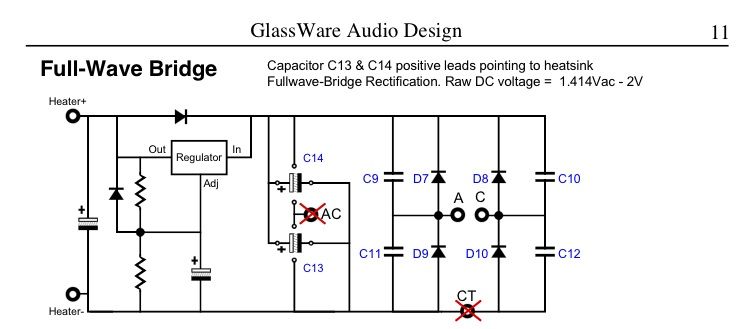

Read pg 9, 10, 11 of the manual, and attach the 6.3v heater winding according to this diagram -

And connect the heater jumpers as necessary for a 6.3v heater with 6.3v tubes. (pg 9, bottom diagram)

Lastly, insulate and tape the ends of the 5v heater winding and ignore them. They will render them inert. Don't cut the leads off, you might use this transformer for something else in the future.

Read page 7 and 8 of the manual, and then build it as in this diagram - -

(Image taken from 9-pin CCDA manual, Tubecad.com)

Hook up the HV wires as above.

Read pg 9, 10, 11 of the manual, and attach the 6.3v heater winding according to this diagram -

And connect the heater jumpers as necessary for a 6.3v heater with 6.3v tubes. (pg 9, bottom diagram)

Lastly, insulate and tape the ends of the 5v heater winding and ignore them. They will render them inert. Don't cut the leads off, you might use this transformer for something else in the future.

Last edited:

My sincere pleasure.

Please feel free to post any questions you have concerning this project in this thread, it's going to be awhile before you proceed, Antek does take awhile, and then you have to ship it...

By the way, I would be very interested in knowing how much it costs all in to your door. pure curiosity.

In the time being, make some plans regarding you chassis, or just plain begin, get the input jacks and selector wired, the pot or attenuator, and your output jacks. As well as Mains input, fuse, power switch, etc...

Also, read the manual a number of times, Broskie puts a ton of information in that document, very densely packed, and it takes a few readings to get your head around all what he says. A lot of it is due to the adaptability of the PCB, but there is still fantastic amounts of info.

Looking forward to seeing how your project comes along!

Cheers,

Jim

Please feel free to post any questions you have concerning this project in this thread, it's going to be awhile before you proceed, Antek does take awhile, and then you have to ship it...

By the way, I would be very interested in knowing how much it costs all in to your door. pure curiosity.

In the time being, make some plans regarding you chassis, or just plain begin, get the input jacks and selector wired, the pot or attenuator, and your output jacks. As well as Mains input, fuse, power switch, etc...

Also, read the manual a number of times, Broskie puts a ton of information in that document, very densely packed, and it takes a few readings to get your head around all what he says. A lot of it is due to the adaptability of the PCB, but there is still fantastic amounts of info.

Looking forward to seeing how your project comes along!

Cheers,

Jim

Hi Jim, the project is in the preparation stage. It would be months away to complete the project. I will post a thread for the process of building the CCDA.

I have read your threads and shared your experience in building of the audio gears. I will post any questions if I need help.

I have read your threads and shared your experience in building of the audio gears. I will post any questions if I need help.

Hi Jim,

I have a question on the transformer heater output voltage required by the CCDA 9 pins 6.3v heaters using the full wave rectification and regulation. The manual on page 10 says:

Heater Regulator = LD1085, LM317, LM350, LT1085,

Vac Input = 7-8Vac @ 5A for 6.3Vdc

The XPWR196-240 heater output is 6.3vac. Is it assuming to be used with 6.3v ac heaters?

I will use the full wave rectification and regulation for 6.3v heaters. What heater output voltage I should go with, the 7-8v or 6.3v?

I have a question on the transformer heater output voltage required by the CCDA 9 pins 6.3v heaters using the full wave rectification and regulation. The manual on page 10 says:

Heater Regulator = LD1085, LM317, LM350, LT1085,

Vac Input = 7-8Vac @ 5A for 6.3Vdc

The XPWR196-240 heater output is 6.3vac. Is it assuming to be used with 6.3v ac heaters?

I will use the full wave rectification and regulation for 6.3v heaters. What heater output voltage I should go with, the 7-8v or 6.3v?

The heater winding on the Edcor (and Hammond, for that matter...) asumes that you are going to be using AC for the heaters.

But when making a preamp AC isn't the best idea, regulated DC is much quieter.

No worries, we will use that heater winding to make DC.

The regulator must see a greater voltage on it's input than it's output.

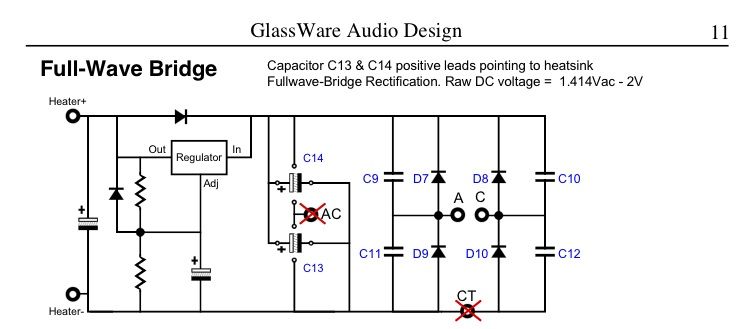

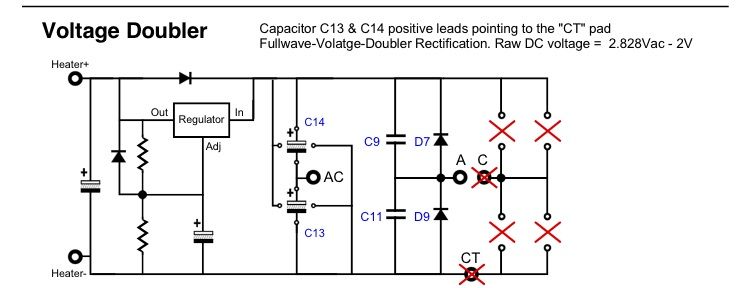

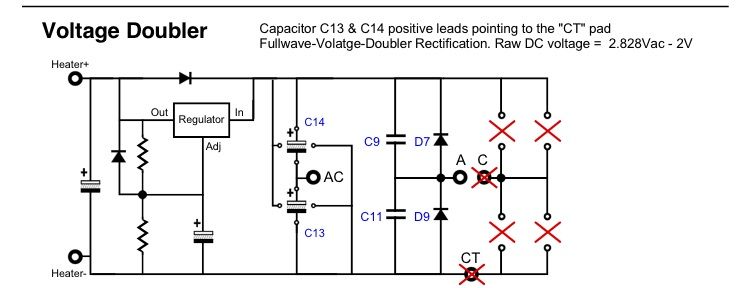

So we will take the AC heater winding and rectify it with a 'voltage doubler' circuit.

This will make DC at about 12v. The 12v DC will be attached to the input of the regulator, and the regulator circuit will reduce it 6.3v DC, and also make it very smooth and quiet.

Specific to your question about the 7-8Vac as input, that is not the configuration that will work with that transformer. With the 6.3Vac winding, you need to use the voltage doubler configuration on the board for the heaters. -- see page 11, bottom diagram.

But when making a preamp AC isn't the best idea, regulated DC is much quieter.

No worries, we will use that heater winding to make DC.

The regulator must see a greater voltage on it's input than it's output.

So we will take the AC heater winding and rectify it with a 'voltage doubler' circuit.

This will make DC at about 12v. The 12v DC will be attached to the input of the regulator, and the regulator circuit will reduce it 6.3v DC, and also make it very smooth and quiet.

Specific to your question about the 7-8Vac as input, that is not the configuration that will work with that transformer. With the 6.3Vac winding, you need to use the voltage doubler configuration on the board for the heaters. -- see page 11, bottom diagram.

SKLau -

I'm very sorry, looking at my previous posts, specifically #11, I see that I pasted the incorrect diagram for the heaters.

My mistake.

This is the proper heater diagram --

It takes the 6.3Vac heater winding, changes the voltage, rectifies, smooths and regulates it to 6.3V DC.

I'm very sorry, looking at my previous posts, specifically #11, I see that I pasted the incorrect diagram for the heaters.

My mistake.

This is the proper heater diagram --

It takes the 6.3Vac heater winding, changes the voltage, rectifies, smooths and regulates it to 6.3V DC.

Thanks Jim for the clarification. Now I have a better understanding for it.

The 6.3v winding has 2 brown wires on the XPWR196-240 schematic. One is 6.3v and the other is common. The Voltage Doubler has two connecting points, the AC and A. Does it require orientation from the 6.3v wiring? If yes, how I differentiate the common brown wire. There may be a dumb question but just want to be sure.

The 6.3v winding has 2 brown wires on the XPWR196-240 schematic. One is 6.3v and the other is common. The Voltage Doubler has two connecting points, the AC and A. Does it require orientation from the 6.3v wiring? If yes, how I differentiate the common brown wire. There may be a dumb question but just want to be sure.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Help for Main Transformer Spec for CCDA