With Filament Bias, I would try to choose the Bias Resistor like this:

- calculate the highest value that you might need, which will be with a starved filament:

say, 7V ÷ 0.8A = 8.75 Ω

5x 47Ω parallel gives 9.4Ω, so that would be an easy-to-buy starting point.

7V bias burns about 5.6W like this, so you could use Welwyn W22 (7W per resistor).

Adding a 100Ω resistor in parallel drops the resistance to 8.6Ω, which is near to your target; and adding another 100Ω in parallel gives 7.9Ω.

Or, you can swap one of the 47Ω Rs for a 100Ω part, to get a slightly higher value.

The Welwyn W22 is good, and low cost:

W22-47RJI - WELWYN - Through Hole Resistor, W22 Series, 47 ohm, 7 W, ± 5%, 200 V, Axial Leaded | Farnell element14

For Ayrton-Perry (non-inductive wirewound construction), the Mills MRA 12 series are at Digi-Key and various audio parts vendors.

These are among the best, but cost is higher.

Yea.. I suppose parallel resistors are the way to go.. What about going with 5W resistors?.. I'd still be way over the power rating required if I had 5 in parallel..

Like this guy:

AC05000004709JAC00 Vishay BC Components | Resistors | DigiKey

Please check that you are OK with the actual operating temperatures in the Data sheet of the part you choose.

Any decent power resistor gives a spec of temperature rise vs power burn. Just beware that some types get over 300°C when running full power!

Any decent power resistor gives a spec of temperature rise vs power burn. Just beware that some types get over 300°C when running full power!

Welwyn W215 series is 5W rated, if you prefer lower cost.

I mention these Welwyn Vitreous Enamelled resistors, as they are known-good in audio.

I mention these Welwyn Vitreous Enamelled resistors, as they are known-good in audio.

Please check that you are OK with the actual operating temperatures in the Data sheet of the part you choose.

Any decent power resistor gives a spec of temperature rise vs power burn. Just beware that some types get over 300°C when running full power!

Good tip.. Though if I'm running 5 (of the same value) in parallel, it's safe to say that my power dissipation per resistor would be 1/5 of the total power, right?

So with 5 resistors, 1.12W per resistor.

Welwyn W215 series is 5W rated, if you prefer lower cost.

I mention these Welwyn Vitreous Enamelled resistors, as they are known-good in audio.

I'm more thinking about the physical size.. Space is limited in this chassis..

Yes, the power-burn shares equally.

5W resistors must be spaced a little further apart then 7W W22 types, due to temperature rise, so the space saving won't be very notable.

5W resistors must be spaced a little further apart then 7W W22 types, due to temperature rise, so the space saving won't be very notable.

I'm more thinking about the physical size.. Space is limited in this chassis..

Mount them on top. These cathode resistors get HOT.....

I'd go straight to the biggest Welwyns you can find in the right value or paralleled up. Start at W24s and work down if you have to. Oversize them at least x2.

Mount them on top. These cathode resistors get HOT.....

I'd go straight to the biggest Welwyns you can find in the right value or paralleled up. Start at W24s and work down if you have to. Oversize them at least x2.

I went with 7W Welwyns.. 47 ohm, a bunch in parallel.. They'll each be dissipating about 1 watt, so I think I should be okay.

Last edited:

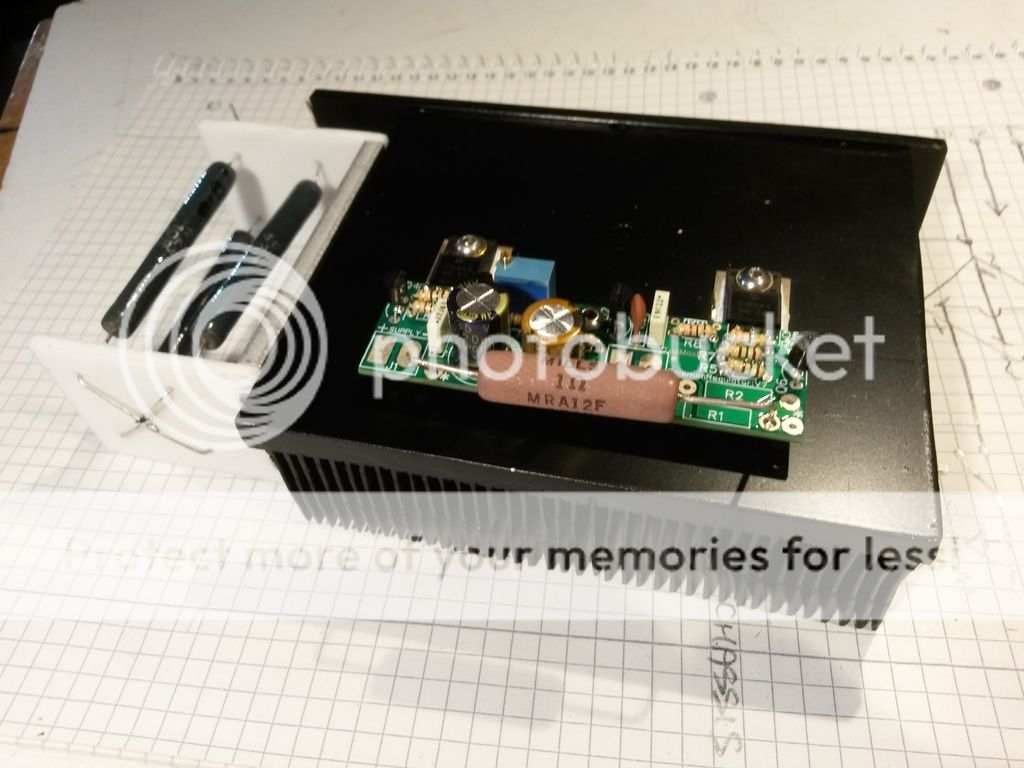

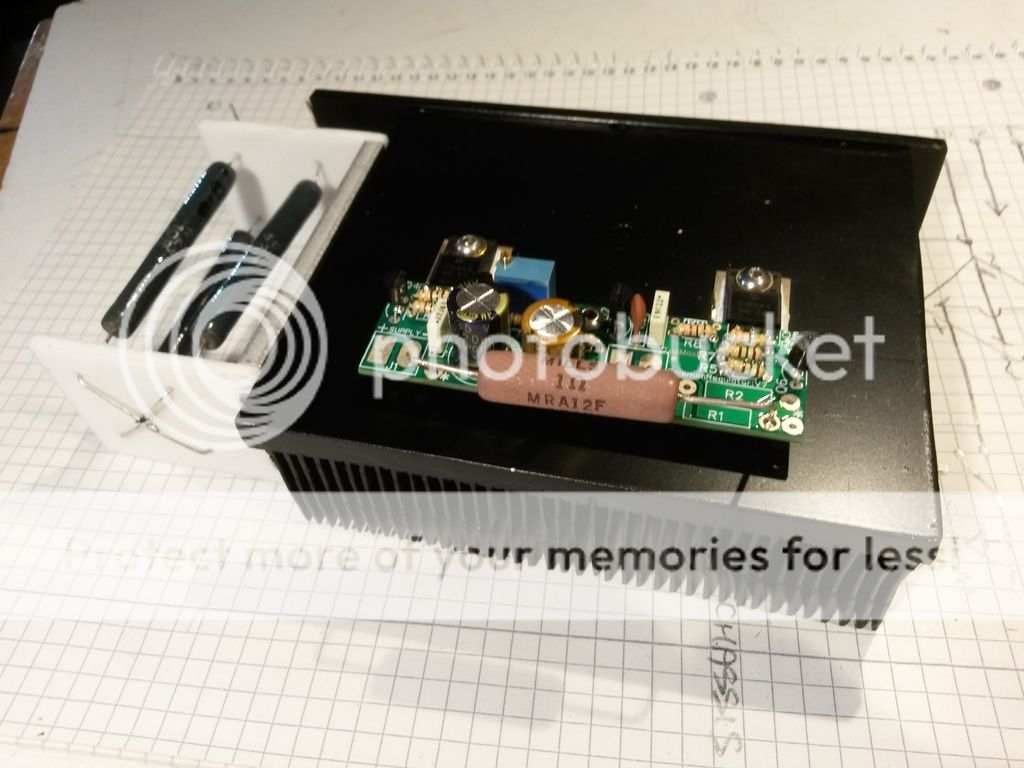

I went with Welwyn W24 12W resistors, 10 ohm series/parallel, but mine are inside the case. (I have drilled a large ventilation hole in the top piece of PTFE since I took this photo.)

I am trying to decide which volume control to use, at least initially, as I would like to try an AVC (probably Slagle for cost reasons) on the output eventually. So although the version I heard (and loved) had the TKD 2CP-2508 on the input, I am reluctant to spend £80 on a pot I may not keep! The PEC carbons are a cheaper possibility, but only available from Digikey. Which means that $33 becomes plus $30 min order charge, plus maybe 25% customs and VAT! So the cheap options are Chinese, either DACT type 21 attenuator (series type I think, about £12 inc p&p) or a Tocos pot (genuine?) at about £10. And a wait of up to a month!

So are there any downsides to using an AVC on the output? I know Thomas recommends them, but I will probably be using a SS power amp, a Parasound Halo A21 if I can find one, with a 33k input impedance. Perhaps I should say that I have been using a basic Promitheus TVC for several years, but my power amps have generally had a 100k input impedance.

Any thoughts? On the AVC question or pot question.

So are there any downsides to using an AVC on the output? I know Thomas recommends them, but I will probably be using a SS power amp, a Parasound Halo A21 if I can find one, with a 33k input impedance. Perhaps I should say that I have been using a basic Promitheus TVC for several years, but my power amps have generally had a 100k input impedance.

Any thoughts? On the AVC question or pot question.

I went with Welwyn W24 12W resistors, 10 ohm series/parallel, but mine are inside the case. (I have drilled a large ventilation hole in the top piece of PTFE since I took this photo.)

PTFE is a neat touch. I originally mounted mine on nylon hexagonal spacers but they melted, so upgraded to the insulated type with metal centres. They held.

http://heatterm.fi.www31.zoner-asiakas.fi/wp-content/uploads/2015/08/insulating-spacers_iso.jpg

I have a few of those left, so I am using them to mount the copper ground strip and a PTFE tag strip.

Simon suggested the PTFE; he uses 4mm, but I went with 3mm so I could use my fancy gold plated turret tags! 50PCS Gold Plated Turrets Post Pins Lugs FR Tube Guitar Amplifier Tag Boards DIY | eBay The 3mm does flex, but is not a problem. I also bought a sheet of 3mm white acetal at the same time, and used that to make up the raw filament supply board; it's much stiffer, and the electrical specs are quite good.

Simon suggested the PTFE; he uses 4mm, but I went with 3mm so I could use my fancy gold plated turret tags! 50PCS Gold Plated Turrets Post Pins Lugs FR Tube Guitar Amplifier Tag Boards DIY | eBay The 3mm does flex, but is not a problem. I also bought a sheet of 3mm white acetal at the same time, and used that to make up the raw filament supply board; it's much stiffer, and the electrical specs are quite good.

I use on my #26 preamp output S&B TX-102 TVC as parafeed OPT, but I have DN2540-IXTP01N100 cascode CCS, with "Lo Z" output. If your preamp output impedance is enough low (below 1k), possible to use TVC/AVC.Any thoughts? On the AVC question or pot question.

In my 801 preamp I use 100k TKD potmeter as input attenuator, because my sources unable to drive my -spare- nano core AVC.

Thanks. I am using Lundahl LL2745 OP trafos, wired for minimum output impedance (5.6:1). I doubt I will need much gain, as I am used to passives with no gain.I use on my #26 preamp output S&B TX-102 TVC as parafeed OPT, but I have DN2540-IXTP01N100 cascode CCS, with "Lo Z" output. If your preamp output impedance is enough low (below 1k), possible to use TVC/AVC.

In my 801 preamp I use 100k TKD potmeter as input attenuator, because my sources unable to drive my -spare- nano core AVC.

I just looked through Ale's site, and he says 300 ohms wired in Alt R. I will take his word for it!🙂

So I was just thinking.. Rather than using a bunch of these 7W Welwyn resistors in parallel for my filament bias resistor, would there be an issue with running a single larger powered chassis mount wirewound resistor? I've got some serious space constraints in my chassis.

Looking at these TE HSA series wirewound chassis mount resistors..

HSA506R8J TE Connectivity AMP Connectors | Resistors | DigiKey

The surface temperature rise graph seems to indicate that the 50W and even the 25W version of their resistor would be at 40 degrees C when dissipating 10W or less, if properly cooled.

I'll be dissipating no more than 8W, so I don't think heat would be a concern..

Is there some reason I shouldn't do this? It would make things much more workable.

Looking at these TE HSA series wirewound chassis mount resistors..

HSA506R8J TE Connectivity AMP Connectors | Resistors | DigiKey

The surface temperature rise graph seems to indicate that the 50W and even the 25W version of their resistor would be at 40 degrees C when dissipating 10W or less, if properly cooled.

I'll be dissipating no more than 8W, so I don't think heat would be a concern..

Is there some reason I shouldn't do this? It would make things much more workable.

Metal clad is an easy solution, but not the best option. When I auditioned a bunch of cathode resistors I didn't like the sound much. So I wouldn't use them myself. They weren't much better than the plain white ceramics, which were the bottom of the pile together with thick film resistors, which were also unexpectedly bad sounding.

What's stopping you using Welwyn W24 resistors on isolated spacers - the ones with metal inserts? I've been using them for years. Sound great, easy to fix, cheap and available. If I need a smaller series or parallel resistor to get the value exact I tend to put those inside to leave a clean look on top. I really don't see a problem.

What's stopping you using Welwyn W24 resistors on isolated spacers - the ones with metal inserts? I've been using them for years. Sound great, easy to fix, cheap and available. If I need a smaller series or parallel resistor to get the value exact I tend to put those inside to leave a clean look on top. I really don't see a problem.

Last edited:

Metal clad is an easy solution, but not the best option. When I auditioned a bunch of cathode resistors I didn't like the sound much. So I wouldn't use them myself. They weren't much better than the plain white ceramics, which were the bottom of the pile together with thick film resistors, which were also unexpectedly bad sounding.

What's stopping you using Welwyn W24 resistors on isolated spacers - the ones with metal inserts? I've been using them for years. Sound great, easy to fix, cheap and available. If I need a smaller series or parallel resistor to get the value exact I tend to put those inside to leave a clean look on top. I really don't see a problem.

Okay, thanks for the info. I'm surprised that the different types of wirewounds would make any difference to sound. I may try auditioning and see if I notice a difference.

How did it affect the sound?

My space constraints are, that I have about a 1.5" x 3" area that I need to work with.. What kind of spacers are you using?

I saw you linked to these http://heatterm.fi.www31.zoner-asiakas.fi/wp-content/uploads/2015/08/insulating-spacers_iso.jpg I'm just trying to figure out how I would work with those..

I'm definitely open to ideas working with my space constraints.

I suppose I could work with something like this http://www.digikey.ca/product-detail/en/keystone-electronics/832/36-832-ND/316947 and then stack them on top of eachother..

Last edited:

I use standoffs like this:

SCHURTER - 9632.52 - Standoff, Nylon 6.6 (Polyamide 6.6), Hex Male-Female, M3, 25 mm | CPC UK

If it doesn't get hot, I use these everywhere with solder tags for mounting components:

DURATOOL - D01497 - Standoff, Nylon 6.6 (Polyamide 6.6), Hex Male-Female, M3, 12 mm | CPC UK

I just stack them up for whatever height or combination of parts I need. Solder tags go in between as necessary. My go-to fastening method. All M3.

ETTINGER - 19.05.039 - SOLDER LUG, ID 3.2MM | CPC UK

SCHURTER - 9632.52 - Standoff, Nylon 6.6 (Polyamide 6.6), Hex Male-Female, M3, 25 mm | CPC UK

If it doesn't get hot, I use these everywhere with solder tags for mounting components:

DURATOOL - D01497 - Standoff, Nylon 6.6 (Polyamide 6.6), Hex Male-Female, M3, 12 mm | CPC UK

I just stack them up for whatever height or combination of parts I need. Solder tags go in between as necessary. My go-to fastening method. All M3.

ETTINGER - 19.05.039 - SOLDER LUG, ID 3.2MM | CPC UK

I use these - BLUE INSULATED CRIMP TERMINALS RING SPADE BUTT FORK BULLET ELECTRICAL CONNECTORS | eBay Available from 3.2mm to 10mm, and they are copper, not brass. I just warm the sleeves, pull them off, crimp and solder. The forks are good too.

I use standoffs like this:

SCHURTER - 9632.52 - Standoff, Nylon 6.6 (Polyamide 6.6), Hex Male-Female, M3, 25 mm | CPC UK

If it doesn't get hot, I use these everywhere with solder tags for mounting components:

DURATOOL - D01497 - Standoff, Nylon 6.6 (Polyamide 6.6), Hex Male-Female, M3, 12 mm | CPC UK

I just stack them up for whatever height or combination of parts I need. Solder tags go in between as necessary. My go-to fastening method. All M3.

ETTINGER - 19.05.039 - SOLDER LUG, ID 3.2MM | CPC UK

Okay, I get it.. I like that idea. Stacking the standoffs on top of eachother.

Thanks for the link. I think I could make that work in my space.

The problem is the dissipation.I really don't see a problem.

8-10W is 8-10W. It's a pure heat, and doubled in stereo preamp.

In the tube preamplifier many component generates heat:

- tubes (heater and anode dissipation);

- anode loads: resistor or active load (yes, yes, choke or OPT is almost cold 🙂 );

- heater regulators (for example Rod Coleman's);

- heater bias resistors;

- HT and LT supplies (unless they are in another box).

My last preamp (801, R.C. regulators, heater bias, SS gyrator, raw supplies in another box) overall dissipation is about 60W!

I personally -as EE- don't like components hotter than necessary inside the preamp box, therefore I use several solutions to reducing of heat: heatsinks, air flow practices, etc.

For me the psychological limits is about 70 Celsius degree. Over it the nearest components (for example electrolyte capacitors) would be in jeopardy, the lifetime would be decrease.

For example the Welwyn W24 has 22C/Watt thermal impedance, so already at 2W dissipation its temperature is 25+2*22= 69C. This temperature at 4w is about 113 C. Accidentally I used these resistors at 200-210 C, but it's not normal!

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp