Because the circuit is cathode-biased, small changes in B+ from rectifier changes won't result in much change in the output tube operating conditions. The circuit automatically tries to compensate. The only way to do it effectively is to make the resistor itself easily swappable or have multiple resistors that are switchable.

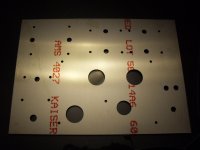

Started working on the simple se top plate. I will be posting pictures of chassis this weekend

Nice! paper templates......they work great!

Judging from the tool marks, a table saw?Your case work looks excellent. I'm planning and SSE project myself, was thinking along similar lines. What tool did you use to cut the 2mm? recess along the edge of the 4 pieces of wood?

Thank you for the compliment, I used a table saw for the recess and just mitered the corners. Blade must have some varnish build up. The top plate is from online metals. I would wait to have the metal on hand befor making any cuts, they only guaranty size to + or - 1/8"

Edcor just sent me a shipping notice so I should have this all done soon!

Edcor just sent me a shipping notice so I should have this all done soon!

Hey...

Regarding "interchangeable bias resistors" (and a switch, or not)... here's one idea I had that has worked really well over the years: RCA jack ... in the place of the resistor. With a little creative soldering, you can make interchangeable plugs ... with a variety of resistance values ... and then its easy to just "shut down the amp, swap resistors, and power it back up". Alternately (and somewhat more double-safe) would be using quarter-inch jacks. In one case, I used "tip-jacks" of the smallest variety (1 millimeter openings), as a pair so that the bias resistor could simply be an external-to-case device. Bend the legs at just the right spot, and again you can neatly and conveniently swap bias resistors any time you like. Get gold-plated jacks, of course.

PS: This also makes it easy (if not trivial) to do "LED biasing" on preamp and line level amplification stages. With no hassle at all, one can swap substitutes in ... in seconds ... and immediately hear the consequence of switching. My friend C implemented a double version of this: DPDT (double pole, double throw) switch, and 2 quarter-inch sockets, so that a pair of values could be SWITCHED while the circuit was hot (sure, a pop was always heard, but the immediacy of the change allowed one to hear it "live with real tracks playing"). An excellent method - if you're as attracted to the art of trying things as Mr. C.

The circuit couldn't be simpler... (the "plugs" can be made pretty complex too - both resistor and bypass capacitor (but the 2nd one without the cap) to see the difference)

GoatGuy

Regarding "interchangeable bias resistors" (and a switch, or not)... here's one idea I had that has worked really well over the years: RCA jack ... in the place of the resistor. With a little creative soldering, you can make interchangeable plugs ... with a variety of resistance values ... and then its easy to just "shut down the amp, swap resistors, and power it back up". Alternately (and somewhat more double-safe) would be using quarter-inch jacks. In one case, I used "tip-jacks" of the smallest variety (1 millimeter openings), as a pair so that the bias resistor could simply be an external-to-case device. Bend the legs at just the right spot, and again you can neatly and conveniently swap bias resistors any time you like. Get gold-plated jacks, of course.

PS: This also makes it easy (if not trivial) to do "LED biasing" on preamp and line level amplification stages. With no hassle at all, one can swap substitutes in ... in seconds ... and immediately hear the consequence of switching. My friend C implemented a double version of this: DPDT (double pole, double throw) switch, and 2 quarter-inch sockets, so that a pair of values could be SWITCHED while the circuit was hot (sure, a pop was always heard, but the immediacy of the change allowed one to hear it "live with real tracks playing"). An excellent method - if you're as attracted to the art of trying things as Mr. C.

The circuit couldn't be simpler... (the "plugs" can be made pretty complex too - both resistor and bypass capacitor (but the 2nd one without the cap) to see the difference)

GoatGuy

Hah! I must have missed that little detail when I ordered mine. It was "close", but it took some work with the belt sander to get that panel squared up.Thank you for the compliment, I used a table saw for the recess and just mitered the corners. Blade must have some varnish build up. The top plate is from online metals. I would wait to have the metal on hand befor making any cuts, they only guaranty size to + or - 1/8"

SSE is running! Sounds awesome! There is enough iron mounted on top this thing to make a half dozen smart cars. I put this together in a basic configuration, I will be adding a aux cap soon. I most say the volume is quite satisfying, which I was alittle worried about. I will post pictures soon.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Tubelab

- Novice SSE build