Is anyone tired of lugging around heavy subs made of plywood or mdf? It doesn't have to be that way if you don't need manly man boxes that can double as car jacks or stepping stools to reach a ceiling light. If portability and ease of transport are important - or you don't want to make sawdust or don't have powertools like a table saw or router - items that are de rigueur for speaker building, this may be the thread for you.

There have been several threads (http://www.diyaudio.com/forums/subwoofers/258275-ppsl-2-sigma-pro-18-2as.html and http://www.diyaudio.com/forums/subwoofers/177905-thread-those-interested-ppsl-enclosures.html and http://www.diyaudio.com/forums/subwoofers/242321-dual-opposed-slot-loaded-port.html and http://www.diyaudio.com/forums/subwoofers/255959-sim-slbp_pp-maybe-more.html) about slot loaded push-pull bandpass subs lately, but almost all with big 15 in or 18 in drivers and requisite heavy plywood boxes that go with them. I have been building lightweight foam core speakers over in the full range forum for some time now and thought I should give a dedicated real subwoofer a go at it with foam construction. Rather than the 3/16in thick paper faced foam core from the dollar store, I will use 1 in thick XPS foam insulation sheathing (pink stuff from HD).

I decided to make a compact sub with two 16-ohm 5 inch class Tang Band subwoofer drivers that I have on hand (W5-876SE). I modeled the design in Akabak and aimed for a moderate 45 Hz tuning frequency in order to keep a good efficiency (planned for a corner loaded placement). The design ended up at about 8 liters per chamber with a 0.5 in deep x 8 in tall x 14.5 in long vent. The central slot was set at 4 in wide x 8 in tall x 8.5 in long. The overall box including thickness of wall panels ended up at 10 in x 11.5 in x 24 in. What I built probably resembles this the most:

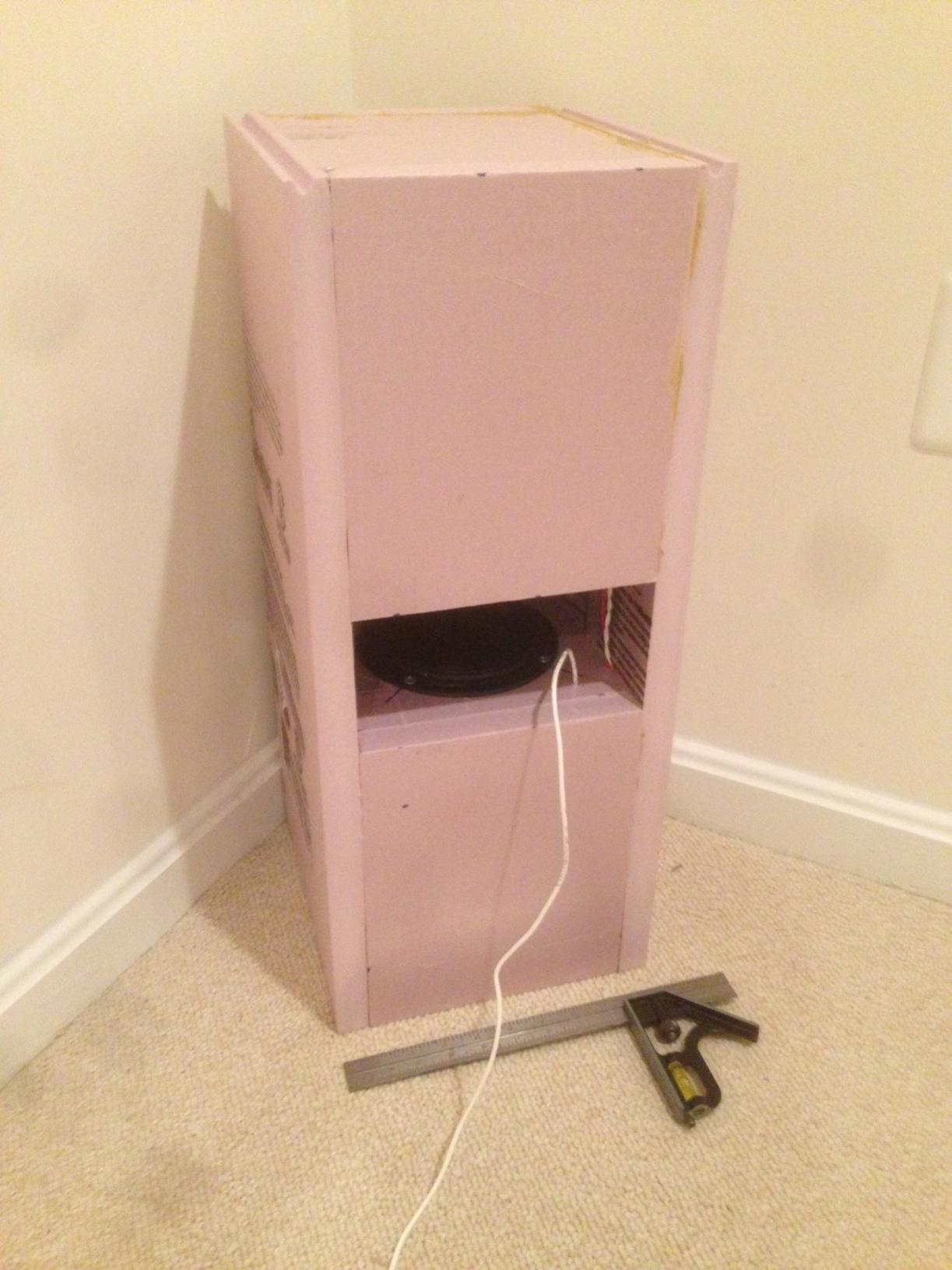

The construction was accomplished using hot melt glue and the final panel was glued with liquid nails. The weight of the enclosure without drivers is very light - I would say on the order of under a pound - feels like air.

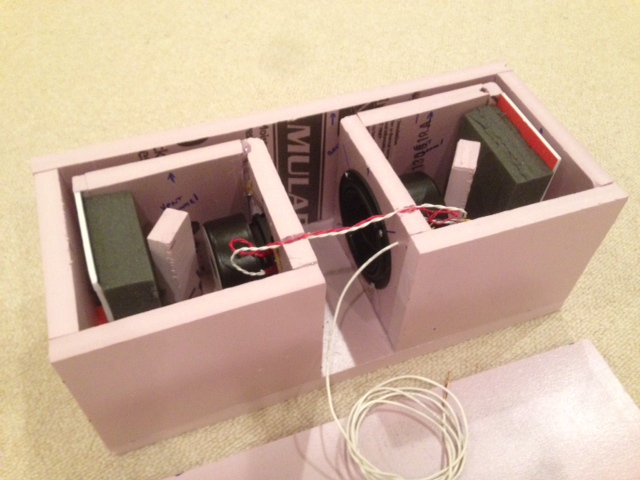

Installing the drivers was tricky because I should have made the slot about 4.25 in wide to accommodate the depth of the driver and magnet during installation. As it is, the surround of the second driver had to rub against the first one in order to get it in. I ended up setting them both face out for easy access to the screws.

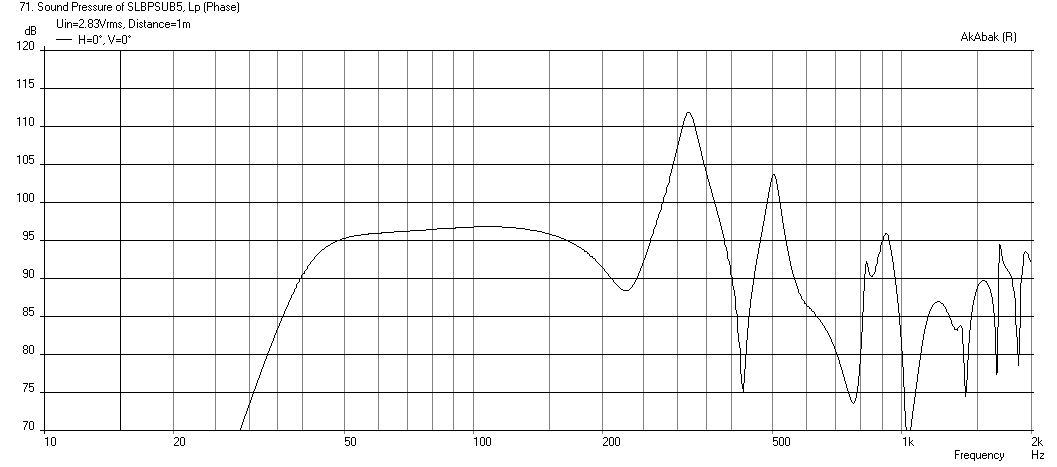

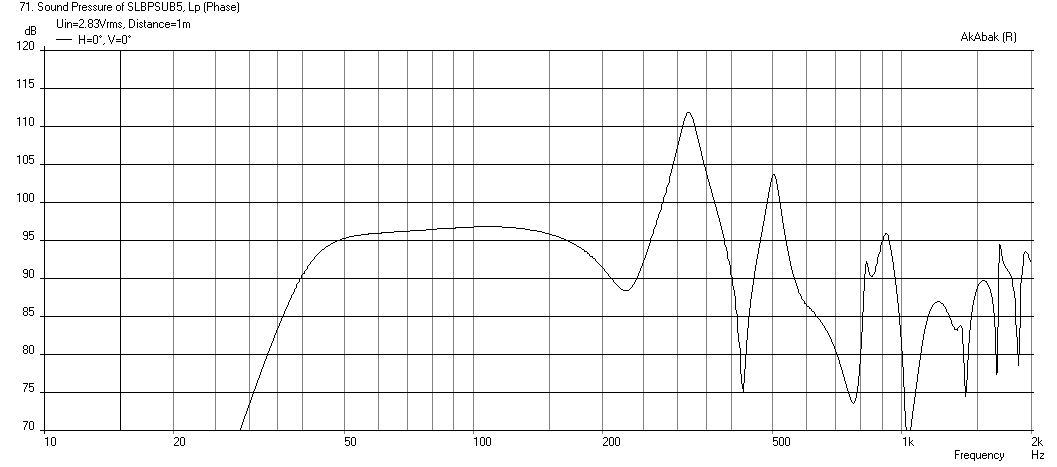

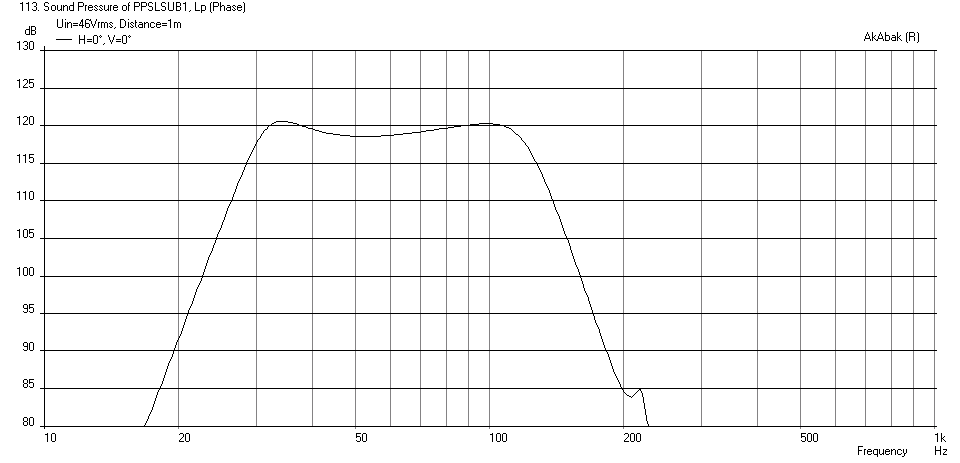

The simulation predicted about 95 dB at 2.83 volts at 1 meter at 45 Hz before falling off:

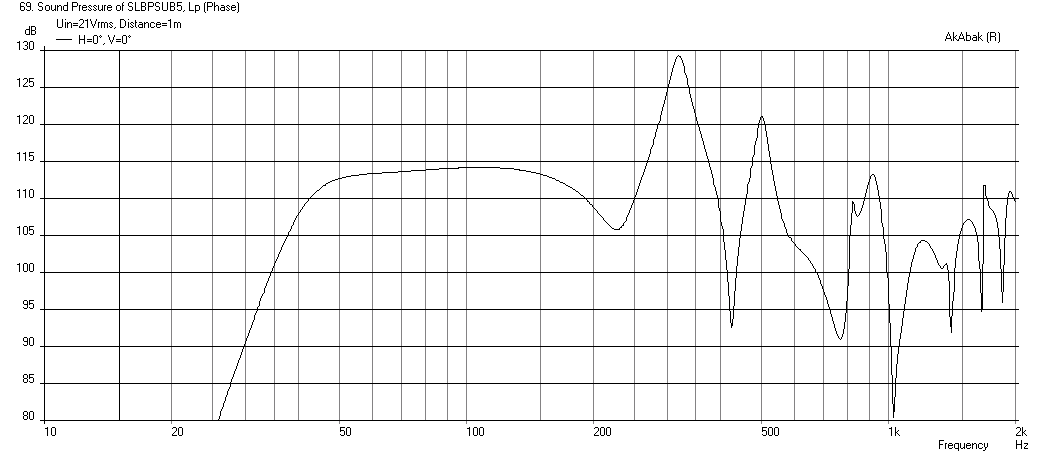

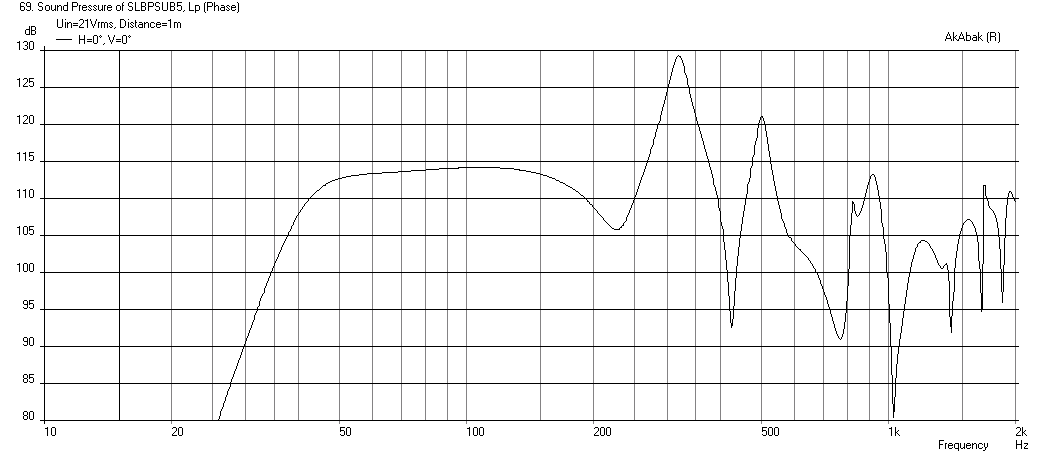

Predicted xmax of 5 mm is reached at 21 volts if using a 39 Hz -24dB/oct high pass filter. Max SPL is about 113 dB - not bad for a couple of 5 in drivers in a foam box:

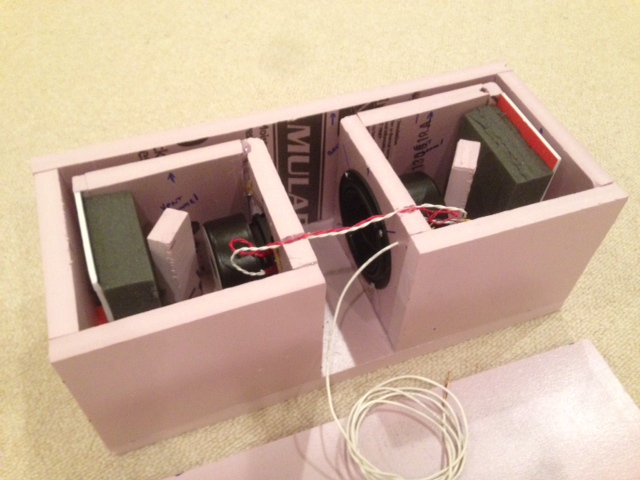

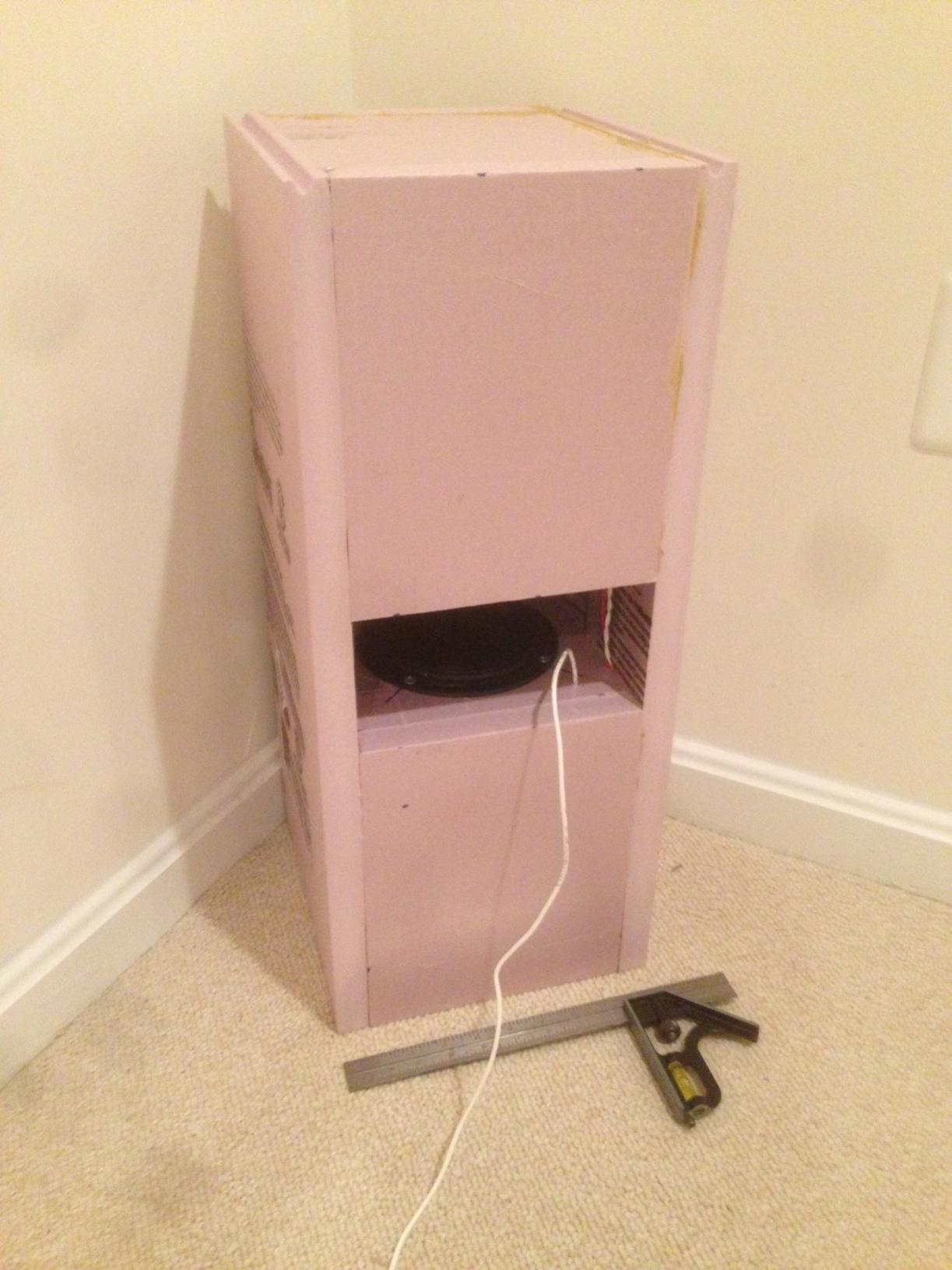

The construction went together very quickly in less than 2 hours and using no more than a razor, straight edge, hot glue, and liquid nails. Here are the construction photos:

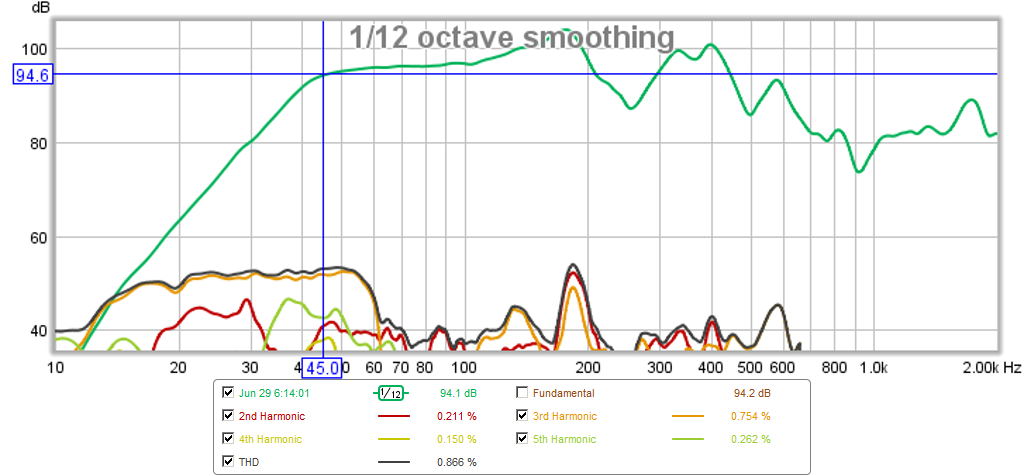

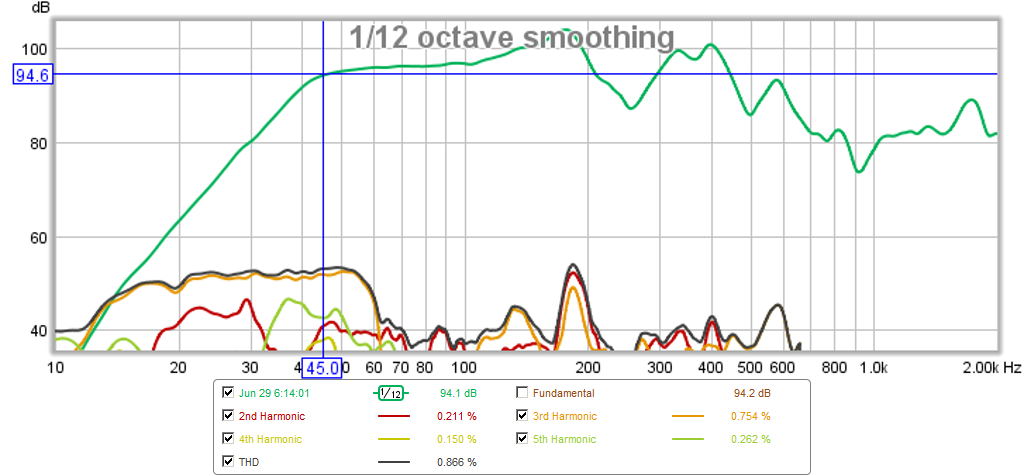

I can't make a measurement in an open field so my basement room is full of room modes and other artifacts that cause pretty big dips. However, I can see that the peak SPL at 2.83 volts and 70 Hz is about 95 or 96 dB. Making a measurement at the exit plane of the vent also seems to mitigate some of the room effects:

How does it sound? Very nice - gets very loud fast. 🙂

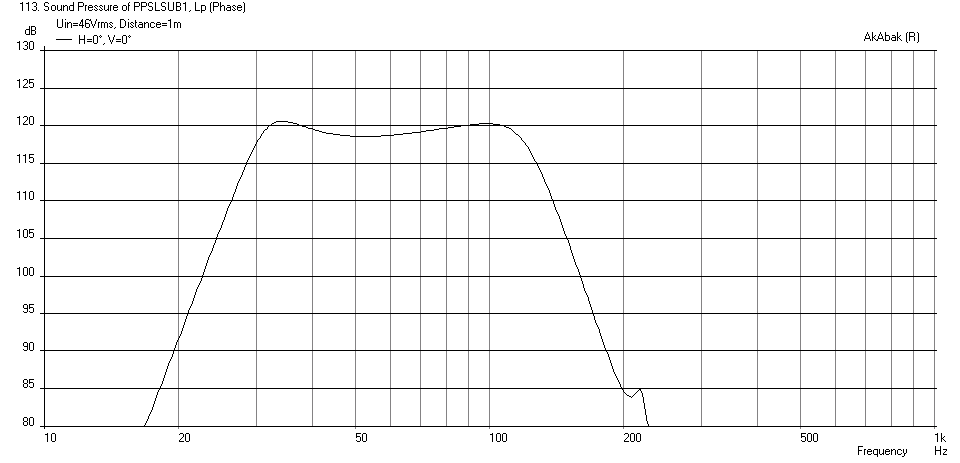

Tb46 made a nice drawing of an implementation using the MCM 55-2421 driver for a 30 Hz capable 120 dB sub: http://www.diyaudio.com/forums/attachments/subwoofers/429073d1405690957-light-air-slot-loaded-band-pass-sub-xrk971_55-2421_ppsl_short.pdf

Response with corner placement:

There have been several threads (http://www.diyaudio.com/forums/subwoofers/258275-ppsl-2-sigma-pro-18-2as.html and http://www.diyaudio.com/forums/subwoofers/177905-thread-those-interested-ppsl-enclosures.html and http://www.diyaudio.com/forums/subwoofers/242321-dual-opposed-slot-loaded-port.html and http://www.diyaudio.com/forums/subwoofers/255959-sim-slbp_pp-maybe-more.html) about slot loaded push-pull bandpass subs lately, but almost all with big 15 in or 18 in drivers and requisite heavy plywood boxes that go with them. I have been building lightweight foam core speakers over in the full range forum for some time now and thought I should give a dedicated real subwoofer a go at it with foam construction. Rather than the 3/16in thick paper faced foam core from the dollar store, I will use 1 in thick XPS foam insulation sheathing (pink stuff from HD).

I decided to make a compact sub with two 16-ohm 5 inch class Tang Band subwoofer drivers that I have on hand (W5-876SE). I modeled the design in Akabak and aimed for a moderate 45 Hz tuning frequency in order to keep a good efficiency (planned for a corner loaded placement). The design ended up at about 8 liters per chamber with a 0.5 in deep x 8 in tall x 14.5 in long vent. The central slot was set at 4 in wide x 8 in tall x 8.5 in long. The overall box including thickness of wall panels ended up at 10 in x 11.5 in x 24 in. What I built probably resembles this the most:

An externally hosted image should be here but it was not working when we last tested it.

The construction was accomplished using hot melt glue and the final panel was glued with liquid nails. The weight of the enclosure without drivers is very light - I would say on the order of under a pound - feels like air.

Installing the drivers was tricky because I should have made the slot about 4.25 in wide to accommodate the depth of the driver and magnet during installation. As it is, the surround of the second driver had to rub against the first one in order to get it in. I ended up setting them both face out for easy access to the screws.

The simulation predicted about 95 dB at 2.83 volts at 1 meter at 45 Hz before falling off:

Predicted xmax of 5 mm is reached at 21 volts if using a 39 Hz -24dB/oct high pass filter. Max SPL is about 113 dB - not bad for a couple of 5 in drivers in a foam box:

The construction went together very quickly in less than 2 hours and using no more than a razor, straight edge, hot glue, and liquid nails. Here are the construction photos:

I can't make a measurement in an open field so my basement room is full of room modes and other artifacts that cause pretty big dips. However, I can see that the peak SPL at 2.83 volts and 70 Hz is about 95 or 96 dB. Making a measurement at the exit plane of the vent also seems to mitigate some of the room effects:

How does it sound? Very nice - gets very loud fast. 🙂

Tb46 made a nice drawing of an implementation using the MCM 55-2421 driver for a 30 Hz capable 120 dB sub: http://www.diyaudio.com/forums/attachments/subwoofers/429073d1405690957-light-air-slot-loaded-band-pass-sub-xrk971_55-2421_ppsl_short.pdf

Response with corner placement:

Attachments

Last edited:

way kooL ! - that pink stuff is pretty stiff - by "razor" what did you use to cut it that square? how is the foam for acoustic "opaqueness" for mids and highs? - two 8" of the right kind should rock- if the foam doesn't flex too much. Are SLPP in general cleaner than single driver horn, pipehorn and TH?

Last edited:

Freddi,

The SLBP has the advantage (similar to K15) of being a 6th order bandpass so the tuning freq corresponds to a cone excursion minimum. This helps to make for very little cone motion at fb, and when designed correctly helps keep HD lower by keeping cone motion low. I would say that dynamics of a bass horn or tapped horn are probably cleaner - and certainly, a K15 is cleaner sounding based on the predicted impulse response. The 1 in XPS is quite stiff and I was surprised how little flex and rattling there was. In fact it was a "quiet" cabinet form a rattling or flexing standpoint. When running fullrange certainly there will be some sound leaking through more so than 18 mm plywood or MDF. However, when running as a low passed sub - it is very quiet as a cabinet as leakage of bass sounds through walls did not matter and could not really be distinguished from sound through port. The biggest problem will be reaction force of vent causing cabinet to move. Either aim port up with box on ground or wedge in corner with port out for corners to contain motion. Portability wise, you can't beat a speaker that weighs hardly anymore than the drivers.

By razor - I used a $0.99 utility knife with blade fully extended and a piece of Masonite paneling as a straight edge. When cutting keep blade vertical to ensure a square edge. This manual approach ended up with several edges that were not square and that is where void filling glues and hot melt comes in handy. Hot melt needs to be used sparingly as it melts foam. I think caulking or expanding polyurethane may be good here.

The SLBP has the advantage (similar to K15) of being a 6th order bandpass so the tuning freq corresponds to a cone excursion minimum. This helps to make for very little cone motion at fb, and when designed correctly helps keep HD lower by keeping cone motion low. I would say that dynamics of a bass horn or tapped horn are probably cleaner - and certainly, a K15 is cleaner sounding based on the predicted impulse response. The 1 in XPS is quite stiff and I was surprised how little flex and rattling there was. In fact it was a "quiet" cabinet form a rattling or flexing standpoint. When running fullrange certainly there will be some sound leaking through more so than 18 mm plywood or MDF. However, when running as a low passed sub - it is very quiet as a cabinet as leakage of bass sounds through walls did not matter and could not really be distinguished from sound through port. The biggest problem will be reaction force of vent causing cabinet to move. Either aim port up with box on ground or wedge in corner with port out for corners to contain motion. Portability wise, you can't beat a speaker that weighs hardly anymore than the drivers.

By razor - I used a $0.99 utility knife with blade fully extended and a piece of Masonite paneling as a straight edge. When cutting keep blade vertical to ensure a square edge. This manual approach ended up with several edges that were not square and that is where void filling glues and hot melt comes in handy. Hot melt needs to be used sparingly as it melts foam. I think caulking or expanding polyurethane may be good here.

Last edited:

Yes, ordinary caulking would also work. Also 1/4" sub baffle plates would make driver mounting more solid. Nice job!

Klbird,

Hey thanks! I thought about the thin wood facing for the driver mounting too and it would have been nice but then would have been counter the "no power tools and no sawdust" goal that I have set for myself. I ended up using pieces of triple wall cardboard glued to the back side of the foam as "nuts" for the wood screws to bite into and hold the drivers. So far not one piece of wood was touched in this project.

X

Hey thanks! I thought about the thin wood facing for the driver mounting too and it would have been nice but then would have been counter the "no power tools and no sawdust" goal that I have set for myself. I ended up using pieces of triple wall cardboard glued to the back side of the foam as "nuts" for the wood screws to bite into and hold the drivers. So far not one piece of wood was touched in this project.

X

Amazing, as always ! 😀 Remarkable for a pair of 5".

For additional possible experiments, may I suggest:

1. make the drivers push-pull, to obtain furthur cancellation of even order distortions

2. tie the drivers with threaded rods (or long screws), and make this assembly 'floating' from the cabinet. (how? no idea yet... )

The actual benefit might be small, it's hot-rodding just for fun. 😀

ps. Build another 2 and hide them from sight, you'll be collecting jaws on your floor during the presentations of your foamcore speakers. LoL !

For additional possible experiments, may I suggest:

1. make the drivers push-pull, to obtain furthur cancellation of even order distortions

2. tie the drivers with threaded rods (or long screws), and make this assembly 'floating' from the cabinet. (how? no idea yet... )

The actual benefit might be small, it's hot-rodding just for fun. 😀

ps. Build another 2 and hide them from sight, you'll be collecting jaws on your floor during the presentations of your foamcore speakers. LoL !

CLS,

Thanks!

That is a good idea about using threaded rods so that the drivers are self-contained force cancelling units. You can float the assembly by mounting it in a square piston housing that floats on felt seals along the 4 walls of the piston that holds the two drivers. Not sure what this achieves though other than to decouple the axial force from the housing - which is not an issue because of the self-cancelling nature of the driver cone motions. Maybe you mean pressure cancellation?

I am listening to this sub with my current Nautaloss speaker system with the miniDSP and bi-amps and it sounds very nice. The bass articulation is a lot cleaner sounding than I anticipated and the punch is there and can be felt which is very cool for a pair of 5 inch drivers. The foam box is also very quiet - no rattling or squeaks.

Here is a sound clip at moderate volume of 80 dB at listening position (night time here).

Thanks!

That is a good idea about using threaded rods so that the drivers are self-contained force cancelling units. You can float the assembly by mounting it in a square piston housing that floats on felt seals along the 4 walls of the piston that holds the two drivers. Not sure what this achieves though other than to decouple the axial force from the housing - which is not an issue because of the self-cancelling nature of the driver cone motions. Maybe you mean pressure cancellation?

I am listening to this sub with my current Nautaloss speaker system with the miniDSP and bi-amps and it sounds very nice. The bass articulation is a lot cleaner sounding than I anticipated and the punch is there and can be felt which is very cool for a pair of 5 inch drivers. The foam box is also very quiet - no rattling or squeaks.

Here is a sound clip at moderate volume of 80 dB at listening position (night time here).

Attachments

I just thought of isolating the residual vibration from the cabinet. But if they're tied together by threaded rods already, this is probably doing nothing.

And, you mentioned "reaction force of vent causing cabinet to move", do you mean it's blowing itself off the position? Wow. (if some check valves are possible, you get yourself an air pump which can drive itself like a jet engine, LoL ... ) This is completely beyond my audio experience.

For mechanical vibration of driver and cabinet, I found the best solution is fully suspended, the next best is supported by very soft feet. Not sure for this blower, though.

And, you mentioned "reaction force of vent causing cabinet to move", do you mean it's blowing itself off the position? Wow. (if some check valves are possible, you get yourself an air pump which can drive itself like a jet engine, LoL ... ) This is completely beyond my audio experience.

For mechanical vibration of driver and cabinet, I found the best solution is fully suspended, the next best is supported by very soft feet. Not sure for this blower, though.

Integrate Foam SLBPsub with Nautaloss II via miniDSP

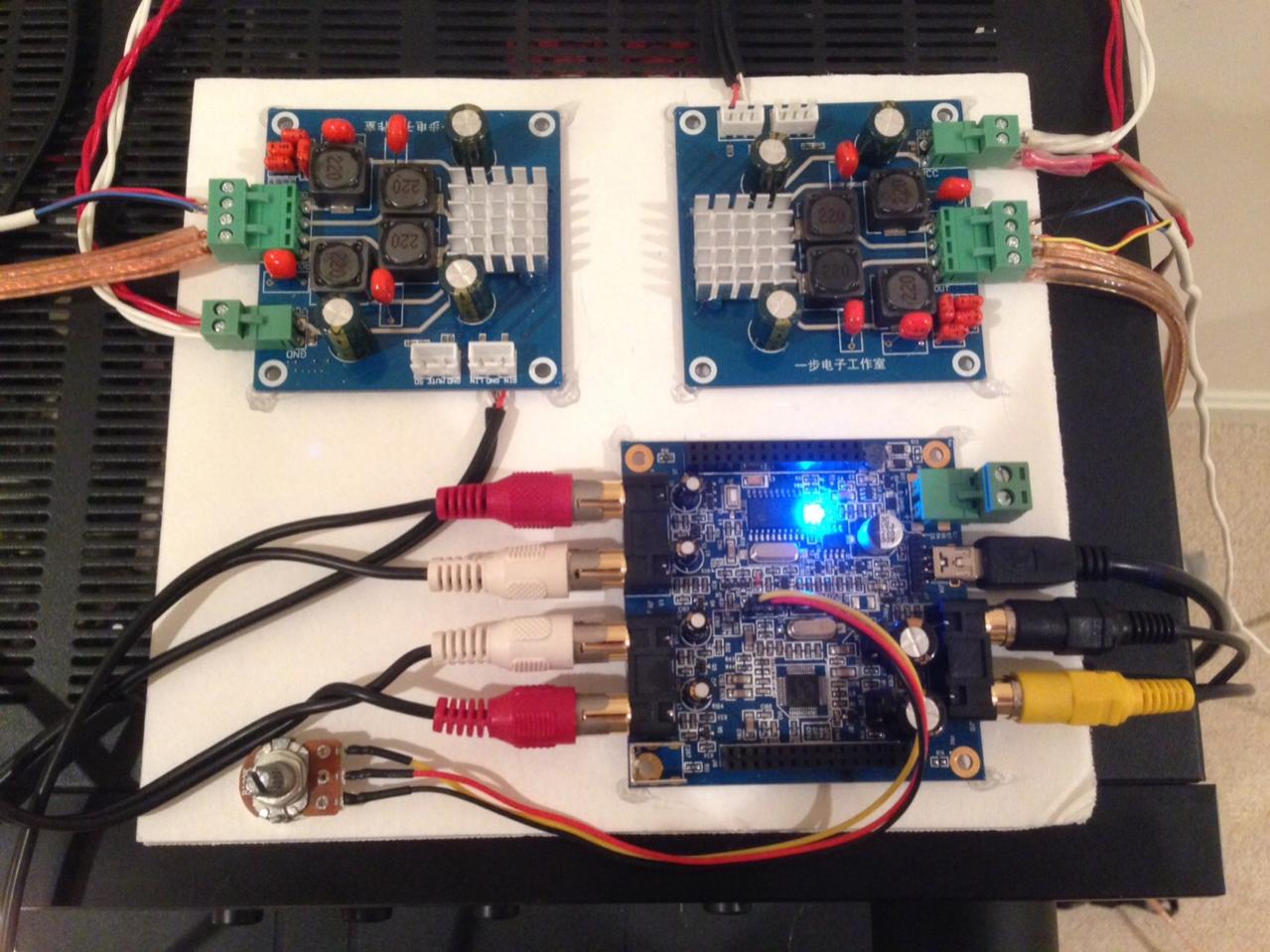

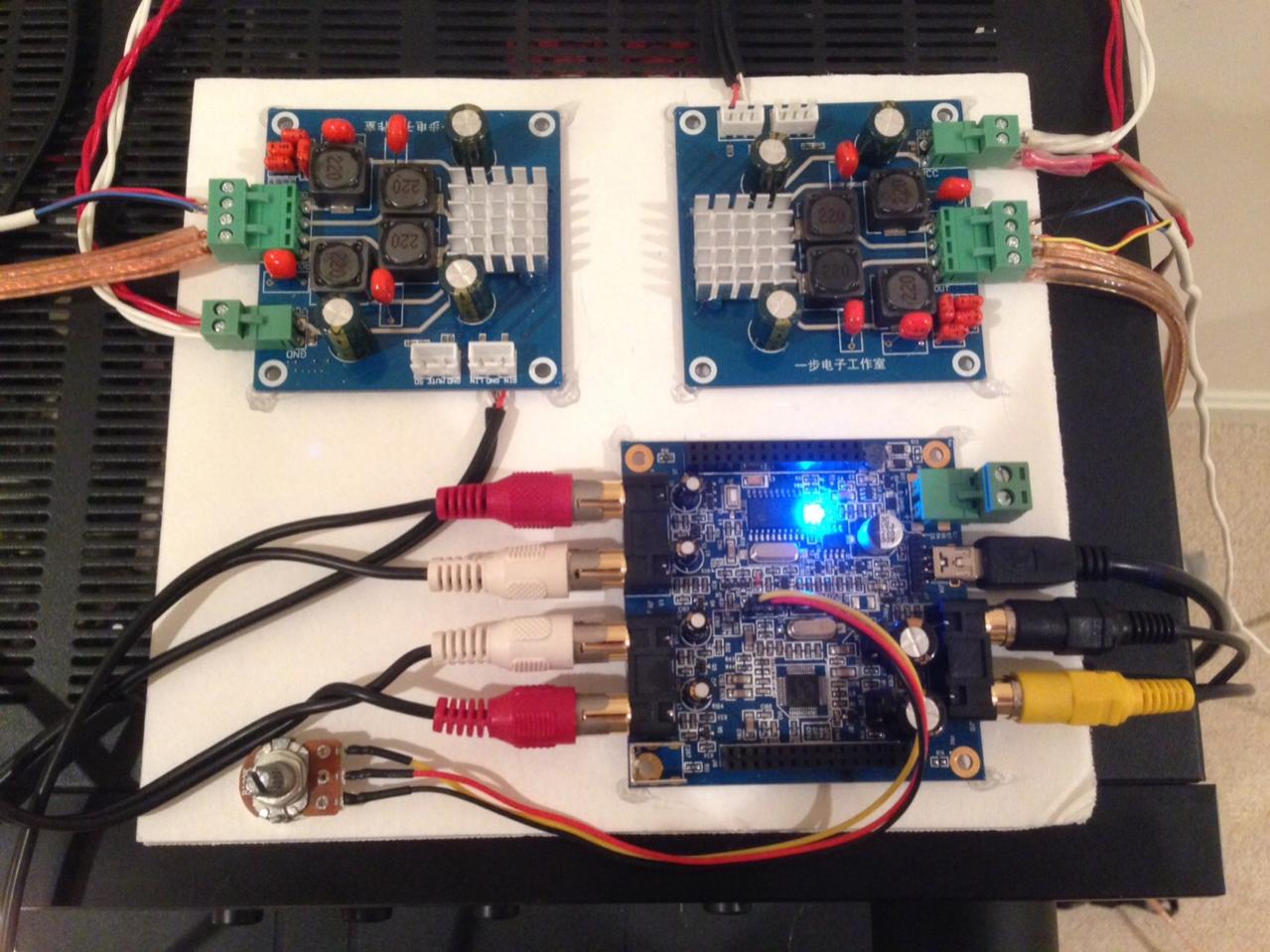

So I had a little more time to do a more careful setup to fully integrate the new sub with my existing system in order to test the sound quality with listening to full range music rather than bass beat heavy dance tracks. My setup is described in detail here http://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor.html. The current setup is the Nautaloss II which uses dual Vifa TC9FD drivers for the fullrange monitors, a miniDSP 2x4 for XO and EQ duties, and TPA3116D2 bi-amps powered by 19 volt laptop bricks. The electronics setup looks like this:

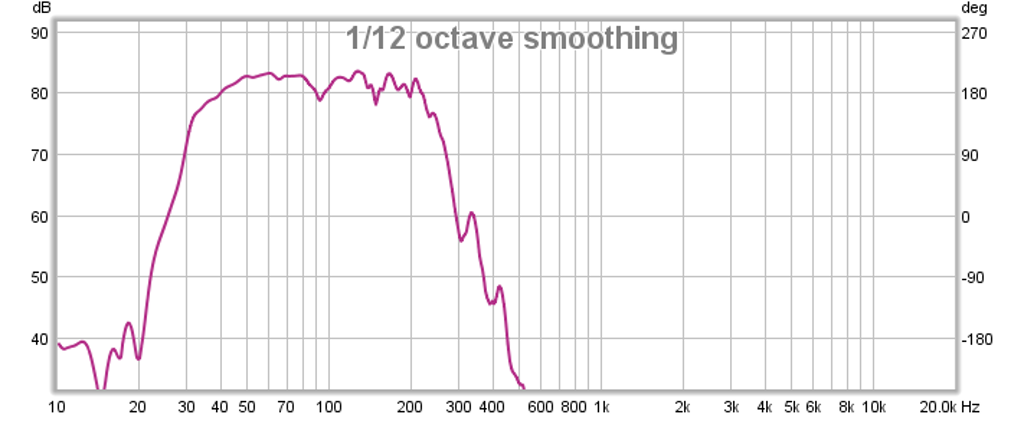

I then proceeded to make a measurement at the listening position near the middle of the room and used REW to smooth the subwoofer response. I selectively removed any major valley-filling (positive gain) EQ in order to avoid increased HD. The goal is to cut peaks and not fill valleys. Here is the response after REW is applied, and the sub has -36dB/oct high pass at 28 Hz and -36dB/oct low pass at 175 Hz to integrate with the fullrange tops. I also applied a +9dB low shelf (Q=0.8) from 45 Hz on down to bring up the deeper notes. Here is the response of the sub after REW:

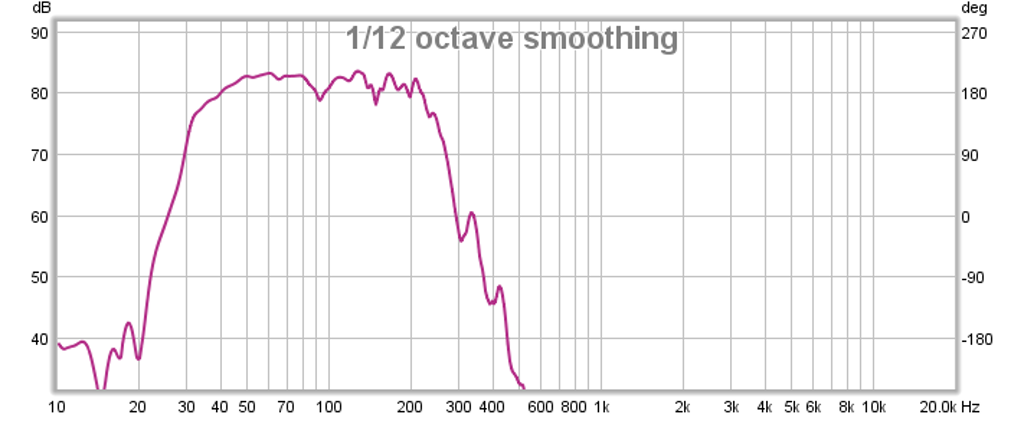

Now, the Nautaloss II tops are switched on and this is the resulting response:

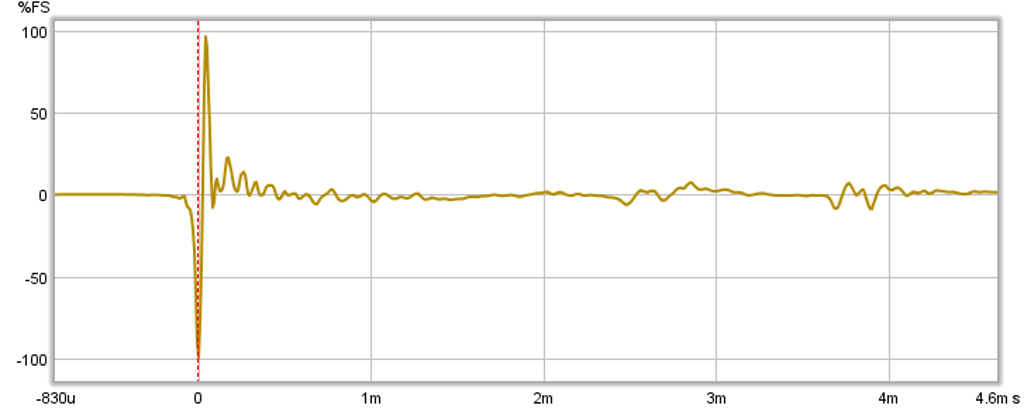

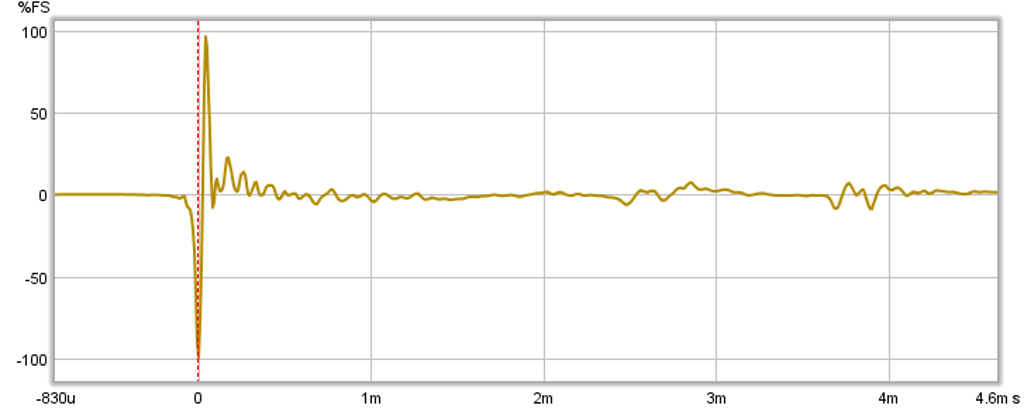

This is the corresponding impulse response from the system:

It sounds very tight and articulate with just enough reach to cover the 41 Hz bass notes. One of my favorite test tracks is SRV's Tin Pan Alley. Sounds fantastic.

I am a new believer in XPS foam for subwoofer builds now! 😀

So I had a little more time to do a more careful setup to fully integrate the new sub with my existing system in order to test the sound quality with listening to full range music rather than bass beat heavy dance tracks. My setup is described in detail here http://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor.html. The current setup is the Nautaloss II which uses dual Vifa TC9FD drivers for the fullrange monitors, a miniDSP 2x4 for XO and EQ duties, and TPA3116D2 bi-amps powered by 19 volt laptop bricks. The electronics setup looks like this:

I then proceeded to make a measurement at the listening position near the middle of the room and used REW to smooth the subwoofer response. I selectively removed any major valley-filling (positive gain) EQ in order to avoid increased HD. The goal is to cut peaks and not fill valleys. Here is the response after REW is applied, and the sub has -36dB/oct high pass at 28 Hz and -36dB/oct low pass at 175 Hz to integrate with the fullrange tops. I also applied a +9dB low shelf (Q=0.8) from 45 Hz on down to bring up the deeper notes. Here is the response of the sub after REW:

Now, the Nautaloss II tops are switched on and this is the resulting response:

This is the corresponding impulse response from the system:

It sounds very tight and articulate with just enough reach to cover the 41 Hz bass notes. One of my favorite test tracks is SRV's Tin Pan Alley. Sounds fantastic.

I am a new believer in XPS foam for subwoofer builds now! 😀

Attachments

Last edited:

BP1Fan,

Hey, thanks! I assume your name stands for bandpass fan? Anyhow, any fan of a bandpass alignment should have a lightweight and portable 6th order slot loaded bandpass sub. 🙂 These are really quite the sub for a 5 in driver in a foam box. I think these W5 drivers just became available at PE again. They are blowout items so will go fast and probably be gone for good. Nice driver - very low distortion.

Hey, thanks! I assume your name stands for bandpass fan? Anyhow, any fan of a bandpass alignment should have a lightweight and portable 6th order slot loaded bandpass sub. 🙂 These are really quite the sub for a 5 in driver in a foam box. I think these W5 drivers just became available at PE again. They are blowout items so will go fast and probably be gone for good. Nice driver - very low distortion.

Yeah, I always try to build BP4 boxes for vehicles. I made a coffee table in 1998 with two 12's in a BP4 box. It's still going strong in my basement. I wish I had room in my F150 Supercrew for a BP4 box. I had to go sealed due to space.

How do they sound when the speakers reach Xmax?Here is a sound clip at moderate volume of 80 dB at listening position (night time here).

Xmax is at 22 volts and sadly my amps only go to 17 volts. I have no big power amp. When cranked up near 15 volts which is really all I need they sound good still bit certainly not as clean as my bass horn made of 3/4 in ply.

15 volts is around 28 watts, 22 volts around 60 watts, so you are pushing them within around 3 dB of predicted Xmax. Is the response linear from the low level testing to that level?Xmax is at 22 volts and sadly my amps only go to 17 volts. When cranked up near 15 volts which is really all I need they sound good still bit certainly not as clean as my bass horn made of 3/4 in ply.

Just trying to get an idea of how much wall "flappage" goes on when used above conversational level.

This a really cool , original idea.

I just finished modding some old favourites into a tv shelf/ 3 channel soundbar.

Looking at a scaled up version of your layout, I bet a force cancelling, shared throat tapped horn wouldn't be so hard to model.

Thanks for the inspiration.

Looks like a nice affordable way to try out prototypes, too.

Thanks again!

I just finished modding some old favourites into a tv shelf/ 3 channel soundbar.

Looking at a scaled up version of your layout, I bet a force cancelling, shared throat tapped horn wouldn't be so hard to model.

Thanks for the inspiration.

Looks like a nice affordable way to try out prototypes, too.

Thanks again!

15 volts is around 28 watts, 22 volts around 60 watts, so you are pushing them within around 3 dB of predicted Xmax. Is the response linear from the low level testing to that level?

Just trying to get an idea of how much wall "flappage" goes on when used above conversational level.

Once SWMBO is out of the house I can crank it to 17 volts and hear how much flapping there is as you say. That will be quite loud in my basement room.

This a really cool , original idea.

I just finished modding some old favourites into a tv shelf/ 3 channel soundbar.

Looking at a scaled up version of your layout, I bet a force cancelling, shared throat tapped horn wouldn't be so hard to model.

Thanks for the inspiration.

Looks like a nice affordable way to try out prototypes, too.

Thanks again!

Yes, a TH was next on my to try list. If you want added stiffness just add a layer of cardboard to one or both sides with 3m fastack contact cement. You are welcome - looking forward to hearing about your TH build.

Question. What are the black rectangles in your box? Are they amplifiers? Suggestion : have you consider using internal bracing in your box?

- Home

- Loudspeakers

- Subwoofers

- Light as Air Slot Loaded Band Pass Sub